Mastering Custom CNC Machining

Struggling with the black box of custom CNC machining? Unclear processes, quality inconsistencies, and unpredictable lead times can derail even the most meticulously planned projects. These common frustrations often lead to costly delays and compromised product integrity.

At ly-machining, we understand these critical pain points. We believe that securing high-quality CNC parts should be a streamlined, predictable, and transparent experience from beginning to end.

Discover how our unique, transparent 3-step custom CNC machining process transforms complexity into certainty, guaranteeing high-quality components, on time and within budget. This guide demystifies the entire journey.

Our transparent, 3-step custom CNC machining process simplifies your journey from concept to high-quality, precision parts, ensuring on-time delivery and predictable results.

Unlock Custom CNC Success

Navigating the landscape of custom CNC machining requires more than just machinery; it demands a structured approach. Our methodology at ly-machining ensures every project, regardless of its complexity, follows a clear and precise trajectory. This commitment to process is fundamental to delivering high-quality CNC parts consistently.

The challenges of sourcing precision components are well-documented, from ensuring exact material specifications to adhering to stringent tolerance requirements. Our integrated workflow addresses these concerns proactively, providing peace of mind for our clients.

Navigating Custom CNC Complexities

Complex designs and tight deadlines often present significant hurdles in the procurement of custom CNC parts. Clients frequently face a lack of transparency regarding manufacturing steps, potential roadblocks, and cost breakdowns. This opacity can lead to unexpected issues.

Our role as a source manufacturer in Shenzhen, China, positions us uniquely to offer direct insight into every stage of the custom CNC machining process. This direct engagement fosters a partnership built on clarity and mutual understanding, eliminating many common complexities.

Why Our 3-Step Process Matters

The “black box” syndrome in manufacturing is a primary source of client anxiety. Our structured 3-step process is designed to eliminate this, providing a clear roadmap from initial design to final delivery. This ensures predictability and control over your project.

This systematic approach minimizes risks associated with quality inconsistencies and unexpected delays, two common pitfalls in custom CNC projects. By standardizing our CNC machining steps, we guarantee a level of service and product quality that sets industry benchmarks.

Your Path to Perfect Parts

Achieving perfect parts begins with a clear understanding of the manufacturing journey. Our process is engineered to guide you through each phase, ensuring your design intent translates flawlessly into a tangible, high-performance component.

This structured engagement is crucial for maintaining the integrity of your design specifications and guaranteeing the functional performance of the final product. It is how we consistently deliver high-quality CNC parts that exceed expectations.

Your 3-Step CNC Journey

Our commitment to excellence is embodied in a meticulous 3-step custom CNC machining process, designed for maximum efficiency and precision. Each step is optimized to provide unparalleled clarity and quality assurance, from conception to completion.

This structured workflow is a cornerstone of our operations, allowing us to manage complex projects with high precision and predictable outcomes. It serves as a benchmark for delivering high-quality CNC parts under stringent deadlines.

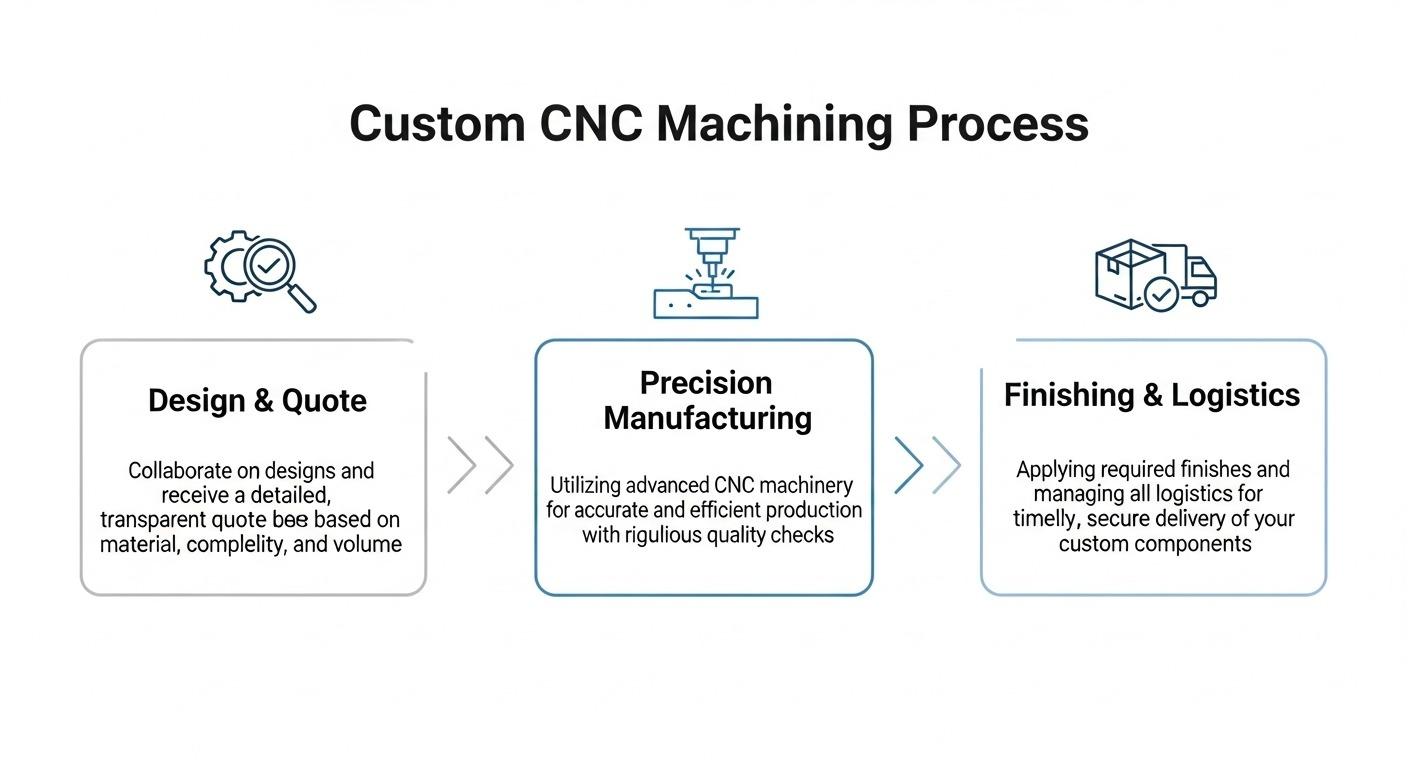

Step 1: Design & Quote Clarity

The initial phase of any custom CNC machining project sets the foundation for its success. This stage involves detailed communication, technical evaluation, and a transparent pricing model to align expectations.

We focus on understanding your precise requirements, ensuring that every specification is captured and validated before any material is cut. This proactive approach minimizes errors and ensures the final product meets your exact needs.

What Your Project Needs

Comprehensive project analysis begins with a deep dive into your design files, material preferences, and functional requirements. We scrutinize CAD models and technical drawings to identify potential manufacturing challenges early on.

Clear communication regarding part dimensions, surface finish requirements, and critical tolerances is paramount. Our engineering team collaborates directly with you to confirm every detail, ensuring alignment before proceeding.

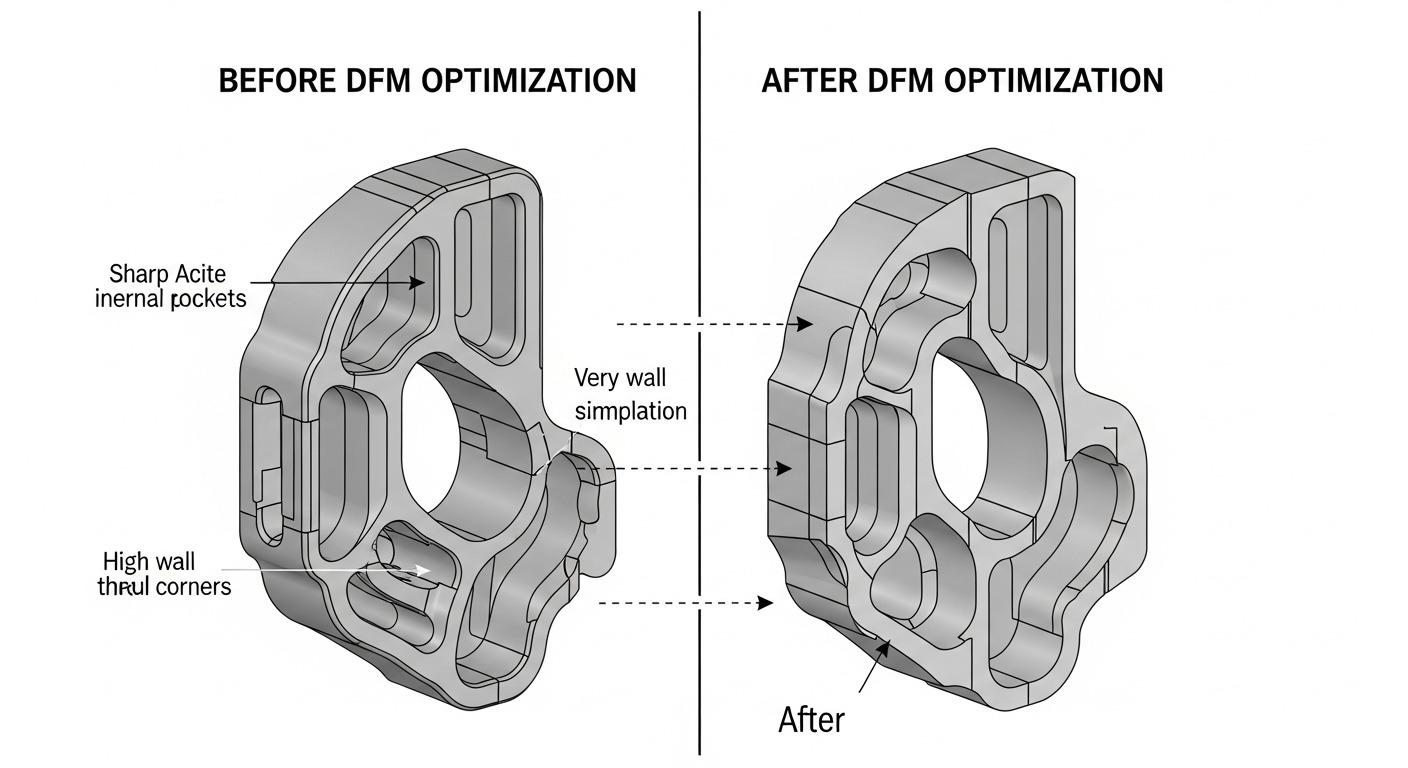

DFM: Optimizing for Success

Design for Manufacturability (DFM) is a critical component of our initial assessment. Our expert engineers review your design to identify opportunities for optimization, reducing complexity, and enhancing manufacturability without compromising performance.

This proactive DFM analysis can significantly reduce production costs and lead times by preventing common design-related issues during the machining phase. It ensures your design is not just innovative but also efficiently producible.

Common DFM Considerations

| Aspect | Optimization Benefit |

|---|---|

| Wall Thickness | Prevents deformation, improves structural integrity |

| Internal Radii | Eases tool access, reduces machining time |

| Tolerances | Reduces costs, improves manufacturability |

| Feature Orientation | Optimizes tool paths, minimizes setups |

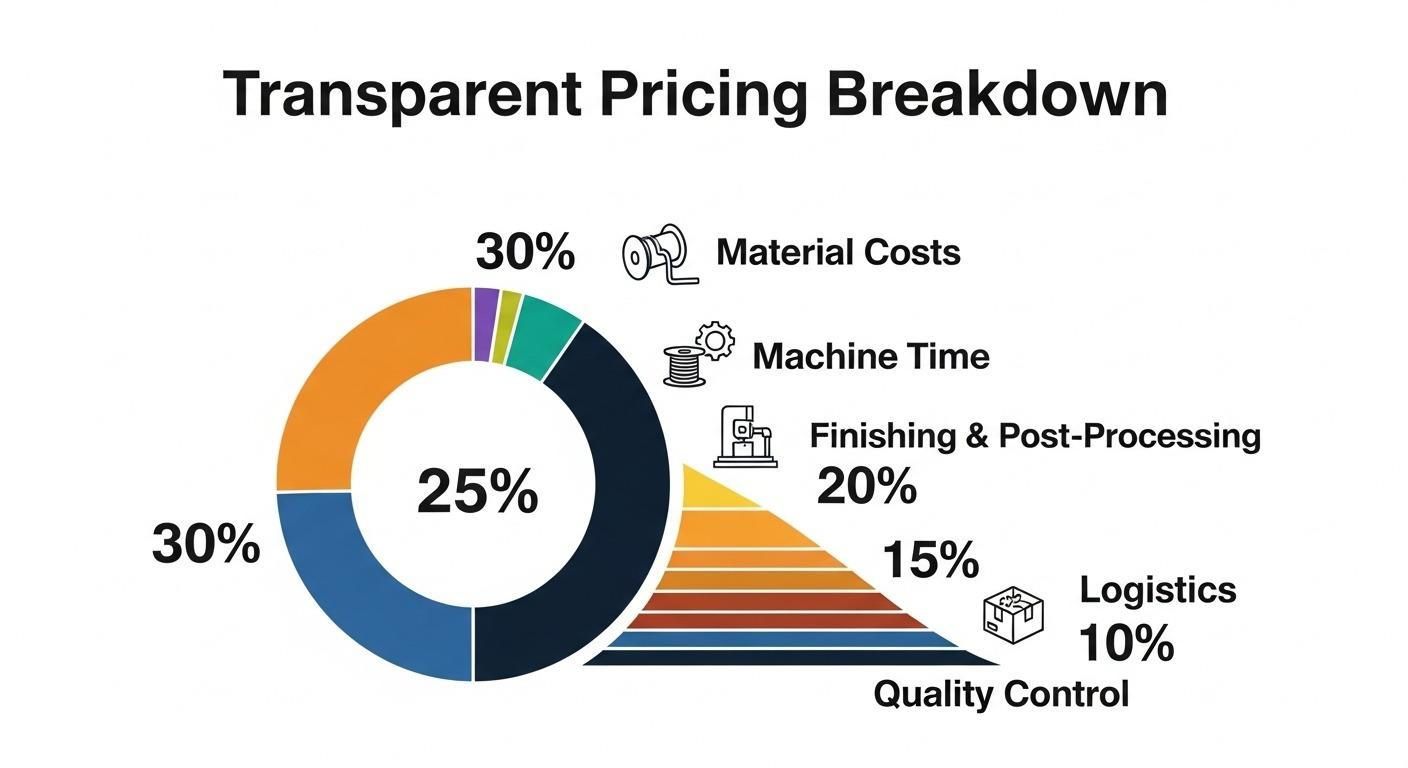

Transparent Pricing, No Surprises

Our commitment to transparent CNC pricing is unwavering. We provide detailed quotations that break down all costs, including material expenses, machining time, finishing processes, and any additional services. This clarity eliminates hidden fees.

This open approach ensures you understand exactly what you are paying for, building trust and fostering long-term partnerships. We believe that predictable costs are as important as predictable quality in custom CNC machining.

Step 2: Precision Manufacturing

Once the design is finalized and the quote approved, the project moves into the precision manufacturing phase. This is where cutting-edge technology meets skilled craftsmanship to bring your high-quality CNC parts to life.

Our state-of-the-art facility in Shenzhen, China, is equipped with advanced CNC machinery operated by highly experienced engineers. This combination ensures every component is manufactured to the most exacting specifications.

Material Selection & Setup

The selection of appropriate materials is crucial for the performance and longevity of your custom CNC parts. We work with a wide range of engineering-grade materials, from various aluminum alloys and stainless steels to high-performance plastics.

Our process includes precise material sourcing and rigorous incoming material inspection to confirm compliance with specifications. Proper machine setup, including tool path programming and fixture design, is meticulously planned to optimize production.

Material Properties for Custom CNC Machining

| Material Type | Key Properties | Typical Applications |

|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | High strength-to-weight, corrosion resistance | Aerospace, automotive, consumer electronics |

| Stainless Steels (e.g., 304, 316) | High strength, corrosion resistance | Medical, marine, food processing |

| Engineering Plastics (e.g., Delrin, PEEK) | Lightweight, chemical resistance, electrical insulation | Medical devices, insulators, gears |

| Titanium | Exceptional strength, biocompatible | Aerospace, medical implants |

High-Quality Production Secrets

Our production floor is optimized for efficiency and precision, utilizing advanced CAM software to generate intricate tool paths. Multi-axis CNC machines allow for complex geometries and superior surface finishes in a single setup, minimizing human error.

Throughout the machining process, our quality control team employs in-process checks using advanced metrology equipment. This continuous monitoring ensures adherence to strict tolerances and immediate detection of any deviations, guaranteeing high-quality CNC parts.

Case Study: Flawless Components

Problem: A client in the medical device sector faced severe delays and quality issues with their existing supplier for a critical surgical instrument component. The previous vendor struggled with tight tolerances (±0.005mm) on an intricate titanium part, leading to numerous rejections and jeopardizing their product launch. Their primary pain point was a lack of precision and reliable lead times.

Our Solution: ly-machining engaged in a thorough DFM review, identifying key areas for minor design adjustments that enhanced manufacturability without impacting functional performance. We leveraged our 5-axis CNC machining capabilities and implemented a stringent in-process quality control protocol, including CMM inspections at multiple stages of the custom CNC machining process. Our team maintained transparent communication, providing weekly progress updates and technical consultations.

Result: We delivered the first batch of titanium components two weeks ahead of the revised schedule, with 100% adherence to all critical tolerances and surface finish specifications. The client successfully launched their new surgical instrument on time, praising ly-machining’s transparent pricing, exceptional precision, and reliable execution. This successful collaboration restored their confidence in custom CNC part sourcing.

Step 3: Finishing & Logistics

The final step in our custom CNC machining process focuses on the meticulous finishing of your components and ensuring their secure, on-time delivery. This phase is just as critical as manufacturing for overall product integrity and client satisfaction.

From surface treatments to precise packaging, every detail is handled with the utmost care. Our logistics team then orchestrates the efficient and safe transport of your high-quality CNC parts to their final destination.

Ensuring On-Time Delivery

Post-machining processes include a variety of finishing options, such as anodizing, plating, heat treatment, and polishing, tailored to your component’s functional and aesthetic requirements. These processes are performed by qualified specialists.

Final inspection is exhaustive, involving comprehensive dimensional checks, surface integrity assessments, and functional testing where applicable. Only parts that pass every stringent quality gate are approved for dispatch, reinforcing our commitment to high-quality CNC parts.

Final Quality Control Checkpoints

| Inspection Stage | Focus Area | Tools/Methods Used |

|---|---|---|

| Dimensional Accuracy | Critical dimensions, tolerances | CMM, Calipers, Micrometers, Gauges |

| Surface Finish | Ra values, visual imperfections | Surface Roughness Tester, Optical Comparator |

| Material Integrity | Cracks, porosity, hardness | Non-destructive testing (NDT), Hardness Tester |

| Assembly Fit | Inter-part compatibility (if applicable) | Go/No-Go Gauges, Assembly Jigs |

Secure packaging is paramount to protect your precision components during transit. We utilize custom-fit inserts and robust outer packaging, carefully selecting shipping methods to optimize for both speed and cost-efficiency. Our logistics planning is integrated directly into our transparent pricing model.

Continuous Improvement & Support

Our engagement extends beyond delivery. We value client feedback as a crucial input for continuous process improvement, consistently refining our CNC machining steps and protocols. This iterative approach ensures we remain at the forefront of manufacturing excellence.

Post-delivery support includes technical assistance and documentation, ensuring you have all necessary information for integrating our components into your final product. Our goal is to be a long-term, trusted partner for all your custom CNC machining needs.

Your CNC Journey Complete

Successfully navigating the custom CNC machining process requires a partner who champions transparency, precision, and reliability. Our 3-step approach at ly-machining is meticulously designed to meet these exacting demands.

From the initial design consultation to the final delivery, we stand as your dedicated source manufacturer, committed to delivering high-quality CNC parts with unwavering consistency and clear communication.

Mastering Custom Machining

Mastering the complexities of custom machining is our core competency. We leverage decades of experience, advanced technology, and a client-centric approach to transform your most challenging designs into flawless physical realities.

Our mastery is evident in our rigorous quality assurance at every stage of the custom CNC machining process, ensuring that each component not only meets but often exceeds industry standards.

Key Takeaways for Quality

The ultimate success of your project hinges on several key factors: a transparent custom CNC machining process, meticulous DFM, precise material handling, and rigorous quality control. These are the pillars of our service.

By prioritizing these elements, we eliminate guesswork and mitigate risks, ensuring that every high-quality CNC part we produce is a testament to our engineering excellence and your design vision.

Get Your Transparent Quote Now!

Ready to experience a truly transparent and efficient custom CNC machining process? Contact our expert team today for a personalized consultation and a detailed, no-obligation quote on your next high-quality part project.

FAQ Section

What is custom CNC machining process?

Custom CNC machining is a manufacturing method that uses computer-controlled machines to create precise, bespoke parts from various materials. It involves a systematic series of steps, from digital design to physical production, tailored to specific client requirements.

This process ensures high accuracy, repeatability, and the ability to produce complex geometries, making it ideal for prototypes, low-volume production, and specialized components.

How does ly-machining ensure quality?

At ly-machining, we ensure quality through a multi-faceted approach integrated into our 3-step custom CNC machining process. This includes rigorous Design for Manufacturability (DFM) analysis, precise material selection, and continuous in-process quality checks.

We utilize advanced metrology equipment, conduct thorough final inspections, and adhere to strict quality control protocols at every stage, from initial design review to final packaging, guaranteeing high-quality CNC parts.

What about transparent pricing?

Our transparent CNC pricing policy means we provide clear, itemized quotations for every project. These quotes detail costs for materials, machining time, surface finishing, and any other services.

This approach ensures there are no hidden fees or unexpected expenses. We believe in open communication and predictable costs, allowing clients to budget accurately and build trust in our custom CNC machining services.