Imagine a critical marine component failing prematurely in the unforgiving ocean depths, causing millions in downtime and jeopardizing safety. Standard materials often cannot withstand this extreme environment, making material choice a lifeline for marine equipment.

Is your current material truly equipped to face relentless saltwater, corrosive chlorides, and extreme pressures? Component reliability in subsea and offshore applications is paramount, directly impacting operational efficiency and safety.

This guide explores the superior advantages of 316L stainless steel for precision CNC machined parts. We reveal how advanced techniques ensure unparalleled durability and performance for your vital marine equipment.

Precision CNC machined 316L stainless steel parts offer unmatched corrosion resistance and mechanical integrity, proving essential for reliable performance in demanding marine and offshore environments.

Overview: Why 316L Matters

Marine Corrosion: Your Deepest Concern

The marine environment presents an exceptionally aggressive challenge to materials. Saltwater, high pressures, and chlorides lead to diverse forms of corrosion, significantly compromising structural integrity.

Premature failure due to corrosion in marine equipment CNC parts poses substantial risks. This mandates costly maintenance, unexpected repairs, and potentially catastrophic safety hazards.

The Cost of Failure in Ocean Environments

When a critical part fails in offshore component manufacturing, financial implications are significant. Downtime on marine vessels or subsea installations can amount to millions daily, encompassing lost productivity and emergency repairs.

Beyond direct financial losses, the reputation of equipment manufacturers is at stake. Reliability in the marine industry makes material selection and precision 316L stainless steel machining paramount.

Criticality of Material Choice in Marine CNC

Selecting the right material is the first crucial step in preventing these failures. Generic stainless steels often fall short, leading to accelerated degradation and compromised performance.

Choosing a material engineered for corrosive environments directly impacts longevity. It safeguards both the investment in sophisticated marine equipment CNC parts and the operational continuity of vital systems.

Mastering Marine Materials: What You’ll Learn

This article provides a deep understanding of 316L stainless steel. We explore its unique properties that confer superior corrosion resistance for marine applications.

We will detail the specialized CNC machining techniques required to process this robust alloy. Our goal is to equip you with knowledge for informed decisions.

Ensuring Durability & Performance with 316L

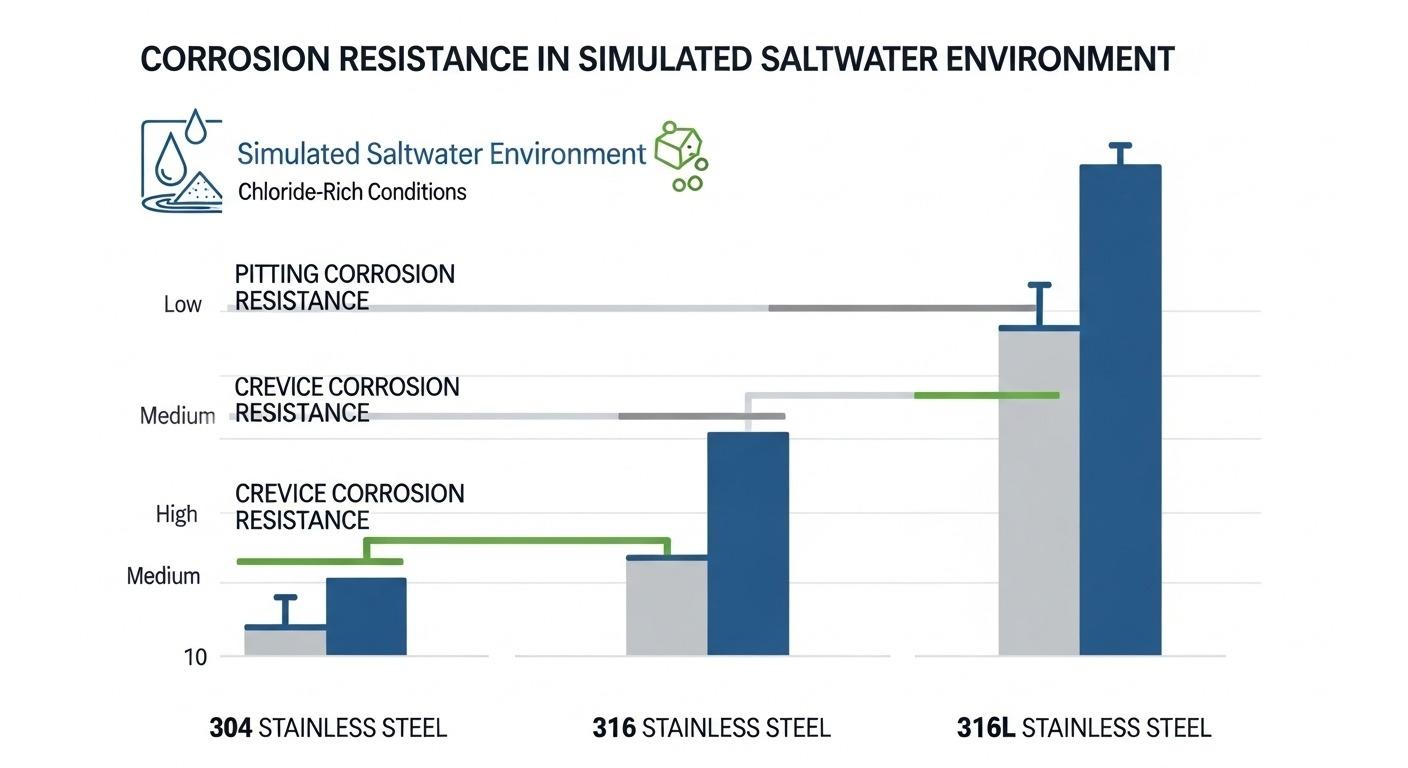

316L stainless steel stands out as a premier material for demanding marine environments. Its inherent resistance to pitting and crevice corrosion, especially in chloride-rich solutions, is exceptional.

This superior performance translates directly into enhanced durability and prolonged operational life for your marine equipment. It ensures consistent reliability under the harshest subsea or offshore conditions.

Exploring 316L Properties, Machining & Solutions

We will delve into 316L’s specific elemental composition, explaining how elements contribute to its resilience. Understanding metallurgical properties is key for corrosion resistant machining.

Subsequently, we examine the precise CNC machining processes that transform raw material into high-performance marine equipment CNC parts. Our expertise ensures optimal results, turning complex designs into reliable components.

316L: Marine Material Edge

Unpacking 316L’s Corrosion Resistance

316L stainless steel is an austenitic chromium-nickel alloy distinguished by its molybdenum content. This specific alloying element primarily enhances resistance to various forms of corrosion.

The ‘L’ denotes its lower carbon content, critical for preventing sensitization. Sensitization can lead to intergranular corrosion, particularly after welding, a common process in offshore component manufacturing.

Defining Molybdenum’s Role in 316L

Molybdenum significantly enhances 316L’s resistance to pitting and crevice corrosion. These localized attacks are prevalent and damaging in chloride-rich environments like seawater.

It strengthens the passive layer on the stainless steel surface, making it more resilient against corrosive agents. This protective film is crucial for the long-term integrity of marine equipment CNC parts.

Here is a typical chemical composition for 316L stainless steel:

| Element | Percentage (%) |

|---|---|

| Chromium | 16.0 – 18.0 |

| Nickel | 10.0 – 14.0 |

| Molybdenum | 2.0 – 3.0 |

| Manganese | Max 2.0 |

| Silicon | Max 1.0 |

| Carbon | Max 0.03 |

| Phosphorus | Max 0.045 |

| Sulfur | Max 0.03 |

| Iron | Balance |

How 316L Fights Saltwater & Chlorides

Chlorides in seawater accelerate corrosion in many metals. 316L’s molybdenum allows it to form a stable, robust passive film, effectively resisting chloride attack.

This enhanced stability means components from 316L stainless steel machining endure prolonged immersion. It directly addresses the primary challenge of marine applications without significant degradation.

Why 316L Delivers Long-Term Value

Investing in 316L stainless steel for your marine equipment CNC parts yields substantial long-term value. Its superior corrosion resistance extends operational lifespans for components, reducing replacement frequency.

This durability minimizes maintenance requirements and associated costs. It also ensures consistent, uninterrupted performance in critical offshore component manufacturing, vital for project timelines.

Direct Benefits for Your Marine Equipment

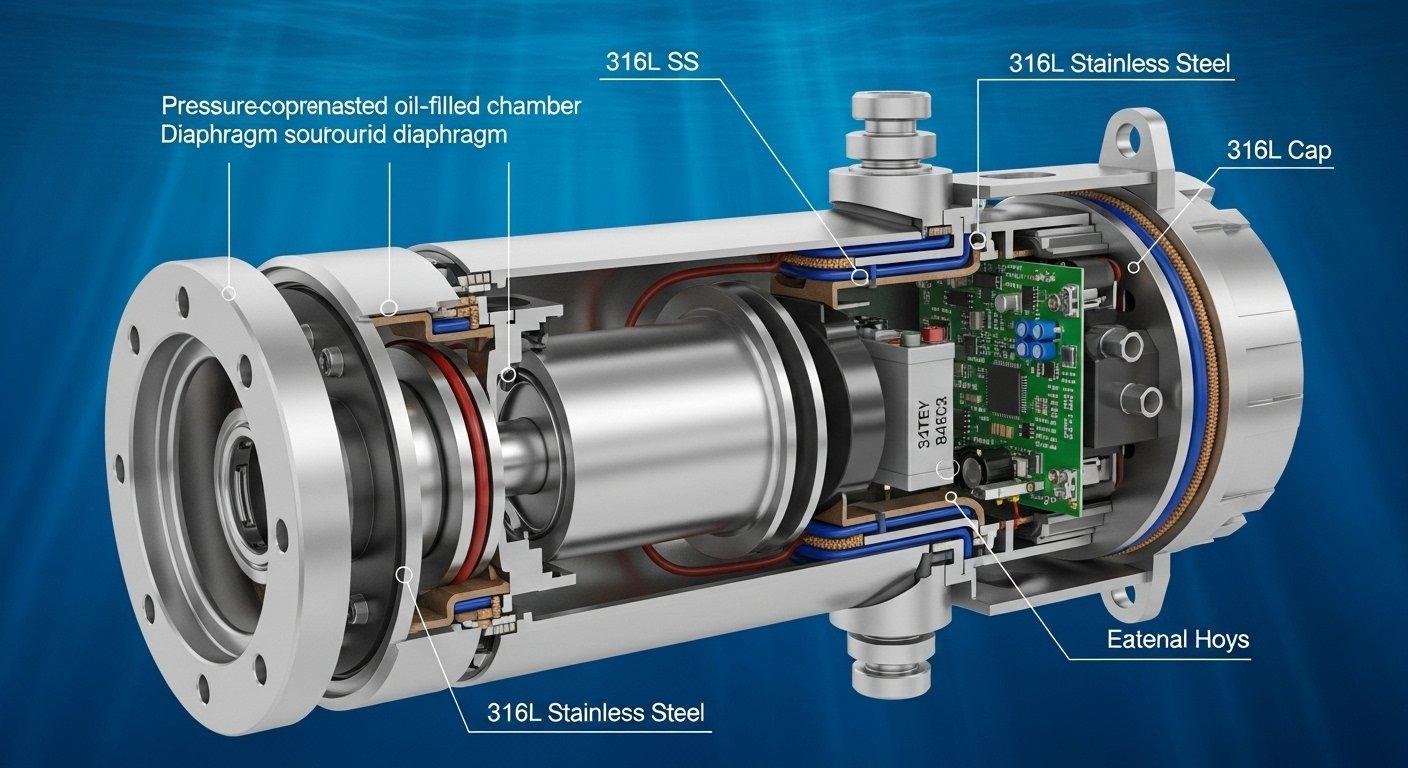

Choosing 316L equips your marine systems with components designed to withstand the harshest conditions. This includes valve bodies, pump shafts, and subsea housings, all benefiting from enhanced resilience.

The reliability afforded by 316L stainless steel machining directly improves the overall safety and efficiency of your operations. It provides peace of mind, knowing your equipment is built to endure.

Reducing Downtime & Replacement Costs

The inherent longevity of 316L components dramatically cuts down on unexpected downtime. Fewer failures mean less time spent on repairs, maximizing operational hours for vessels and platforms.

Over the lifecycle of marine equipment, the initial investment in high-quality 316L stainless steel parts often results in significant cost savings. This is due to reduced maintenance and minimized disruption.

CNC Machining 316L Parts

Precision Machining Techniques for 316L

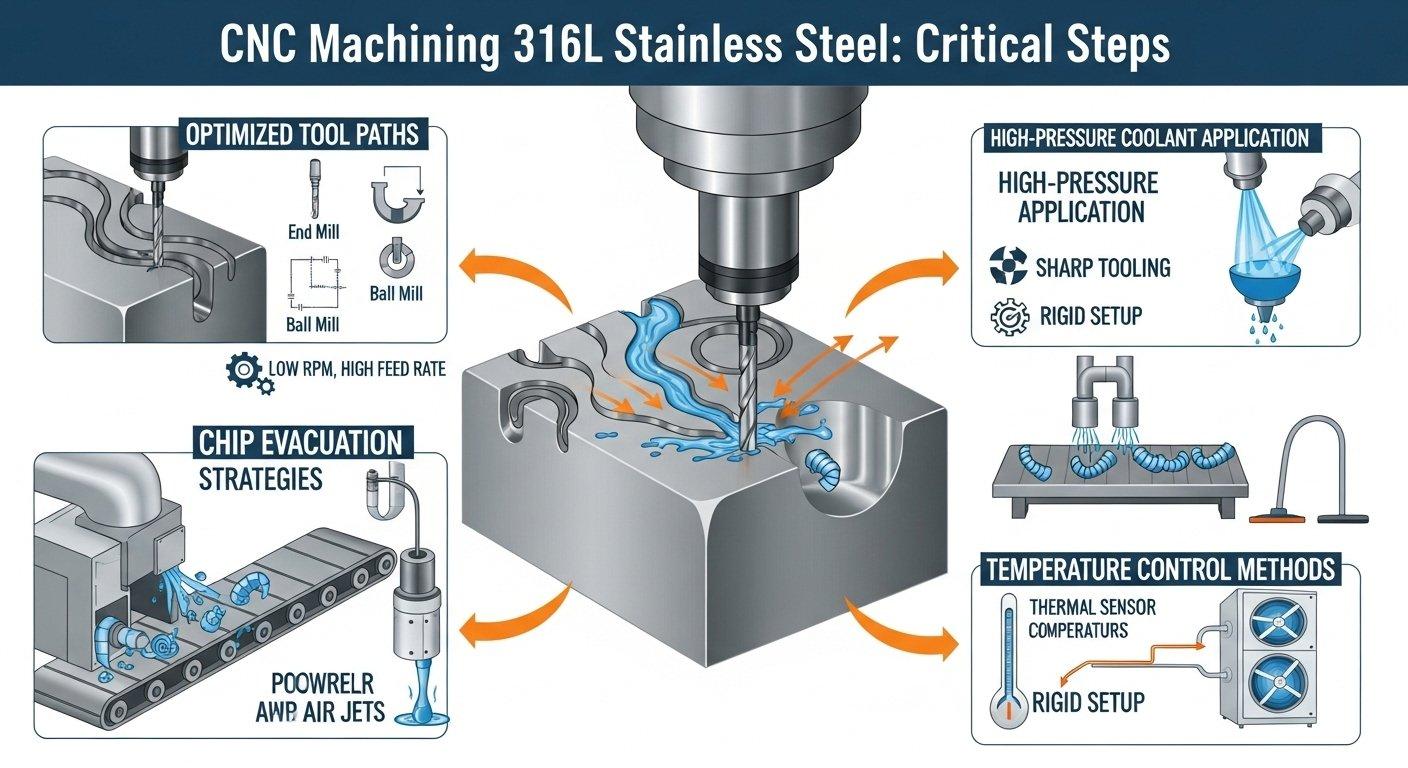

While 316L stainless steel offers exceptional properties, its machining presents specific challenges due to toughness and work-hardening tendencies. Successful 316L stainless steel machining requires specialized techniques.

Our factory utilizes advanced CNC milling and turning, coupled with optimized cutting strategies. These include lower speeds, higher feed rates, and constant chip breaking to manage heat and prevent material deformation.

Optimizing Tooling & Parameters for 316L

The choice of tooling is paramount when machining 316L. We employ specific carbide inserts with positive rake angles to reduce cutting forces and minimize work hardening.

Coolant selection and delivery are critical for managing heat and evacuating chips effectively. High-pressure coolant systems extend tool life and achieve superior surface finishes.

Here are some general recommendations for CNC machining parameters for 316L stainless steel:

| Parameter | Recommendation |

|---|---|

| Cutting Speed (Sfpm) | 150-300 |

| Feed Rate (Ipr) | 0.005-0.015 (Roughing), 0.002-0.008 (Finishing) |

| Depth of Cut (Inches) | 0.050-0.200 (Roughing), 0.005-0.020 (Finishing) |

| Tool Material | Coated Carbide (e.g., AlTiN, TiAlN) |

| Rake Angle | Positive (6-10 degrees) |

| Coolant | High-pressure soluble oil or synthetic (flood/mist) |

Managing Heat & Surface Finish Challenges

Controlling heat generation is a constant concern during 316L stainless steel machining. Excessive heat can lead to material distortion, tool wear, and compromised surface integrity.

Achieving the required surface finish for marine equipment CNC parts demands careful process control. Our techniques minimize roughness, ensuring components resist environmental fouling and cavitation erosion.

Real-World 316L Marine Case Studies

Our extensive experience in offshore component manufacturing provides a wealth of real-world applications for 316L stainless steel. These projects demonstrate its superior performance when precision machined.

From subsea connectors to intricate valve components, our factory has a proven track record. We consistently deliver durable parts, overcoming material challenges for critical marine applications.

Success Story: Critical Valve Components

One notable project involved precision 316L stainless steel machining for critical valve components. These were destined for an advanced subsea oil and gas extraction system, facing extreme pressures and corrosive conditions.

Our engineered solution ensured tight tolerances and an immaculate surface finish. This was crucial for preventing leakage and maintaining system integrity, directly impacting offshore operational success.

Comparing Quality: Our Approach vs. Others

Our factory distinguishes itself through a rigorous quality control regimen and unwavering commitment to technical excellence. We understand that in marine applications, there is no room for compromise.

From material sourcing to final inspection, every step of our 316L stainless steel machining process is meticulously managed. This contrasts with less specialized approaches that might lead to inconsistent quality.

Overcoming 316L Challenges

Ensuring Quality & Performance for 316L

Quality assurance for 316L stainless steel components extends beyond visual inspection. We implement comprehensive testing protocols to verify material integrity, dimensional accuracy, and surface finish.

This includes metallurgical analysis, dimensional metrology, and non-destructive testing methods. These measures guarantee that every marine equipment CNC part meets the most stringent industry standards.

Here are key quality checks performed for machined 316L parts:

| Quality Check | Description |

|---|---|

| **Material Verification** | Spectrographic analysis to confirm 316L chemical composition. |

| **Dimensional Accuracy** | CMM (Coordinate Measuring Machine) inspection for critical tolerances. |

| **Surface Finish** | Profilometer measurements to ensure specified Ra/Rz values. |

| **Visual Inspection** | Microscopic examination for burrs, cracks, or imperfections. |

| **Nondestructive Testing** | Dye Penetrant Inspection (DPI) or Eddy Current for surface flaws. |

| **Hardness Testing** | Vickers or Rockwell tests to verify material hardness. |

Addressing Common Machining Hurdles (FAQ)

Common challenges in 316L stainless steel machining include its tendency to work-harden, causing rapid tool wear, and producing tough, stringy chips. Effective chip evacuation is also a key concern.

Our engineering team continuously refines machining strategies. We optimize tool geometry, feed rates, and cooling methods to efficiently overcome these material characteristics and deliver consistent quality.

Future of 316L in Marine Engineering

316L stainless steel continues as a cornerstone material for marine and offshore applications. Its proven performance and cost-effectiveness ensure sustained relevance in emerging technologies.

As marine engineering evolves, the demand for highly reliable, corrosion resistant machining will only increase. 316L provides a strong foundation for future innovations, balancing performance with practicality.

Advanced Alloys & Sustainable Practices

While 316L is highly effective, research into more advanced corrosion-resistant alloys continues. Our factory stays abreast, evaluating new materials for potential in offshore component manufacturing.

We also prioritize sustainable machining practices, including optimizing material usage and reducing waste. This aligns with global environmental responsibility efforts through energy-efficient processes.

Your Partner in Marine CNC

Key Takeaways: 316L & Our Expertise

This guide has underscored the critical role of 316L stainless steel in demanding marine environments. Its unique properties, particularly enhanced corrosion resistance, make it indispensable for reliable marine equipment.

Our factory’s specialized expertise in 316L stainless steel machining ensures these benefits are fully realized. We combine advanced technology with deep material knowledge to deliver exceptional results.

Reaffirming 316L’s Critical Role

For any application requiring unyielding durability against saltwater and chlorides, 316L remains the benchmark. It is a material that consistently delivers where others fail, safeguarding investments and operational safety.

Choosing 316L for your marine equipment CNC parts is a strategic decision that pays dividends in long-term performance. It is a commitment to reliability, reducing risks associated with harsh environments.

Summary: Properties, Machining, Solutions

We’ve explored the enhanced corrosion resistance of 316L due to molybdenum and low carbon. We detailed precision CNC machining techniques essential for this robust, challenging alloy.

Our solutions are tailored to ensure superior surface finishes, tight tolerances, and consistent quality. This comprehensive approach results in marine equipment CNC parts that perform reliably under pressure.

Ready to Elevate Your Marine Projects?

The performance of your marine equipment is directly tied to the quality of its components. Partnering with a specialist in 316L stainless steel machining ensures you receive parts engineered for longevity and resilience.

Do not compromise on the integrity of your critical marine equipment. Our team is equipped to handle the most complex requirements, transforming your designs into robust, ocean-ready realities.

Request a Quote for 316L CNC Parts Today

Take the definitive step towards superior marine component reliability. Our engineers are ready to provide technical consultation and competitive, transparent pricing for your next project.

We are your trusted partner in achieving unparalleled performance for marine equipment CNC parts. Reach out now to ensure your operations are supported by components that truly withstand the test of the seas.

**Case Study: Reinforcing Subsea Integrity**

**Problem:** A client specializing in deep-sea geological surveying faced persistent issues with subsea sensor housings. Despite using commercially available stainless steel, crevice corrosion and stress corrosion cracking led to premature failures at depths exceeding 2,000 meters. This caused costly data loss and retrieval operations, jeopardizing critical research schedules due to inadequate standard solutions.

**Our Solution:** Our engineering team collaborated with the client, recommending a redesign utilizing precision CNC machined 316L stainless steel for the sensor housings. We meticulously optimized the geometry to eliminate crevice-forming features and applied specialized corrosion resistant machining techniques. This achieved an exceptionally smooth, uniform surface finish, crucial for preventing localized corrosion initiation.

We implemented rigorous material traceability and in-house testing protocols, ensuring the 316L raw material met certified specifications. Our 316L stainless steel machining process focused on managing residual stresses and maintaining dimensional accuracy, critical for deep-sea pressure integrity.

**Result:** The new 316L stainless steel housings significantly extended the operational lifespan of the subsea sensors. The client reported no further incidents of crevice corrosion or stress corrosion cracking over a two-year deployment period, a marked improvement from the previous 6-month average failure rate. This enhancement in reliability translated into substantial cost savings by reducing retrieval missions and minimizing downtime for critical research vessels. This successful offshore component manufacturing project reinforced the client’s confidence in their deep-sea equipment and our expertise.

Don’t compromise on marine durability. Contact our expert engineering team today to discuss your 316L stainless steel CNC machining needs and receive a transparent, competitive quote for parts that perform. Partner with us for unwavering quality in the harshest environments.

FAQ

Why 316L over 304 for marine?

316L stainless steel includes molybdenum, a key alloying element not present in 304. This addition significantly boosts its resistance to pitting and crevice corrosion, common and severe in chloride-rich marine environments.

The lower carbon content in 316L also reduces the risk of sensitization and intergranular corrosion after welding. This makes it a far more reliable choice for long-term exposure to seawater and harsh offshore conditions.

What tolerances can be achieved?

With advanced CNC machining capabilities and skilled operators, we consistently achieve very tight tolerances for 316L stainless steel parts. Depending on part geometry and size, tolerances typically reach ±0.005mm to ±0.01mm.

These precise tolerances are crucial for the proper fit, function, and sealing of critical marine equipment. Our stringent quality control measures ensure these specifications are met and maintained throughout production.

How is corrosion resistance ensured?

Ensuring corrosion resistance starts with using certified 316L raw material with the correct chemical composition. During CNC machining, we manage process parameters to minimize work hardening and achieve optimal surface finishes.

After machining, comprehensive quality checks, including visual inspection, dimensional verification, and non-destructive testing, confirm part integrity. This holistic approach guarantees maximum resistance to marine corrosion.