Unlock Custom CNC Machining Cost Optimization through DFM for CNC, smart material choices, and efficient batching for significant CNC Parts Cost Reduction and better Precision Machining Pricing.

Are soaring custom CNC machining costs jeopardizing your project profitability, or worse, forcing compromises on quality? Discover how a strategic approach can unlock significant savings without sacrificing an ounce of precision. This article details the critical cost drivers in custom CNC machining and presents actionable strategies to achieve substantial CNC parts cost reduction.

In our experience as a direct manufacturer, understanding these factors is paramount. We will guide you through effective DFM for CNC principles and smart partnering strategies that ensure superior quality alongside optimized precision machining pricing. Our goal is to empower your projects with both technical excellence and financial efficiency.

Understanding Custom CNC Machining Cost Drivers

To effectively manage Custom CNC Machining Cost Optimization, one must first identify the primary cost drivers. These elements are interconnected and significantly influence the final precision machining pricing for any custom component. A thorough analysis reveals areas ripe for CNC parts cost reduction.

In our factory, we meticulously track these variables. Ignoring them often leads to unexpected budget overruns and compromises in project timelines. Our engineering team routinely consults clients on these specific aspects.

Material Selection: Impact on Costs

Material choice is often the single largest variable impacting custom CNC machining costs. The price of raw stock directly affects overall project budgets, but other factors are equally critical. These include machinability, lead time, and specific material certifications.

For instance, exotic alloys typically cost more per kilogram and demand slower machining speeds. This increases both material expenditure and machine time, directly influencing precision machining pricing. Standard materials like aluminum 6061 generally offer better machinability and lower raw material costs.

Our procurement team constantly evaluates market prices. They also assess supplier reliability to ensure stable material flow. This proactive approach helps us maintain competitive CNC parts cost reduction strategies.

| Material Type | Typical Machinability | Relative Raw Material Cost | Common Applications |

|---|---|---|---|

| Aluminum 6061 | Excellent | Low | Aerospace, Automotive |

| Stainless Steel 304 | Good | Medium | Medical, Food Industry |

| Titanium Grade 5 | Challenging | High | Aerospace, Implants |

| Brass C360 | Excellent | Medium-Low | Connectors, Fittings |

Design Complexity: Geometry, Tolerances

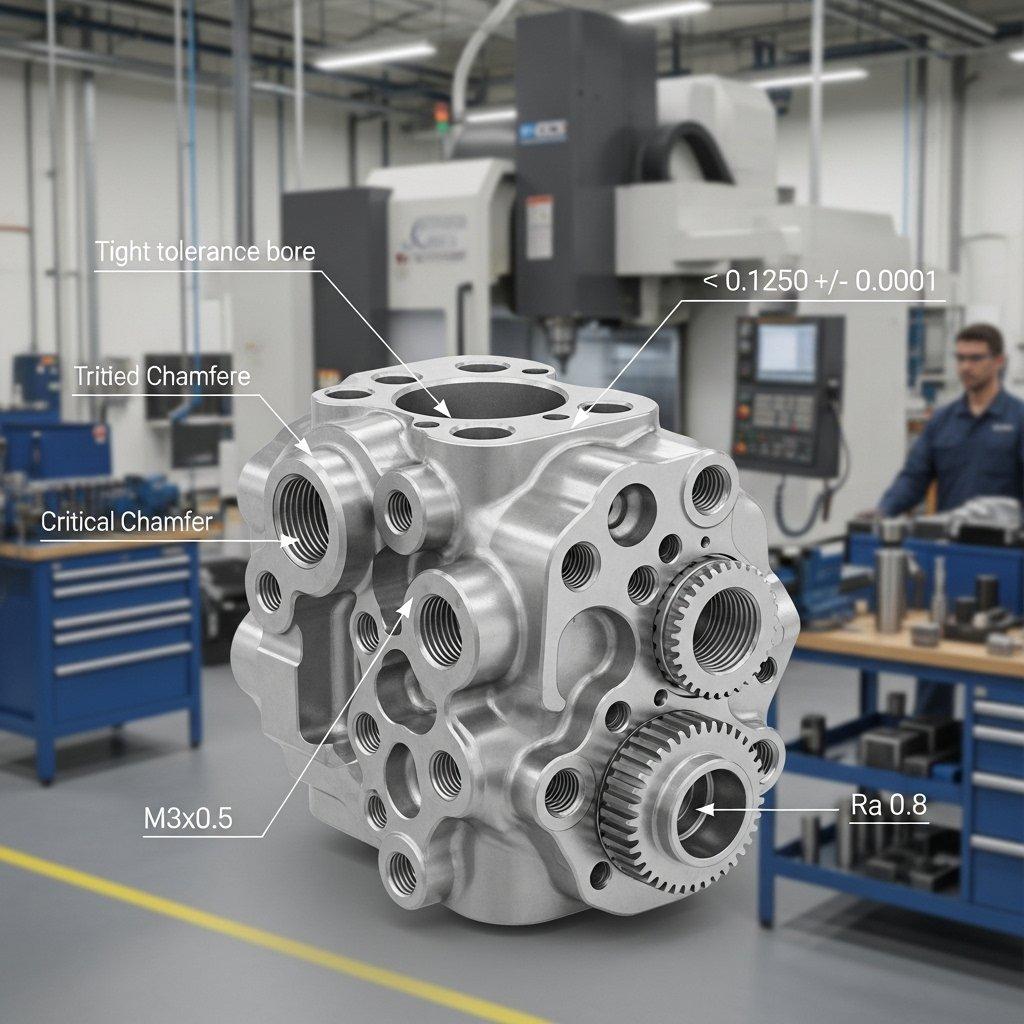

The complexity of a part’s geometry and the tightness of its specified tolerances are major determinants of CNC parts cost reduction potential. Intricate features, thin walls, and complex curves require more sophisticated programming and longer machining times. They also necessitate specialized tooling.

Tight tolerances, such as those under ±0.01mm, demand higher precision machines, more careful setup, and often multiple machining passes. This extends production time and increases inspection costs. It’s a key factor in precision machining pricing.

In our experience, unnecessary tight tolerances on non-critical features are a common culprit for inflated custom CNC machining costs. Implementing DFM for CNC principles early in the design phase can mitigate these issues significantly.

| Tolerance Level | Typical Cost Impact | Machining Requirements | Inspection Complexity |

|---|---|---|---|

| Standard (±0.1mm) | Baseline | Standard tooling, speeds | Basic |

| Fine (±0.05mm) | Moderate Increase | High-precision machines, slower speeds | Intermediate |

| Precision (±0.01mm) | Significant Increase | Advanced machines, multiple passes, temperature control | Advanced CMM, meticulous |

Production Volume vs. Setup Costs

Setup costs are a fixed expense incurred for each production run, regardless of the number of parts produced. These include programming, tool preparation, fixture design, and initial machine calibration. High setup costs can disproportionately affect smaller batch orders.

For low-volume custom CNC machining, these fixed costs are amortized over fewer units, driving up the per-part price. As production volume increases, the setup cost per part decreases, leading to significant CNC parts cost reduction. This is a fundamental principle of manufacturing economics.

Our team works with clients to determine optimal batch sizes. We analyze the balance between inventory holding costs and the savings achieved through reduced per-part setup costs, providing an informed precision machining pricing model.

Post-Processing and Finishing

Beyond machining, various post-processing steps contribute to the overall custom CNC machining costs. These can include deburring, heat treatment, surface finishing (e.g., anodizing, plating, polishing), and assembly. Each step adds labor, material, and time.

Some finishes are purely aesthetic, while others serve critical functional purposes, such as corrosion resistance or improved wear characteristics. The choice of finish should always align with the part’s functional requirements. Over-specifying finishes can unnecessarily inflate precision machining pricing.

Our engineers recommend the most appropriate and cost-effective finishing processes. This ensures the part meets performance criteria without incurring excessive CNC parts cost reduction penalties. We avoid unnecessary steps.

Strategic Paths for CNC Cost Optimization

Achieving substantial Custom CNC Machining Cost Optimization requires a proactive, strategic approach. It involves a deep understanding of manufacturing processes and a willingness to collaborate between design and production teams. We advocate for a partnership model in this endeavor.

Our factory emphasizes a holistic view of the entire production lifecycle. This perspective allows us to identify and implement effective strategies. The following methods are critical for significant CNC parts cost reduction.

DFM Principles for Savings

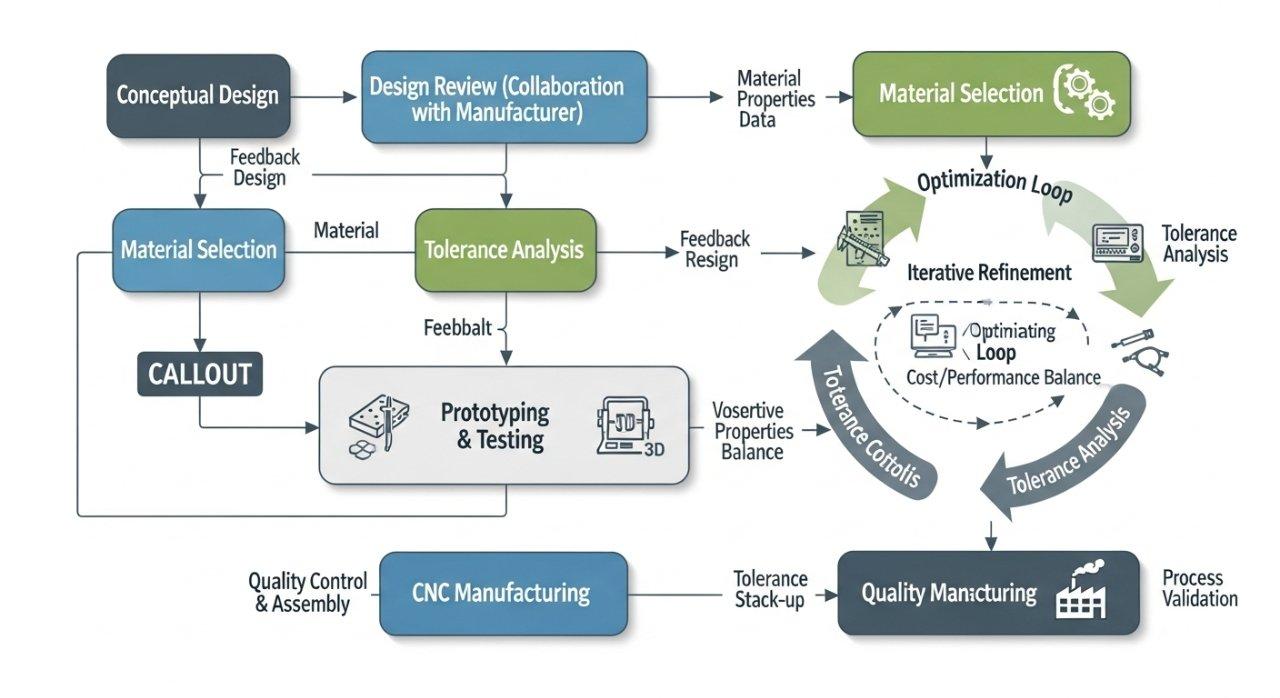

Design for Manufacturability (DFM for CNC) is perhaps the most powerful tool for Custom CNC Machining Cost Optimization. It involves evaluating a design’s manufacturability early in the product development cycle. This ensures that parts can be produced efficiently and economically.

Key DFM principles include minimizing part features, simplifying geometries, standardizing hole sizes, and avoiding excessively thin walls. These considerations reduce machining time, tooling costs, and the likelihood of errors. Early DFM integration is critical for precision machining pricing.

Our engineering team offers extensive DFM consultation. We work closely with clients to refine designs, identifying opportunities for significant CNC parts cost reduction without compromising functionality or performance. This collaborative approach yields superior results.

Material Selection & Sourcing

Beyond initial material cost, strategic material selection considers machinability, strength-to-weight ratio, and long-term availability. Sometimes, a slightly more expensive material with superior machinability can lead to overall CNC parts cost reduction due to reduced machining time and tool wear.

We maintain strong relationships with a diverse network of material suppliers. This allows us to source high-quality materials competitively. Our purchasing power and extensive supply chain management expertise benefit our clients directly, impacting precision machining pricing positively.

Choosing the right material for the application, not just the lowest cost, is a sophisticated aspect of Custom CNC Machining Cost Optimization. We advise on alternatives that balance performance and cost.

Optimizing Batch Sizes

As discussed, batch size has a significant impact on cost per part. For CNC parts cost reduction, finding the “sweet spot” between high-volume efficiency and inventory management is key. Our factory employs advanced production planning systems to achieve this balance.

We help clients analyze their demand forecasts and production schedules. This allows us to recommend optimal batch sizes that minimize setup costs per unit while avoiding excessive inventory. This balance is crucial for effective precision machining pricing.

Flexible manufacturing capabilities enable us to accommodate various batch sizes efficiently. This makes us a reliable partner for both prototyping and full-scale production runs.

Advanced Machining Techniques

Leveraging advanced CNC machining techniques can unlock further Custom CNC Machining Cost Optimization. Multi-axis machining (e.g., 5-axis CNC) can reduce setup changes and improve efficiency for complex geometries. High-speed machining (HSM) reduces cycle times for certain materials.

While these machines may have higher hourly rates, their ability to combine operations and reduce total machining time often leads to overall CNC parts cost reduction. It is a nuanced calculation, where initial perceptions of higher cost are often misleading.

Our continuous investment in state-of-the-art equipment reflects our commitment to offering the most efficient production methods. This translates into competitive precision machining pricing for our clients.

Streamlining Post-Processing

Simplifying or strategically selecting post-processing steps directly impacts custom CNC machining costs. For example, consolidating multiple finishing operations or choosing standard finishes over highly specialized ones can lead to significant savings.

We assess each part’s functional requirements rigorously. This ensures that no unnecessary post-processing steps are performed. Our aim is to achieve the required performance and aesthetics with the most cost-effective methods for CNC parts cost reduction.

Automated deburring or vibratory finishing can replace manual processes, further reducing labor costs. This careful consideration of every step helps us deliver exceptional precision machining pricing.

Partnering for Cost-Effective Custom CNC

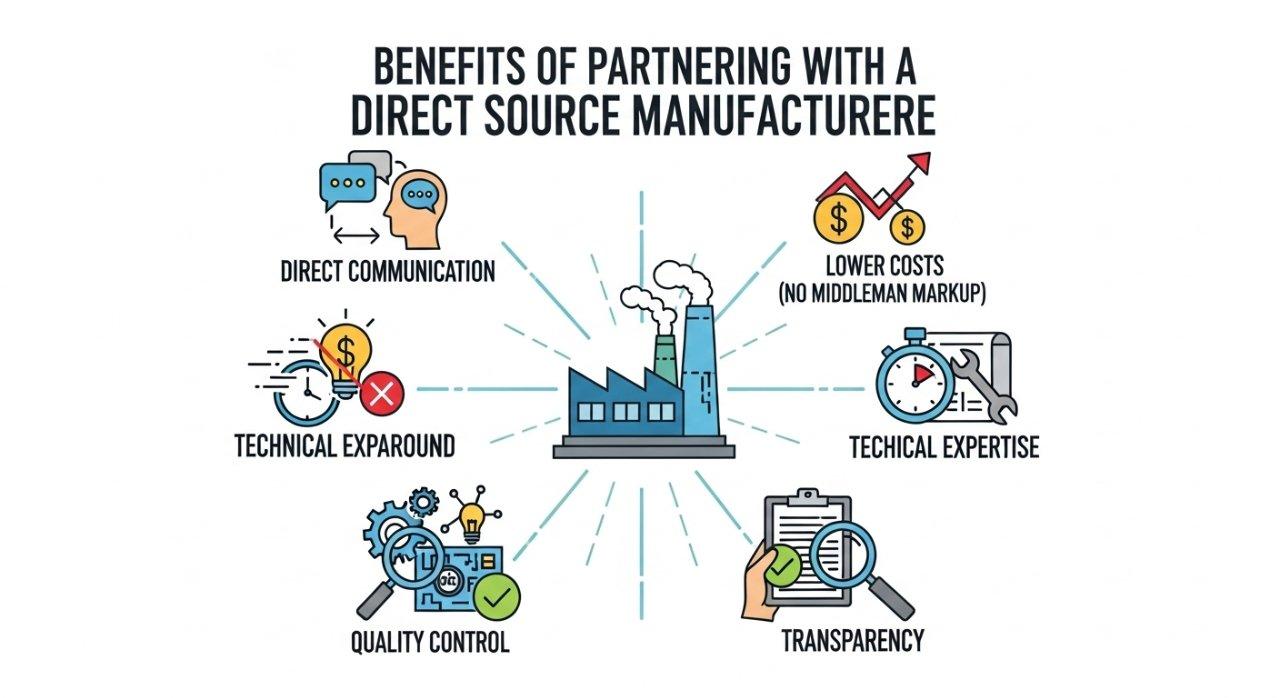

Selecting the right manufacturing partner is a critical decision in Custom CNC Machining Cost Optimization. A direct source manufacturer with deep technical expertise offers distinct advantages over intermediaries. This partnership ensures both quality and efficient CNC parts cost reduction.

Our factory prides itself on being a partner, not just a supplier. We work collaboratively to achieve your project goals. This approach fosters trust and leads to long-term success.

Source Manufacturer Benefits

Partnering directly with a source manufacturer like ly-machining bypasses middleman markups. This inherently leads to more favorable precision machining pricing. You gain direct access to our production lines and engineering team.

This direct relationship facilitates faster communication and problem-solving. It also ensures greater transparency throughout the entire custom CNC machining process. Our clients appreciate this direct line of sight into their projects.

This transparency is key to building trust and achieving maximum CNC parts cost reduction. It eliminates ambiguities and allows for quick adjustments when needed.

Leveraging Technical Expertise

Our team of experienced engineers provides invaluable technical consultation from concept to completion. We offer proactive DFM for CNC guidance. This helps refine designs for optimal manufacturability and cost efficiency even before production begins.

This deep technical expertise is a cornerstone of our Custom CNC Machining Cost Optimization strategy. It ensures that potential issues are identified and addressed early. This proactive approach prevents costly reworks.

We translate complex engineering specifications into efficient manufacturing processes. This is how we consistently achieve outstanding CNC parts cost reduction for our clients.

Quality Assurance, Rework Prevention

Robust quality assurance protocols are non-negotiable in precision machining. Our factory adheres to stringent quality management systems. These include ISO and AS9100 standards, ensuring consistent, high-quality parts. This commitment prevents costly reworks.

Every part undergoes thorough inspection using advanced metrology equipment. This includes Coordinate Measuring Machines (CMMs). Our proactive quality control minimizes scrap and ensures parts meet specifications the first time. This is critical for CNC parts cost reduction.

By preventing defects and reworks, we safeguard project timelines and budgets. This commitment to quality directly contributes to predictable and optimized precision machining pricing.

Transparent Communication, Success

Clear and transparent communication is vital for successful Custom CNC Machining Cost Optimization. We provide regular updates and detailed progress reports. Our project managers ensure you are always informed about your order status.

Any potential challenges are communicated promptly. Our team also offers solution-oriented advice. This proactive and open dialogue ensures projects stay on track and within budget.

This level of transparency builds strong, trusting relationships with our clients. It is fundamental to achieving sustained CNC parts cost reduction and overall project success.

Realizing Your Cost Savings in CNC Machining

The true measure of Custom CNC Machining Cost Optimization lies in tangible results. By applying the strategies discussed, businesses can realize significant CNC parts cost reduction. This enhances project profitability and market competitiveness.

Our factory is committed to delivering these measurable benefits. We focus on continuous improvement. This ensures that our clients consistently receive the best value and precision machining pricing.

Case Study: Optimized Aerospace Part

A client approached us with a complex aerospace bracket, initially designed with extremely tight tolerances on all features. The precision machining pricing was proving prohibitive for their mass production plans. Their primary concern was Custom CNC Machining Cost Optimization.

Our DFM for CNC expert engineers reviewed the design. We identified non-critical features where tolerances could be relaxed without impacting performance. We also suggested a minor material adjustment to improve machinability.

Through this collaborative process, we streamlined the design and optimized the manufacturing steps. The result was a 20% CNC parts cost reduction per unit while maintaining all essential performance specifications. This partnership ensured both quality and significant savings.

Future-Proofing CNC Procurement

Adopting a strategic approach to custom CNC machining costs helps future-proof your procurement processes. By understanding cost drivers and DFM for CNC principles, you can make more informed decisions. This leads to long-term savings and more predictable precision machining pricing.

We encourage clients to view us as an extension of their engineering team. This allows for proactive planning and design optimization for future projects. This partnership is crucial for sustainable CNC parts cost reduction.

Our goal is to help you build resilient supply chains. We also aim to develop cost-effective manufacturing strategies for your evolving needs.

Get a Free Custom CNC Cost Analysis Today

Ready to optimize your custom CNC project costs without compromising quality? Contact our expert engineering team for a personalized cost analysis and a free, transparent quote today. Let us partner with you to achieve significant CNC Parts Cost Reduction and superior Precision Machining Pricing.

Contact Our Experts for Your Project

Our team of dedicated engineers is ready to discuss your specific custom CNC machining requirements. We provide expert guidance tailored to your unique challenges. Our objective is to find the most efficient and cost-effective solutions for you.

Reach out today to schedule a technical consultation. We look forward to exploring how our DFM for CNC expertise can benefit your next project. We are committed to your success.

Request a Detailed Quote

Receive a comprehensive, transparent quote for your custom CNC parts. Our pricing reflects our commitment to fairness and value. There are no hidden fees.

We provide a detailed breakdown of costs. This helps you understand every aspect of your investment. Get started on your path to Custom CNC Machining Cost Optimization.

What is DFM for CNC?

DFM for CNC, or Design for Manufacturability for Computer Numerical Control, is an engineering methodology. It focuses on optimizing product designs to make them easier and more cost-effective to manufacture using CNC machines. This process involves close collaboration between designers and manufacturers.

It helps identify and eliminate potential manufacturing challenges early. This reduces material waste, machining time, and production errors. Ultimately, DFM for CNC leads to significant CNC parts cost reduction and improved precision.

How can material choice reduce CNC costs?

Strategic material choice can significantly impact custom CNC machining costs. Selecting materials with good machinability reduces machining time and tool wear. This directly lowers labor and tooling expenses.

Sometimes, a slightly higher-priced material with better properties can yield overall savings. It results in fewer post-processing steps or faster production cycles. Our experts advise on the best balance of cost and performance.

What factors influence precision machining pricing?

Precision machining pricing is influenced by several critical factors. These include material cost, design complexity, tolerance requirements, production volume, and post-processing needs. Setup costs also play a significant role.

The chosen manufacturing partner’s expertise and efficiency also heavily weigh on the final price. Engaging with a direct source manufacturer like us often provides better value. This is due to direct communication and no middleman markups.