Struggling to choose the right stainless steel for your CNC machining project? The choice between 304 and 316 grades can be confusing, leading to costly errors in material selection that impact your product’s durability and performance. This decision paralysis often results in project delays and budget overruns, leaving you with a component that may corrode prematurely or lack the required strength. At [Company Name], we provide expert guidance to help you select the ideal alloy, ensuring optimal results for your specific application.

When selecting between 304 and 316 stainless steel for CNC machining, the primary deciding factors are corrosion resistance and cost. 316 steel offers superior resistance, particularly against chlorides and marine environments, due to its molybdenum content. In contrast, 304 steel provides good corrosion resistance in most environments and is a more budget-friendly option, making it suitable for a wide range of general-purpose applications.

The distinction between these two popular stainless steel grades is crucial for the success of any manufacturing project. Therefore, understanding their unique properties will empower you to make an informed decision. Furthermore, this knowledge is essential for optimizing the CNC machining process itself, from tooling selection to cycle times. Consequently, we will explore the key differences to guide you toward the perfect material choice for your needs, ensuring both quality and cost-effectiveness.

Key Differences: 304 Steel vs. 316 Steel

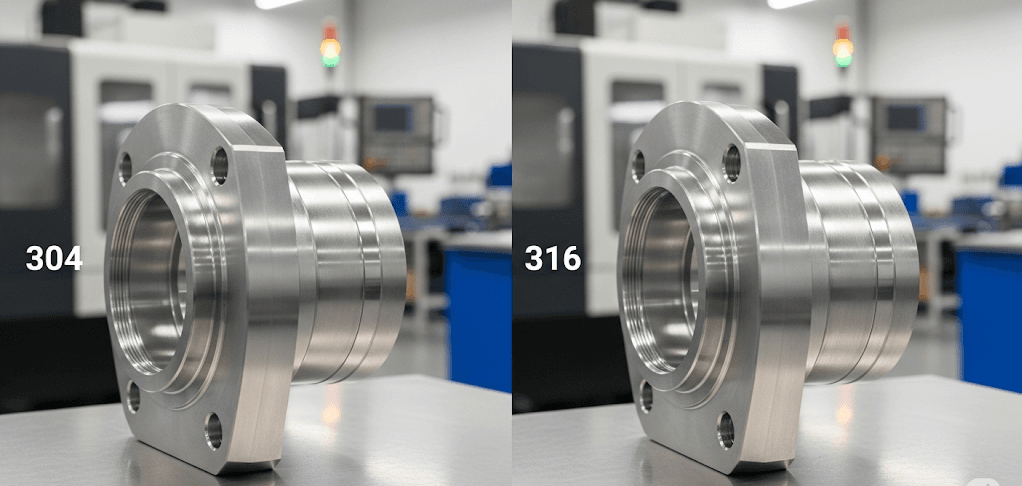

When diving into CNC milling, the material you choose is foundational. The debate between 304 steel and 316 steel is common, as they are two of the most prevalent austenitic stainless steels. While they look similar, their underlying metallurgy dictates their ideal use cases. Understanding these differences ensures your components meet their performance and longevity requirements.

The primary distinction lies in the addition of molybdenum to 316 steel, an element not present in 304 steel. This single alloying difference dramatically enhances 316 steel’s resistance to corrosion, especially from chlorides and other industrial solvents. For any CNC machining project destined for harsh environments, this makes 316 steel a superior, albeit more expensive, choice. We handle both materials with precision at [Company Name].

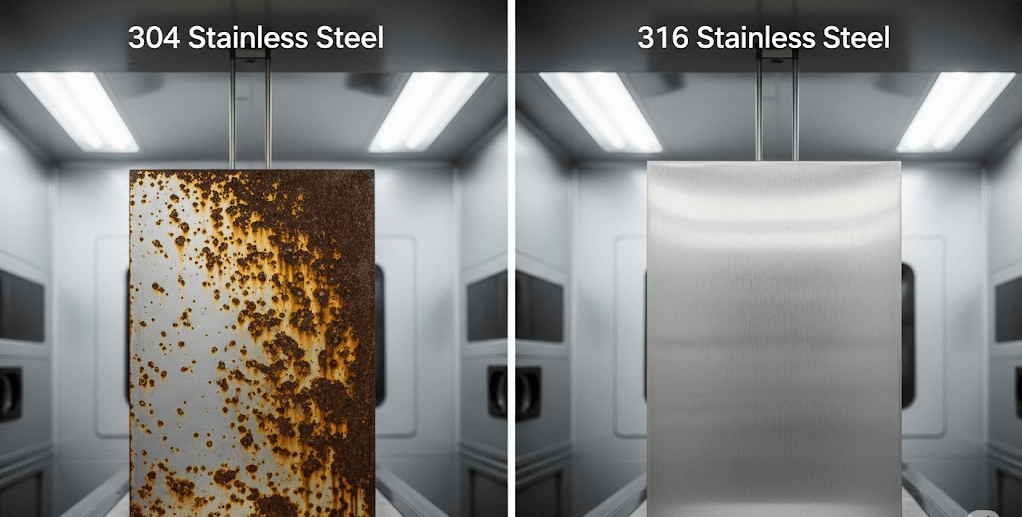

Corrosion Resistance: When to Choose 316 Steel

The most significant advantage of 316 steel is its enhanced corrosion resistance. If your component will be exposed to saltwater, de-icing salts, or aggressive chemical solutions, opting for 316 steel is a wise long-term investment. Its molybdenum content helps prevent pitting and crevice corrosion, which can compromise a part’s structural integrity.

For applications in marine hardware, medical implants, and chemical processing equipment, 316 steel is the industry standard. While the upfront cost for CNC machining 316 steel is higher, it prevents premature failure and costly replacements. Our quality control processes ensure that the material’s integrity is maintained throughout the CNC milling process, delivering a reliable final product.

Cost vs. Performance: The 304 Steel Advantage

For applications where severe corrosion is not a primary concern, 304 steel offers an excellent balance of performance and affordability. This alloy provides good general corrosion resistance, solid formability, and is readily weldable, making it a versatile workhorse for many industries. Its lower cost makes it an attractive option for high-volume production runs.

You will find 304 steel used in everything from kitchen appliances and automotive trim to architectural paneling and storage tanks. Our expertise in CNC machining allows us to optimize tool paths and cutting speeds for 304 steel, passing the cost savings and efficiency on to you. We help you determine if 304 steel meets your project’s demands without over-engineering the solution.

Understanding the “L” Grades: 304L and 316L

The “L” designation in 304L and 316L stands for “low carbon.” These variants were developed to address weld decay (sensitization), a phenomenon where chromium carbides precipitate at grain boundaries during welding, reducing corrosion resistance. The lower carbon content in 316L and 304L steel minimizes this issue, making them the preferred choice for welded components.

If your CNC machined part requires welding, choosing the ‘L’ version is critical, especially for thicker sections. For parts that do not require welding, the standard grades are often sufficient. Our team can advise on whether 304L or 316L is necessary for your project, ensuring excellent post-machining fabrication results.

| Feature | 304 Stainless Steel | 316 Stainless Steel | 304L Stainless Steel | 316L Stainless Steel |

| Composition | 18% Cr, 8% Ni | 16% Cr, 10% Ni, 2% Mo | 18% Cr, 8% Ni, Low C | 16% Cr, 10% Ni, 2% Mo, Low C |

| Corrosion Resistance | Good | Excellent | Good | Excellent, Weld-Resistant |

| Best For | General Purpose, Kitchens | Marine, Medical, Chemical | Welded Structures | Welded Marine/Chemical Parts |

| CNC Machining Cost | Lower | Higher | Lower | Higher |

| Weldability | Good | Fair | Excellent | Excellent |

Frequently Asked Questions (FAQ)

Q1: Is 316 steel harder to machine than 304 steel? Yes, 316 steel is generally more challenging for CNC machining than 304 steel. Its higher nickel content and the inclusion of molybdenum contribute to a higher work-hardening rate and tougher material characteristics. This requires slower cutting speeds, robust tooling, and careful heat management during the CNC milling process to achieve precise tolerances and prevent tool wear. Our advanced CNC machines at [Company Name] are specifically calibrated to handle the demands of 316 steel effectively.

Q2: Can I substitute 304 steel for 316 steel to save on costs? Substituting 304 steel for 316 steel is only advisable if the component will not be exposed to corrosive agents like salt or harsh chemicals. While you would save on initial material costs, the part could fail prematurely if used in an environment that demands the superior corrosion resistance of 316 steel. We always recommend a thorough application review to prevent long-term performance issues and ensure the material selected, whether it’s 304 or 316 steel, is fit for purpose.

Q3: How does surface finish affect the corrosion resistance of 304 and 316 steel? A smoother surface finish, achieved through precision CNC machining and post-processing techniques like polishing, enhances the corrosion resistance of both 304 and 316 steel. A rougher surface has more microscopic peaks and valleys where corrosive elements can accumulate and initiate pitting. We offer a range of surface finishing services to maximize the longevity and performance of your CNC machined parts, regardless of the steel grade chosen.