Tired of Inconsistent Color?

Setting the Scene: The Color Conundrum

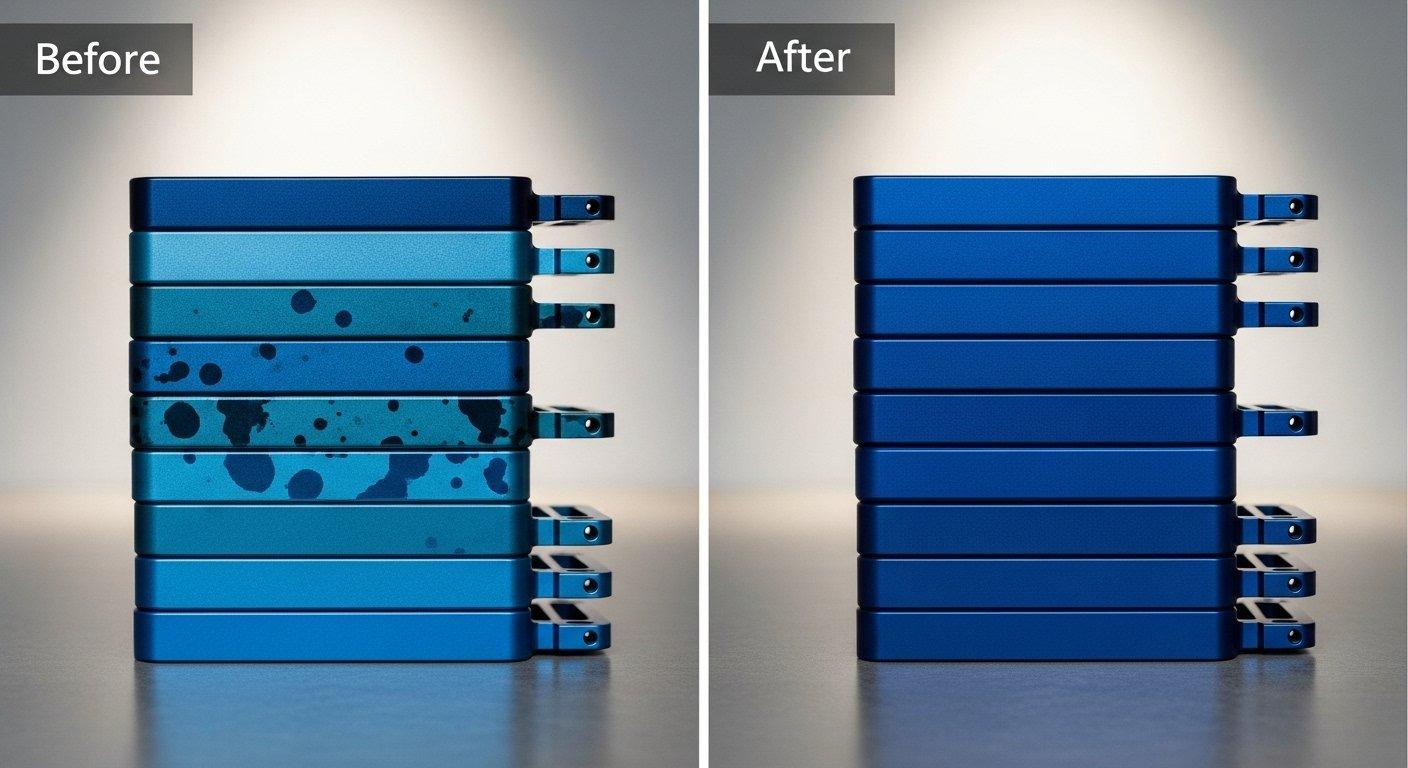

Is your brand’s reputation suffering due to inconsistent anodized colors on your premium CNC machined aluminum parts? This pervasive challenge often leads to costly rejects and delays, undermining product quality and customer trust.

The slightest variations in hue can compromise the aesthetic integrity of meticulously designed components. This guide addresses the root causes of anodizing color differences and provides actionable solutions.

The High Cost of Anodized Color Variation

Anodizing color difference causes significant financial strain through rework, material waste, and missed market opportunities. Each inconsistent batch impacts production schedules and profitability.

Furthermore, these discrepancies can damage a brand’s perception of quality, making it difficult to maintain market leadership. Effective anodized aluminum quality control is paramount to mitigate these risks.

Why Consistent Color Matters to Your Brand

Consistent color is not merely an aesthetic preference; it is a critical quality indicator for high-end products. Brand identity often hinges on the uniform appearance of its components.

Maintaining aluminum anodizing consistency across all production runs reassures customers and reinforces brand excellence. It signifies attention to detail and a commitment to superior manufacturing standards.

Your Guide to Flawless Finishes

What You’ll Learn: Achieving Perfect Anodized Hues

This comprehensive guide delves into the intricate factors influencing anodizing color consistency. We will explore material science, machining precision, and critical process parameters.

Understanding these elements is key to preventing color variations. Our aim is to equip you with the knowledge to demand and achieve perfectly uniform anodized finishes every time.

Exploring Causes, Solutions, & Best Practices

We will systematically break down the primary anodizing color difference causes. From subtle material inconsistencies to precise process controls, each factor will be examined.

Our discussion will highlight best practices in CNC machined aluminum anodizing. This ensures that you can implement robust solutions and maintain stringent anodized aluminum quality control throughout your supply chain.

The Unseen Culprits: Material & Machining

Foundation First: Alloy & Structure

Aluminum Alloys & Their Anodizing Impact

The choice of aluminum alloy profoundly affects the final anodized color. Different alloys contain varying amounts of alloying elements like silicon, copper, and magnesium.

These elements react distinctly during the anodizing process, influencing the oxide layer’s thickness and porosity. This directly contributes to anodizing color difference causes, even under identical processing conditions.

Table: Common Aluminum Alloys and Anodizing Characteristics

| Alloy Designation | Key Alloying Element | Anodizing Performance |

|---|---|---|

| 6061 | Magnesium, Silicon | Good, consistent color |

| 7075 | Zinc, Magnesium | Good, slightly darker |

| 2024 | Copper | Difficult, gray tone |

| 5052 | Magnesium | Excellent, clear |

Grain Structure & Purity: The Hidden Variables

Beyond alloy composition, the internal grain structure and purity of the aluminum billet are critical. Inconsistent grain sizes or precipitates can lead to localized variations in the oxide layer.

These microscopic differences manifest as visible color streaks or blotches after anodizing. Ensuring material homogeneity is a fundamental step toward achieving aluminum anodizing consistency.

Machining’s Subtle Scars

CNC Machining Effects on Surface Uniformity

The surface finish left by CNC machining directly impacts how the aluminum reacts during anodizing. Tool marks, chatter, or residual stresses can create microscopic irregularities.

These surface inconsistencies can trap contaminants or cause uneven oxide formation, leading to visible anodizing color difference causes. Precision machining is crucial for a uniform substrate.

Table: Machining Parameters and Surface Finish Impact

| Machining Parameter | Surface Effect | Anodizing Implication |

|---|---|---|

| High Feed Rate | Pronounced Tool Marks | Uneven oxide, color variation |

| Dull Cutting Tool | Surface Smearing | Impaired pre-treatment adhesion |

| Optimized Speeds/Feeds | Smooth, Uniform Finish | Consistent oxide, even coloration |

| Coolant Application | Debris Removal | Prevents contamination build-up |

Process Precision: Anodizing Variables

Critical Steps & Control Points

Pre-Treatment’s Role in Color Consistency

The pre-treatment phase, including cleaning and etching, is indispensable for anodizing color consistency. Any residual oils, oxides, or contaminants on the surface will hinder uniform anodization.

Precise control over bath chemistry, temperature, and immersion times ensures a pristine surface. This foundational step eliminates a significant percentage of potential anodizing color difference causes.

Electrolyte, Current, & Temperature Control

During the anodizing process itself, the electrolyte composition, current density, and temperature must be meticulously controlled. Deviations in these parameters directly influence the oxide layer’s properties.

Inconsistent current flow, fluctuating electrolyte concentrations, or temperature variations can lead to uneven oxide growth. This is a primary factor in the final color disparity of CNC machined aluminum anodizing.

Table: Key Anodizing Parameters and Their Influence

| Parameter | Control Importance | Impact on Color Consistency |

|---|---|---|

| Electrolyte Concentration | Strict adherence to formulation | Affects oxide porosity & thickness |

| Current Density | Uniform distribution is key | Determines oxide growth rate & density |

| Bath Temperature | Maintained within narrow range | Influences oxide hardness & absorption |

| Anodizing Time | Precise duration | Dictates overall oxide layer thickness |

Fixture Design & Post-Treatment

Optimizing Fixturing for Uniform Current Flow

Proper fixturing is often overlooked but plays a crucial role in achieving aluminum anodizing consistency. Inadequate fixturing can lead to hot spots, uneven current distribution, or poor electrical contact.

These issues prevent the formation of a uniform oxide layer, resulting in distinct color variations across the part. Expert fixture design ensures consistent electrical potential across the entire surface.

Sealing & Dyeing: Ensuring Lasting Color

Following anodization, the dyeing and sealing processes are critical for the final color. Inconsistent dye bath concentrations, immersion times, or sealing quality can drastically alter the final hue.

Effective sealing closes the pores of the oxide layer, locking in the dye and preventing fading or leaching. Precise control in these stages is vital for lasting and uniform anodized colors, crucial for anodized aluminum quality control.

Our Expertise: Guaranteed Color Uniformity

Solving Your Anodizing Challenges

Addressing Common Color Difference Issues

At ly-machining, we leverage decades of expertise in CNC machined aluminum anodizing to address and mitigate all common anodizing color difference causes. Our engineers meticulously analyze material specifications and machining processes.

We implement bespoke solutions, from optimizing pre-treatment to fine-tuning anodizing parameters. This proactive approach ensures consistent and high-quality finishes, eliminating costly production setbacks.

Advanced Strategies & Quality Assurance

Proprietary QC & Material Selection Insights

Our commitment to anodized aluminum quality control extends to proprietary inspection methods and rigorous material selection protocols. We work with trusted suppliers to ensure material homogeneity and optimal alloy composition.

Advanced spectrophotometers and visual inspection techniques are employed at every stage to verify color consistency. This comprehensive approach guarantees that every component meets the strictest aesthetic and functional standards.

Achieve Flawless Anodized Parts

Key Takeaways for Perfect Finishes

Recap: Master CNC Aluminum Anodizing

Achieving perfect anodized colors on CNC machined aluminum requires a holistic approach. It encompasses careful material selection, precise machining, and rigorous control over every anodizing process step.

Understanding the interplay of these factors is crucial. This integrated knowledge is the foundation for consistently producing aesthetically superior and functionally robust components.

Your Path to Consistent Anodized Color

By meticulously controlling all variables, from alloy composition to sealing, you can virtually eliminate anodizing color difference causes. This commitment to detail ensures superior aluminum anodizing consistency.

Partnering with an expert source manufacturer provides the technical depth and process control necessary to achieve these results reliably. It streamlines your supply chain and protects your brand’s reputation.

Partner for Anodizing Excellence

Consult Our Experts for Consistent Quality

Our team of engineers at ly-machining possesses unparalleled expertise in CNC machined aluminum anodizing. We are dedicated to delivering parts with impeccable surface finishes and perfect color uniformity.

Let us help you achieve the consistent, high-quality anodized results your products demand. Our advanced anodized aluminum quality control processes ensure excellence on every order.

**Problem:** A client manufacturing premium smart home devices faced severe challenges with their anodized aluminum enclosures. Despite consistent alloy specifications, batch-to-batch and even part-to-part color variations were leading to an unacceptable reject rate. This inconsistency damaged their brand’s luxury image and delayed product launches.

**Our Solution:** Our engineering team conducted a detailed analysis of their existing CNC machining and anodizing processes. We identified that subtle variations in their supplier’s etching bath concentration, combined with inconsistent fixturing, were creating microscopic surface differences and uneven current density during anodizing. We recommended adjusting pre-treatment parameters, re-designing custom fixtures for optimal current flow, and implementing a real-time spectrophotometric quality check.

**Result:** Within weeks, the client observed a dramatic improvement in anodized aluminum consistency. Reject rates plummeted by over 80%, and their products now boast perfectly uniform, vibrant finishes. This led to significant cost savings, expedited market entry for their new line, and a reinforced reputation for premium quality.

What causes color variation in anodizing?

The primary anodizing color difference causes stem from multiple factors. These include variations in aluminum alloy composition, inconsistencies in CNC machining surface finish, and uncontrolled anodizing parameters.

Electrolyte concentration, current density, bath temperature, and even the purity of rinse waters can all contribute. Inconsistent pre-treatment and fixturing are also significant contributors to color discrepancies.

How can anodizing consistency be improved?

Improving aluminum anodizing consistency requires stringent control over the entire process. This begins with selecting uniform material and ensuring precise CNC machining.

Meticulous pre-treatment, tightly controlled anodizing parameters, and optimized fixturing are critical. Post-treatment steps like dyeing and sealing must also be precisely executed to prevent variations.

What is anodized aluminum quality control?

Anodized aluminum quality control encompasses a series of systematic checks and procedures. These are implemented at every stage of the manufacturing process to ensure consistent quality.

It includes material verification, in-process monitoring of anodizing parameters, and final inspection using spectrophotometers. This ensures parts meet specified aesthetic and functional requirements, preventing anodizing color difference causes.