Ever received a quote for CNC parts that was much higher than you anticipated? Unpredictable manufacturing costs can derail project budgets and timelines, leaving you scrambling to find a more affordable solution. The complexity of the CNC machining process often hides the specific elements that inflate the price, making it difficult to optimize your design for cost-effectiveness.

This uncertainty can be a major roadblock, forcing you to compromise on quality or delay critical production schedules. You need a clear understanding of what influences the final price to make informed design decisions. At [ly-machining], we believe in transparency and empowering our clients. By understanding the seven key cost drivers in CNC milling, you can significantly reduce expenses without sacrificing the quality of your CNC parts.

The primary factors influencing CNC machining costs are material choice, design complexity, required tolerances, part quantity, finishing services, and machine setup time. Optimizing these elements in your design is the most effective way to achieve a lower price per part. Let’s explore how to manage these factors to your advantage.

1. Material Selection

The material you choose is a foundational cost driver. Raw material prices vary widely, from affordable plastics and aluminum alloys to expensive specialty metals like titanium and Inconel. However, the cost goes beyond the raw price per kilogram. The material’s machinability—how easily it can be cut—plays a huge role in the overall expense.

Harder, more difficult-to-machine materials require slower cutting speeds, specialized tooling, and more machine time, all of which increase the cost. For example, machining stainless steel can take significantly longer than machining aluminum 6061. This additional time on the CNC machine directly translates to a higher price for your CNC parts.

To manage costs, consider if a more machinable and less expensive material can meet your application’s requirements. Below is a comparison of common materials used in CNC machining.

| Material | Relative Cost | Machinability | Key Characteristics |

| Aluminum 6061 | Low | Excellent | Great strength-to-weight ratio, good corrosion resistance. |

| Stainless Steel 304 | Medium | Fair | Excellent corrosion resistance, high strength. |

| ABS Plastic | Low | Excellent | Good impact resistance, easy to machine. |

| PEEK | High | Fair | High-performance, chemical and temperature resistant. |

| Titanium | Very High | Difficult | Exceptional strength-to-weight ratio, biocompatible. |

2. Design Complexity and Part Geometry

The more complex your part’s design, the more it will cost to produce. Features like intricate curves, deep pockets, and small-radius internal corners require more advanced CNC machining operations and longer run times. Every additional surface and feature adds to the programming and machining time.

Deep pockets are particularly time-consuming because the machine must remove a large volume of material layer by layer with a tool that has sufficient reach. Similarly, parts with features on multiple faces require repositioning and re-fixturing, which adds significant setup time and cost. If a part needs to be flipped multiple times, it may even require a more advanced 5-axis CNC milling machine.

To reduce costs, simplify your design as much as possible. Combine features where feasible, avoid unnecessarily deep pockets, and use standard tool sizes for holes and radii. A design that can be machined from a single setup will always be more economical.

3. Tolerances

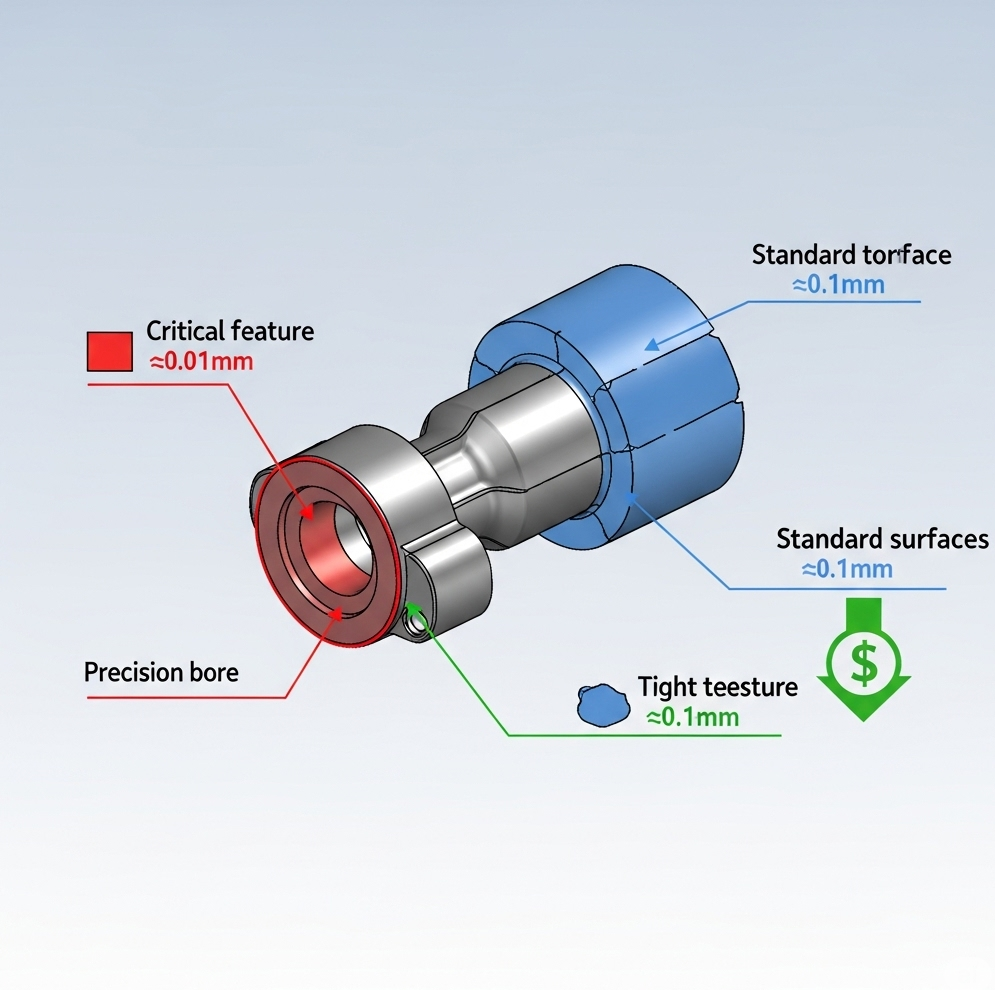

Tolerances refer to the acceptable deviation for a specific dimension. While tight tolerances are essential for some critical features, applying them unnecessarily across your entire part is a common and costly mistake. The tighter the tolerance, the more care, time, and specialized processes are needed to achieve it.

Achieving very high precision requires slower machine speeds, more frequent tool changes, and multiple inspection steps using calibrated measurement equipment. This meticulous process significantly increases the cycle time for each part. Standard tolerances are often sufficient for non-critical features and are much cheaper to produce.

As a best practice, specify tight tolerances only on surfaces and features where they are functionally necessary, such as mating surfaces or bearing bores. For all other dimensions on your CNC parts, apply standard commercial tolerances. This simple step can lead to substantial savings in your CNC machining project.

4. Part Quantity and Batch Size

The number of parts you order has a significant impact on the price per unit. CNC machining involves initial setup costs for programming the machine and creating any necessary fixtures. These are one-time costs that get spread across the entire batch of parts.

When you order a small quantity, the setup cost constitutes a large portion of the final price for each part. As the quantity increases, this fixed cost is distributed over more units, drastically reducing the price per part. This is why a prototype or a one-off part is always proportionally more expensive than a part from a larger production run.

If you anticipate needing more parts in the future, it is often more cost-effective to order a larger batch at once. Discuss your project’s lifecycle with your manufacturing partner. At [ly-machining], we can help you plan your order sizes to optimize the balance between inventory and unit cost for your CNC parts.

5. Finishing and Post-Processing Requirements

The raw machined part that comes off the CNC mill is often not the final product. Many CNC parts require secondary finishing services, such as anodizing, bead blasting, powder coating, or heat treatment. Each of these post-processing steps adds to the overall cost and lead time.

- Anodizing: Adds a protective, colored oxide layer to aluminum parts.

- Bead Blasting: Creates a uniform matte or satin surface finish.

- Powder Coating: Applies a durable, decorative polymer finish.

- Heat Treatment: Alters mechanical properties like hardness and strength.

While these finishes can be critical for appearance or function, it’s important to specify only what is necessary. If a part is internal to a machine and not visible, it likely doesn’t need an expensive cosmetic finish. Clearly defining your finishing requirements ensures you aren’t paying for unnecessary extras.

6. Machine and Operator Setup Time

Before any cutting begins, a skilled operator must prepare the CNC machine. This setup involves programming the machine with the CAM file, mounting the workpiece in a fixture, loading the correct cutting tools, and calibrating the machine’s starting position. This process takes time and expertise, contributing to the overall cost.

Complex parts that require multiple setups (e.g., machining on different faces) amplify this cost. Each time the part is re-oriented, a new setup is required. The use of custom fixtures to hold unusually shaped parts also adds to the upfront cost. Designing parts that can be machined in a single setup or held with standard vises is a key strategy for cost reduction.

7. Wall Thickness and Feature Size

The physical limitations of cutting tools also impact cost. Designing very thin walls or tiny features can be challenging and expensive. Thin walls are prone to vibration and warping during the CNC machining process, forcing the machine to run at slower speeds to avoid damaging the part.

Similarly, very small features may require micro-tooling, which is fragile and breaks easily, increasing tooling costs and machine downtime. As a general rule, it’s best to design walls with a thickness of at least 0.8mm for metals and 1.5mm for plastics. Avoiding features that are smaller than what standard tools can create will keep your CNC milling costs down.

Related Questions

How can I get a fast quote for my CNC parts?

To get a fast and accurate quote, ensure your CAD files are complete and include a technical drawing with all necessary information. Specify the material, quantity, required tolerances for critical features, and any surface finishes. Providing clear documentation helps partners like [ly-machining] to quickly assess the project and eliminate back-and-forth communication.

Does 5-axis CNC milling always cost more?

While 5-axis machines are more advanced, they don’t always result in a higher cost. For complex parts with features on multiple sides, a 5-axis machine can complete the job in a single setup. This avoids the labor-intensive process of re-fixturing the part multiple times on a 3-axis machine, which can ultimately make 5-axis CNC machining the more cost-effective option for such geometries.

Frequently Asked Questions

1. What is the easiest way to reduce my CNC machining cost?

The simplest way to reduce costs is to review and relax your tolerances. Only apply tight tolerances to mission-critical surfaces and features. For all other non-critical aspects of your design, use standard commercial tolerances. This single change can significantly decrease machining time and inspection requirements.

2. How much does quantity affect the price of CNC parts?

Quantity has a major effect on the unit price. Moving from a prototype quantity (1-5 units) to a low-volume production run (100+ units) can reduce the price per part by 50% or more. This is because the initial programming and setup costs are amortized over a larger number of parts.

3. Will adding text or logos to my part increase the cost?

Yes, adding engraved or embossed text and logos will increase the cost. This is an extra feature that requires specific tooling (like an engraving tool) and adds to the total CNC machining time. To minimize the cost, use a simple, sans-serif font and opt for engraving (cutting into the surface) rather than embossing (leaving raised text), as engraving is generally a faster operation.