CNC machining enables rapid prototype manufacturing, allowing engineers to quickly test and validate designs with high precision, optimizing product development across diverse industries.

Are slow, costly prototyping cycles stifling your innovation? Product development managers and R&D engineers often grapple with extended timelines and budget overruns, impacting critical time-to-market goals. We understand the pressure to innovate rapidly while maintaining uncompromising quality.

Discover how industry leaders across seven diverse sectors are dramatically accelerating product development and achieving unparalleled design precision. This guide reveals how harnessing the power of rapid prototyping CNC empowers breakthroughs, providing the fast, high-quality, and cost-effective solutions needed to transform concepts into market-ready products.

The Power of Rapid Prototyping CNC

Accelerating Product Development Cycles

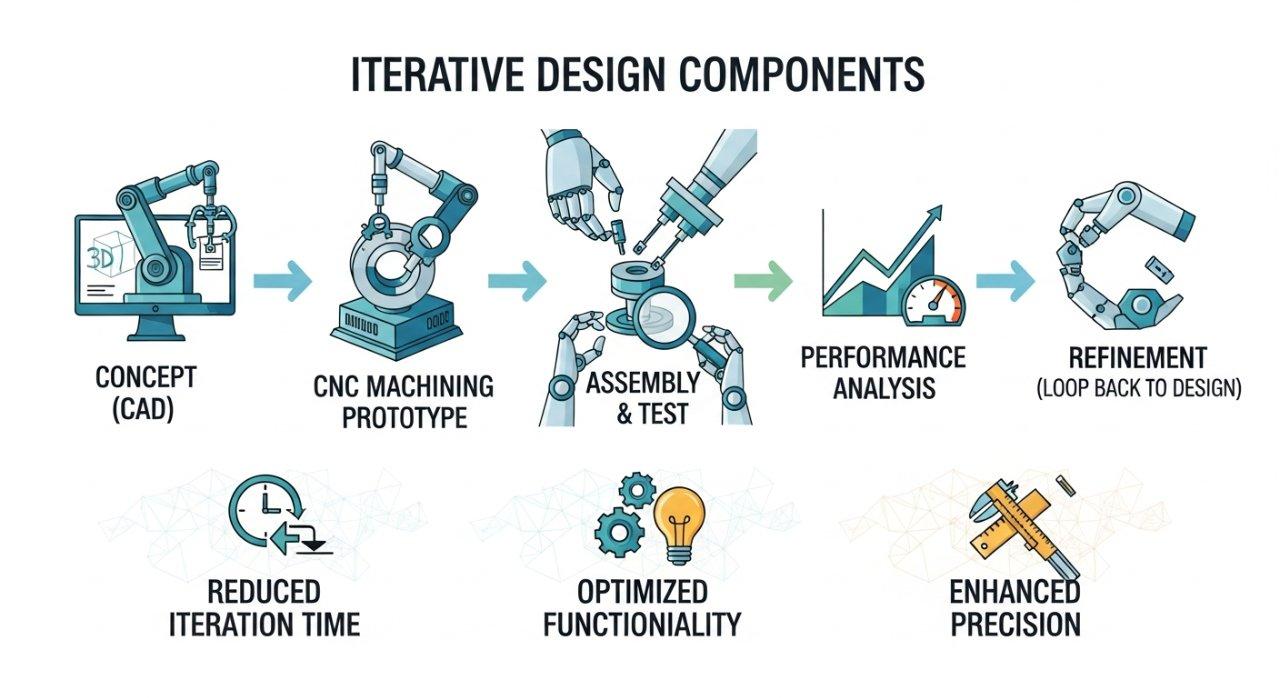

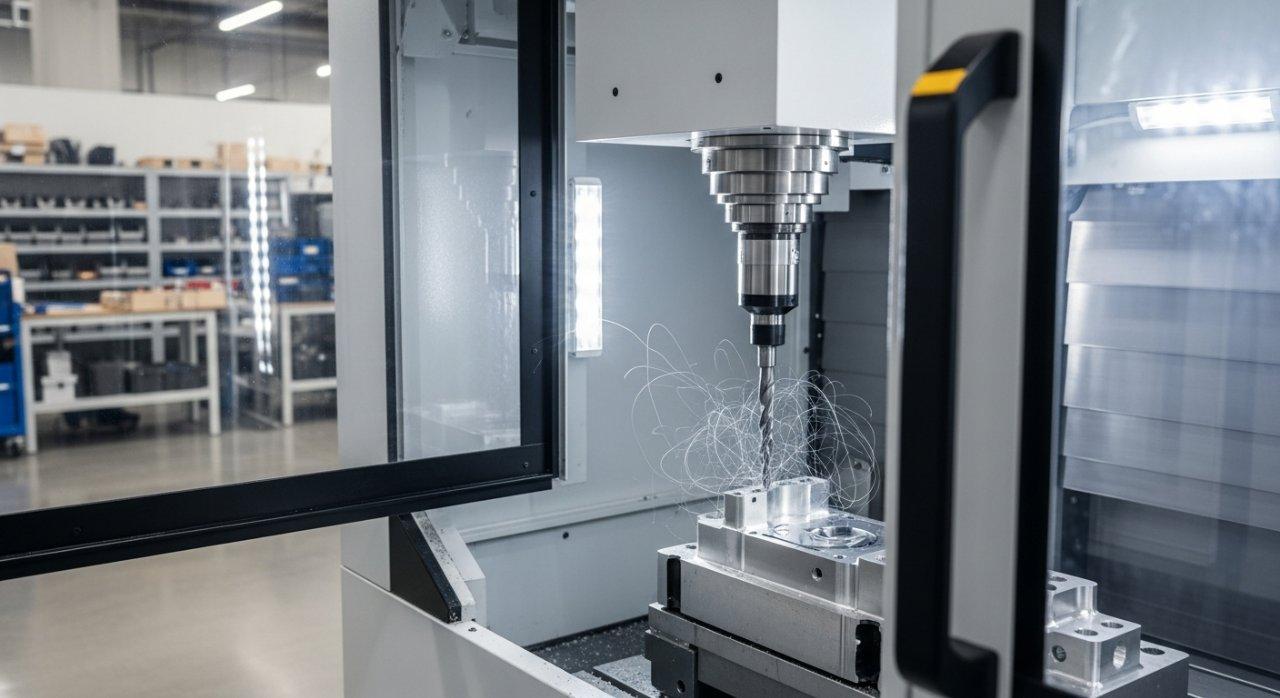

In our experience, the ability to rapidly iterate on designs is paramount for innovation. Rapid prototyping CNC machining significantly compresses the development timeline, allowing engineers to move from concept to physical part in days, not weeks. This speed is critical for maintaining competitive advantage.

This swift turnaround enables multiple design iterations, facilitating comprehensive testing and validation of form, fit, and function early in the product lifecycle. Addressing design flaws promptly reduces the risk of costly changes later in the manufacturing process.

Cost Efficiency in Design Iterations

Traditional prototyping methods can incur substantial costs with each design revision. Rapid prototyping CNC, by leveraging efficient machining processes and optimized material usage, offers a more economical pathway to validate designs. It minimizes waste and reduces tooling expenses.

A common issue we see is the expense associated with custom tooling for early prototypes; CNC machining eliminates this need. It allows for direct machining from CAD models, providing high-quality parts without the upfront investment in molds or dies, making design exploration more affordable.

Uncompromising Quality and Precision

The inherent precision of CNC machining ensures that prototypes accurately reflect the intended design specifications, often achieving tolerances down to ±0.005 inches or better. This level of accuracy is essential for functional testing and ensuring components integrate seamlessly.

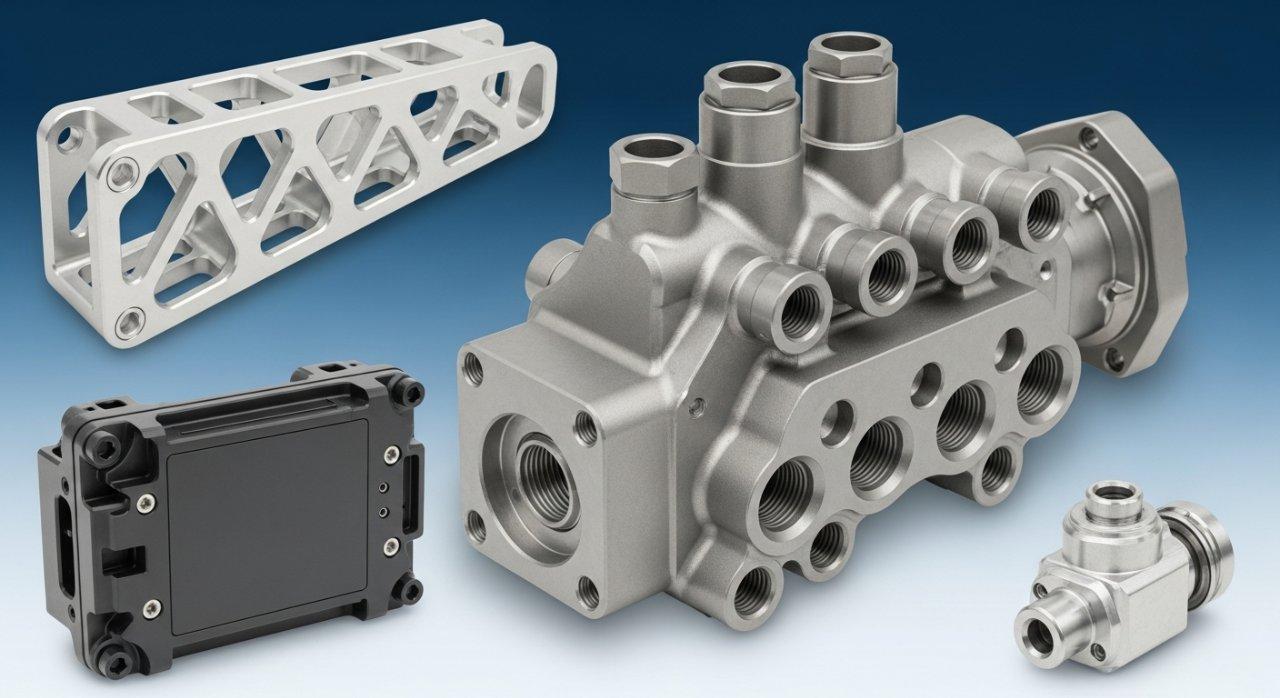

Furthermore, CNC machining accommodates a wide array of engineering-grade materials, from robust metals like aluminum and stainless steel to high-performance plastics such as ABS and PEEK. This material versatility means prototypes can closely mimic the properties of final production parts.

Why Choose a Source Manufacturer for Prototypes

Choosing a source manufacturer like ly-machining for rapid prototyping means direct access to engineering expertise and the entire production chain. This ensures unparalleled quality control from material selection through to final inspection. Our transparent pricing also provides clear cost structures without hidden fees.

Working directly with the factory eliminates intermediaries, streamlining communication and reducing lead times. It builds a foundation of trustworthiness, ensuring your intellectual property is secure and your project benefits from deep technical insights and hands-on manufacturing experience.

Automotive Industry CNC Applications

Functional Component Testing

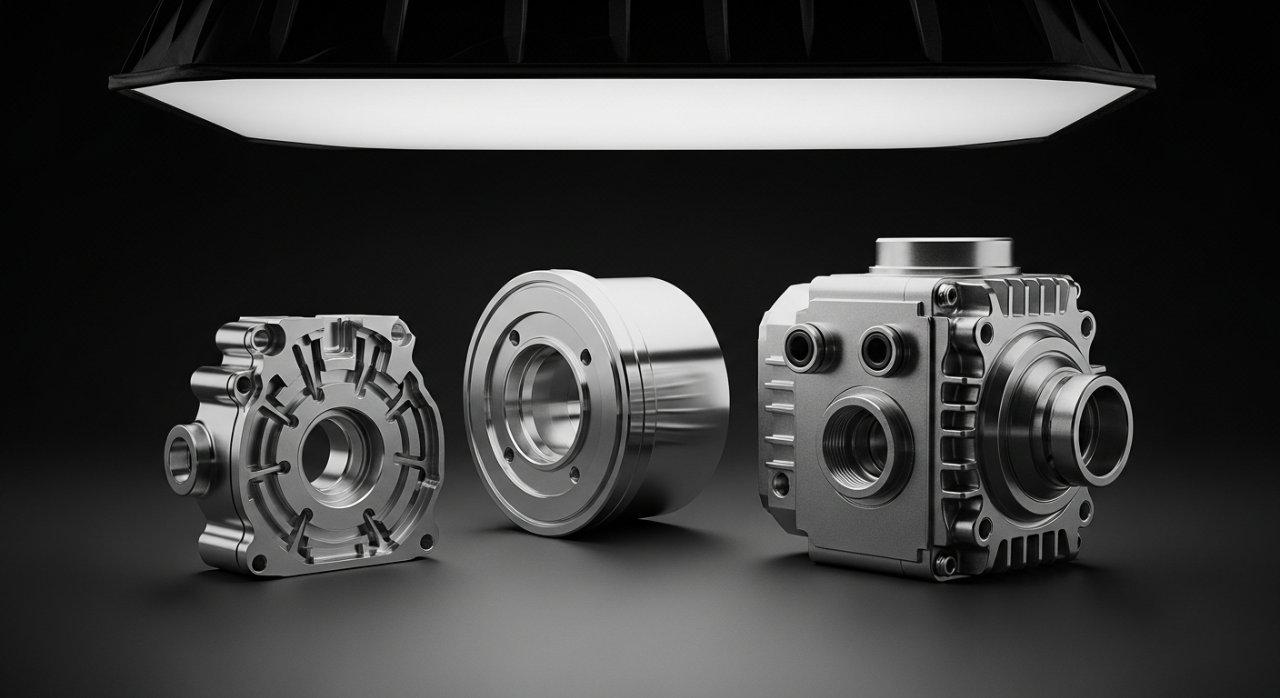

In the automotive sector, rapid prototyping CNC is invaluable for creating functional components such as intake manifolds, engine brackets, and transmission housings. These parts are subjected to rigorous testing to validate their performance under real-world conditions.

Engineers can quickly assess fitment, airflow dynamics, and structural integrity, accelerating the development of critical systems. This allows for rapid fine-tuning of designs before committing to expensive production tooling.

Interior Design Mock-ups Validation

Beyond mechanical parts, CNC machining is crucial for interior design validation. High-fidelity mock-ups of dashboard components, console prototypes, and trim pieces are machined to evaluate ergonomics, aesthetics, and material feel.

This enables designers to physically interact with proposed layouts, ensuring driver and passenger comfort, visual appeal, and ease of use are optimized. Rapid iterations help achieve the perfect balance between form and function.

Engine & Powertrain Prototype Parts

For powertrain development, CNC machining produces intricate engine block components, cylinder heads, and custom gears. These prototypes are vital for performance testing, thermal management analysis, and optimizing fuel efficiency.

The precision offered by CNC ensures that complex geometries, critical for high-performance engines, are accurately replicated. This capability drives innovation in propulsion systems, from traditional combustion to electric vehicle drivetrains.

Medical Device Rapid Prototyping

Surgical Instrument Validation

The medical industry relies heavily on rapid prototyping CNC for validating surgical instruments. Prototypes of clamps, handles, and intricate tooling are machined from biocompatible materials to ensure sterility, ergonomics, and precise functionality.

This allows surgeons and medical professionals to provide feedback on instrument design, leading to safer and more effective tools. Validation ensures instruments meet stringent regulatory standards like ISO 13485.

Custom Prosthetics & Orthotics

For custom prosthetics and orthotics, CNC machining offers unparalleled customization. Patient-specific prototypes can be quickly produced, allowing for precise fit, comfort, and functional testing tailored to individual needs.

Materials like medical-grade plastics and lightweight metals are machined to create durable and highly specialized devices. This rapid iteration capacity greatly improves patient outcomes and device efficacy.

Diagnostic Equipment Enclosures

CNC prototyping is also essential for diagnostic equipment. Enclosures for MRI machines, ultrasound devices, and laboratory instruments are prototyped to verify internal component fitment, cooling airflow, and user interface ergonomics.

Precision machining ensures that sensitive electronics are housed securely, meeting strict industry standards for electromagnetic compatibility and patient safety. Iteration cycles are significantly reduced, accelerating market entry.

Consumer Electronics CNC Solutions

Ergonomic Casing Design

In consumer electronics, ergonomic casing design is crucial for user experience. Rapid prototyping CNC allows for quick iteration of smartphone bodies, tablet enclosures, and wearable device casings from various plastics and metals.

Designers can physically assess the feel, grip, and aesthetic appeal of devices, ensuring they are comfortable and visually appealing to the end-user. This hands-on evaluation refines the tactile experience.

Internal Component Fitment Testing

Beyond aesthetics, CNC machined prototypes are vital for verifying the internal fitment of electronic components. Boards, batteries, and connectors are integrated into prototype casings to ensure optimal layout, preventing interference and maximizing space utilization.

This early testing phase identifies potential assembly issues or thermal management challenges, leading to more robust and reliable final products. It minimizes costly redesigns once tooling begins.

Pre-production Sample Creation

For pre-production, CNC machining creates high-fidelity samples that closely resemble final products. These samples are used for marketing demonstrations, regulatory compliance testing, and early customer feedback.

The ability to produce small batches of highly accurate samples allows companies to gauge market reception and make final adjustments before mass production. This strategy significantly de-risks product launches.

Aerospace Rapid Prototyping Cases

Lightweight Structural Components

The aerospace industry demands incredibly lightweight yet strong structural components. Rapid prototyping CNC produces prototypes for brackets, housings, and structural frames from advanced alloys like aluminum and titanium.

These prototypes undergo rigorous stress testing and fatigue analysis to ensure they meet the stringent performance and safety standards of AS9100. This process is critical for reducing aircraft weight and improving fuel efficiency.

Avionics System Integration Parts

For avionics, rapid prototyping CNC creates specialized enclosures and mounting components for sensitive electronic systems. These prototypes ensure proper fitment, vibration damping, and thermal dissipation for critical onboard equipment.

In our experience, accurate component integration is paramount to prevent system failures. CNC machining allows for the precise fabrication of custom interfaces and housings, ensuring seamless operation of navigation, communication, and control systems.

Custom Tooling & Fixtures Fabrication

The aerospace manufacturing process often requires highly specialized tooling and fixtures. CNC machining is used to rapidly produce custom jigs, fixtures, and molds for composite layups, assembly, and inspection.

This capability significantly reduces lead times for complex tooling, ensuring production lines remain efficient and precise. It enables the quick creation of bespoke solutions for unique manufacturing challenges.

Industrial Machinery CNC Uses

Heavy Equipment Part Prototyping

For heavy industrial equipment, CNC machining facilitates the prototyping of large, robust parts such as gearboxes, specialized housings, and critical linkage components. These prototypes are crucial for evaluating durability and performance under harsh operating conditions.

Testing these high-stress components early in the design phase helps prevent costly failures in the field. It also allows for optimization of material selection and structural design for longevity.

Automation System Components

Automation systems rely on precise, custom-engineered components. Rapid prototyping CNC is essential for creating prototype parts for robotic arms, conveyor systems, and specialized grippers.

These components are tested for accuracy, repeatability, and endurance within automated environments. This iterative process ensures that industrial automation solutions are reliable and perform efficiently in high-volume production settings.

Custom Jig & Fixture Development

The development of custom jigs and fixtures is a continuous need in industrial manufacturing. CNC machining allows for the rapid fabrication of these production aids, tailored to specific assembly or processing requirements.

In our factory, we frequently leverage this for our own internal process optimization. These custom tools improve accuracy, reduce setup times, and enhance worker safety, directly impacting manufacturing efficiency and product quality.

Robotics Rapid Prototyping Impact

Robotic Arm Joint Fabrication

For robotics, rapid prototyping CNC is crucial for fabricating high-precision joints and linkages for robotic arms. These parts require extreme dimensional accuracy to ensure smooth, repeatable motion and structural rigidity.

Prototypes are machined from various metals and plastics to test different material properties and designs, optimizing for strength-to-weight ratio and dynamic performance. This accelerates the development of agile and precise robotic systems.

Sensor Housing & Mounts

Robots incorporate numerous sensors for perception and control. CNC machining produces custom housings and mounts for these delicate sensors, ensuring they are precisely positioned, protected, and integrated into the robotic system.

Accuracy in these components is paramount to maintain sensor calibration and prevent interference. Iteration allows for optimal placement and material selection for environmental robustness.

End-Effector Design Verification

End-effectors, the tools attached to robotic arms, are often highly specialized. Rapid prototyping CNC is used to verify the design and functionality of grippers, welding torches, and other custom tooling.

This enables engineers to test different gripping mechanisms, material handling capabilities, and tool geometries. Our experience shows this iterative approach is vital for developing versatile and effective robotic applications.

Renewable Energy CNC Applications

Wind Turbine Blade Prototypes

In the renewable energy sector, rapid prototyping CNC is used to create scaled models or sectional prototypes of wind turbine blades. These models are crucial for aerodynamic testing and structural analysis.

Engineers evaluate design efficiency, material stress, and potential manufacturing challenges at a smaller scale. This helps optimize blade designs for maximum energy capture and structural integrity before full-scale production.

Solar Panel Mounting Hardware

Solar panel installations require robust and durable mounting hardware. CNC machining prototypes brackets, frames, and custom connection components from corrosion-resistant materials to ensure longevity in various environments.

These prototypes are tested for structural load-bearing capacity and ease of installation. Rapid iteration helps optimize designs for cost-effectiveness and durability, crucial for large-scale solar farms.

Energy Storage System Components

For advanced energy storage systems, such as large-scale battery enclosures and power converter housings, rapid prototyping CNC is invaluable. It creates precise internal structures and external casings.

These components are tested for thermal management, structural integrity, and integration with complex electronic systems. The precision of CNC supports the development of safe and efficient energy solutions.

Choosing Your CNC Prototyping Partner

The Advantage of Deep Technical Expertise

When selecting a CNC prototyping partner, deep technical expertise is non-negotiable. An experienced factory understands not only the machining process but also design for manufacturability (DFM) principles.

Our team offers invaluable insights into material selection, tolerance optimization, and surface finish options. This expertise ensures your designs are not just produced, but perfected, leading to superior prototype quality.

Ensuring High-Quality Parts Production

High-quality parts production starts with rigorous quality control, from raw material inspection to final dimensional verification. Adherence to standards like ISO 9001 and AS9100 is paramount.

We employ advanced metrology equipment to guarantee every prototype meets your exact specifications. Our commitment to precision means you receive parts that perform as intended, every time.

Transparent Pricing for Prototyping Projects

Transparent pricing builds trust and facilitates budgeting. A reliable partner provides clear, detailed quotes that account for materials, machining time, finishing, and any specialized processes.

You should expect a breakdown of costs without hidden fees or unexpected surcharges. Our commitment to transparency ensures you understand the value you receive at every stage of your rapid prototyping project.

Future of Rapid Prototyping CNC

Emerging Trends in Manufacturing

The future of rapid prototyping CNC is marked by increasing automation and integration with advanced digital workflows. Artificial intelligence and machine learning are optimizing tool paths and predictive maintenance.

These trends promise even faster turnaround times and further reductions in manufacturing costs. We continuously invest in these technologies to stay at the forefront of precision manufacturing.

Continuous Innovation in Materials

Material science is constantly evolving, bringing new alloys, ceramics, and high-performance polymers to the forefront. Rapid prototyping CNC must adapt to these innovations to offer expanded capabilities.

Our factory remains agile in sourcing and machining these novel materials, providing clients with cutting-edge options for their prototype needs. This continuous innovation unlocks new design possibilities.

A Prototyping Success Story

Problem: A client in the medical device sector faced delays in developing a new surgical instrument, struggling to find a manufacturer who could produce high-precision prototypes from a specific medical-grade titanium quickly and consistently. Their previous vendor lacked the expertise to meet the tight tolerance and surface finish requirements essential for clinical trials.

Our Solution: Leveraging our deep technical expertise and advanced 5-axis CNC machining centers, ly-machining partnered closely with the client’s R&D team. We provided Design for Manufacturability (DFM) feedback, optimizing the instrument’s geometry for precision machining while maintaining its critical functionality. We sourced certified medical-grade titanium and implemented a specialized machining strategy.

Positive Result: We delivered a batch of fully functional, high-precision prototypes within 7 days, significantly faster than their previous lead times. The prototypes met all stringent quality and surface finish specifications, allowing the client to accelerate their clinical trials by several weeks. This partnership reinforced the client’s trust in our ability to handle complex, critical projects with speed and accuracy.

Take Your Concepts to Reality

Partner with a Trusted CNC Expert

Choosing the right partner is crucial for successful prototype manufacturing. Our expertise as a source manufacturer means your projects are handled with precision, efficiency, and unwavering commitment to quality.

Request a Consultation for Your Project

Ready to transform your innovative ideas into high-quality, rapidly validated prototypes? Connect with our deep technical experts today for a transparent quote and a personalized consultation. Let our source manufacturing advantage and precision CNC capabilities accelerate your product’s journey from concept to market.

How does rapid prototyping CNC save costs?

Rapid prototyping CNC minimizes the need for expensive production tooling during early development stages. It allows for quick, affordable design iterations, catching errors early and avoiding costly rework down the line. This efficient process ensures resources are allocated optimally.

What materials can be used for CNC prototypes?

Our CNC machining services support a wide range of engineering-grade materials. This includes various metals like aluminum, stainless steel, titanium, and brass, as well as high-performance plastics such as ABS, Nylon, PEEK, and Delrin. Material selection depends on the prototype’s functional requirements.

What quality standards do you adhere to?

As a high-end CNC machining factory, we adhere to stringent quality standards, including ISO 9001 for general quality management. For specialized industries like aerospace, we comply with AS9100, ensuring the highest levels of precision and reliability for critical components.