Choosing the optimal stainless steel for your CNC machining project is a critical decision that impacts part performance, longevity, and overall cost. Between 304 stainless steel and 316 stainless steel, engineers often face a dilemma. Selecting the wrong material can lead to compromised quality, excessive tooling costs, or project delays.

This comprehensive guide from ly-machining will deep dive into the CNC machining performance comparison of 304 and 316 stainless steels. We will provide the essential technical insights to help you make an informed CNC material selection for your specific application needs.

Quick Comparison Table:

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Core Advantage | Excellent formability, good general-purpose corrosion resistance, cost-effective | Superior corrosion resistance (especially pitting and crevice), enhanced high-temperature strength |

| Key Differentiator | Absence of molybdenum | Presence of 2-3% molybdenum |

| Machinability | Generally good, prone to work hardening | More challenging due to higher strength and work hardening |

| Ideal for | General purpose, kitchenware, architectural, automotive components | Marine, chemical processing, medical, food processing, pharmaceutical equipment |

| Cost | Lower material cost | Higher material cost |

| Main Compromise | Less resistant to chlorides and strong acids | More difficult to machine, higher cost |

What is 304 Stainless Steel?

Definition

304 stainless steel is the most common austenitic chromium-nickel stainless steel. It is known for its excellent corrosion resistance, good formability, and ease of fabrication. It is a non-magnetic alloy in its annealed condition but can become slightly magnetic when cold worked.

In our experience, 304 is often the default choice due to its balance of properties and cost-effectiveness. It contains approximately 18% chromium and 8% nickel, giving it the common designation 18/8 stainless steel.

Core Features

Key features of 304 stainless steel include its good weldability and excellent deep drawing characteristics. It offers good resistance to oxidation and many corrosive agents in atmospheric conditions and freshwater. It does not contain molybdenum, which differentiates it from 316.

From a manufacturing perspective, its versatility makes it suitable for a vast array of applications. However, its susceptibility to chloride-induced pitting and stress corrosion cracking in aggressive environments is a known limitation.

Table: 304 Stainless Steel Key Properties

| Property | Value (Typical) |

|---|---|

| Chemical Composition | 18% Cr, 8% Ni, 0.08% C max |

| Tensile Strength (min) | 515 MPa (75 ksi) |

| Yield Strength (min) | 205 MPa (30 ksi) |

| Hardness (Brinell) | 201 HB max |

| Corrosion Resistance | Good general, poor in chlorides |

| Relative Machinability | Moderate (50-60% of B1112 free-machining steel) |

Typical Use Cases

Due to its balanced properties, 304 stainless steel is extensively used across various industries. Common applications include kitchen sinks, cutlery, food processing equipment, architectural trim, chemical containers, and automotive components like exhaust manifolds. Its widespread use in consumer goods highlights its blend of performance and affordability, often benefiting from efficient 304 stainless steel CNC machining.

What is 316 Stainless Steel?

Definition

316 stainless steel is another widely used austenitic stainless steel, primarily distinguished from 304 by the addition of molybdenum. This alloying element significantly enhances its corrosion resistance, especially against pitting and crevice corrosion in chloride-rich environments and strong acids.

As a manufacturer, we often recommend 316 when applications demand superior protection against harsh chemicals or marine exposure. It is sometimes referred to as “marine-grade” stainless steel.

Core Features

The primary advantage of 316 stainless steel is its enhanced resistance to a wider range of corrosive media. This makes it ideal for environments where 304 might fail prematurely. It also exhibits higher strength at elevated temperatures compared to 304. The molybdenum content typically ranges from 2-3%.

However, this improved performance comes with machining challenges. Its higher strength and work-hardening characteristics mean that 316 stainless steel CNC machining requires more careful parameter selection and robust tooling.

Table: 316 Stainless Steel Key Properties

| Property | Value (Typical) |

|---|---|

| Chemical Composition | 16-18% Cr, 10-14% Ni, 2-3% Mo, 0.08% C max |

| Tensile Strength (min) | 515 MPa (75 ksi) |

| Yield Strength (min) | 205 MPa (30 ksi) |

| Hardness (Brinell) | 217 HB max |

| Corrosion Resistance | Excellent, especially in chlorides |

| Relative Machinability | Lower (40-50% of B1112 free-machining steel) |

Typical Use Cases

The superior corrosion resistance of 316 stainless steel makes it indispensable for demanding applications. These include marine components, chemical processing equipment, medical implants and surgical instruments, pharmaceutical manufacturing, and food and beverage processing equipment that handles acidic or saline solutions. For critical applications, selecting 316 for CNC material selection is often non-negotiable.

304 vs 316: Detailed Head-to-Head Comparison

Machinability & Tool Wear

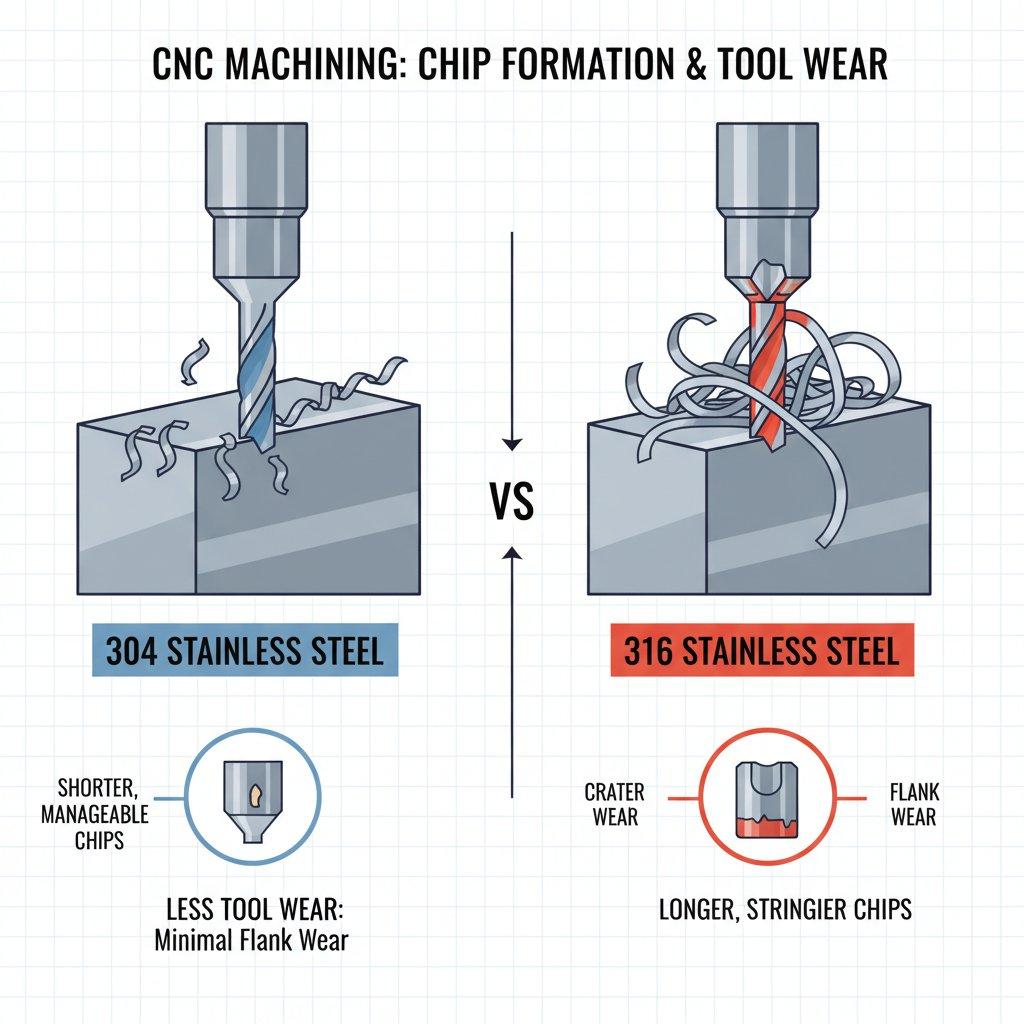

When it comes to CNC machining performance, 304 and 316 stainless steels present distinct challenges. Both are austenitic stainless steels, notorious for their work-hardening tendencies, which can lead to rapid tool wear if not managed correctly. However, 316, with its higher strength and molybdenum content, generally exhibits lower machinability.

In our workshop, we find that 304 stainless steel CNC machining, while still challenging, allows for slightly higher cutting speeds and feed rates compared to 316. The higher abrasiveness and greater propensity for work hardening of 316 lead to increased heat generation at the cutting edge and accelerated tool wear. This necessitates lower surface feet per minute (SFM), more rigid setups, and specialized tooling for 316. Chip control can also be more difficult with 316, forming stringier chips.

Table: CNC Machining Performance Comparison

| Aspect | 304 Stainless Steel CNC Machining | 316 Stainless Steel CNC Machining |

|---|---|---|

| Machinability Index | Higher (approx. 50-60%) | Lower (approx. 40-50%) |

| Work Hardening | High | Very High |

| Tool Wear | Significant, but manageable | More severe, requires robust tools |

| Chip Formation | Stringy, but can be controlled | Tougher, more continuous, harder to break |

| Surface Finish | Good potential, careful parameters needed | Good potential, even finer control needed |

| Heat Dissipation | Moderate | Lower due to higher strength |

Corrosion Resistance

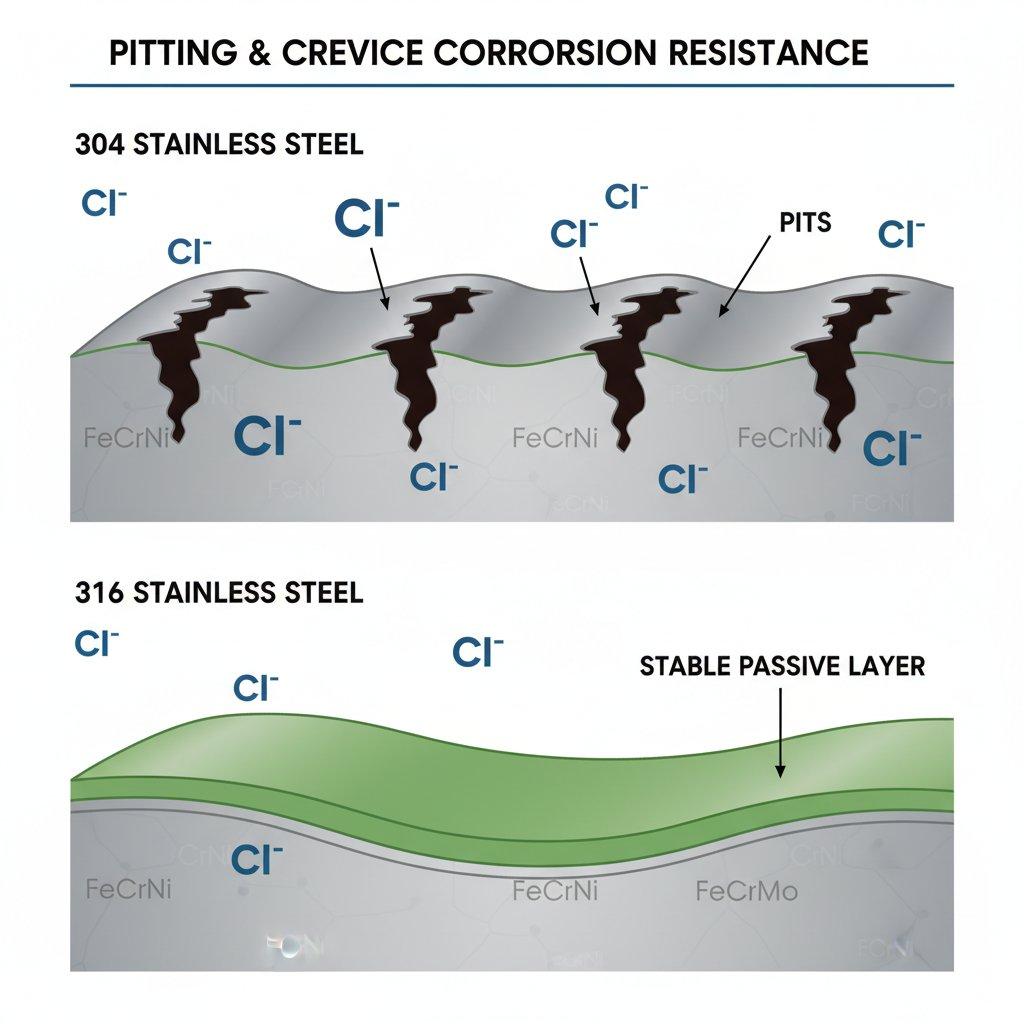

The most significant differentiator between 304 and 316 is their corrosion resistance. Both offer excellent general corrosion resistance, but 316 excels in specific environments due to its molybdenum content. Molybdenum creates a more robust passive layer, providing superior resistance to chlorides.

This means 316 stainless steel is highly resistant to pitting and crevice corrosion, which are common failure modes in saline solutions, seawater, and chemical processing fluids. 304, lacking molybdenum, is more susceptible to these localized forms of attack. For applications in marine or chemical processing, 316 offers a critical longevity advantage, directly influencing CNC material selection.

Mechanical Properties

While their tensile and yield strengths are quite similar in the annealed condition, 316 stainless steel generally maintains its strength better at elevated temperatures. Both exhibit excellent ductility and toughness, characteristic of austenitic stainless steels.

The higher nickel and molybdenum content in 316 contributes to its slightly higher hardness in some conditions and improved creep resistance. This can be a factor in high-temperature or stress-bearing applications where maintaining structural integrity is paramount.

Weldability & Post-Processing

Both 304 and 316 are generally considered highly weldable using common fusion welding techniques. However, 316L (a low-carbon version of 316) is often preferred for welding, especially for heavy sections, to minimize sensitization and intergranular corrosion. Similarly, 304L is available for improved weldability.

Post-machining processes like passivation are critical for both materials to maximize their inherent corrosion resistance by removing free iron and forming a stable chromium-rich oxide layer. For 316, proper passivation is even more crucial to leverage its superior properties.

Pros and Cons Analysis

Advantages and Disadvantages of 304 Stainless Steel

Advantages of 304 Stainless Steel:

* Excellent formability and ductility, making it easy to bend and shape.

* Good general corrosion resistance in a wide range of atmospheric and freshwater environments.

* More cost-effective material compared to 316, leading to lower raw material costs.

* Good weldability and aesthetic finish potential.

* Relatively easier to machine compared to 316, potentially allowing for faster cycle times.

Disadvantages of 304 Stainless Steel:

* Poor resistance to chloride corrosion, making it unsuitable for marine or highly saline environments.

* Susceptible to pitting and crevice corrosion in acidic or high-chloride solutions.

* Not ideal for high-temperature applications requiring enhanced creep resistance.

Advantages and Disadvantages of 316 Stainless Steel

Advantages of 316 Stainless Steel:

* Superior corrosion resistance, especially against pitting and crevice corrosion in chlorides.

* Enhanced resistance to a broader spectrum of acids and chemical media due to molybdenum.

* Higher strength and improved creep resistance at elevated temperatures.

* Excellent hygienic properties, preferred for medical and pharmaceutical applications.

Disadvantages of 316 Stainless Steel:

* Higher material cost, which can significantly impact project budgets.

* More challenging to machine due to increased strength and work-hardening, leading to slower cycle times and higher tooling costs.

* Requires specialized cutting tools and machining parameters to achieve optimal results.

* Less formable than 304, though still considered ductile.

Cost and Pricing Comparison

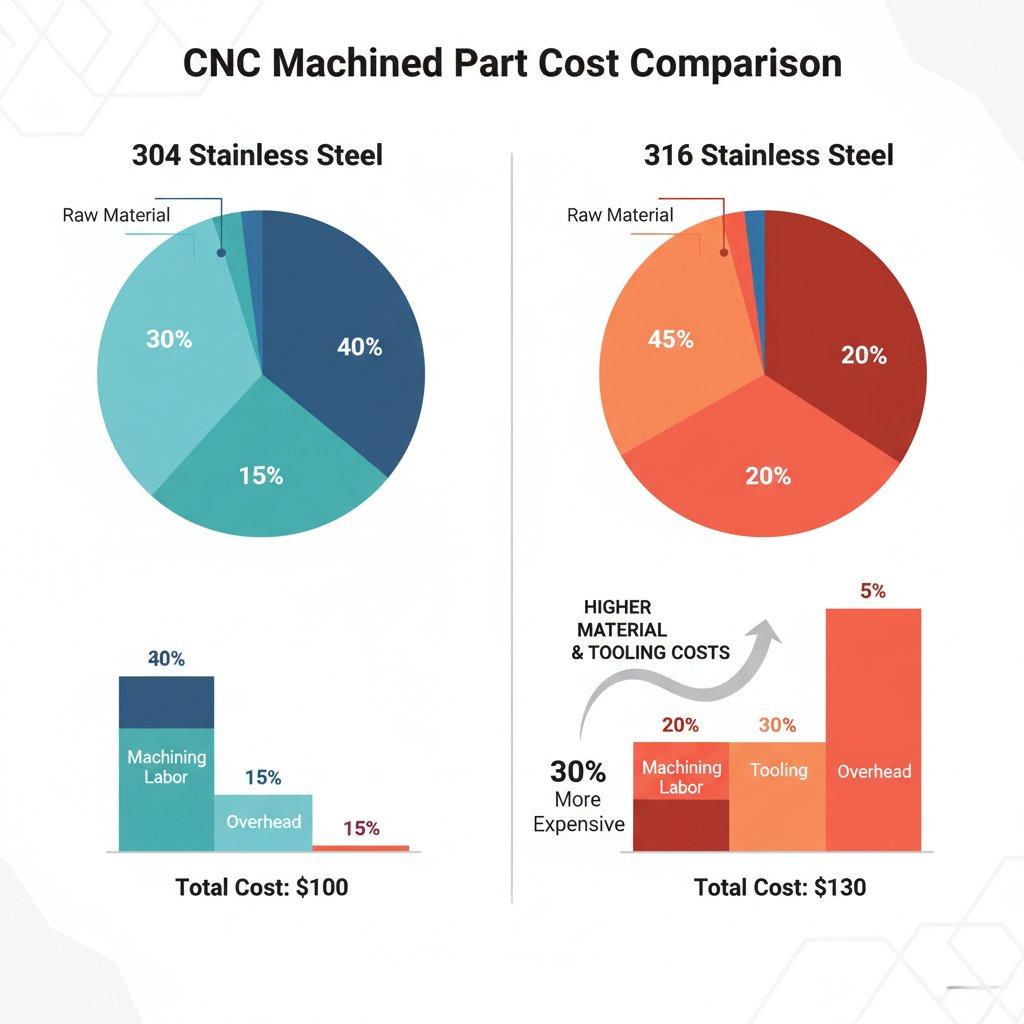

The cost difference between 304 and 316 stainless steel is a significant factor in CNC material selection. Generally, 316 stainless steel commands a higher price due to the addition of molybdenum and often nickel, which are more expensive alloying elements. This difference can vary based on market conditions and alloy surcharges, but 316 is consistently more expensive per kilogram.

Beyond raw material cost, the machining characteristics also influence overall project pricing. While 304 stainless steel CNC machining might have lower material input, the increased difficulty of 316 stainless steel CNC machining can lead to higher processing costs. This includes increased tool wear, longer cycle times, and the need for more specialized coolants and setups.

From a procurement manager’s perspective, it’s essential to consider the total cost of ownership. A cheaper 304 part might fail prematurely in a corrosive environment, leading to costly replacements and downtime, making the initial higher investment in 316 more economical in the long run.

Table: Typical Cost Factors

| Cost Factor | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Raw Material Cost | Lower | Higher |

| Tooling Cost | Moderate | Higher (due to faster wear) |

| Machining Time | Shorter | Longer (due to slower feeds/speeds) |

| Post-Processing Cost | Moderate (e.g., passivation) | Moderate (e.g., critical passivation) |

| Lifecycle Cost (in corrosive environments) | Potentially higher due to failures | Potentially lower due to longevity |

Real-World Use Cases / Customer Testimonials

Use Case 1: Application of 304 Stainless Steel

A client approached us for components for their general-purpose industrial machinery – internal shafts and housing parts that would operate in a controlled, non-corrosive indoor environment. After reviewing their specifications and budget, we recommended 304 stainless steel. The primary drivers were cost-effectiveness and good mechanical strength.

Our 304 stainless steel CNC machining expertise allowed us to produce high-volume, precise parts efficiently, leveraging the material’s good machinability. The project was completed ahead of schedule, meeting all dimensional tolerances and surface finish requirements, proving 304 was the ideal CNC material selection for their application.

Use Case 2: Application of 316 Stainless Steel

Another client, a medical device manufacturer, required highly precise, small components for a new surgical instrument. These parts would be exposed to various sterilization chemicals and biological fluids. Due to the critical nature of the application and stringent FDA requirements for corrosion resistance, 316L stainless steel was the mandated choice.

Our engineers carefully developed specific 316 stainless steel CNC machining strategies, utilizing high-pressure coolant and specialized carbide tooling to manage work hardening and ensure exceptional surface integrity. Despite the machining challenges, the superior corrosion resistance of 316L was indispensable, and the finished parts passed all qualification tests, highlighting the value of expert 316 stainless steel machining.

Decision Framework: Which One Should You Choose?

Making the right CNC material selection between 304 and 316 stainless steel boils down to a clear understanding of your application’s demands, environmental conditions, and budget. Here at ly-machining, we guide our clients through this crucial choice.

Choose 304 Stainless Steel if you…

* Require good general corrosion resistance for atmospheric or freshwater environments.

* Are working with a tighter budget and need to optimize material costs.

* Need parts that are easily formable and weldable.

* Your application does not involve exposure to chlorides, strong acids, or high temperatures requiring enhanced creep resistance.

* Value higher machinability for faster production cycles and lower tooling overheads in non-critical applications.

Choose 316 Stainless Steel if you…

* Require superior corrosion resistance, particularly against pitting and crevice corrosion in chloride-rich environments (e.g., marine, coastal, saltwater).

* Your application involves exposure to strong acids, caustic solutions, or harsh chemicals.

* Need enhanced strength and stability at elevated temperatures.

* Are manufacturing medical implants, pharmaceutical equipment, or food processing components where hygiene and resistance to aggressive cleaning agents are paramount.

* Prioritize long-term performance and reliability over initial material and machining cost savings for critical applications.

Conclusion

The choice between 304 and 316 stainless steel for CNC machining is a nuanced one, heavily dependent on your project’s unique requirements. While 304 offers a cost-effective solution with good general properties and easier machinability, 316 stands out for its superior corrosion resistance, especially in demanding environments, albeit with higher material and machining costs.

Understanding the specific performance nuances of 304 stainless steel CNC machining versus 316 stainless steel CNC machining is essential for successful product development. As a leading source manufacturer, ly-machining possesses the deep expertise in stainless steel machining comparison and CNC material selection to guide you. Ready to optimize your next CNC machining project with the right stainless steel? Contact our expert engineering team today for a personalized material consultation and a transparent quote. Leverage our deep technical expertise and source manufacturer advantages to ensure your parts are of the highest quality, delivered efficiently and cost-effectively.

FAQ Section

What is the main difference between 304 and 316 stainless steel for CNC machining?

The primary difference lies in the chemical composition, specifically the addition of molybdenum in 316 stainless steel. This molybdenum provides 316 with significantly enhanced corrosion resistance, particularly against pitting and crevice corrosion in chloride environments, making it ideal for marine or chemical applications. For CNC machining, 316 is generally tougher and more prone to work hardening than 304, requiring more specialized tooling and slower speeds.

Why is 316 stainless steel more difficult to CNC machine than 304?

316 stainless steel contains molybdenum, which increases its strength and toughness, particularly at elevated temperatures. This leads to higher resistance to deformation during cutting, greater heat generation, and a stronger propensity for work hardening. These factors combined result in faster tool wear, more challenging chip control, and often necessitate reduced cutting speeds and feed rates compared to 304 stainless steel CNC machining.

When should I choose 304 over 316 for my CNC project, considering cost?

You should choose 304 stainless steel when your application does not involve aggressive corrosive environments, such as exposure to chlorides or strong acids, and where general atmospheric or freshwater corrosion resistance is sufficient. Its lower material cost and relatively easier machinability make it a more cost-effective option for projects where the superior properties of 316 are not strictly required, thus optimizing your CNC material selection from a budget perspective.