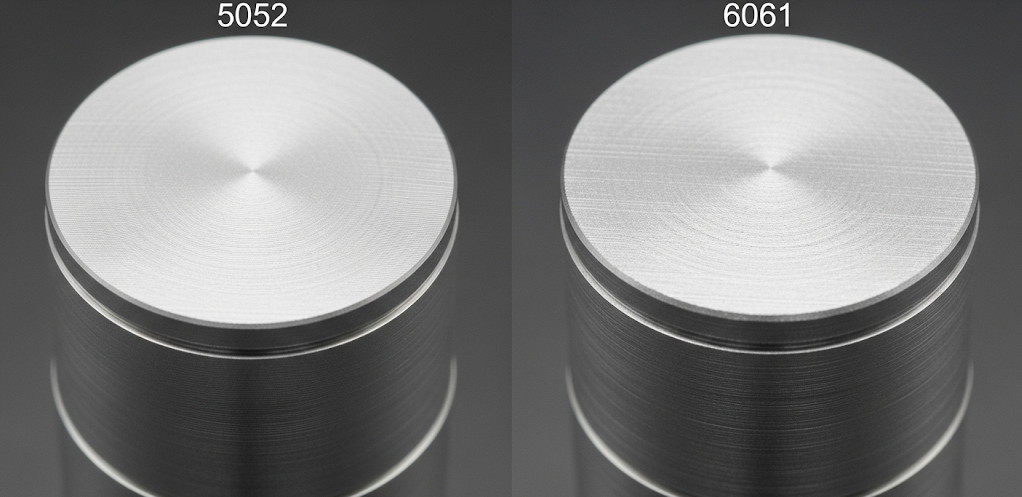

Struggling to select the right aluminum for your CNC machined parts? The choice between 5052 and 6061 aluminum often leads to concerns about long-term durability, especially when corrosion is a factor. Making the wrong decision can result in premature failure, costly replacements, and a tarnished reputation for your products.

This guide directly compares 5052 aluminum and 6061 aluminum, focusing on corrosion resistance in various environments. We provide the clarity needed to select the ideal alloy for your CNC machining project, ensuring both performance and longevity.

Understanding the subtle yet critical differences in corrosion resistance between 5052 aluminum and 6061 aluminum is crucial for the success of your CNC parts. Consequently, this detailed comparison will explore their properties and performance. Furthermore, by examining specific applications and surface treatments, we will guide you toward making a well-informed material choice.

Why Aluminum Choice Matters for CNC Part Corrosion Protection

The Role of 5052 and 6061 Aluminum in Industry

Both 5052 aluminum and 6061 aluminum are popular choices in CNC machining due to their excellent properties. Their widespread use spans across marine, aerospace, and consumer electronics, making the material selection process vital.

Importance of Corrosion Resistance

The corrosion resistance of CNC machined parts directly impacts their performance, lifespan, and overall cost. For any CNC machining project, choosing an alloy like 5052 aluminum or 6061 aluminum that withstands its operational environment is key.

Goal of This Guide

This guide aims to provide engineers and designers with a clear comparison of 5052 aluminum and 6061 aluminum. We focus on their corrosion resistance to help you make an informed decision for your CNC parts.

Deep Dive into 5052 Aluminum: Properties and Corrosion Resistance

Chemical and Physical Characteristics of 5052 Aluminum

5052 aluminum is a non-heat-treatable alloy, with magnesium as its primary alloying element. This composition gives 5052 aluminum exceptional corrosion resistance, particularly in saltwater environments. The material selection often favors 5052 for its durability.

Primary Applications

Due to its superior performance against corrosion, 5052 aluminum is frequently used for marine hardware, fuel tanks, and pressure vessels. These applications demand high resistance to moisture and chemical exposure, making 5052 aluminum an ideal choice for CNC machining these components.

Performance in Corrosive Environments

In environments with high salt spray content, such as coastal or marine settings, 5052 aluminum excels. Its ability to resist common forms of corrosion makes it a reliable material for CNC parts exposed to harsh conditions.

Exploring 6061 Aluminum: Properties and Corrosion Resistance

Chemical and Physical Characteristics of 6061 Aluminum

6061 aluminum is a precipitation-hardened alloy containing magnesium and silicon. This popular alloy is heat-treatable, offering good mechanical properties and weldability, making it a versatile option for CNC machining.

Primary Applications

The strength and versatility of 6061 aluminum make it suitable for structural components, aerospace parts, and bicycle frames. These applications often require a balance of strength and moderate corrosion resistance.

Performance in Common Environments

While 6061 aluminum offers good corrosion resistance in atmospheric and freshwater conditions, it is more susceptible to corrosion than 5052 aluminum in saltwater. Its performance is often enhanced through surface treatments.

Core Comparison: 5052 vs. 6061 Aluminum in Corrosive CNC Parts

Performance Differences by Corrosion Type

Seawater and Salt Spray: 5052 aluminum shows superior resistance, making it the preferred choice for marine CNC parts. 6061 aluminum can be used but typically requires a protective coating.

Chemical Media: The response of 5052 aluminum and 6061 aluminum to chemicals varies. 5052 generally offers broader resistance, especially against alkaline solutions.

Stress Corrosion Cracking (SCC): Heat-treated alloys like 6061 aluminum can be more susceptible to SCC. For CNC parts under constant stress in corrosive environments, 5052 aluminum is often a safer material selection.

Pitting and Crevice Corrosion: The higher magnesium content in 5052 aluminum contributes to its excellent resistance against pitting and crevice corrosion, common issues for many CNC parts.

How CNC Machining Affects Corrosion Resistance

The CNC machining process itself can introduce residual stress and create surface textures that may impact corrosion resistance. Proper machining techniques are vital for both 5052 aluminum and 6061 aluminum parts.

Enhancing Corrosion Resistance with Surface Treatments

| Surface Treatment | 5052 Aluminum | 6061 Aluminum | Key Benefits |

| Anodizing | Forms a very hard, durable, clear protective layer. | Excellent for anodizing; offers a wide range of color options. | Improves hardness, wear resistance, and corrosion protection. |

| Chem Film | Good paint adhesion and moderate corrosion resistance. | Provides good corrosion protection and electrical conductivity. | A cost-effective alternative to anodizing. |

| Painting/Powder Coat | Excellent adhesion with proper pretreatment. | Excellent adhesion, provides a decorative and protective finish. | Adds a robust barrier against environmental factors. |

Choosing Between 5052 and 6061 Aluminum for CNC Machining

Mechanical Strength Requirements

If your CNC parts require high strength, the heat-treatable 6061 aluminum is generally the better choice, offering higher tensile and yield strength than 5052 aluminum.

Machinability and Cost

6061 aluminum is known for its excellent machinability, producing good chip formation during CNC machining, which can lead to lower costs. 5052 aluminum is slightly gummier but is still readily machined.

Weldability and Assembly

For CNC parts that need to be welded, 5052 aluminum provides excellent results and maintains more of its post-weld strength compared to 6061 aluminum.

Application Environment

The single most important factor is the end-use environment. For marine or high-salinity applications, 5052 aluminum is the superior choice. For general structural use, 6061 aluminum is often sufficient.

Aesthetics and Finishing

Both 5052 aluminum and 6061 aluminum can be finished to a high standard. However, 6061 aluminum is often preferred for decorative anodizing due to the quality and consistency of the resulting finish.

Real-World Application Case Studies

Marine Electronics Housings

5052 aluminum is the standard material selection for CNC machining marine electronics enclosures due to its unmatched resistance to saltwater corrosion.

Outdoor Structural Supports

For outdoor architectural elements, 6061 aluminum strikes a balance between strength for structural integrity and adequate corrosion resistance, often enhanced by anodizing or powder coating.

Automotive Chassis Components

In automotive applications, CNC parts made from 6061 aluminum provide the necessary strength for components like chassis braces while relying on coatings to manage long-term corrosion from road salt and moisture.

Frequently Asked Questions (FAQ)

Which is better for high-strength welding, 5052 aluminum or 6061 aluminum?

5052 aluminum is generally considered superior for welding. It does not lose as much strength in the heat-affected zone as the heat-treatable 6061 aluminum, resulting in more durable welded assemblies for CNC parts.

In a humid or high-salinity environment, which aluminum alloy is safer?

For any CNC machining project in a humid or salty environment, 5052 aluminum is the safer and more reliable choice. Its inherent resistance to marine corrosion significantly outperforms 6061 aluminum in these conditions.

How can I further improve the corrosion resistance of 5052 or 6061 aluminum parts?

Applying a surface treatment is highly effective. Anodizing is a popular choice for both 5052 aluminum and 6061 aluminum, as it creates a hard, non-reactive surface layer that dramatically enhances corrosion resistance for CNC parts.

Conclusion: Optimizing Your Choice for CNC Parts

Recap of Key Decision Points

The choice between 5052 aluminum and 6061 aluminum hinges on a balance of corrosion environment, mechanical strength needs, and cost. Prioritize the demands of the end-use application.

Recommendations for Specific CNC Parts

Choose 5052 aluminum for any CNC part exposed to saltwater or consistent moisture. Opt for 6061 aluminum when strength is the primary concern and the corrosive environment is mild.

Future Trends in Aluminum Alloys

Innovations continue to bring new aluminum alloys with enhanced properties. Staying informed about material advancements can provide even better solutions for future CNC machining projects requiring a blend of strength and corrosion resistance.