Enhancing Lightsaber CNC Parts: 12 Finishing Techniques

Imagine the seamless gleam of a perfectly polished hilt, the satisfying texture of a finely bead-blasted grip, or the vibrant, durable color of an expertly anodized emitter. For high-end CNC parts, especially those as iconic as a lightsaber component, the surface finish isn’t merely an afterthought; it is the definitive element distinguishing the ordinary from the extraordinary.

Achieving this pinnacle of craftsmanship demands profound technical expertise and precision. The challenges in material science, aesthetic integrity, and functional durability are substantial, requiring advanced solutions.

This guide delves into 12 meticulously engineered surface finishing techniques. It reveals how our deep technical expertise transforms raw CNC parts into masterpieces of touch and sight, ensuring unparalleled aesthetics, durability, and performance for your “lightsaber CNC parts.”

Featured Snippet: Elevate “lightsaber CNC parts” from functional to iconic with “precision machining finishes” and “metal finishing techniques” that guarantee unparalleled aesthetics and durability.

Unveiling Precision: The Art of CNC Surface Finishes

Setting the Scene & The Core Challenge

The Quest for Perfect Lightsaber CNC Aesthetics

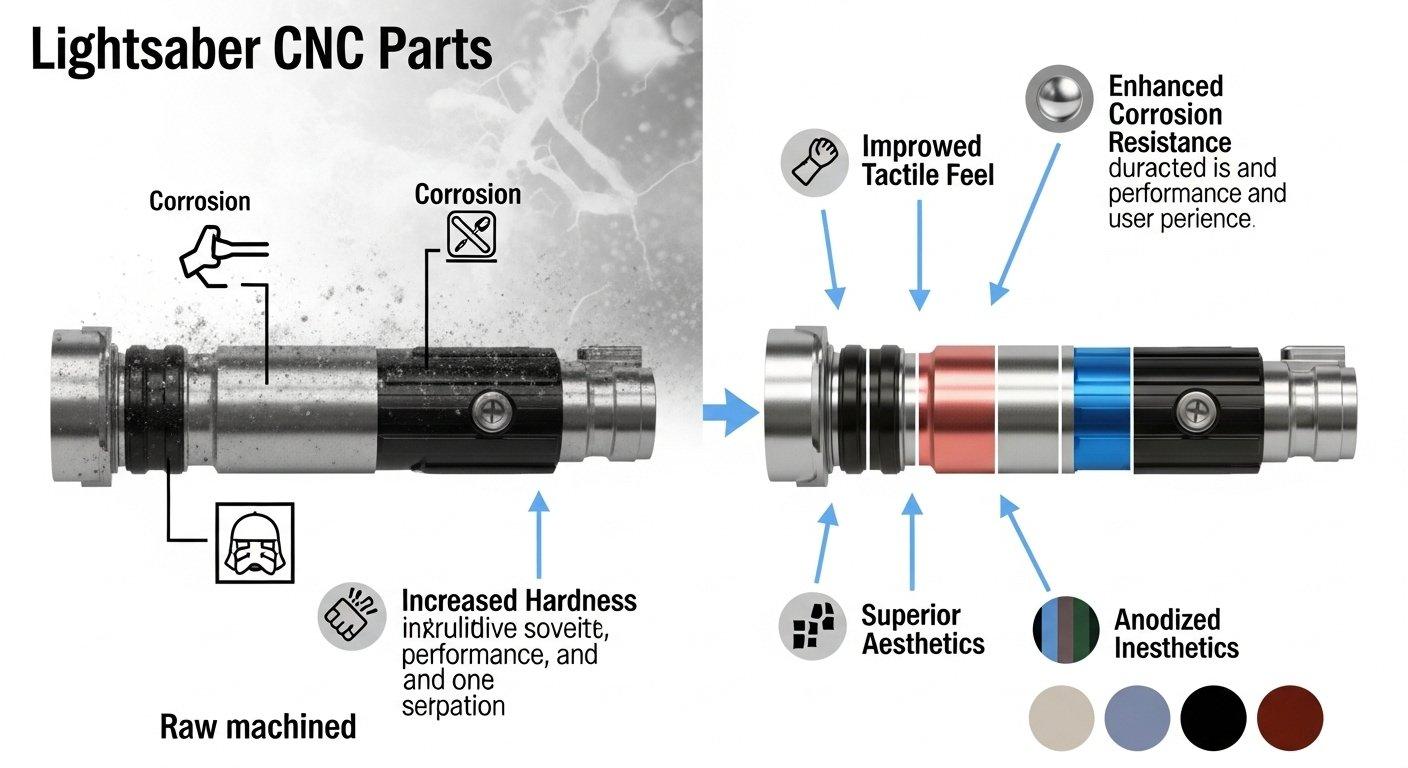

The creation of “lightsaber CNC parts” involves more than just precise dimensioning; it extends to the visual and tactile characteristics of the final product. Engineers and designers constantly seek finishes that not only meet stringent functional requirements but also convey a premium aesthetic. This often necessitates “metal finishing techniques” that push conventional boundaries.

Achieving consistent, high-quality finishes across complex geometries and various metal alloys presents significant challenges. Deviations in surface roughness, color uniformity, or protective layers can compromise both the product’s appeal and its expected lifespan.

Why Surface Finishing Elevates Your Design

Surface finishing transcends mere aesthetics; it is an integral aspect of product engineering that enhances durability, improves tactile experience, and ensures optimal component performance. The choice of finish directly impacts resistance to corrosion, abrasion, and fatigue.

A superior finish significantly elevates perceived quality, solidifying brand identity and commanding market differentiation. It transforms a functional component into an engaging, high-value item, particularly crucial for high-end consumer products and prop replicas.

Your Path to Mastering Lightsaber Part Finishes

What You’ll Discover in This Guide

This comprehensive guide serves as an authoritative technical resource for selecting and implementing advanced “CNC surface finishing” solutions. It provides a detailed understanding of the processes involved in achieving specific visual and tactile outcomes.

We aim to empower engineers and designers with the knowledge to make informed decisions, ensuring their “lightsaber CNC parts” meet the highest standards of quality and aesthetic appeal. The focus remains on practical application and technical precision.

Preview of Our 12 Game-Changing Techniques

Our expertise encompasses a broad spectrum of “metal finishing techniques,” from mechanical enhancements to sophisticated chemical and electrochemical processes. Each method offers unique advantages in terms of appearance, protection, and functionality.

These techniques are critical for transforming raw materials into components with enhanced properties, addressing diverse design and performance specifications for demanding applications. We specialize in tailoring solutions to exact project requirements.

Foundation of “Cooler” CNC Part Finishes

Defining Surface Finishing for Lightsaber Parts

Understanding Key Terms in CNC Finishing

In “CNC surface finishing,” several key terms define the characteristics and quality of the treated material. “Surface roughness,” often quantified by Ra (arithmetic average roughness) or Rz (mean peak-to-valley height), measures the texture of a surface.

“Tolerances” refer to the permissible variations in dimensions, crucial for fit and function. “Material compatibility” dictates which “metal finishing techniques” can be effectively applied to specific alloys, influencing adhesion and performance.

Table: Key Surface Finish Terminology

| Term | Definition | Importance for “Lightsaber CNC Parts” |

|---|---|---|

| Surface Roughness | The finely spaced irregularities on a surface texture. | Influences tactile feel, light reflection, and coating adhesion. |

| Adhesion | The strength of the bond between a coating and the substrate. | Critical for coating durability and preventing peeling. |

| Corrosion Resistance | Ability of a material to withstand deterioration by chemical reaction. | Extends product lifespan, maintains aesthetic integrity. |

| Hardness | Resistance to localized plastic deformation. | Enhances wear resistance and prevents scratching. |

How Finishing Techniques Transform Raw Metal

Finishing techniques fundamentally alter the surface properties of raw metal components. These transformations can involve changes in physical texture, chemical composition, or the application of protective layers.

For “lightsaber CNC parts,” this ensures that the final component not only achieves the desired visual aesthetic but also acquires enhanced functional characteristics such as improved wear resistance or electrical insulation. Each technique is precisely controlled to yield specific outcomes.

The Critical Impact on Design & Performance

Benefits for Lightsaber Durability & Feel

The strategic application of “precision machining finishes” significantly enhances the durability and tactile quality of “lightsaber CNC parts.” A well-chosen finish can create a robust barrier against environmental degradation, extending product longevity.

Furthermore, the surface texture directly influences the user’s interaction, providing a superior haptic experience. This blend of enhanced protection and refined touch is paramount for high-end, interactive components.

Mastering 12 Lightsaber CNC Finishing Steps

Practical Execution: Techniques 1-6

Detailed Guide to Mechanical Polishing

Mechanical polishing involves abrasive processes to smooth and refine a metal surface, reducing its roughness and increasing its reflectivity. This technique is often used to achieve a mirror-like finish on “lightsaber CNC parts.”

It can be executed through manual buffing, vibratory finishing, or automated robotic systems, depending on the part’s complexity and required finish quality. Careful control of abrasive media and pressure is essential to prevent material removal inconsistencies.

Unlocking the Power of Anodizing & Blasting

Anodizing is an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. Particularly effective on aluminum alloys, it can also incorporate vibrant colors, highly desired for unique “lightsaber CNC parts.

Abrasive blasting, conversely, uses a stream of abrasive media propelled at high velocity to alter the surface texture, achieving finishes from matte to satin. This method is excellent for cleaning, deburring, and preparing surfaces for subsequent coatings.

Table: Comparison of Common Mechanical & Anodizing Finishes

| Finish Type | Primary Effect | Suitable Materials | Key Benefit for “Lightsaber CNC Parts” |

|---|---|---|---|

| Mechanical Polishing | Smooth, reflective surface | Aluminum, Steel, Titanium | High aesthetic appeal, mirror-like gleam |

| Bead Blasting | Matte or satin texture | Aluminum, Steel, Titanium | Improved grip, reduced glare, uniform finish |

| Sand Blasting | Aggressive texture, surface prep | Aluminum, Steel, Titanium | Strong adhesion for coatings, rustic aesthetic |

| Anodizing (Type II) | Hard, corrosion-resistant, colored | Aluminum alloys | Durable color, enhanced protection, aesthetic variety |

Advanced Applications: Techniques 7-12

Mastering Electroplating & Chemical Coatings

Electroplating involves depositing a thin layer of metal onto a substrate through an electrochemical process, enhancing properties like corrosion resistance, wear resistance, or aesthetics. Common choices include nickel, chrome, or gold.

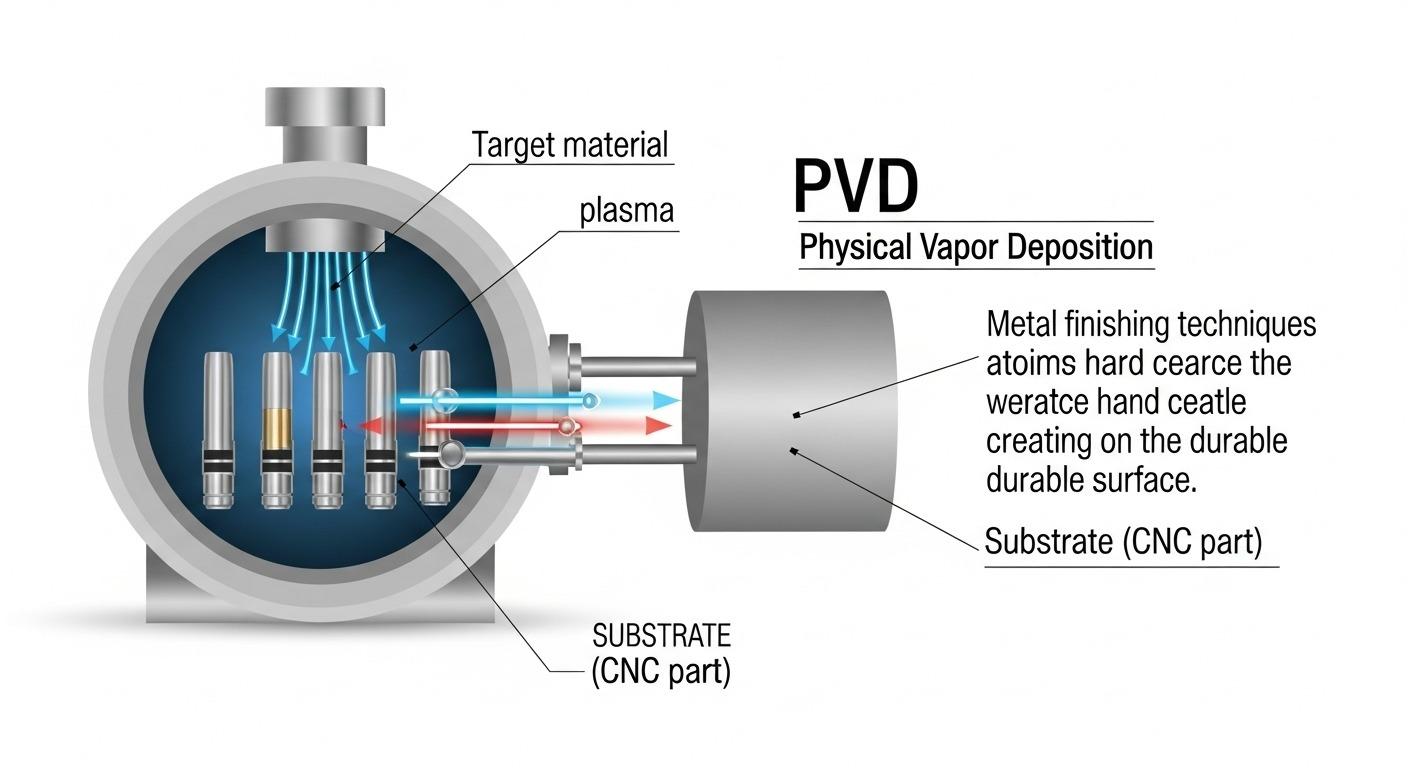

Chemical coatings, such as PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition), apply extremely thin, hard, and durable films to surfaces. These “precision machining finishes” provide superior wear and corrosion protection, often with unique colors.

Surface Hardening and Other Expert Finishes

Surface hardening techniques, like nitriding or carburizing, chemically alter the surface layer of a metal to increase its hardness and wear resistance without affecting the core properties. This is vital for components enduring high friction.

Passivation, a chemical process, creates a protective oxide layer on stainless steel, enhancing its corrosion resistance by removing free iron and forming a passive film. This improves the longevity and cleanliness of “lightsaber CNC parts.” Other expert finishes include powder coating for robust color, and laser texturing for intricate patterns.

Table: Advanced Finishing Techniques Overview

| Finish Type | Primary Function | Example Application | Key Advantage |

|---|---|---|---|

| Electroplating (Nickel) | Corrosion, wear resistance, aesthetics | Internal hilt components | Enhanced durability and sleek appearance |

| PVD/CVD Coatings | Extreme hardness, wear resistance | High-contact surfaces | Unrivaled surface protection |

| Nitriding | Surface hardening | Moving mechanical parts | Significantly increased wear life |

| Passivation | Corrosion resistance | Stainless steel parts | Maintains pristine condition |

| Powder Coating | Durable color, protective layer | External hilt sections | Robust, customizable aesthetic |

| Laser Texturing | Intricate patterns, grip | Grip sections | Unique aesthetics, improved tactile function |

Overcoming Finishing Hurdles & Future Trends

Troubleshooting Common Lightsaber Finish Issues

Addressing Imperfections in CNC Part Surfacing

Even with “precision machining finishes,” imperfections can arise, such as inconsistent color in anodizing, peeling in coatings, or uneven textures from blasting. These issues often stem from inadequate surface preparation, incorrect process parameters, or material inconsistencies.

Effective troubleshooting requires a systematic approach, analyzing each stage of the “CNC surface finishing” process, from initial machining to final treatment. Our engineers meticulously identify root causes to ensure impeccable results.

Innovating Beyond Today: Future of Finishes

Advanced Strategies for Premium CNC Parts

The landscape of “metal finishing techniques” is continuously evolving, with ongoing advancements in nanomaterials, bio-mimetic coatings, and intelligent surfaces. These innovations promise even greater durability, functionality, and aesthetic possibilities for “lightsaber CNC parts.”

Our factory actively invests in research and development, exploring novel “CNC surface finishing” methods and optimizing existing processes. This commitment ensures we remain at the forefront of providing cutting-edge solutions for the most demanding applications.

Elevate Your Lightsaber Parts: Key Actions

Recap: Mastering Lightsaber CNC Finishes

Your Blueprint for Exceptional Part Aesthetics

Achieving exceptional aesthetics and performance for “lightsaber CNC parts” hinges on a deep understanding and precise application of advanced surface finishing techniques. The selection process must consider material, intended function, and desired visual and tactile qualities.

This blueprint emphasizes the critical role of choosing the right “metal finishing techniques” to transform raw CNC components into high-quality, iconic products that stand out in the market. Each decision is a step towards perfection.

A Summary of 12 Essential Techniques

We have explored 12 essential “CNC surface finishing” techniques, from mechanical polishing and abrasive blasting to advanced electroplating and chemical coatings. Each method offers distinct advantages in enhancing durability, feel, and appearance.

The mastery of these “precision machining finishes” enables designers and engineers to overcome complex challenges and realize their most ambitious product visions. Our expertise ensures reliable, top-tier results.

Partnering for Flawless CNC Part Production

Connect with Our CNC Finishing Experts Today

Our team of expert engineers is dedicated to providing unparalleled “CNC surface finishing” solutions for your high-end projects. Leveraging extensive experience and state-of-the-art facilities, we ensure precision and quality at every stage.

We are ready to collaborate with you to define the optimal finishing strategy for your “lightsaber CNC parts,” from initial concept to final production. Our commitment is to transform your design vision into a tactile and visually stunning reality.

Case Study: The “Solar Flare” Hilt Prototype

Problem: A client approached ‘ly-machining’ with a challenge to produce a prototype for a high-end “lightsaber CNC part” called the “Solar Flare” hilt. The design demanded an intricate, multi-textured surface and a distinct, vibrant, heat-resistant finish on aerospace-grade aluminum, which proved difficult to achieve with standard anodizing methods due to inconsistencies in color saturation and minor surface imperfections.

Our Solution: Our engineers proposed a multi-stage “metal finishing technique” that began with ultra-fine precision machining, followed by a controlled abrasive blasting to establish a consistent, even surface texture without obscuring fine details. We then developed a custom, two-step anodizing process tailored to the specific aluminum alloy, incorporating precise temperature and current controls to ensure a uniform, deep crimson hue and superior abrasion resistance. Finally, critical tactile zones received a laser etching for enhanced grip and aesthetic detailing.

Result: The “Solar Flare” hilt prototypes delivered by ‘ly-machining’ not only met the client’s stringent aesthetic and functional requirements but exceeded their expectations. The combination of “precision machining finishes” resulted in a visually stunning component with a rich, consistent color, an ideal tactile feel, and exceptional durability, perfectly embodying the high-end vision. This successful collaboration allowed the client to move forward confidently with their product launch.

Call to Action: Ready to elevate your CNC parts with world-class “CNC surface finishing”? Don’t let your vision be limited by conventional approaches. Contact our expert engineers today for a personalized, transparent consultation and a detailed quote.

FAQ Section

What is “CNC surface finishing”?

“CNC surface finishing” refers to the various processes applied to the surface of a CNC machined part to enhance its aesthetic, functional, or protective properties. These techniques alter the surface texture, color, hardness, or corrosion resistance.

It is a critical step in manufacturing high-quality components, ensuring they meet specific design requirements and perform optimally in their intended application environments.

Why is finishing important for “lightsaber CNC parts”?

For “lightsaber CNC parts,” finishing is paramount because it directly impacts both the visual appeal and the tactile experience, which are crucial for high-end replicas and products. Beyond aesthetics, it provides essential protection against wear, corrosion, and environmental factors.

A superior finish enhances durability, extends the product’s lifespan, and contributes significantly to the overall perceived value and authenticity of the item.

Can you handle complex “metal finishing techniques”?

Yes, our factory specializes in handling complex “metal finishing techniques” with deep technical expertise. We offer a comprehensive suite of “precision machining finishes” tailored to intricate geometries and diverse material requirements.

Our engineering team works closely with clients to overcome challenges, developing custom solutions that ensure flawless execution for even the most demanding projects.