Is achieving a truly exceptional surface finish on H59 brass CNC parts an elusive challenge for your projects? Many find the complexities of brass machining lead to inconsistent results and unexpected costs. This often compromises both aesthetic appeal and critical functional performance.

But what if you could reliably achieve a mirror-like Ra 0.2µm finish, or precisely meet any specific functional requirement, every single time? Our deep technical expertise as a source manufacturer ensures your critical brass components are manufactured to the highest standards, solving these persistent issues.

We leverage precise technical strategies and deep material science knowledge to consistently deliver superior surface finishes on H59 brass components, guaranteeing optimal performance and aesthetic quality.

Overview: Grasping Surface Finish Potential

Setting the Scene: Industry Challenges

Navigating Brass Machining Hurdles

Procurement managers and R&D engineers often face significant hurdles when sourcing H59 Brass CNC Machining. Inconsistent Brass Surface Finish quality is a prevalent issue, leading to frequent rejections and costly rework. This directly impacts project timelines and overall budget adherence.

The unique properties of H59 brass, particularly its composition and ductility, present specific machining challenges. Without specialized expertise, achieving the required surface quality can be difficult, resulting in parts that do not meet critical design specifications.

Why Surface Finish Matters for H59 Brass

The surface finish of Precision CNC Brass Parts is not merely an aesthetic consideration; it directly impacts functionality. For components requiring precise sealing, such as valves or connectors, an inadequate surface finish can lead to leaks and system failures.

Furthermore, wear resistance and friction are heavily influenced by surface roughness. A superior Brass Surface Finish ensures enhanced longevity and optimal performance in dynamic applications, crucial for High-Quality Brass Machining.

Our Promise: Unlock Brass Perfection

What You’ll Learn About H59 Brass

This article delves into the precise methodologies and technical considerations for achieving exceptional surface finishes on H59 brass. You will gain insights into material properties, cutting parameters, and advanced techniques.

We aim to equip project managers and engineers with the knowledge to specify and procure truly High-Quality Brass Machining components. This ensures your designs benefit from our unparalleled expertise.

Blueprint of Our Expert Insights

Our approach combines deep material science understanding with decades of practical machining experience. We transparently outline the processes that distinguish our H59 Brass CNC Machining capabilities.

The goal is to demystify the complexities, demonstrating how consistent, superior Brass Surface Finish is not just achievable, but our standard. This builds confidence and trust in our manufacturing capabilities.

Mastering H59 Brass Surface Basics

Defining H59 Brass Finish Standards

Key Surface Roughness Metrics Explained

Understanding surface roughness metrics is fundamental to specifying and achieving the desired Brass Surface Finish. Ra (Roughness Average) is the most common metric, representing the arithmetic average of the absolute values of the profile deviations from the mean line.

However, other metrics like Rz (Ten-Point Mean Roughness) and RMS (Root Mean Square) offer additional insights into peak and valley characteristics. Specifying the appropriate metric is crucial for High-Quality Brass Machining.

Table: Common Surface Roughness Metrics

| Metric | Description | Application |

|---|---|---|

| Ra | Arithmetic average of profile deviations | General industrial, widely used |

| Rz | Average difference between highest peak and lowest valley | Sealing surfaces, functional requirements |

| RMS | Root Mean Square of profile deviations | Critical applications, statistical analysis |

H59 Brass Properties & Machinability

H59 brass is a common alloy, known for its good machinability, strength, and corrosion resistance. Its specific composition, primarily copper and zinc, influences chip formation and surface integrity during H59 Brass CNC Machining.

The material’s relatively soft nature and tendency to form long, stringy chips can pose challenges for achieving fine surface finishes. Precise control over cutting parameters is essential to manage chip evacuation and prevent surface marring.

Table: Key Properties of H59 Brass for Machining

| Property | Value/Characteristic | Relevance to Machining |

|---|---|---|

| **Composition** | Cu 57-60%, Zn 38-41%, Pb <0.5% | Influences chip formation and ductility |

| **Hardness (HV)** | 90-120 | Affects tool wear and cutting forces |

| **Density (g/cm³)** | ~8.4 | Material removal rate considerations |

| **Thermal Conductivity** | High | Efficient heat dissipation, prevents thermal distortion |

Core Factors Affecting Finish Quality

Tool Geometry & Material Selection

The choice of cutting tool geometry is paramount for achieving a superior Brass Surface Finish on H59. Sharp cutting edges with a positive rake angle are preferred to minimize cutting forces and reduce the risk of burr formation and surface tearing.

Tool material, such as carbide or high-speed steel (HSS), must be selected based on cutting speed and desired tool life. Specific coatings can further enhance tool performance and surface quality during Precision CNC Brass Parts production.

Machining Parameters: Speed, Feed, Depth

Optimizing machining parameters—cutting speed, feed rate, and depth of cut—is critical for H59 Brass CNC Machining. High cutting speeds with appropriate feed rates generally lead to better surface finishes by reducing built-up edge formation.

However, excessive speeds can generate too much heat, affecting dimensional accuracy and surface integrity. A balanced approach, often determined through empirical testing, is essential for High-Quality Brass Machining.

Table: Optimized Machining Parameters for H59 Brass

| Parameter | Recommendation (Fine Finishing) | Impact on Surface Finish |

|---|---|---|

| **Cutting Speed** | 200-400 m/min | Reduces built-up edge, improves finish |

| **Feed Rate** | 0.02-0.08 mm/rev | Controls chip load, minimizes tool marks |

| **Depth of Cut** | 0.05-0.2 mm | Light cuts reduce stress and improve surface integrity |

| **Coolant Type** | Soluble oil emulsion | Lubrication, chip evacuation, thermal control |

Precision Techniques for H59 Brass

Advanced Machining Strategies

Optimizing H59 Toolpaths & Coolants

Employing advanced toolpath strategies is key to achieving superior Brass Surface Finish. Climb milling, where the cutter rotates in the same direction as the feed, can significantly reduce burr formation and improve surface quality.

The strategic application of coolants, such as soluble oil emulsions, plays a vital role in H59 Brass CNC Machining. Coolants lubricate the cutting zone, evacuate chips efficiently, and dissipate heat, preventing thermal distortion and maintaining dimensional accuracy.

Mitigating Imperfections & Defects

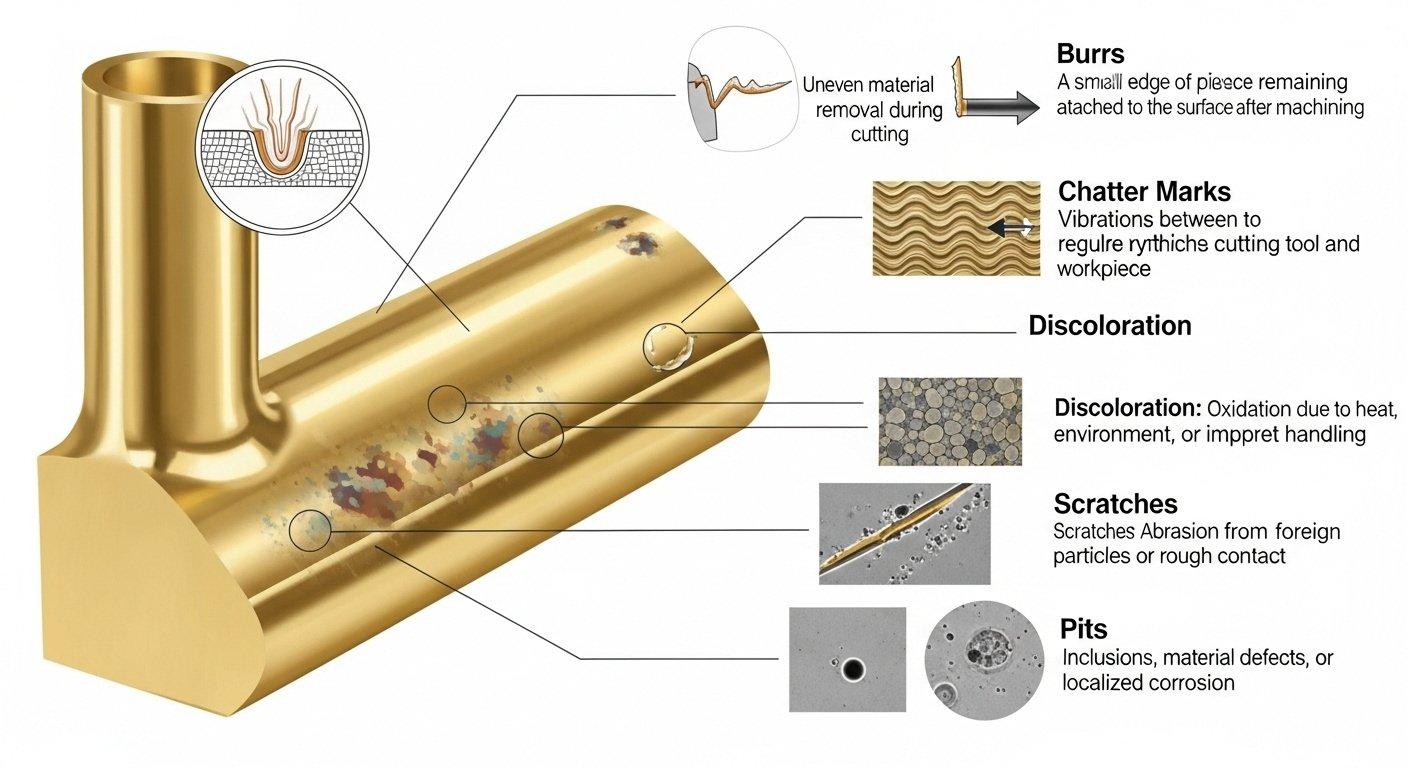

Common imperfections like burrs, chatter marks, and discoloration can compromise the Brass Surface Finish. Our expert engineers utilize techniques such as micro-deburring tools and optimized post-machining cleaning processes.

Precision CNC Brass Parts benefit from stringent process control, including fine-tuned cutting parameters and vibration dampening measures. These proactive steps ensure minimal defects and a consistently high-quality output.

Case Studies: H59 Brass Excellence

High-Gloss H59 Brass Success Story

**Problem:** A client required small, intricate H59 brass optical components for a scientific instrument, demanding an exceptionally smooth Brass Surface Finish of Ra 0.2µm for critical light reflection properties. Previous suppliers struggled with achieving this consistency, often delivering parts with micro-scratches and inconsistent reflectivity.

**Our Solution:** Our engineering team conducted a thorough analysis of the H59 Brass CNC Machining process. We selected specialized diamond-tipped tools with specific geometries and implemented a multi-pass finishing strategy at optimized, low feed rates and high spindle speeds. A highly refined soluble oil coolant system was employed to manage thermal conditions and ensure effective chip evacuation. Every batch of these Precision CNC Brass Parts underwent rigorous profilometry and visual inspection under magnification.

**Result:** We consistently delivered components that not only met the stringent Ra 0.2µm specification but often exceeded it, achieving a near-mirror finish. The client reported a significant reduction in optical component rejection rates and praised the consistency and High-Quality Brass Machining, leading to improved instrument performance and accelerated product development.

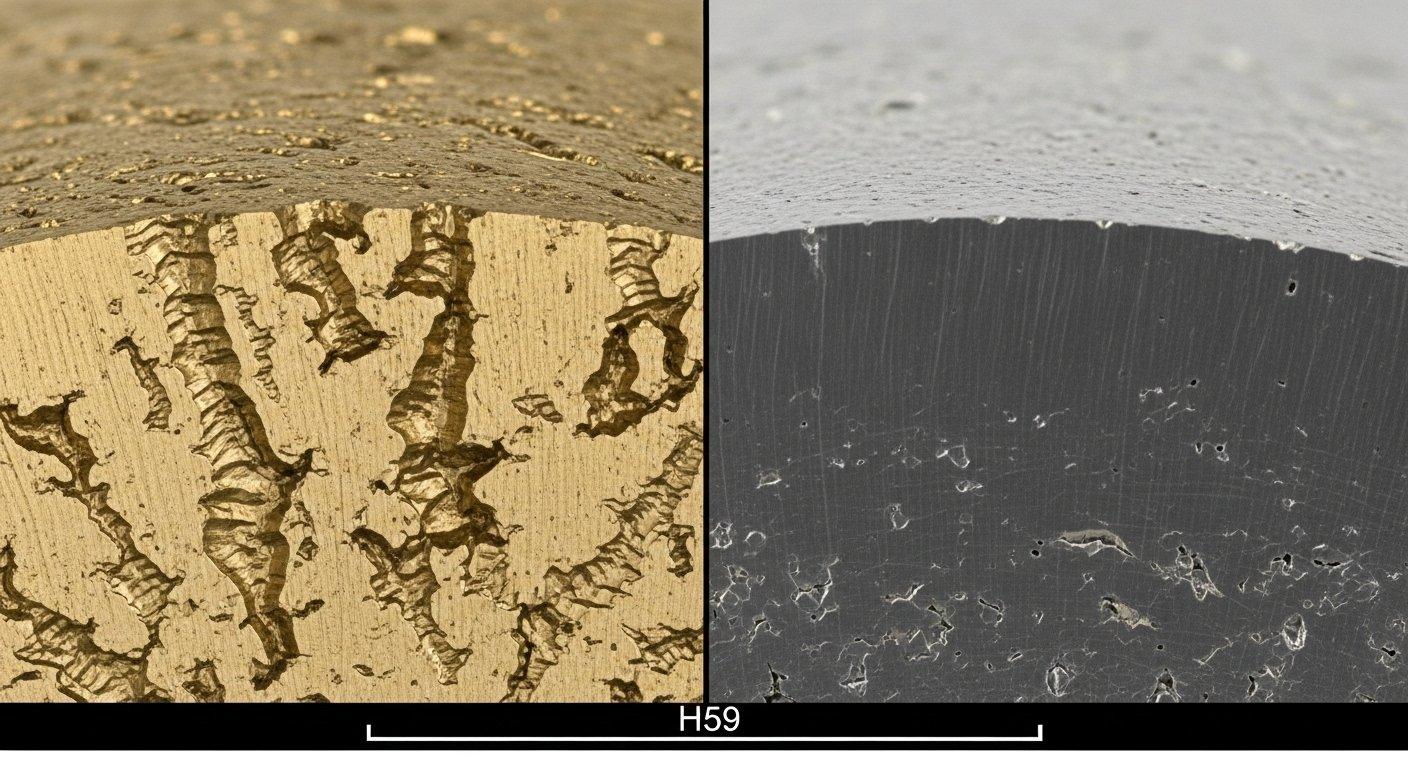

Comparing Finishes: Data & Visuals

Our success is underpinned by measurable data and visual evidence of superior finishes. We provide comprehensive reports detailing surface roughness metrics against specified tolerances. This transparency reinforces our commitment to High-Quality Brass Machining.

Clients receive tangible proof of our capabilities, often through detailed microscopic images and profilometer readings. This approach fosters confidence in our ability to deliver on complex H59 Brass CNC Machining requirements.

Partnering for H59 Brass Perfection

Overcoming H59 Brass Challenges

Addressing Common Finish Issues (FAQ)

Clients frequently inquire about specific challenges in achieving optimal Brass Surface Finish. Our technical team is adept at diagnosing and resolving issues ranging from uneven textures to discolored surfaces, ensuring consistent results.

We offer expert consultation to preemptively address potential issues, guiding you through material selection and design for manufacturability. This collaborative approach minimizes risks in your Precision CNC Brass Parts projects.

Future Trends & Our Expertise

Next-Gen H59 Brass Machining

The field of H59 Brass CNC Machining is continually evolving, with advancements in machine tool technology and cutting tool materials. We actively invest in the latest innovations, including advanced CAM software and automated inspection systems.

Our factory in China Shenzhen is at the forefront of adopting sustainable practices, optimizing coolant usage, and minimizing waste. This ensures not only High-Quality Brass Machining but also environmentally responsible manufacturing.

Conclusion: Your H59 Brass Solution

Key Insights for H59 Brass Finishes

Recapping H59 Brass Core Takeaways

Achieving optimal Brass Surface Finish for H59 Brass CNC Machining demands a blend of material science knowledge, precise tooling, and meticulous parameter control. The right partner can transform challenging specifications into consistent realities.

Our factory’s commitment to precision ensures that your Precision CNC Brass Parts meet the most stringent requirements. We stand as a testament to High-Quality Brass Machining delivered reliably and efficiently.

Reinforcing Our Technical Prowess

Our engineering-driven approach and status as a source manufacturer enable us to offer unparalleled expertise. We provide transparency in our processes and competitive pricing, giving you peace of mind.

Trust ‘ly-machining’ to elevate the quality and performance of your H59 brass components, reducing design risks and ensuring superior product outcomes.

Take Action: H59 Brass Project Quote

Request Your Custom H59 Brass Quote

Ready to elevate the quality of your H59 brass components? Contact our expert engineering team today for a transparent quote and a personalized consultation on achieving your specific surface finish requirements.

—

**Case Study: Ultra-Smooth Brass Manifold for Medical Devices**

**Problem:** A medical device manufacturer required a complex H59 brass manifold with internal channels demanding an ultra-smooth Brass Surface Finish (Ra 0.4µm) to prevent bacterial growth and ensure fluid flow integrity. Their previous supplier consistently failed to meet this internal roughness, leading to costly rejections and delays in FDA approval.

**Our Solution:** Our engineering team developed a specialized H59 Brass CNC Machining protocol. This involved multi-axis machining with custom-ground, polished carbide tools, followed by a proprietary micro-honing process for the internal channels. We precisely controlled coolant flow and pressure to ensure optimal chip evacuation and prevent scratching. In-process profilometry was integrated to monitor the Brass Surface Finish of critical internal features, ensuring real-time adherence to specifications.

**Result:** ‘ly-machining’ successfully produced manifolds consistently achieving Ra 0.35µm or better on both external and internal surfaces. This level of High-Quality Brass Machining not only met but exceeded the client’s stringent requirements, significantly accelerating their device’s regulatory approval. The client praised our technical capabilities and the reliability of our Precision CNC Brass Parts, leading to a long-term partnership.

—

**Call to Action:**

Invite readers to get a free quote or technical consultation.

—

**FAQ Section:**

How is Ra measured on brass?

Ra, or Roughness Average, is typically measured using a contact profilometer. This instrument traces a stylus across the Brass Surface Finish, detecting microscopic peaks and valleys.

The data collected is then averaged to provide a quantitative value representing the arithmetic mean deviation of the surface profile. This method ensures objective and repeatable measurements for H59 Brass CNC Machining.

What prevents a mirror finish?

Achieving a mirror Brass Surface Finish on H59 brass can be hindered by several factors. These include incorrect cutting tool geometry, which can lead to tearing or poor chip evacuation.

Suboptimal machining parameters, such as an insufficient cutting speed or an excessive feed rate, can also leave visible tool marks. Material imperfections or vibration during High-Quality Brass Machining also impact the final finish.

Why choose H59 over other brass?

H59 brass is often selected for its excellent balance of machinability, strength, and corrosion resistance. Its specific composition makes it highly suitable for Precision CNC Brass Parts requiring intricate details and good formability.

While other brass alloys may offer slightly different properties, H59 provides a cost-effective solution with consistent material characteristics for a wide range of applications, especially where a High-Quality Brass Machining finish is critical.