CNC DFM Optimization: An Engineer’s Mandate

The notion that design ends at the drawing board is, frankly, a monumental misconception. From our vantage point here at ly-machining, in China’s bustling Shenzhen, we contend that a design truly begins its life—its real, tangible, and often costly existence—the moment it encounters the manufacturing process. Our specific angle for this discourse, then, is purely the manufacturer’s indispensable guide to DFM, ensuring client success through our deep technical insights and transparent, optimized production methodologies.

Neglecting manufacturability? That’s not just an oversight; it’s a direct pathway to exorbitant expenditures, protracted lead times, and, let’s be blunt, profound frustration for everyone involved.

Are your meticulously crafted CNC part designs inadvertently costing you a fortune? Indeed, this is a question that frequently plagues even the most astute product designers. The truth is, without a steadfast commitment to Design for Manufacturability (DFM), countless projects spiral into unforeseen expenses, production delays, and compromised quality.

But here’s the game-changer: by implementing these ten critical DFM tips, you could drastically reduce your manufacturing expenditure, potentially by up to 30%, and remarkably accelerate your product’s journey from an abstract concept to tangible market reality. This isn’t merely advice; it’s an imperative for anyone seeking genuinely efficient and successful CNC machining outcomes.

Simplify Geometries for CNC Efficiency

One truly cannot overstate the profound impact of geometric complexity on machining costs. We often observe designs brimming with unnecessary flourishes, those intricate curves and features that, while visually appealing, impose an unconscionable burden on our machines and, ultimately, your budget. What a pity! Simplifying these geometries is not a compromise; it’s an intelligent optimization.

Utilize standard shapes in your CNC designs. Rectangular pockets, simple holes, and straightforward chamfers are not merely easier to program; they demand less specialized tooling and significantly less machine time. Consider this an axiom of efficient manufacturing, a golden rule, if you will.

For goodness sake, design for fewer setups in machining! Each time a part must be re-fixtured, precious minutes—and thus, precious capital—are squandered. Fewer setups mean reduced potential for error, superior part consistency, and a markedly faster throughput. It truly is a non-negotiable principle.

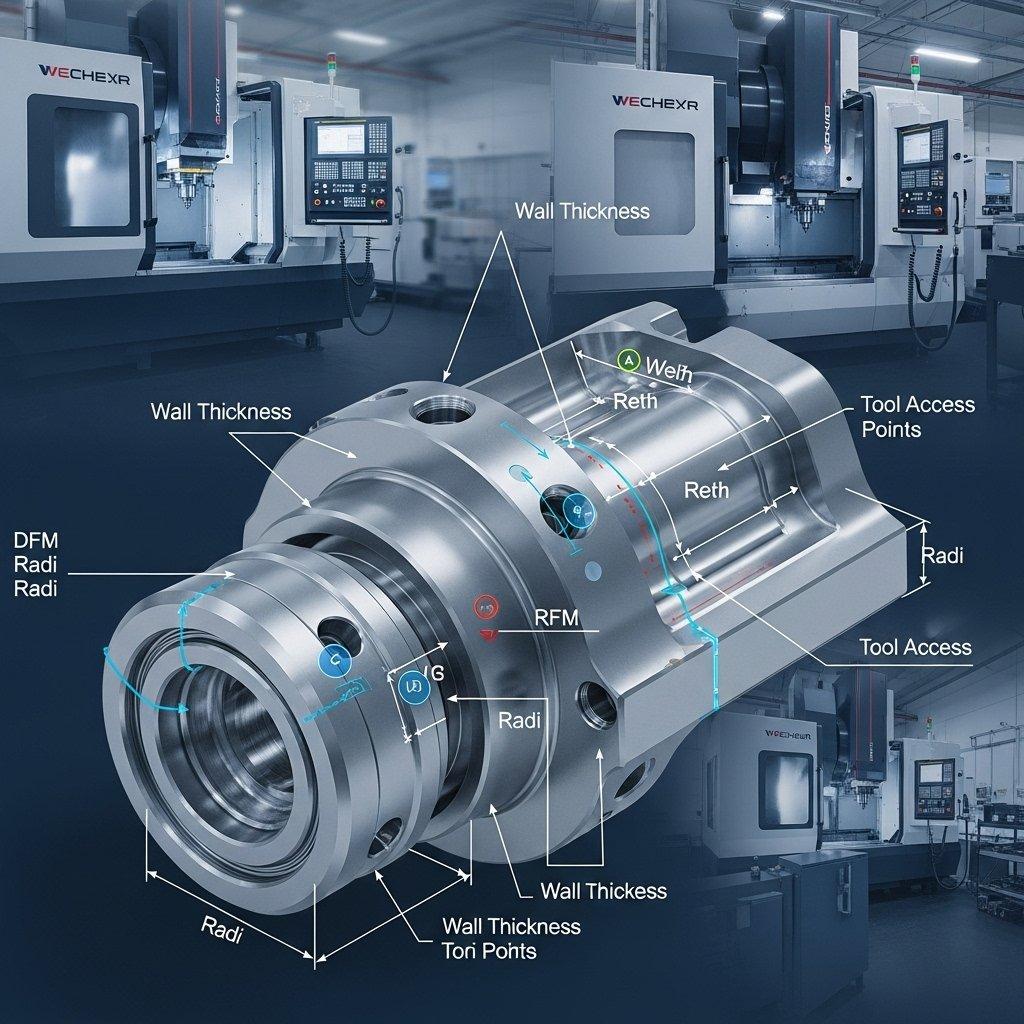

Optimize Internal Radii in CNC Parts

Ah, internal radii—a frequently underestimated, yet absolutely pivotal, design consideration. Specifying generous internal radii for tooling is an incredibly astute move. Sharp internal corners? They are nothing short of anathema to efficient CNC machining, demanding specialized, diminutive tools that are both expensive and prone to breakage.

One truly must avoid sharp internal corners in designs whenever possible. Think about the tool itself—a rotating cylinder. It simply cannot create a perfectly sharp internal corner. We at ly-machining always recommend matching your specified radii to standard CNC tool sizes. This minimizes tool changes, maximizes cutting efficiency, and dramatically reduces machining time. It’s a simple truth, yet its impact is immense.

Standardize Hole Designs for Machining

Honestly, how often do designers realize the sheer inefficiency of non-standard hole sizes? It’s a recurring pattern, sadly. We urge, no, we implore you: use standard drill sizes for holes! Custom tools for idiosyncratic hole dimensions? An unnecessary expenditure, period. Standard drills are readily available, cost-effective, and provide predictable results.

Furthermore, ensuring adequate depth-to-diameter ratios is undeniably critical. A shallow, wide hole is simple. A deep, narrow hole—especially in challenging materials—presents a myriad of difficulties, from chip evacuation issues to tool deflection.

We often observe designs where through-holes would be perfectly acceptable, yet a blind hole is specified for no functional reason. Specify through-holes where possible; they are invariably easier and faster to machine, not to mention less prone to debris accumulation.

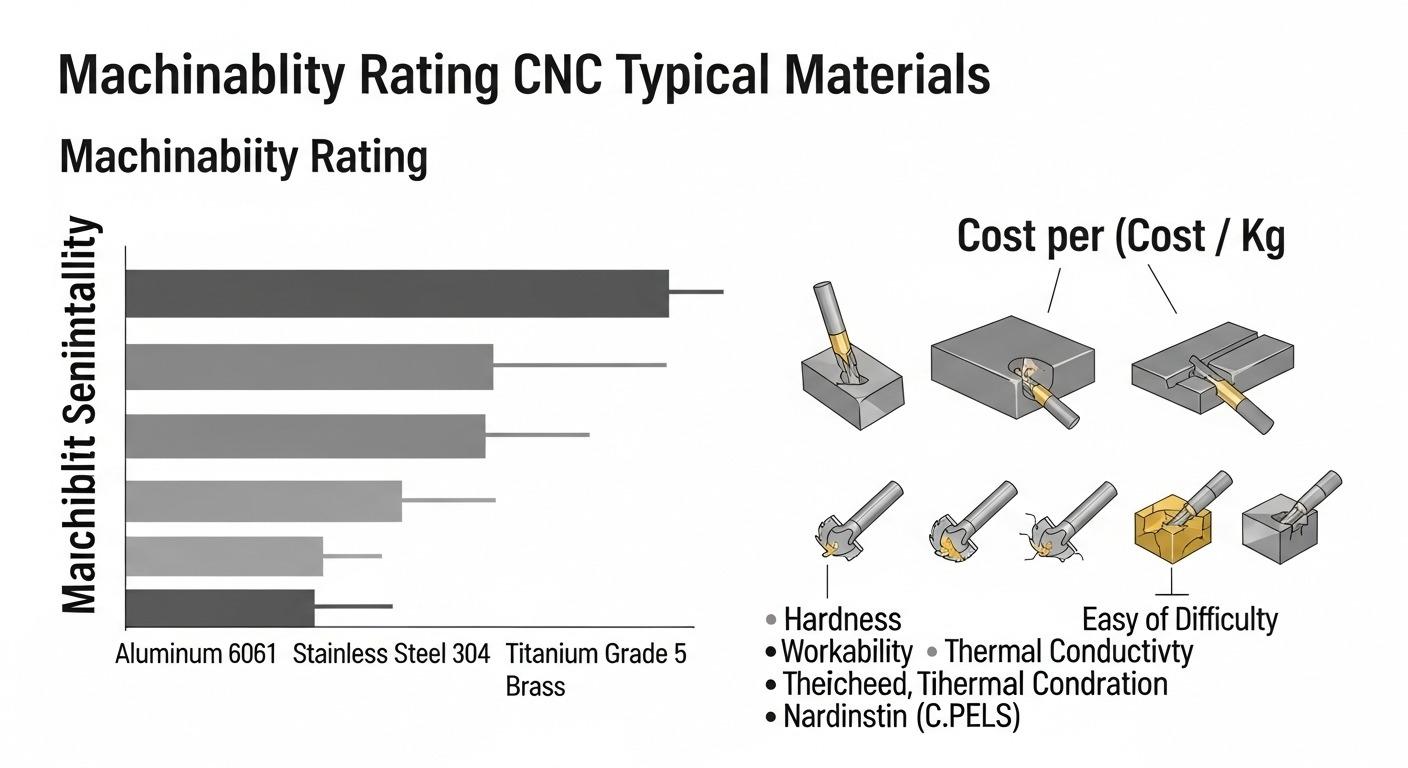

Select Machinable Materials for DFM

The material choice is, without question, a truly foundational decision, perhaps the most pivotal. You must apprehend material properties and their profound cost impact before even a single cut is contemplated. Some materials are simply a joy to machine; others are an absolute nightmare, demanding specialized coatings, slower speeds, and frequent tool replacements.

Choosing materials optimized for CNC cutting isn’t just shrewd; it’s a strategic imperative. We at ly-machining possess extensive experience across a spectrum of alloys. Consider alternative, more machinable alloys if your performance requirements allow. Sometimes a slight material adjustment can unlock unbelievable cost savings, without sacrificing a millisecond of performance.

Manage Tolerances to Reduce CNC Costs

This is where the rubber truly meets the road, where design idealism collides with manufacturing reality. Applying realistic tolerances for functional needs is paramount; anything less is an exercise in futility and financial imprudence. I have seen firsthand the devastating impact of over-specified tolerances.

Avoid excessively tight tolerances in your designs, unless, of course, the functionality absolutely, unequivocally demands it. Each increment of precision exponentially elevates the machining cost. It’s a cruel truth of physics and economics. You must understand the cost implications of precision CNC; a 0.01mm tolerance versus a 0.05mm tolerance could mean the difference between a viable product and an exorbitant one.

| Tolerance Grade (ISO 2768-1) | Typical Cost Multiplier (Approx.) | Machining Method Implications |

|---|---|---|

| Fine (f) | 3.0x – 5.0x | Grinding, EDM, Advanced Machining |

| Medium (m) | 1.5x – 2.5x | High-precision CNC Milling/Turning |

| Coarse (c) | 1.0x (Baseline) | Standard CNC Milling/Turning |

| Very Coarse (v) | 0.8x – 0.9x | Rough Machining, Non-critical Fits |

Ensure Ample Wall Thickness in Designs

Think about structural integrity, about the very essence of the part itself. Maintaining uniform wall thickness for stability is absolutely indispensable. Thin walls, particularly those of inconsistent thickness, are a truly disastrous approach. They are inherently prone to vibration during machining, leading to chatter, tool deflection, and ultimately, distorted, unusable parts.

Prevent thin walls prone to vibration or warp; it’s a non-negotiable requirement for quality. We’ve witnessed countless engineering teams overlook this, only to encounter catastrophic failures during production. You must consider material-specific thickness guidelines. A wall thickness perfectly acceptable for aluminum might be utterly insufficient for a more brittle material like certain ceramics or hardened steels. It’s a nuanced consideration, yet one of immense consequence.

Improve Tool Access for CNC Operations

What good is a brilliant design if our tools cannot reach its features efficiently, or indeed, at all? None, I say! Design features accessible by standard tools; this is foundational. We often see engineers specifying deep, narrow pockets or blind slots that necessitate custom-ground, extended-reach tools. This is an avoidable expense.

Minimize deep pockets requiring specialized tooling. Such features dramatically increase tool wear, elevate cycle times, and introduce significant risks of tool breakage. Allow clear tool entry and exit paths; this simple foresight prevents tool collisions, improves chip evacuation, and maintains surface finish integrity. This is not about sacrificing design; it is about intelligent, practical application.

Specify Appropriate Surface Finishes

Here’s an area where cost-conscious decisions can truly shine through, or, conversely, be completely obscured by unnecessary demands. Define finish only where functionally required! A mirror polish on an internal surface that never sees the light of day? That’s an unbelievably foolish mistake, a pure waste of resources.

You must understand the various methods for achieving different surface finishes—milling, turning, grinding, polishing—and their respective cost implications. Balance cost with aesthetic and performance needs. Sometimes, a simple as-machined finish is perfectly adequate, saving you a fortune compared to an exacting Ra requirement. Trust me, our expertise here is invaluable.

Consider Part Orientation for CNC Setup

This is a subtle, yet absolutely critical, DFM element often overlooked by even seasoned designers. Designing for stable fixturing during machining is paramount for ensuring part accuracy and preventing damage. A wobbling workpiece? That’s a recipe for disaster, pure and simple.

Minimize potential for chatter or distortion. The way a part is held, the forces exerted by cutting tools, the inherent rigidity of its geometry—all contribute to the final part quality. Optimize for minimal material removal passes; this implies considering the rough stock and the most efficient path to the final geometry.

Seldom does one encounter truly optimized parts without careful consideration of their orientation throughout the manufacturing lifecycle. Wait, I must interject here—this isn’t merely about cost, but about sheer integrity. A part poorly fixtured will never achieve its intended precision, regardless of how tight your tolerances are!

Collaborate Early on CNC Design for DFM

Let’s be honest, the most potent DFM tip is not found within CAD software, but within communication itself. Engage manufacturers during the design phase! ly-machining thrives on early collaboration; our engineers are not merely operators, they are problem-solvers, experts in the very tangible physics of material removal. Leveraging our expertise for design iteration can prevent countless headaches and save astounding sums of money down the line.

Review manufacturability before production; this is an absolutely irreplaceable truth. Catching potential issues on a screen, rather than on the shop floor with ruined material and broken tools, is a truly inspiring miracle of modern engineering. We welcome these early discussions, for they forge stronger partnerships and superior products. It is the cornerstone of our operational philosophy.

Case Study: Reimagining a Complex Enclosure

A client, a burgeoning tech firm, approached us with a truly complex electronic enclosure design—a veritable masterpiece of intricate internal geometries and exacting external aesthetics. Their initial prototype estimates from other shops were astronomical, threatening to derail their entire product launch. They had, regrettably, focused solely on functionality and form, with little regard for manufacturability.

Our solution was simple, yet profound: a comprehensive DFM review. We identified several problematic sharp internal corners, overly thin walls in critical areas, and an unnecessary array of custom hole sizes.

Our engineers proposed minor adjustments: increasing internal radii, subtly thickening non-critical walls, and standardizing hole dimensions to common drill sizes. We even suggested a slight modification to a mounting feature to allow for a single, more stable fixture setup, dramatically reducing machining time.

The result? The client saved a staggering 28% on their manufacturing costs, primarily due to reduced cycle times and minimized tooling expenses. More importantly, we delivered the first batch of high-quality, fully functional enclosures ahead of schedule, enabling their swift market entry. This wasn’t merely machining; it was a partnership in optimization, a testament to what deep technical collaboration can achieve.

Article Summary

This article emphasized the critical importance of Design for Manufacturability (DFM) in CNC machining, particularly from a manufacturer’s perspective. We explored ten key DFM tips, including simplifying geometries, optimizing radii, standardizing holes, selecting machinable materials, and judiciously managing tolerances.

Furthermore, we highlighted the necessity of ensuring ample wall thickness, improving tool access, specifying appropriate surface finishes, considering part orientation for setup, and engaging in early collaboration with manufacturers. Each tip aims to reduce costs, shorten lead times, and enhance the quality of CNC machined parts.

Frequently Asked Questions

What is the biggest DFM mistake?

Over-specifying tolerances for non-critical features is undeniably the most egregious error. It balloons costs unnecessarily. Focus precision where it truly matters, allowing broader tolerances elsewhere.

This simple adjustment can dramatically reduce machining time and extend tool life, impacting your budget significantly. It truly is a non-negotiable optimization.

How does material choice affect cost?

Material selection profoundly impacts machinability, tool wear, and cycle times. Easily machinable materials like aluminum reduce costs. Difficult materials, such as titanium, demand specialized tools and slower processing, escalating expenditures.

Choosing the right material isn’t just a technical decision; it’s a critical economic one. We always advise clients on optimal material selection for their specific applications.

Why collaborate with manufacturers early?

Early collaboration is the cornerstone of cost-effective DFM. It allows our engineers to identify potential manufacturing challenges and suggest design improvements before production begins. This proactive approach saves immense time and money.

It eliminates costly redesigns and retooling down the line. Trust us, catching errors on paper is far cheaper than correcting them on the machine.

Ready to optimize your CNC part designs? Contact our engineering team today for a free DFM consultation and a transparent quote on your next project. Leverage our source manufacturing advantage for unparalleled quality and cost efficiency.