Imagine holding a keyboard enclosure that feels as premium as it looks – what defines that perfect surface finish? For critical components like CNC aluminum keyboard enclosures, the surface treatment isn’t just an afterthought; it’s the defining touch that dictates durability, aesthetics, and user experience.

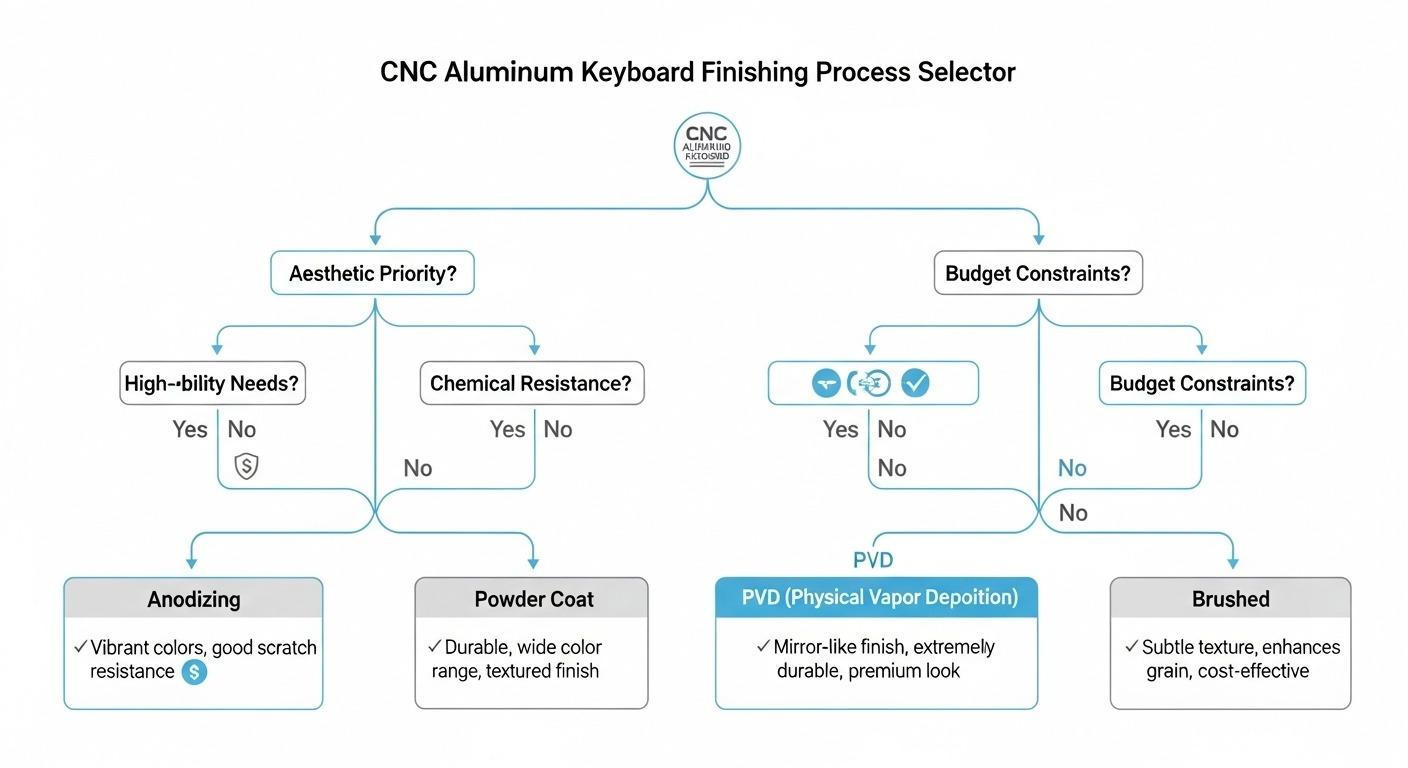

With countless options, how do you choose the right CNC aluminum keyboard finishing process to elevate your product? This guide provides an in-depth analysis of the most popular processes, ensuring informed decisions for your custom keyboard shell CNC machining projects.

We aim to demystify complex choices, presenting a systematic framework for selecting optimal keyboard enclosure surface treatment, backed by data-driven insights.

The right keyboard enclosure surface treatment enhances both durability and aesthetic appeal, extending product lifespan and elevating user satisfaction.

Unveiling Precision Keyboard Finishes

Setting the Scene & Questions

Addressing CNC Machining Surface Challenges

The selection of an appropriate surface finish for CNC aluminum keyboard finishing is a critical engineering decision. It directly impacts the component’s performance, tactile qualities, and visual presentation. Unaddressed, initial surface conditions can compromise end-product integrity.

Variations in initial CNC machined surfaces, such as tool marks or micro-scratches, necessitate specific pre-treatment strategies. These preparatory steps are fundamental to achieving a uniform and high-quality keyboard enclosure surface treatment, forming the basis for subsequent finishing processes.

Importance of Quality Aluminum Enclosure Finishes

A superior keyboard enclosure surface treatment is not merely cosmetic; it is a vital functional enhancement. It provides increased wear resistance, corrosion protection, and improved tactile feel, directly influencing user satisfaction and product longevity.

High-quality finishes contribute significantly to brand perception, positioning products within the premium segment of the custom keyboard shell CNC machining market. This perceived value often translates into stronger market demand and competitive differentiation.

Core Thesis & Content Preview

Discovering Optimal Keyboard Surface Treatment

Selecting the optimal keyboard enclosure surface treatment requires a comprehensive understanding of various processes. It necessitates balancing aesthetic requirements with functional demands, cost implications, and manufacturing lead times. Our analysis quantifies these trade-offs.

This systematic approach minimizes risk and maximizes return on investment for custom keyboard shell CNC machining projects. By examining key performance indicators for each finish, we enable precise, data-backed decision-making.

A Look at 4 Popular CNC Aluminum Processes

This article will meticulously detail four popular CNC aluminum keyboard finishing processes. These include anodizing, powder coating, e-coating, PVD, electroplating, brushing, and polishing, each offering distinct advantages.

We will deconstruct their technical principles, suitable applications, and specific performance characteristics. This structured comparison aids in identifying the most effective keyboard enclosure surface treatment for diverse design and functional objectives.

Process 1: Anodizing Aluminum Keyboards

Anodizing Basics & Performance

Definition & Workings for Aluminum Shells

Anodizing is an electrolytic passivation process that increases the thickness of the natural oxide layer on the surface of aluminum parts. For custom keyboard shell CNC machining, it forms a hard, durable, and corrosion-resistant layer.

This process involves immersing the aluminum enclosure in an acid electrolyte bath and passing an electric current through it. The resulting anodic oxide layer integrates with the underlying aluminum, ensuring excellent adhesion and longevity for the keyboard enclosure surface treatment.

Advantages for Keyboard Durability & Color

Anodized CNC aluminum keyboard finishing provides superior scratch and wear resistance, significantly extending the lifespan of the enclosure. The hard oxide layer protects against daily abrasion and environmental factors.

Furthermore, anodizing allows for a wide range of vibrant, fade-resistant colors. Dyes are absorbed into the porous oxide layer before sealing, offering rich aesthetic options that are crucial for market differentiation in custom keyboards.

Key Anodizing Benefits:

| Benefit Category | Description |

|---|---|

| Durability | Enhanced scratch and wear resistance. |

| Corrosion | Superior protection against oxidation. |

| Aesthetics | Wide spectrum of stable, fade-resistant colors. |

| Adhesion | Oxide layer integrates with base metal. |

Typical Anodizing Types for Keyboards:

| Type | Description | Primary Use |

|---|---|---|

| Type II | Standard, decorative, good corrosion/wear resistance. | General aesthetic and protective finishes. |

| Type III | Hardcoat, thicker, superior wear resistance, less decorative color range. | High-durability applications, industrial use. |

Design Impact & Application Tips

Custom Anodized Finishes in Keyboards

The ability to achieve consistent, saturated colors makes anodizing a premier choice for aesthetic differentiation in custom keyboard shell CNC machining. Designers can specify exact color codes, ensuring brand consistency across product lines.

Considerations for custom anodized finishes include surface preparation, as any imperfections on the bare aluminum will be amplified by the anodizing process. Proper initial CNC aluminum keyboard finishing is paramount for a flawless outcome.

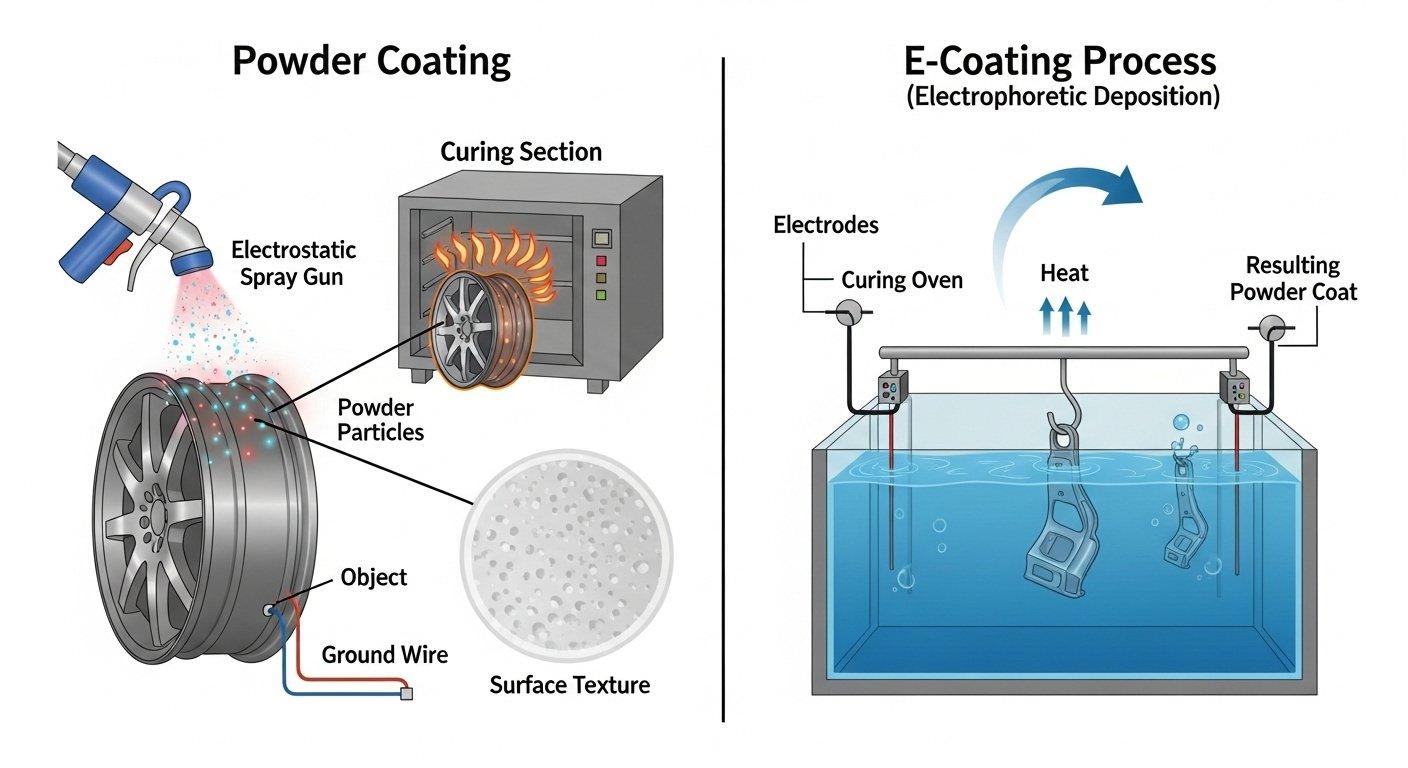

Process 2: Powder & E-Coating for Enclosures

Coating Methods & Characteristics

Powder Coating: Process & Texture Options

Powder coating involves applying a dry powder through electrostatic attraction to the CNC aluminum keyboard part, which is then cured under heat. This melts the powder, allowing it to flow and form a uniform, hard finish.

It offers exceptional durability, chip resistance, and a broad palette of colors and textures, from smooth gloss to textured matte. This makes it a versatile keyboard enclosure surface treatment for diverse design requirements.

Powder Coating Attributes:

| Attribute | Description |

|---|---|

| Application | Electrostatic spray followed by heat cure. |

| Durability | High resistance to chipping, scratching, fading. |

| Texture | Wide range: smooth, matte, glossy, textured, wrinkled. |

| Environmental | Low VOC, environmentally friendly process. |

Electrophoresis (E-Coat) for Smooth Finishes

E-coating, or electrophoretic deposition, uses an electrical current to deposit a uniform coating onto the CNC aluminum keyboard. The process ensures complete coverage, even in complex geometries and recessed areas.

This keyboard enclosure surface treatment provides excellent corrosion resistance and a very smooth, consistent finish, often thinner than powder coating. It is frequently used as a primer or a final finish where thin, uniform layers are essential.

E-Coating Characteristics:

| Characteristic | Description |

|---|---|

| Application | Immersion in bath, electrical current deposition. |

| Coverage | Excellent uniformity, even on complex parts. |

| Layer | Thin, smooth, consistent film. |

| Resistance | Good corrosion protection, often a base coat. |

Comparing Durability & Cost

When to Choose Coatings for Keyboard Parts

Powder coating generally offers superior impact and abrasion resistance due to its thicker layer. It is a robust choice for keyboard enclosures requiring maximum protection against physical damage.

E-coating provides excellent coverage and corrosion resistance with a thinner, smoother finish, often at a lower material cost for large volumes. It’s ideal when fine tolerances or internal surface protection are critical for custom keyboard shell CNC machining.

| Feature | Powder Coating | E-Coating |

|---|---|---|

| Durability | High impact, abrasion, and chip resistance. | Good corrosion resistance, uniform thin film. |

| Aesthetic Range | Wide color and texture options. | Limited color options, typically smooth finish. |

| Cost (Initial) | Moderate to High (setup dependent). | Moderate (can be efficient for high volume). |

| Thickness | Thicker, more substantial layer. | Thinner, more precise layer. |

| Best Use | Exterior parts, textured finishes, high wear. | Internal parts, corrosion protection, thin films. |

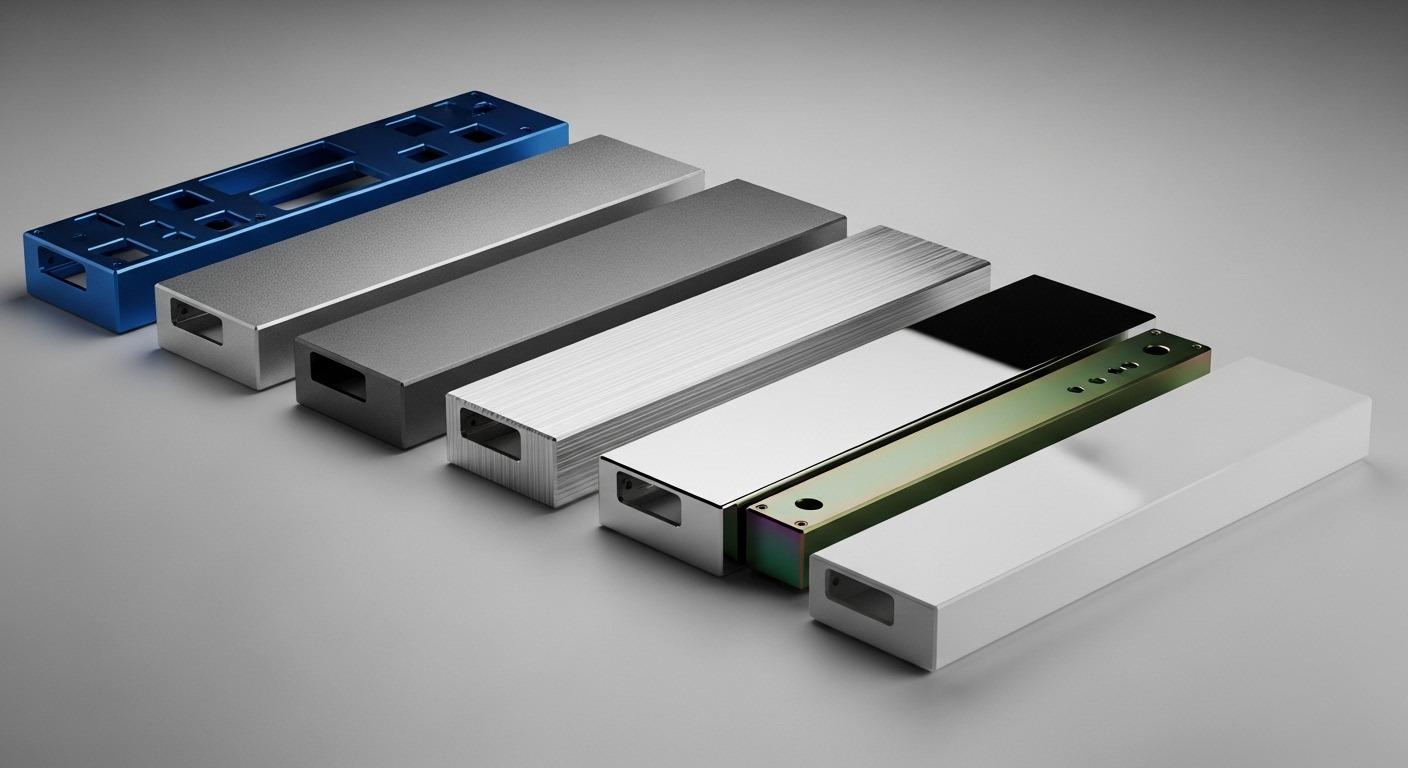

Process 3: Premium & Mechanical Finishes

PVD & Electroplating for Aesthetics

PVD: Vibrant Colors on Aluminum Surfaces

Physical Vapor Deposition (PVD) is a vacuum deposition technique that coats CNC aluminum keyboard components with a thin film of various materials. It produces incredibly hard, durable, and brilliant finishes in a range of metallic colors.

PVD offers excellent scratch and corrosion resistance while allowing for unique, high-end aesthetics, such as rainbow or specific metallic hues. It is a premium keyboard enclosure surface treatment often chosen for its distinctive visual appeal and enhanced longevity.

Electroplating for Metallic Luster on Keyboards

Electroplating involves depositing a thin layer of metal onto the aluminum surface through an electrical current. This process can enhance the aesthetic appeal, corrosion resistance, and hardness of the CNC aluminum keyboard enclosure.

While direct electroplating on aluminum can be challenging due to its passive oxide layer, specialized pre-treatment processes (like zincating) enable this application. It provides a true metallic luster, highly prized in custom keyboard shell CNC machining for luxury finishes.

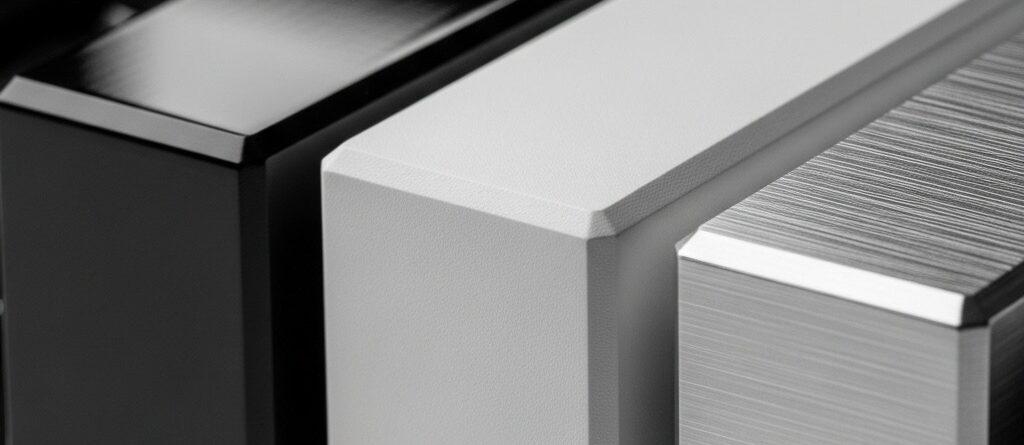

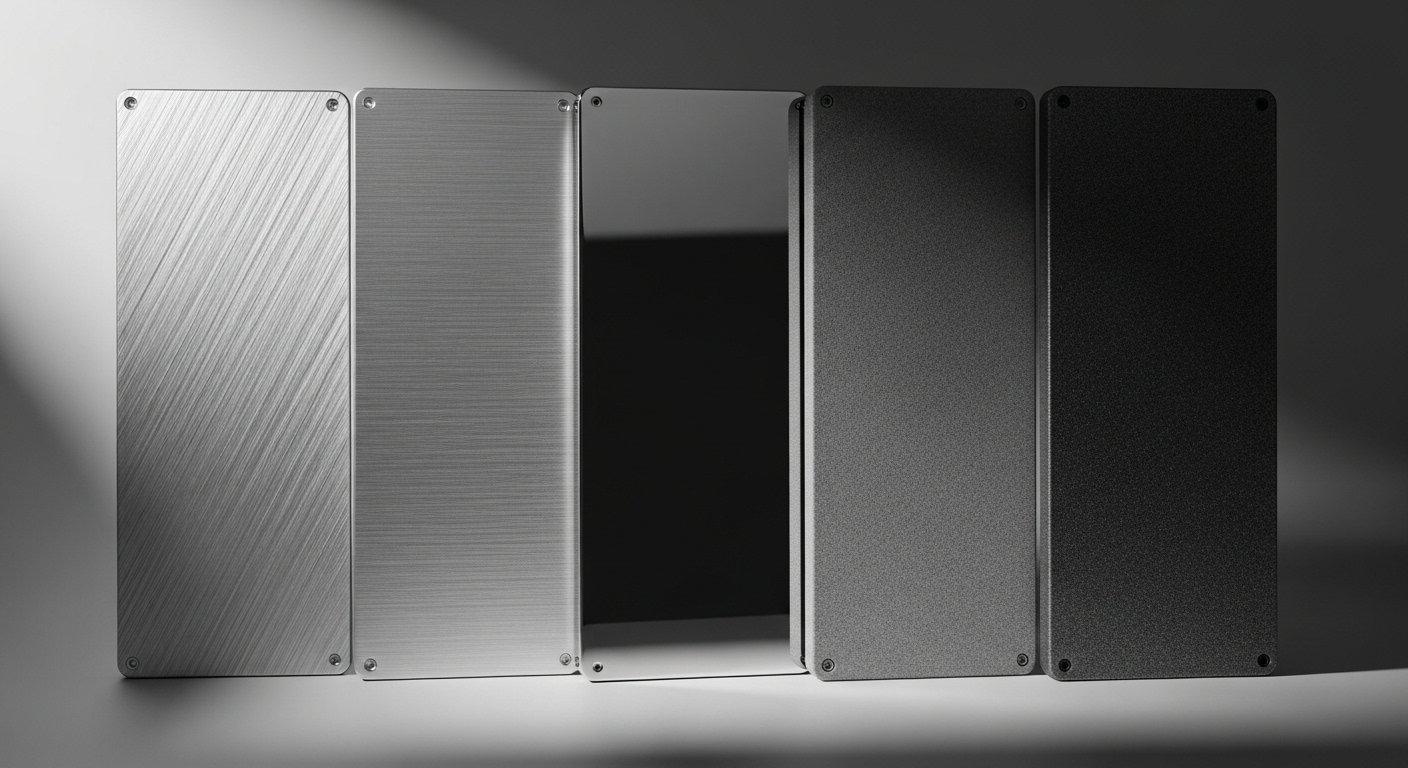

Brushed, Polished CNC Techniques

Achieving Unique Textures on Keyboard Cases

Brushing involves mechanically abrading the surface of the CNC aluminum keyboard part in a unidirectional pattern. This creates a fine, satin-like texture that diffuses light, giving a sophisticated, understated appearance.

Polishing, conversely, uses abrasive compounds to remove material and achieve a mirror-like, highly reflective surface. Both techniques are purely mechanical CNC aluminum keyboard finishing processes that enhance tactile feel and visual depth.

| Mechanical Finish | Description | Aesthetic Impact | Durability Enhancement |

|---|---|---|---|

| Brushing | Fine, unidirectional abrasive marks. | Satin, matte, diffused light. | Minimal direct; masks minor wear. |

| Polishing | Multi-stage abrasive removal to a smooth, reflective surface. | Mirror-like, high reflectivity, lustrous. | Minimal direct; susceptible to fingerprints. |

Choosing Your Ideal Keyboard Finish

Key Takeaways: Selecting Optimal Processes

Reviewing the 4 Popular Surface Treatments

The selection of the optimal CNC aluminum keyboard finishing process hinges on a precise evaluation of design objectives, performance requirements, and budget constraints. Each of the popular finishing processes offers a unique set of advantages.

Anodizing excels in durability and color stability. Powder and E-coating provide robust protection with varied textures and uniform coverage. PVD and electroplating deliver premium aesthetics and enhanced hardness, while brushing and polishing offer classic mechanical textures.

Summarizing Aluminum Enclosure Finishing Needs

For high-volume production of custom keyboard shell CNC machining, cost-effectiveness and process consistency are paramount. Anodizing and powder coating often present the most balanced solutions.

When premium aesthetics and extreme durability are primary drivers, PVD or electroplating may be justified. For a classic, tactile feel, mechanical finishes like brushing or polishing remain excellent choices for keyboard enclosure surface treatment.

Call to Action: Partnering with Experts

Consult Our CNC Experts for Your Project

Ready to define the perfect finish for your next CNC aluminum keyboard enclosure? Leverage our deep technical expertise and transparent pricing. Contact us today for a personalized consultation and a detailed, no-obligation quote on your custom keyboard shell CNC machining and surface treatment project. As your trusted source manufacturer, we ensure unparalleled quality from concept to completion.

Case Study: Elevating a Premium Keyboard Brand

A client, a rapidly growing premium keyboard brand, faced challenges achieving consistent color matching and scratch resistance for their high-end custom keyboard shell CNC machining projects. Their existing supplier struggled with batch-to-batch color variation and insufficient surface hardness, leading to customer complaints about durability.

Our solution involved meticulous pre-treatment combined with Type III hard anodizing for their CNC aluminum keyboard enclosures. We optimized the anodizing parameters to ensure precise color control and significantly increased the surface hardness, delivering superior scratch resistance.

The result was a product line with exceptional aesthetic consistency and significantly enhanced durability. This improved customer satisfaction, reduced warranty claims, and solidified the brand’s reputation for high-quality, long-lasting keyboard enclosures.

FAQ: Surface Finishing Keyboards

What is anodizing’s main benefit?

Anodizing provides a highly durable, corrosion-resistant, and aesthetically versatile finish for CNC aluminum keyboard enclosures. It integrates with the aluminum, offering excellent adhesion and extending the component’s lifespan.

This process allows for a wide range of vibrant, fade-resistant colors, making it ideal for custom branding and premium product differentiation. It significantly enhances the tactile and visual quality of the keyboard enclosure surface treatment.

Are coatings more durable than anodizing?

Powder coating generally offers superior impact and chip resistance due to its thicker layer. It can withstand significant physical abuse better than anodized finishes in certain scenarios.

Anodizing, particularly hard anodizing, provides excellent scratch and wear resistance. The choice between coatings and anodizing depends on the specific durability requirements and aesthetic goals for the keyboard enclosure surface treatment.

Why choose PVD for keyboards?

PVD (Physical Vapor Deposition) is chosen for CNC aluminum keyboard finishing when seeking premium aesthetics and exceptional hardness. It creates a thin, highly durable film with unique metallic or iridescent colors.

This process provides superior scratch and corrosion resistance, elevating the perceived value and longevity of custom keyboard shell CNC machining. It is a high-end keyboard enclosure surface treatment for distinctive product lines.