2026’s Top Recommended CNC Machining Manufacturers for Precision Parts

Precision demands have intensified, making the `2026 Ranking of Recommended CNC Machining Manufacturers for Precision Parts` critical. The `best precision CNC machining manufacturers` combine advanced capabilities, stringent quality, and strategic partnership to deliver `high-quality parts` reliably.

The year 2026 is poised for unprecedented innovation, demanding precision components that push the boundaries of engineering. Yet, the challenge remains: How do you identify the true leaders among `CNC machining` manufacturers capable of delivering uncompromising quality, technical brilliance, and strategic partnership?

This definitive analysis unveils the critical criteria and top players shaping the future of precision manufacturing. It empowers you to make informed decisions when selecting `Top CNC precision parts suppliers` who will drive your project’s success.

Understanding 2026 CNC Machining Excellence

What defines a `Top CNC precision parts supplier` in 2026?

A top `CNC precision parts supplier` in 2026 is characterized by more than just advanced machinery; it’s about a holistic commitment to excellence. These manufacturers possess an unparalleled depth of material expertise and a robust quality control infrastructure.

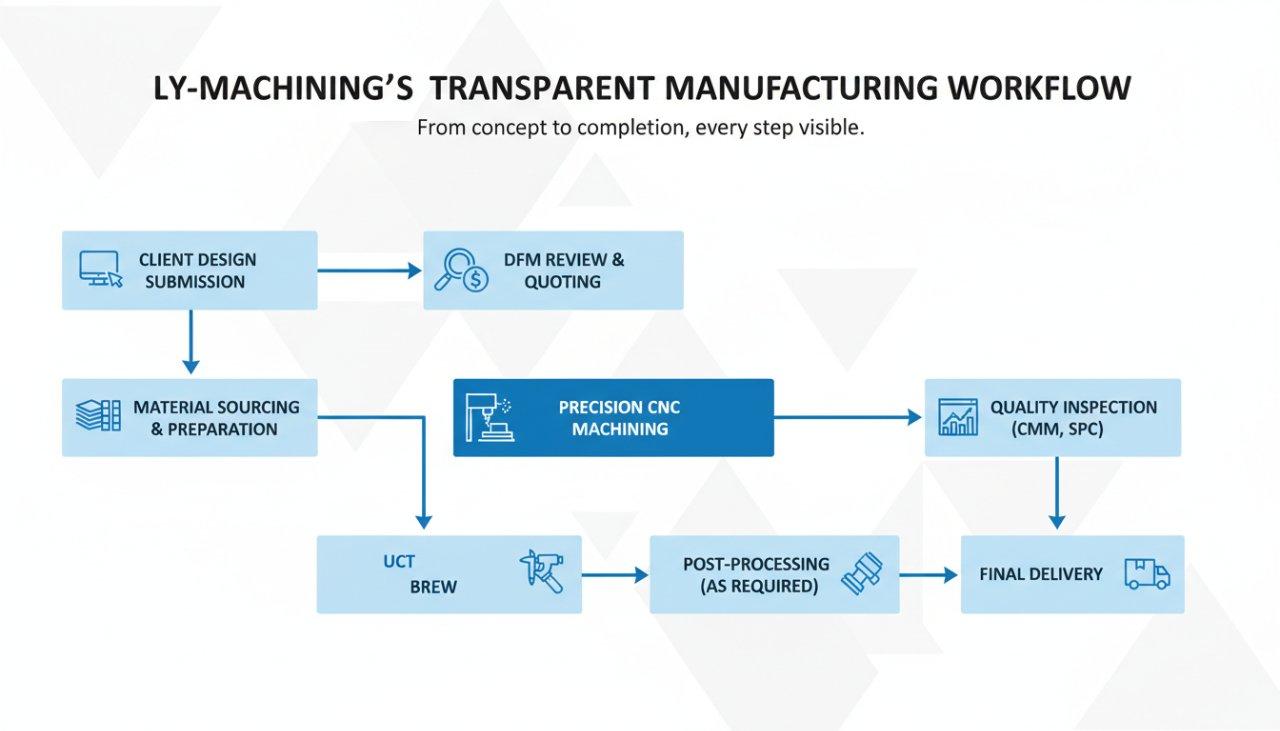

They integrate Design for Manufacturability (DFM) early in the process and foster transparent client collaboration. In ly-machining’s experience, this proactive approach is key to achieving optimal outcomes.

Why the `2026 Ranking of Recommended CNC Machining Manufacturers` matters.

For procurement managers and R&D engineers, navigating the complex landscape of `recommended CNC machining companies` is crucial. The `2026 Ranking of Recommended CNC Machining Manufacturers` serves as a vital guide.

It helps mitigate supply chain risks, ensures access to cutting-edge capabilities, and secures a competitive edge. Partnering with top-tier firms directly impacts product innovation and market readiness.

Evolving demands for `precision CNC machining` quality.

The market’s demands for `precision CNC machining` quality are continuously evolving, pushing boundaries. We see increasing requirements for tighter tolerances, often in the micron range, especially for aerospace and medical applications.

Clients require complex geometries that challenge conventional manufacturing methods and demand flawless surface finishes. Working with exotic materials also necessitates specialized expertise and processes for `CNC manufacturing`.

Criteria for Top CNC Precision Suppliers

Technical prowess: Advanced `CNC machining` capabilities.

Exceptional technical prowess is non-negotiable for `best precision CNC machining manufacturers`. This includes mastery of multi-axis machining (3-axis, 4-axis, and especially 5-axis CNC), which enables the production of highly complex parts in a single setup.

Advanced capabilities also encompass Wire EDM, sinker EDM, and precision grinding, crucial for intricate features and demanding finishes. ly-machining consistently invests in the latest machinery to stay at the forefront of `CNC machining` technology.

Table: Advanced Machining Capabilities

| Capability | Typical Tolerance (mm) | Material Suitability |

|---|---|---|

| 5-Axis CNC Milling | +/- 0.005 | Aerospace alloys, Titanium, Inconel |

| Wire EDM | +/- 0.002 | Tool steels, Carbides, Conductive |

| Precision Grinding | +/- 0.001 | Hardened steels, Ceramics |

Quality assurance: Elevating `high-quality parts` standards.

Maintaining `high-quality parts` standards requires a robust and uncompromising quality assurance system. `Top CNC precision parts suppliers` adhere to rigorous certifications like ISO 9001 and AS9100, which are paramount in aerospace and defense sectors.

Tools such as Coordinate Measuring Machines (CMM) and Statistical Process Control (SPC) are essential for validating dimensional accuracy and process consistency. ly-machining’s in-house metrology lab ensures every part meets exacting specifications before shipment.

Transparency and value in `recommended CNC machining companies`.

Transparency is a hallmark of trust in `recommended CNC machining companies`. Clients seek clear, itemized quotes with no hidden costs and reliable lead time estimations.

A common issue ly-machining sees is opaque pricing that leads to budget overruns and project delays. ly-machining prioritizes open communication, providing regular updates and promptly addressing any concerns.

Strategic partnerships with `best precision CNC machining manufacturers`.

The `best precision CNC machining manufacturers` function as strategic partners, not just vendors. They offer invaluable Design for Manufacturability (DFM) input, helping optimize designs for cost-effective and efficient production.

These partnerships are built on long-term support and a shared commitment to problem-solving. ly-machining’s engineering team works closely with clients from concept to completion, ensuring seamless integration.

DFM and innovation from `Top CNC precision parts suppliers`.

Innovation is driven by effective DFM from `Top CNC precision parts suppliers`. This involves rapid prototyping capabilities that accelerate product development cycles.

Such suppliers offer expert engineering support and guidance on optimal material selection for specific applications. ly-machining’s DFM expertise helps clients achieve superior performance and often reduce manufacturing costs.

Top 2026 Recommended CNC Manufacturers

Methodology for our `2026 Ranking of Recommended CNC Machining Manufacturers`.

Our `2026 Ranking of Recommended CNC Machining Manufacturers` is based on a rigorous methodology. We evaluate firms based on industry certifications, their investment in state-of-the-art equipment, and documented client testimonials.

Innovation in processes and materials, as well as their commitment to sustainability, also play significant roles. This comprehensive approach ensures an objective assessment of leading `precision CNC machining` providers.

Spotlight on `best precision CNC machining manufacturers`: Case studies.

The `best precision CNC machining manufacturers` consistently demonstrate their capabilities through successful projects. They showcase how they overcome challenges like ultra-tight tolerances or complex material properties.

These firms leverage advanced technologies and deep engineering insights to deliver exceptional results. Their track record of reliability and problem-solving defines their leadership in the industry.

Hidden gems among `recommended CNC machining companies`.

Beyond the widely recognized names, there are often `recommended CNC machining companies` that qualify as hidden gems. These might be smaller, specialized firms with niche expertise in particular materials or complex geometries.

They offer highly personalized service and often possess unique technical capabilities that set them apart. Discovering these specialized manufacturers can be a strategic advantage for specific projects.

Our factory as a `source manufacturer` for precision needs.

ly-machining stands out as a true `source manufacturer` for diverse precision needs. This means ly-machining handles the entire manufacturing process in-house, from raw material to finished product.

This vertical integration allows ly-machining to maintain stringent quality control at every stage. It also results in significant cost efficiencies and more reliable lead times for clients seeking `precision CNC machining`.

Partnering with Best CNC Machining

Evaluating `Top CNC precision parts suppliers` for long-term fit.

Evaluating `Top CNC precision parts suppliers` for a long-term fit extends beyond merely comparing price quotes. It involves assessing their cultural alignment, responsiveness, and problem-solving capabilities.

Understanding their operational scale and capacity for future growth is also vital. A strong partnership is built on mutual trust and consistent performance over time.

Table: Key Evaluation Criteria for CNC Suppliers

| Criterion | Description | Why it Matters |

|---|---|---|

| Certifications (AS9100) | Industry-specific quality standards | Guarantees adherence to stringent process control |

| DFM Expertise | Design optimization for manufacturing | Reduces costs, improves part performance, shortens lead times |

| Communication | Responsiveness and clarity in interactions | Ensures project alignment and quick issue resolution |

| Production Capacity | Ability to meet volume demands | Supports scalability and consistent supply |

The benefit of a `source manufacturer` in `CNC machining` supply chains.

Engaging a `source manufacturer` like ly-machining offers significant benefits in `CNC machining` supply chains. It eliminates middlemen, streamlining communication and reducing potential misinterpretations.

This direct relationship often translates to faster lead times and greater accountability for quality. ly-machining’s integrated approach provides clients with better control and a single point of contact.

How `transparent pricing` enhances client-supplier trust.

`Transparent pricing` is fundamental to building lasting client-supplier trust. It involves providing detailed breakdowns of costs, including materials, labor, and overhead.

This clarity avoids unexpected charges and fosters a relationship built on honesty. ly-machining is committed to complete financial transparency, ensuring clients understand the value they receive.

Leveraging `deep technical expertise` for project success.

Leveraging `deep technical expertise` is paramount for ensuring project success. ly-machining’s engineering team provides invaluable insights into material science, advanced tooling, and post-processing techniques.

Their expertise helps clients overcome complex design challenges and achieve optimal part functionality. This collaborative technical support is a hallmark of `best precision CNC machining manufacturers`.

Future of Precision CNC Machining

Emerging trends impacting `2026 Ranking of Recommended CNC Machining Manufacturers`.

Emerging trends are profoundly impacting the `2026 Ranking of Recommended CNC Machining Manufacturers`. Increased automation, including robotics and cobots, is enhancing efficiency and consistency on the factory floor.

The integration of AI and machine learning for predictive maintenance and process optimization is also becoming standard. Hybrid manufacturing processes, combining `CNC machining` with additive techniques, open new design possibilities.

Sustainable practices in `best precision CNC machining manufacturers`.

Sustainable practices are becoming a core expectation for `best precision CNC machining manufacturers`. This includes investing in energy-efficient machinery and optimizing processes to reduce waste.

Material recycling programs and responsible sourcing are also vital components. ly-machining actively implements green initiatives to minimize its environmental footprint.

Innovations in materials and `CNC machining` processes.

Innovations in materials and `CNC machining` processes continue to redefine capabilities. New high-performance alloys and advanced composites demand specialized tooling and machining strategies.

Developments in cutting tools, such as ceramic and diamond-coated inserts, enable faster material removal rates and superior surface finishes. Lights-out manufacturing, where machines operate autonomously, further optimizes production efficiency.

Case Study: Accelerating Aerospace Innovation with Ultra-Precision

Problem: A leading aerospace client approached ly-machining with a challenge to produce a critical fuel system component. The part required exceptionally tight tolerances of +/- 0.005mm on complex internal geometries, made from a high-temperature resistant Inconel alloy known for its machinability challenges.

ly-machining’s Solution: ly-machining leveraged its advanced 5-axis `CNC machining` centers and developed a custom tooling strategy using specialized ceramic inserts. ly-machining’s engineering team provided critical DFM feedback, optimizing specific features for manufacturability without compromising performance. In-process CMM measurements ensured real-time quality control.

Result: ly-machining successfully delivered the `high-quality parts` ahead of the client’s aggressive schedule, surpassing all tolerance and surface finish requirements. This allowed the client to accelerate their engine testing phase, ultimately saving significant development costs and time in their innovation cycle.

Conclusion

Securing your competitive edge with `Top CNC precision parts suppliers`.

Securing a competitive edge in 2026 demands strategic partnerships with `Top CNC precision parts suppliers`. These manufacturers offer more than just parts; they provide reliability, innovation, and technical leadership.

By choosing wisely, businesses can ensure their products meet the highest standards of quality and performance. ly-machining embodies the rigorous criteria discussed, offering a trusted path to manufacturing excellence.

Call to Action

Partner with a `source manufacturer` for your `precision CNC machining` needs.

Ready to elevate your product’s performance with a proven leader in `precision CNC machining`? Connect with ly-machining’s technical experts today for a confidential DFM review and a transparent quote on your next critical project.

Discover the difference a true `source manufacturer` makes in quality, reliability, and innovation. ly-machining is ready to be your strategic partner.

FAQ

What defines a top CNC manufacturer?

A top `CNC machining` manufacturer is defined by advanced technical capabilities, rigorous quality certifications like AS9100, and comprehensive DFM support. They demonstrate consistent reliability, transparent processes, and `deep technical expertise`.

In ly-machining’s view, a commitment to innovation and customer collaboration also sets the leaders apart. These attributes ensure the production of `high-quality parts` consistently.

How does ly-machining ensure quality?

ly-machining ensures uncompromising quality through a multi-faceted approach. This includes adhering to ISO 9001 and AS9100 quality management systems, utilizing advanced CMM for precise measurements, and implementing Statistical Process Control (SPC).

ly-machining’s skilled technicians conduct in-process checks at every stage of `CNC manufacturing`. This layered inspection strategy guarantees `high-quality parts` for every client.

What materials does ly-machining specialize in?

ly-machining specializes in machining a wide array of materials, from common metals to exotic alloys and high-performance plastics. This includes stainless steel, aluminum, brass, and titanium.

ly-machining also routinely works with Inconel, Monel, and various engineering plastics like PEEK and Delrin. This versatility allows ly-machining to meet diverse client requirements for `precision CNC machining`.