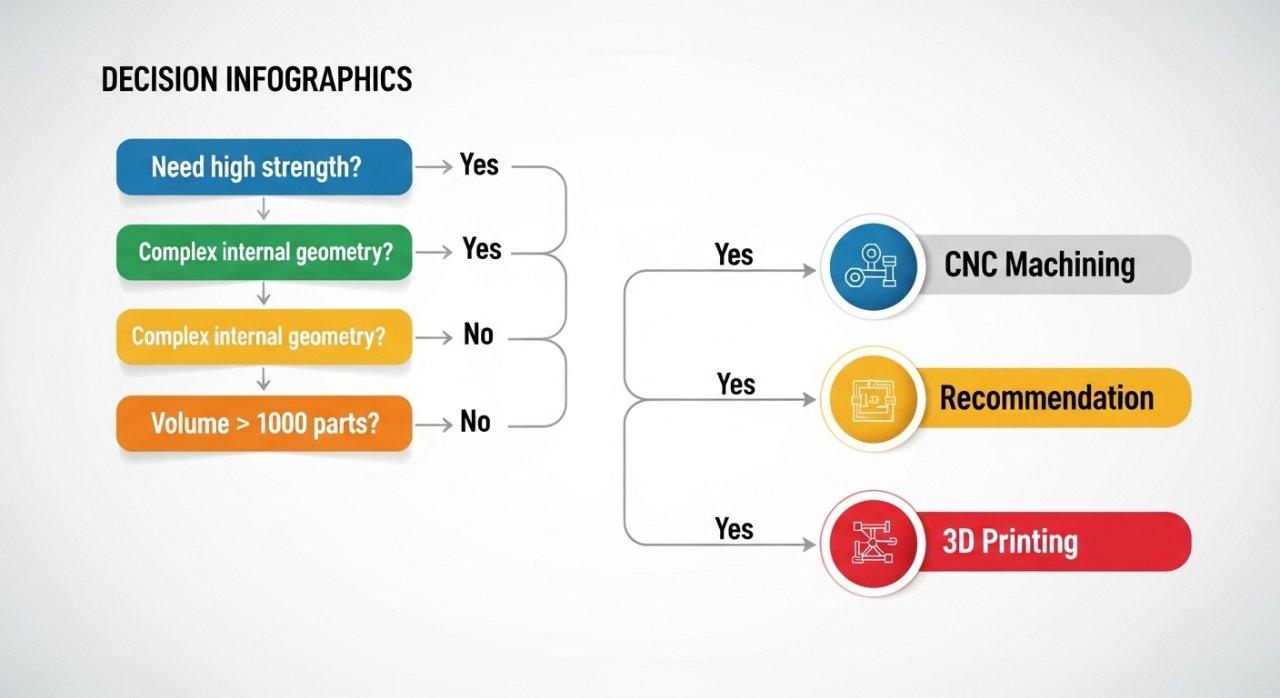

Choosing between CNC Machining and 3D Printing for part manufacturing hinges on material, geometry, volume, and cost, with CNC excelling in precision and volume, and 3D printing in complexity and rapid prototyping.

In the intricate world of product development, the choice between CNC machining and 3D printing is more than just a technical decision. It’s a strategic pivot point for your project’s success. Are you truly optimizing for quality, cost, and speed in your part manufacturing?

The wrong path can lead to significant setbacks, from budget overruns to compromised part performance. Our experience as a leading manufacturing partner shows this is a critical crossroads for many engineers and designers.

We will guide you through this essential manufacturing decision, offering deep technical insights to ensure your parts meet the highest standards. Leveraging our expertise, you can confidently navigate this choice for optimal results.

The Core Dilemma: CNC vs 3D Printing

Understanding Each Manufacturing Technology

What is CNC Machining?

CNC Machining is a subtractive manufacturing process where material is removed from a solid block using computerized controls. Tools like drills, mills, and lathes precisely shape the desired part.

This method is renowned for its exceptional accuracy, repeatability, and ability to work with a wide range of engineering-grade materials. It’s a cornerstone of modern part manufacturing for high-performance applications.

What is 3D Printing (Additive Mfg)?

3D Printing, or Additive Manufacturing, builds parts layer by layer from a digital design file. It adds material, unlike CNC’s subtractive approach.

Technologies like FDM, SLA, SLS, and DMLS enable the creation of highly complex geometries that are often impossible with traditional methods. It excels in design freedom and rapid iteration.

Why This Manufacturing Decision Matters

Impact on Cost & Time-to-Market

The choice between these technologies directly influences your project’s overall cost structure and the speed at which your product reaches the market. Understanding these impacts is crucial for strategic planning.

Initial setup costs, material waste, and per-part production times vary significantly between CNC machining and 3D printing. These factors dictate the economic viability of your manufacturing decisions.

Impact on Part Quality & Performance

The manufacturing method profoundly affects the mechanical properties, surface finish, and dimensional accuracy of the final part. These attributes are critical for performance and reliability.

For demanding applications, specific material integrity and tight tolerances are non-negotiable. Our expertise helps clients ensure their parts meet all required quality and performance standards.

Key Factors for Your Part Manufacturing Choice

Material Considerations for Your Part

Material Options in CNC Machining

CNC machining offers an unparalleled selection of robust engineering materials. These include various metals like aluminum, stainless steel, titanium, brass, and hardened tool steels.

It also processes high-performance plastics such as ABS, Nylon, Delrin (Acetal), PEEK, and UHMW. This versatility is critical for achieving specific mechanical and thermal properties in a finished part.

Material Options in 3D Printing

3D printing’s material palette has expanded significantly but often differs from CNC’s. Common options include photopolymers (resins), thermoplastics (PLA, ABS, Nylon), and metal powders.

While impressive, 3D printed materials may not always match the isotropic mechanical strength or temperature resistance of their CNC machined counterparts directly.

Selecting the Right Material for Performance

The optimal material selection is paramount for your part’s intended function and environment. It requires a deep understanding of stress, temperature, chemical resistance, and wear.

Our engineers collaborate with clients to specify materials that will deliver required performance. This ensures longevity and reliability for your critical part manufacturing.

Geometric Complexity & Design Freedom

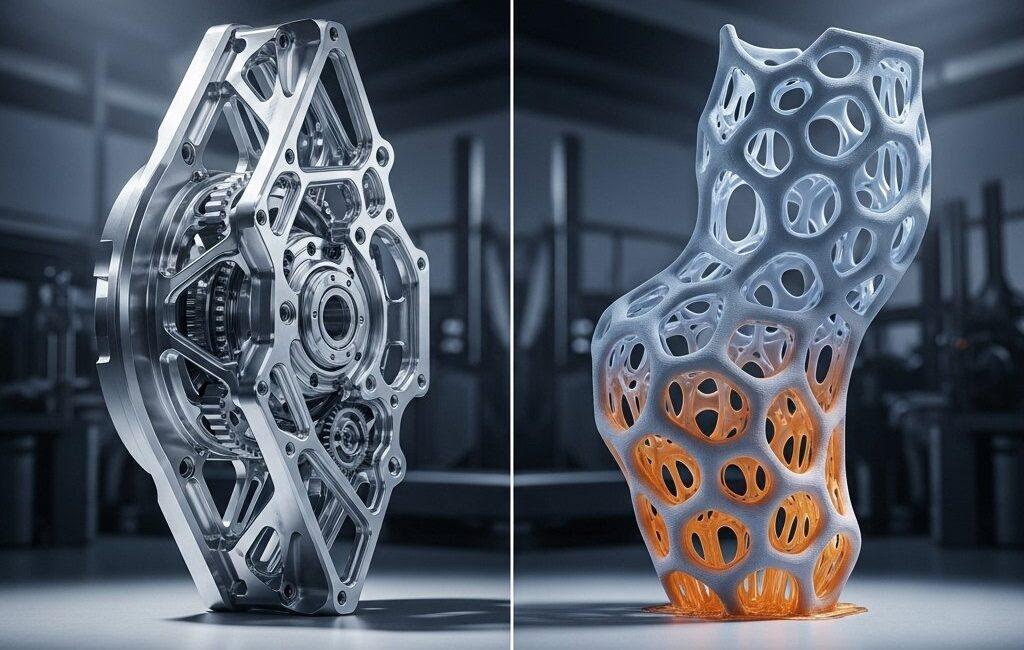

CNC’s Strengths in Precision Geometries

CNC machining excels at producing parts with precise flat surfaces, exact bore diameters, and sharp external corners. It offers superior dimensional accuracy and tight tolerances.

However, CNC is limited by tooling access and cannot easily create complex internal channels or highly organic, undercut features without multi-axis machining or assembly.

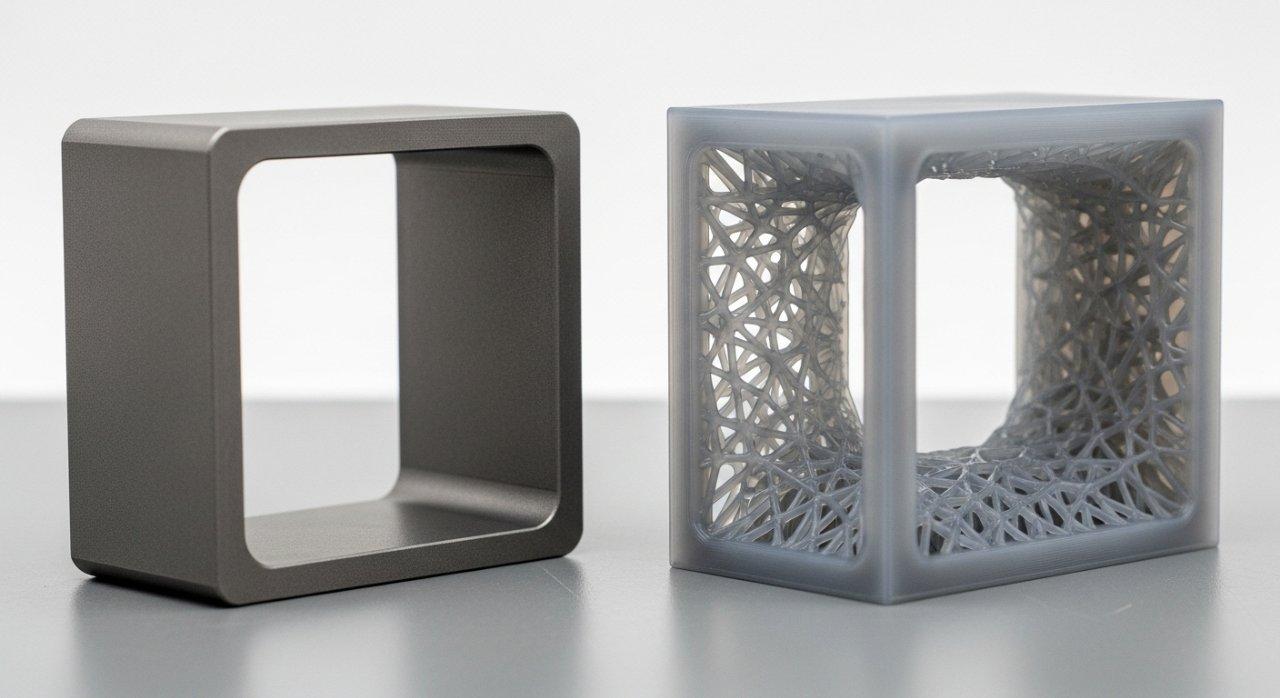

3D Printing for Complex Internal Features

3D printing shines when geometric complexity is a primary design driver. It can create intricate internal lattice structures, conformal cooling channels, and highly organic shapes.

These capabilities are invaluable for lightweighting, part consolidation, and optimizing fluid flow. It grants designers immense freedom previously unattainable.

Design Optimization for Each Method

Designing for manufacturability (DFM) is critical for both processes. Parts optimized for CNC prioritize simple cuts and tool access, reducing production time and cost.

For 3D printing, design optimization focuses on minimizing support structures and orienting the part for optimal print quality and mechanical properties. Our engineering consultation advises on both.

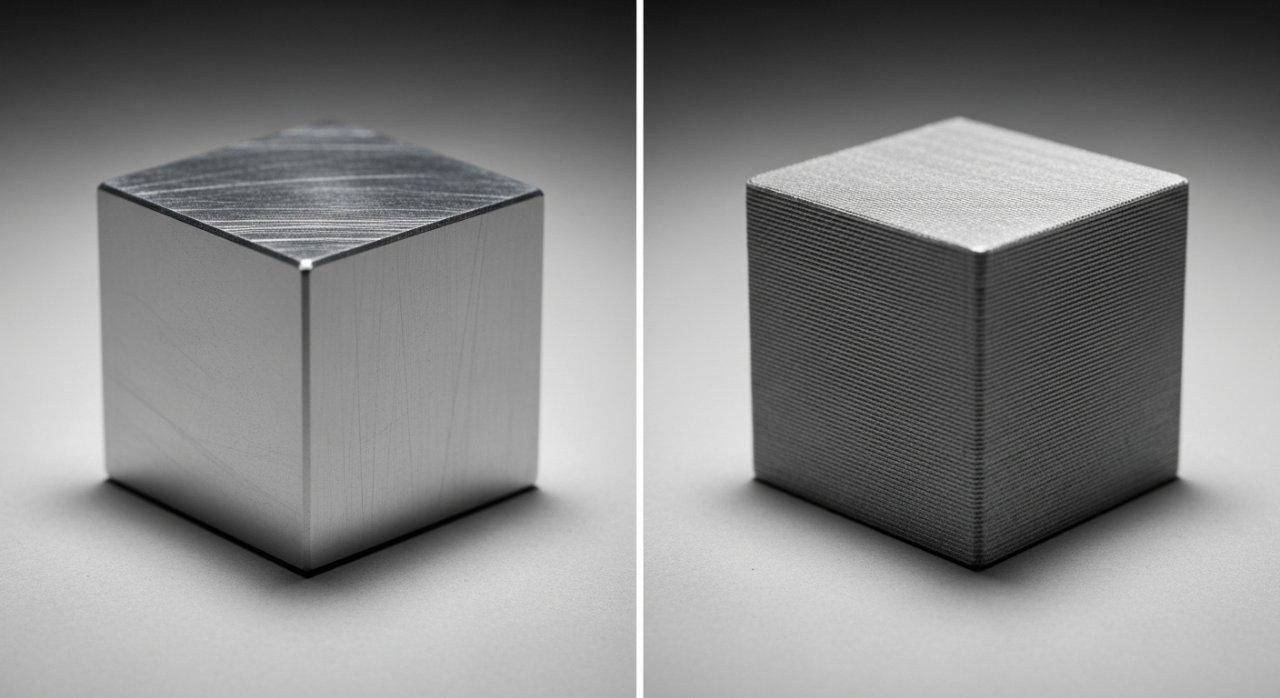

Tolerances, Surface Finish & Quality

Achieving High Precision with CNC

CNC machining is the industry benchmark for achieving tight dimensional tolerances. We regularly work to tolerances as fine as ±0.005mm or better, essential for critical mating components.

Our advanced quality control systems, including CMM inspection, ensure every part meets stringent specifications, adhering to standards like ISO 2768 (fine).

Surface Finish in 3D Printing

The surface finish of 3D printed parts typically has a visible layer-line effect, which can be rougher than CNC machined surfaces. Post-processing steps like sanding or polishing are often required.

While advancements are being made, achieving a mirror-like or extremely smooth finish directly from a 3D printer for metal parts usually involves significant post-machining.

Meeting High-Quality Part Standards

For applications demanding superior mechanical performance, precise fit, and aesthetic appeal, CNC machining generally delivers higher quality parts. This is particularly true for metal components.

Our commitment to high-quality part manufacturing means we meticulously inspect every detail. We ensure your components conform to the most demanding industry standards.

Production Volume & Cost Efficiency

CNC for High Volume & Economy of Scale

For medium to high production volumes, CNC machining becomes significantly more cost-effective per part. The initial setup cost is amortized across many units.

Tooling and programming are a one-time investment. The speed and efficiency of modern CNC machines lead to substantial economies of scale for large batches.

3D Printing for Prototyping & Low Volume

3D printing excels in prototyping, low-volume production, and custom one-off parts. Its strength lies in minimal setup costs and rapid turnarounds for unique designs.

The per-part cost for 3D printing often remains relatively constant regardless of volume, making it less economical for mass production compared to CNC.

Transparent Pricing & Cost Breakdown

Understanding the full cost implication is vital for your manufacturing decisions. We provide transparent quotes that detail material, machining time, tooling, and any post-processing.

This clarity ensures you can accurately budget your projects. It also helps in comparing the true cost-efficiency between CNC machining and 3D printing for your specific part.

Lead Time & Speed of Delivery

Rapid Prototyping with 3D Printing

3D printing offers unparalleled speed for initial design iterations and functional prototypes. A design can go from CAD to a physical part in hours or days.

This allows for quick validation and iterative development, significantly compressing the design cycle and accelerating time-to-market.

Efficient Production Runs with CNC

While initial setup might take longer than 3D printing, once programmed, CNC machines can produce batches of identical parts very quickly. Our optimized workflows ensure efficient delivery.

For established designs requiring precision and volume, CNC offers predictable and efficient lead times. This makes it ideal for consistent production schedules.

When to Choose CNC Machining for Parts

Optimal Scenarios for CNC Machining

High Strength & Durability Requirements

When your part demands exceptional strength, durability, and resistance to stress, temperature, or wear, CNC machining is generally the superior choice. It processes true engineering-grade metals and plastics.

The structural integrity of CNC machined parts is often higher due to the use of solid stock material and isotropic properties. This makes them ideal for critical mechanical applications.

Tight Tolerances & Critical Dimensions

For parts requiring precise dimensions, very tight tolerances, and consistent repeatability, CNC machining is unmatched. This is vital for interlocking components or exact fit assemblies.

Our CNC capabilities ensure components meet the most stringent specifications, crucial for industries like aerospace, medical, and automotive.

Large Production Runs & Scalability

If you are moving beyond prototyping to medium to high-volume production, CNC machining offers the best scalability and cost efficiency. The per-part cost decreases significantly with volume.

Investment in programming and tooling pays off over thousands of units. This makes CNC the preferred method for long-term production needs.

Superior Surface Finish & Aesthetics

For components where surface finish is critical for function (e.g., sealing surfaces, optical parts) or aesthetics (visible consumer products), CNC machining delivers superior results.

We offer various post-processing options to achieve desired textures, from smooth finishes to specific aesthetic requirements, enhancing the final part quality.

When to Choose 3D Printing for Parts

Optimal Scenarios for 3D Printing

Rapid Prototyping & Design Iteration

For initial concepts, form and fit testing, and rapid design iterations, 3D printing is exceptionally effective. It allows designers to quickly validate ideas before committing to expensive tooling.

This accelerates the development cycle, enabling faster experimentation and refinement. It minimizes risk in early-stage product development.

Complex Geometries & Organic Shapes

When a part’s design features intricate internal structures, highly organic forms, or geometries impossible to machine conventionally, 3D printing offers a unique solution.

This freedom allows for innovative designs that can optimize performance or integrate multiple functions into a single part, reducing assembly complexity.

Low Volume Production & Custom Parts

For specialized tools, jigs, fixtures, or limited production runs of highly customized parts, 3D printing can be more cost-effective than CNC. It eliminates the need for expensive tooling setup.

This flexibility makes it ideal for bespoke medical implants, custom enclosures, or niche industrial components where quantities are low.

Lightweighting & Part Consolidation

3D printing enables the creation of complex internal lattice structures and hollow designs, significantly reducing part weight while maintaining strength. This is crucial for aerospace and automotive.

It also facilitates the consolidation of multiple components into a single printed part. This simplifies assembly, reduces part count, and improves overall system reliability.

Expert Guidance on Your Manufacturing Decisions

Leveraging Deep Technical Expertise

Making the optimal manufacturing decision requires more than just understanding the basic differences; it demands deep technical expertise. Our engineers bring years of hands-on experience.

We provide comprehensive analysis of your part’s requirements. This ensures you select the most suitable process for achieving performance, cost, and timeline goals.

Our Engineering Consultation Process

Our process begins with a detailed review of your 3D CAD models and specifications. We discuss material properties, tolerance requirements, and projected production volumes.

We then offer informed recommendations, considering both CNC machining and 3D printing, along with any necessary design modifications for optimal manufacturability.

Case Studies: Optimal Part Manufacturing

In our experience, clients often benefit from a hybrid approach. For instance, a robotics company utilized 3D printing for rapid functional prototypes of complex end-effectors.

Once the design was validated, our team transitioned the critical components to CNC machining for high-volume production. This ensured required strength, precision, and cost-efficiency for launch.

This dual-strategy saved the client significant development time and ensured their final products met rigorous performance standards. It optimized their manufacturing decisions for success.

Partnering with a Source Manufacturer

Benefits of Direct Manufacturer Access

Partnering directly with a source manufacturer like ly-machining provides direct access to our engineering team and production capabilities. This streamlines communication and problem-solving.

It eliminates intermediaries, ensuring full transparency in pricing, lead times, and quality control. You work directly with the experts fabricating your parts.

Assured High-Quality Parts Production

As a dedicated CNC machining factory, we maintain stringent quality control processes and adhere to industry standards (e.g., ISO 9001, AS9100). Our commitment is to deliver parts of uncompromising quality.

We leverage advanced inspection equipment and skilled technicians. This guarantees that every part we deliver meets your exact specifications and exceeds your expectations.

Make the Right Part Manufacturing Choice Today

Get a Transparent Quote & Consultation

Discuss Your Project with Our Experts

Ready to make the optimal manufacturing decision for your next project? Leverage our deep technical expertise. Contact our engineering team today for a free, no-obligation consultation.

We are eager to understand your specific part manufacturing needs. Our team will provide tailored advice and strategic insights to achieve your project goals.

Receive a Personalized Strategy

Based on your unique requirements, we will outline a personalized manufacturing strategy. This will include recommendations for either CNC machining or 3D printing, or a combination thereof.

We will provide a transparent quote, ensuring high-quality parts and efficient production from a trusted source manufacturer.

Case Study: Robotics Innovator’s Precision Drive Assembly

A burgeoning robotics company approached us with a challenge: develop a lightweight, yet incredibly robust, drive assembly for a new industrial automation arm. The initial prototypes, 3D printed for speed, lacked the required wear resistance and dimensional stability for critical gearing.

Our engineering team conducted a detailed DFM analysis. We recommended transitioning the main housing to high-strength 6061-T6 aluminum, CNC machined to aerospace-grade tolerances, and the internal gears to hardened stainless steel via CNC milling. This preserved the lightweight design while vastly improving performance.

The result was a drive assembly that not only met but exceeded the client’s demanding specifications for durability and precision. By strategically choosing CNC machining for the final production parts, the client achieved a 30% increase in operational lifespan and reduced warranty claims by 15%, solidifying their market position.

Call to Action:

Ready to make the optimal manufacturing decision for your next project? Leverage our deep technical expertise. Contact our engineering team today for a free, no-obligation consultation and transparent quote tailored to your specific part requirements. Ensure high-quality parts and efficient production from a trusted source manufacturer.

FAQ: CNC vs 3D Printing

Which is cheaper for prototypes?

For single-unit or very low-volume prototypes, 3D printing is often more cost-effective. It requires minimal setup, quickly turning your CAD into a physical object.

CNC machining involves higher initial setup costs due to programming and tooling. However, it delivers higher precision and material versatility for functional prototypes.

What about part strength and durability?

CNC machined parts generally offer superior mechanical strength, durability, and material integrity. They are made from solid, homogenous stock materials.

3D printed parts, while improving, can sometimes exhibit anisotropic properties and layer-line weaknesses. Material selection and print parameters significantly influence their performance.

Can both methods use metal?

Yes, both CNC machining and 3D printing can process metals, but with different capabilities. CNC works with a vast array of metal alloys, ensuring isotropic properties.

Metal 3D printing (e.g., DMLS, SLM) can produce complex metal parts. However, material options are more limited, and post-processing like heat treatment is often required for optimal properties.