Struggling to select the right material for your CNC machining project? You need a versatile alloy that balances strength, cost, and workability, but the sheer number of options can be overwhelming. Choosing the wrong material can lead to poor performance, difficult machining, and budget overruns.

This uncertainty can cause significant project delays and compromises. You might be facing issues like rapid tool wear during CNC milling or finding that your finished parts lack the necessary corrosion resistance for their intended environment. It’s a frustrating position that puts your design’s success at risk.

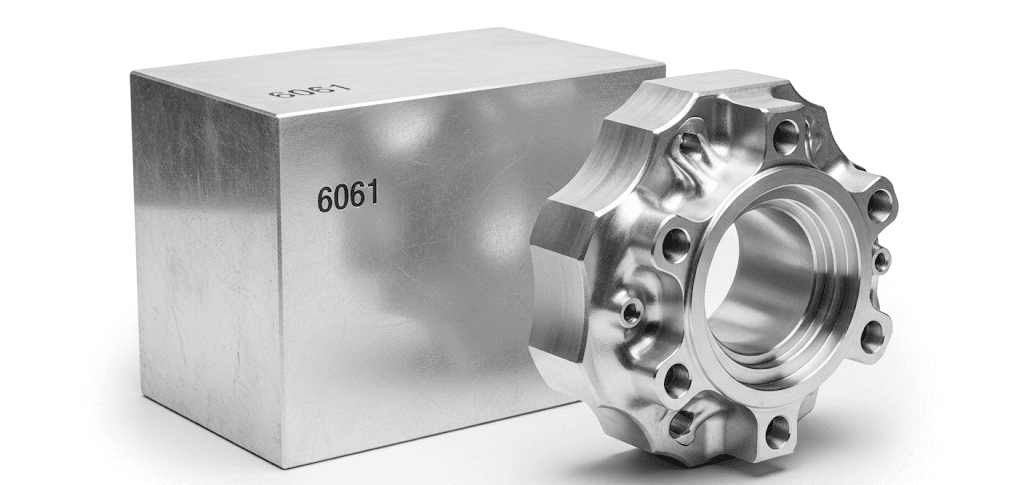

The solution is often found in one of the most reliable and well-understood materials in the industry: 6061 aluminum. This guide provides a deep dive into 6061 aluminum, exploring its unique properties, excellent machinability, and wide range of applications, making it a go-to choice for countless CNC machining projects.

Therefore, understanding the characteristics of this alloy is fundamental to leveraging its full potential. Furthermore, a deep knowledge of its behavior during CNC milling will allow for optimized results. Consequently, let’s delve into why 6061 aluminum is a superior choice for your manufacturing needs.

Properties of 6061 Aluminum

6061 aluminum is highly regarded in manufacturing for its excellent mechanical properties and versatility. As a precipitation-hardened alloy, its primary alloying elements are magnesium and silicon, which give it a unique combination of strength, corrosion resistance, and workability.

One of its most significant attributes is its high strength-to-weight ratio, making it ideal for applications where reducing weight without sacrificing durability is critical. This is a key reason why it’s so prevalent in aerospace and automotive components produced via CNC machining.

Mechanical & Thermal Properties of 6061-T6 Aluminum:

| Property | Value |

| Ultimate Tensile Strength | 310 MPa (45,000 psi) |

| Yield Strength | 276 MPa (40,000 psi) |

| Hardness, Brinell | 95 |

| Modulus of Elasticity | 68.9 GPa (10,000 ksi) |

| Thermal Conductivity | 167 W/m-K |

| Melting Point | 582 – 652 °C (1080 – 1205 °F) |

Moreover, 6061 aluminum exhibits strong resistance to atmospheric corrosion. This quality ensures longevity and reliability for parts exposed to various environmental conditions, reducing the need for protective coatings in some applications. At ly-machining, we often recommend 6061 for parts that require both structural integrity and surface durability.

Machinability of 6061 Aluminum

When it comes to CNC machining, 6061 aluminum is celebrated for its superb machinability. It allows for high cutting speeds and feeds, which translates directly to shorter cycle times and lower production costs.

The alloy produces predictable and manageable chips during the CNC milling process. This characteristic is crucial for efficient machining, as it helps prevent chip buildup around the tool, which can lead to tool breakage and a poor surface finish. Proper chip evacuation is key to successful high-speed milling.

Furthermore, 6061 aluminum is relatively easy on cutting tools, resulting in less tool wear compared to harder materials like steel or titanium. This means longer tool life and more consistent part quality over a production run. For companies like ly-machining, this machinability makes it an efficient and cost-effective material to work with.

Best Practices for CNC Machining 6061 Aluminum

To achieve optimal results when performing CNC machining on 6061 aluminum, a few best practices should be followed. Using the right cutting tools is paramount. We recommend sharp, two- or three-flute carbide end mills with a high helix angle for effective chip evacuation.

Coolant or lubrication is also essential. A steady supply of coolant not only prevents the aluminum from sticking to the cutting tool (a common issue known as “galling”) but also helps maintain thermal stability in the workpiece. This is critical for holding tight tolerances during long CNC milling operations.

Finally, optimizing your speeds and feeds is crucial. 6061 aluminum can be machined at high speeds, but the feed rate must be balanced to ensure a clean cut and excellent surface finish. Starting with the tool manufacturer’s recommendations and adjusting based on the specific machine and setup is a sound strategy.

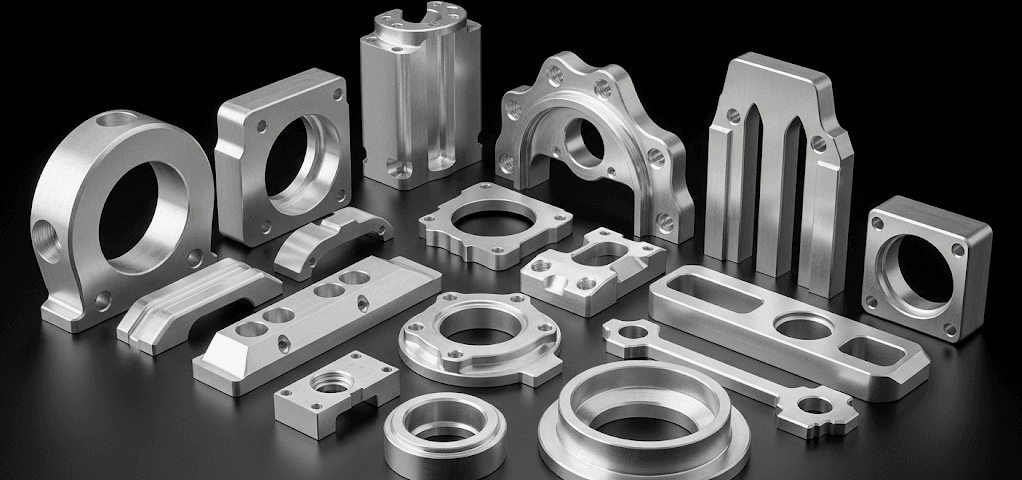

Typical Applications of CNC Machined 6061 Aluminum

The versatility of 6061 aluminum makes it a popular choice across numerous industries. Its combination of light weight, strength, and corrosion resistance is invaluable for creating a wide array of components through CNC machining.

In the aerospace industry, it is used for aircraft structures, such as fuselage and wing components. The automotive sector utilizes it for chassis parts, suspension components, and engine blocks. You will also find it in high-end bicycle frames and scuba tanks, where its light weight and strength are significant advantages.

Consumer electronics frequently use 6061 aluminum for casings and enclosures, like those for laptops and smartphones, due to its premium feel and durability. The CNC milling process allows for the creation of the intricate and precise features these products require. From structural parts to aesthetic components, 6061 aluminum is a proven performer.

Surface Treatments for 6061 Aluminum

While 6061 aluminum naturally has good corrosion resistance, various surface treatments can further enhance its properties. Anodizing is one of the most common treatments applied after CNC machining.

Anodizing creates a hard, durable, and corrosion-resistant oxide layer on the surface of the part. It can also be dyed in various colors, which is excellent for aesthetic purposes. This makes it a popular choice for consumer products and architectural components.

Other options include powder coating for a durable, colored finish, and chromate conversion coating (alodine), which provides excellent corrosion resistance and acts as a primer for paint. The team at ly-machining can help you select the appropriate surface treatment based on your application’s specific functional and aesthetic requirements.

Frequently Asked Questions

1. What is the difference between 6061-T6 and other tempers?

The “T6” in 6061-T6 refers to a specific temper condition. It means the aluminum has been solution heat-treated and then artificially aged. This T6 temper significantly increases the strength of the alloy, making it the most common and generally useful form of 6061 aluminum for CNC machining applications that require high strength and durability.

2. Can 6061 aluminum be welded after CNC machining?

Yes, 6061 aluminum has very good weldability. It can be readily welded using techniques like TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. However, it’s important to note that the heat from welding will lower the strength of the material in the heat-affected zone. For T6-tempered parts, a post-welding heat treatment may be necessary to restore the material to its full strength.

3. Is 6061 aluminum a sustainable material choice?

Aluminum is one of the most recycled and recyclable materials on the planet. The process of recycling aluminum requires only a fraction of the energy needed to produce new primary aluminum, making it an environmentally friendly choice. Using 6061 aluminum for your CNC machining projects supports sustainability efforts, especially when sourced from suppliers who utilize recycled content.