Mastering Copper Selection for CNC Machining

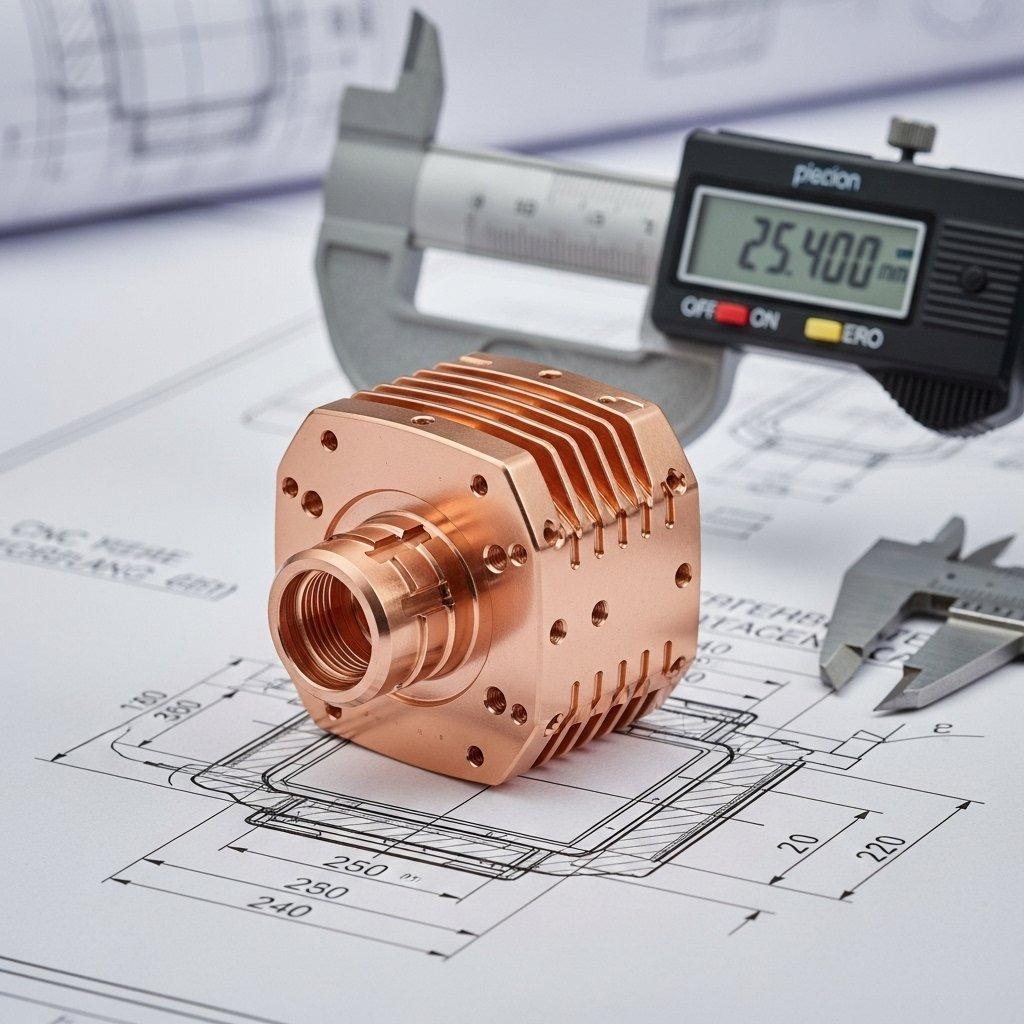

In the world of high-precision CNC machining, material selection isn’t just a decision—it’s a critical differentiator. Overlooking the nuances of copper materials can silently undermine your project’s performance and profitability, leading to costly failures.

Many engineers face anxieties related to quality consistency, cost-performance balance, and supplier reliability. The vast array of copper alloys and their specific properties often creates a complex challenge in achieving optimal component integrity.

This guide will systematically unveil the seven critical factors for informed copper material selection. We will equip you with the knowledge to make superior choices, ensuring unparalleled performance and reliability for your high-precision CNC components.

Optimal copper material selection for CNC machining hinges on balancing alloy composition, temper, surface quality, machinability, certifications, cost, and supplier reliability to achieve high-quality copper parts.

Navigating Copper Material Choices

Setting the Stage: Critical Choices

Is your choice of copper material silently undermining your high-precision CNC project’s performance and profitability? The subtle differences in copper alloy properties can profoundly impact final product reliability.

In precision manufacturing, the integrity of a component begins with its raw material. Informed copper material selection is not merely an engineering task; it is a strategic imperative that dictates the success or failure of critical applications.

This comprehensive exploration provides a framework for evaluating copper materials. We aim to empower engineers and procurement specialists with the insights needed to navigate complex material choices for high-quality copper parts.

Blueprint for Optimal Selection

Our discussion will systematically address the crucial aspects of copper material selection. We focus on transparent quality, superior parts, and optimized costs, reflecting our expertise in CNC copper machining.

We will meticulously cover alloy composition, temper, surface finish, and machinability. Furthermore, we delve into the essential aspects of certifications, cost-effectiveness, and the critical role of supplier reliability.

By understanding these elements, readers can confidently choose the right copper material. This reduces project risks, improves part quality, and achieves long-term cost efficiencies through a trusted, technically proficient partner.

Understanding Copper Fundamentals

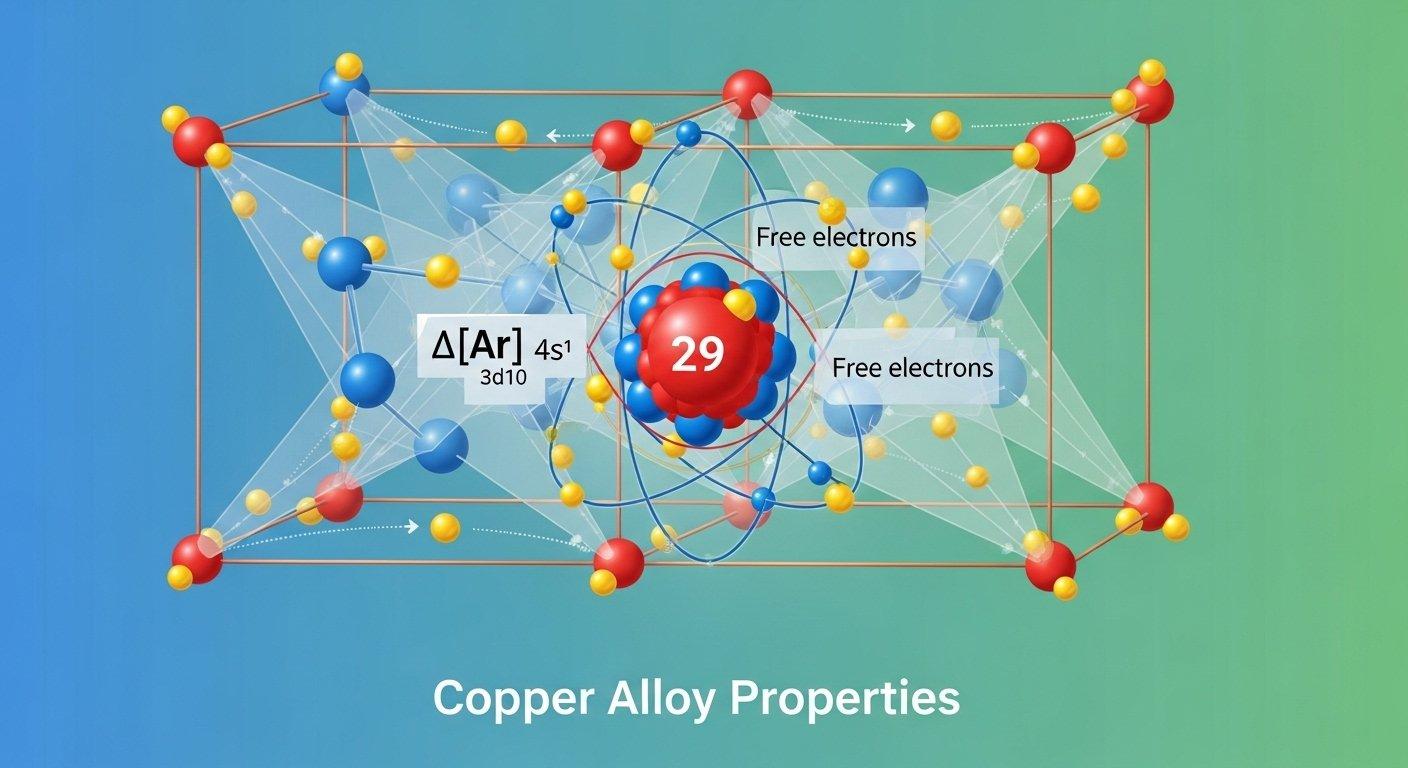

Key Point 1: Alloy Composition & Purity

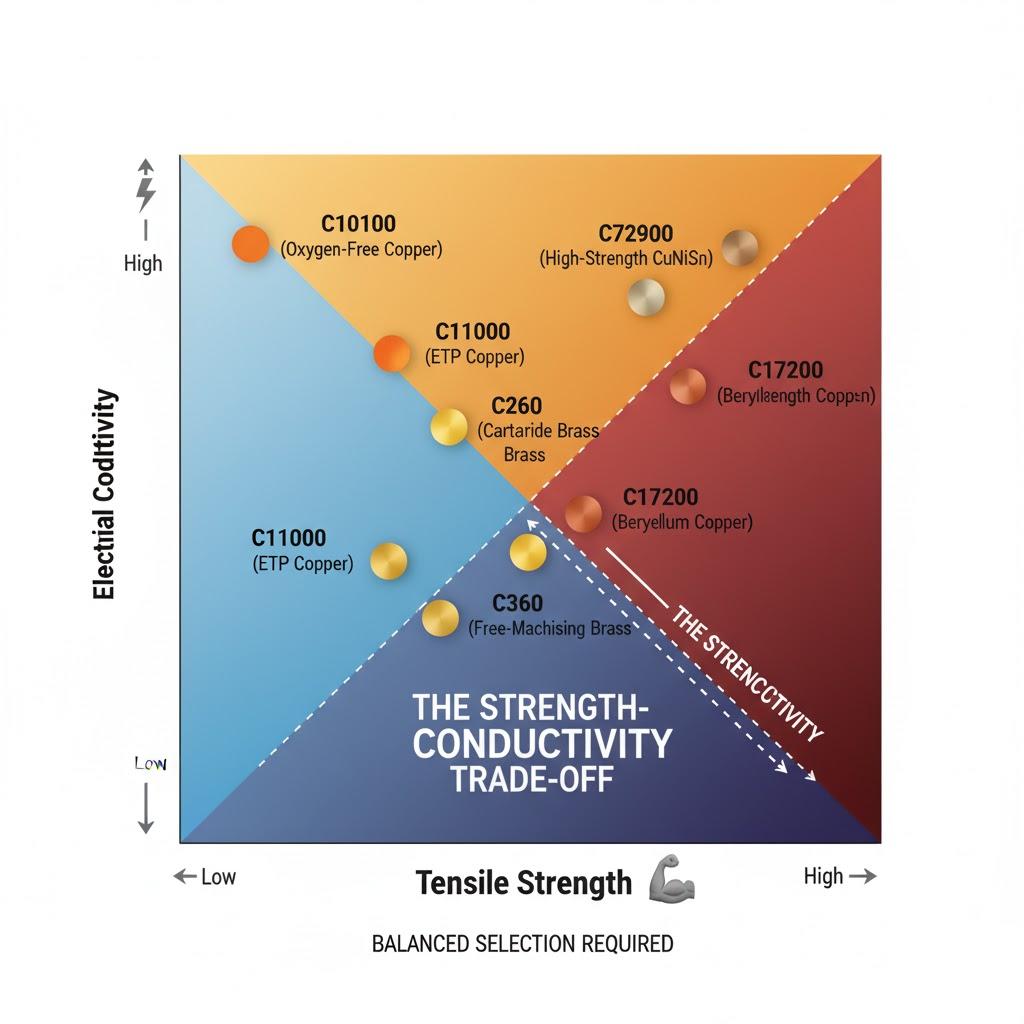

The foundational aspect of any copper material selection is its alloy composition. The presence and proportion of alloying elements fundamentally alter mechanical, thermal, and electrical properties.

Purity, defined by the absence of impurities, is paramount for applications demanding high electrical or thermal conductivity. Even trace elements can significantly diminish these critical attributes, affecting the performance of high-quality copper parts.

For instance, high-purity oxygen-free copper (OFHC, C10100) is preferred for electrical connectors due to its exceptional conductivity. Conversely, brass (copper-zinc alloys) offers enhanced machinability but reduced conductivity.

| Copper Alloy (Example) | Primary Alloying Elements | Key Characteristic | Typical Application |

|---|---|---|---|

| C10100 (OFHC Copper) | Pure Copper (99.99%) | High Conductivity | Electrical, Vacuum |

| C11000 (ETP Copper) | Pure Copper (99.90%) | Good Conductivity | Electrical Wiring |

| C17200 (Beryllium Copper) | Beryllium (1.8-2.0%) | High Strength | Connectors, Springs |

| C36000 (Free-Machining) | Zinc (35-37%), Lead (2.5-3.7%) | Excellent Machinability | Fittings, Gears |

Key Point 2: Temper, Hardness & Form

Temper refers to the mechanical properties imparted by cold working or heat treatment, directly influencing a copper alloy’s hardness, strength, and ductility. It is a critical factor in CNC copper machining.

Selecting the correct temper is crucial for machinability and the final component’s performance. For example, softer tempers are more ductile but may require specific machining strategies to prevent burring or deformation.

Conversely, harder tempers offer greater dimensional stability during machining but can increase tool wear. The physical form—rod, plate, or tubing—also impacts initial processing and material utilization.

| Temper Designation (Common) | Condition | Relative Hardness | Relative Ductility | Impact on Machining |

|---|---|---|---|---|

| O (Annealed) | Soft | Low | High | Prone to burring |

| H01 (Light Cold Rolled) | Semi-Hard | Medium | Medium | Balanced properties |

| H04 (Hard Cold Rolled) | Hard | High | Low | Good surface finish |

| TF00 (Solution Heat Treated) | Varies | Can be tailored | Can be tailored | Specific to alloys |

Assessing Quality & Performance

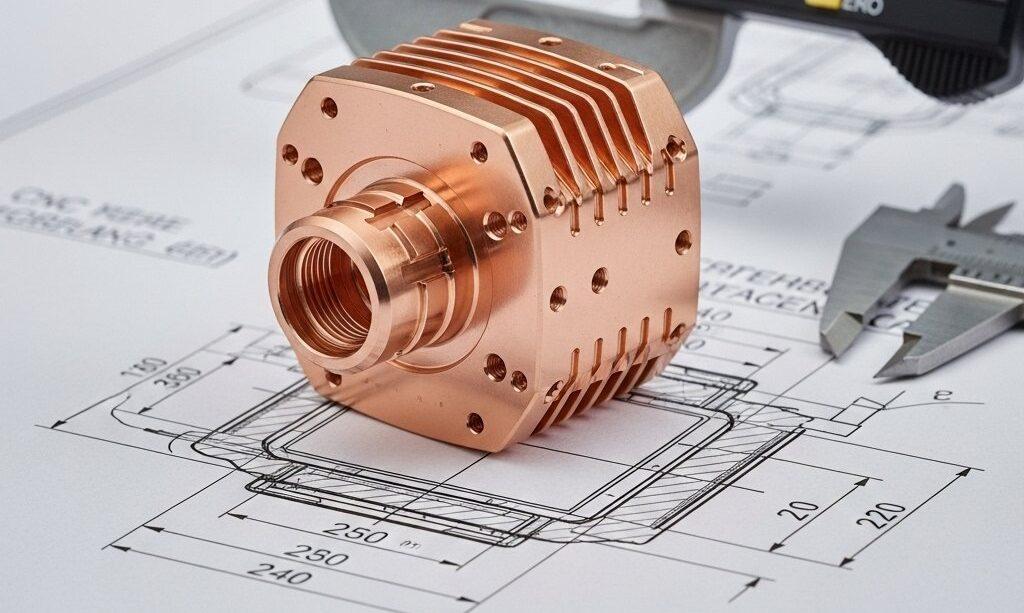

Key Point 3: Surface Quality & Finish

The surface quality of the raw copper material profoundly impacts the final component’s finish and integrity. Defects such as scratches, pits, or inclusions can propagate during machining and compromise critical dimensions.

A pristine surface minimizes the need for extensive post-machining finishing operations. This directly contributes to cost savings and maintains the tight tolerances required for high-quality copper parts.

Invisible surface contaminants can also interfere with subsequent plating or bonding processes, which is a common pitfall. Careful inspection and sourcing from reliable suppliers are essential to mitigate these risks.

| Surface Condition Aspect | Description | Impact on CNC Machining | Risk Mitigation |

|---|---|---|---|

| Scratches/Marks | Physical damage on surface | Transfer to part, aesthetic defects | Visual inspection, material handling |

| Pitting/Corrosion | Localized material degradation | Weak points, surface inconsistency | Proper storage, quality control |

| Inclusions | Foreign particles embedded | Tool wear, compromised material integrity | Supplier audits, material analysis |

| Oxidation | Surface tarnishing, discoloration | Affects conductivity, post-processing | Controlled atmosphere storage |

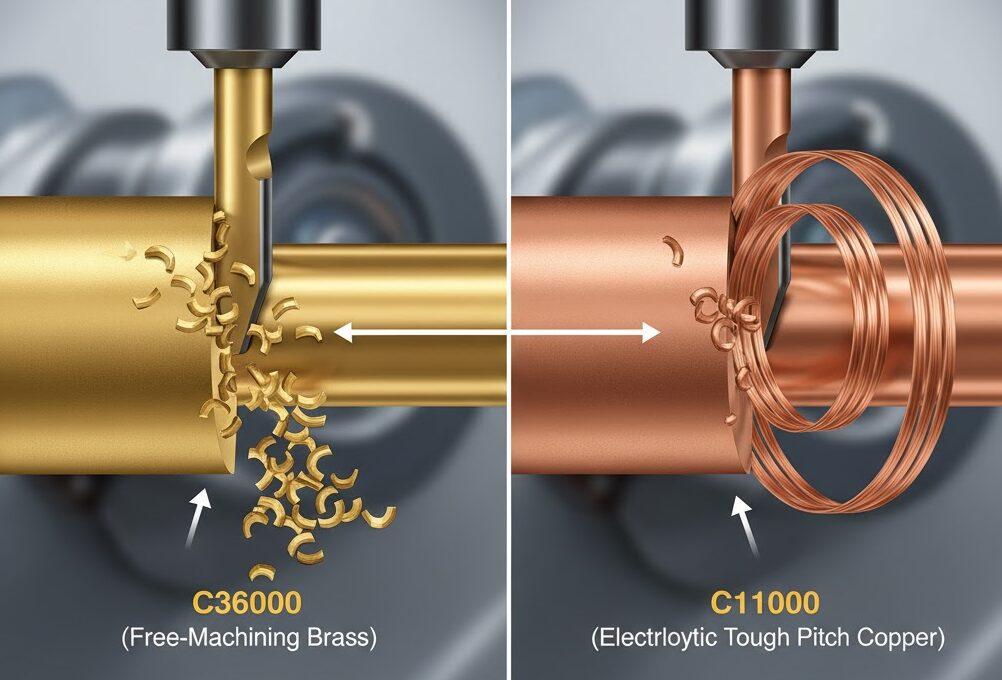

Key Point 4: Machinability & Processability

Machinability refers to how easily a material can be cut, drilled, or shaped using CNC equipment without excessive tool wear or poor surface finish. This is a critical factor in CNC copper machining.

Copper alloys vary significantly in their machinability ratings, primarily influenced by composition and temper. For instance, free-machining brass (C36000) is known for its excellent chip control and low tool wear.

Conversely, pure copper (C11000) can be gummy, leading to long, stringy chips that entangle tools and require specific machining parameters. Understanding these nuances prevents costly production delays.

Key Point 5: Certifications & Traceability

Material certifications are vital, providing documented assurance of a copper alloy’s composition, mechanical properties, and compliance with industry standards (e.g., ASTM, ISO). This is non-negotiable for high-quality copper parts.

Traceability ensures that the material’s origin, processing history, and test results can be tracked throughout its lifecycle. This is crucial for industries like aerospace and medical devices where accountability is paramount.

Without robust certifications and traceability, the risk of using substandard or counterfeit materials increases. This can lead to catastrophic component failures and significant liability, undermining project integrity.

Strategic Sourcing & Value

Key Point 6: Cost-Effectiveness vs. Quality

Balancing material cost with required performance characteristics is a perpetual challenge in copper material selection. Opting for cheaper alternatives can lead to higher long-term costs due to rework, scrap, or warranty issues.

A technically informed decision often involves a higher upfront material cost that yields significant savings. This is achieved through reduced machining time, fewer rejections, and superior end-product reliability.

Understanding the total cost of ownership, including processing, assembly, and service life, is essential. This perspective guides towards a truly cost-effective solution for high-quality copper parts.

Key Point 7: Supplier Reliability & Support

Choosing a reliable supplier is as crucial as selecting the right material. A dependable partner provides consistent material quality, accurate certifications, and on-time delivery.

Furthermore, a strong supplier relationship offers invaluable technical support. This includes expert advice on material selection, machinability, and troubleshooting potential processing challenges during CNC copper machining.

Transparency in pricing, robust quality control, and comprehensive post-sales support are hallmarks of a trustworthy source manufacturer. This ensures peace of mind and minimizes project risks for the client.

Mastering Your Copper Selection

Core Points for Success

Mastering copper material selection is pivotal for the success of any high-precision CNC machining project. This process demands a holistic understanding of both material science and application requirements.

The seven key factors—alloy composition, temper, surface quality, machinability, certifications, cost-effectiveness, and supplier reliability—form a robust framework for informed decision-making. Each plays a crucial role.

By prioritizing these considerations, engineers and project managers can ensure that every component meets stringent performance specifications. This guarantees the delivery of high-quality copper parts consistently.

Reinforcing Optimal Choices

Selecting the optimal copper material fundamentally enhances component performance and longevity. It directly contributes to reduced production costs by minimizing errors and maximizing efficiency in CNC copper machining.

The insights provided enable a strategic approach to material sourcing. This ensures that every choice is not merely functional but contributes to a competitive advantage for the end product.

Ultimately, an informed copper material selection cultivates confidence, mitigates risks, and builds trust. This translates into superior results for demanding high-precision applications.

Case Study: Enhanced Conductivity in Aerospace Connectors

**Problem:** A client in the aerospace sector encountered persistent issues with inconsistent electrical conductivity in their high-frequency connectors. Their existing copper material, sourced from a generic supplier, exhibited varying purity levels, leading to unpredictable performance in flight-critical components. This inconsistency caused significant scrap rates and retesting delays.

**Our Solution:** ly-machining partnered with the client to analyze their specific performance requirements. Leveraging our deep technical expertise, we recommended a switch to C10100 oxygen-free electronic (OFE) copper, known for its ultra-high purity and consistent electrical properties. Our stringent material sourcing protocols ensured full traceability and comprehensive material certifications, guaranteeing material integrity.

**Result:** By implementing ly-machining’s recommended C10100 OFE copper and utilizing our precise CNC copper machining capabilities, the client achieved consistent electrical conductivity across all batches. This significantly reduced their scrap rate by 18% and eliminated the need for extensive retesting, ultimately enhancing the reliability of their aerospace connectors and streamlining their production process.

Get Expert Assistance

Ready to ensure your next project benefits from perfectly matched, high-quality copper materials? Contact our material specialists today for a personalized consultation and transparent pricing, or request a quote for your custom CNC machining needs.

FAQ Section

Why is alloy composition critical?

Alloy composition directly dictates the mechanical, thermal, and electrical properties of copper materials. Different alloying elements are introduced to achieve specific characteristics, making precise selection essential for meeting application demands.

Even minor variations in composition can significantly alter performance. Understanding the role of each element helps ensure the material precisely fits the intended function, impacting CNC copper machining directly.

How does temper affect machinability?

Temper refers to the material’s hardness and ductility, which are crucial for machinability. Softer tempers can be gummy, leading to long chips and burring, while harder tempers can increase tool wear but offer better surface finishes.

Selecting the appropriate temper ensures efficient CNC copper machining. It optimizes chip formation, reduces tool wear, and helps achieve the desired surface quality and dimensional accuracy for high-quality copper parts.

What are essential material certifications?

Essential material certifications include documents confirming alloy composition, mechanical properties, and compliance with industry standards like ASTM or ISO. These certifications provide verifiable proof of material quality and adherence to specifications.

Traceability, often part of certifications, tracks the material’s origin and processing history. This is vital for critical applications where material integrity and accountability are paramount for high-quality copper parts.