CNC Parts: Prototype to Mass Production

Transforming precise CNC machining parts from initial prototype to flawless mass production demands expert navigation of complex challenges. Our engineered approach ensures high-quality CNC parts, overcoming production hurdles for seamless scale.

The journey from a single, perfect CNC prototype to thousands of flawlessly identical parts is where innovation often meets its toughest test. Are you prepared to navigate the hidden complexities of scaling, or will your groundbreaking design get lost in the transition?

Success in manufacturing hinges on bridging this gap, ensuring that initial design integrity translates into consistent, high-volume output. This guide, from our perspective as a seasoned source manufacturer, explores the critical **CNC production challenges** and strategies for achieving **high-quality CNC parts** from **prototype to mass production**.

The Core CNC Production Challenges

From prototype to parts: Why it’s hard?

Moving from a single prototype to large-scale production presents inherent difficulties. A prototype is often hand-tuned or made with less optimized processes.

Scaling up means replicating that precision thousands of times, under production-speed conditions. This requires a fundamental shift in approach and engineering rigor.

The delicate balance between speed, cost, and maintaining the original design intent often poses the greatest **CNC production challenges**.

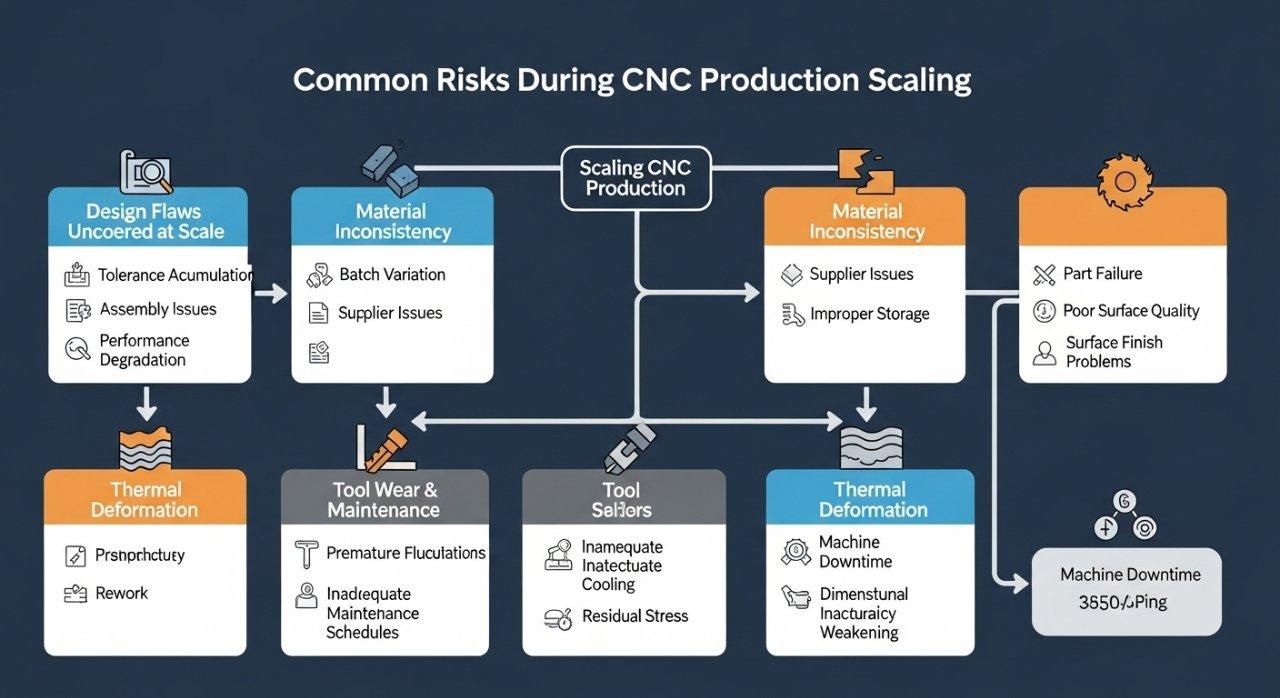

Common risks in scaling production

In our experience, a common issue we see is the underestimation of process variability. Small deviations acceptable in a prototype become critical flaws in mass production.

Tool wear management, thermal stability, and consistent material properties are magnified risks. These can lead to significant scrap rates and cost overruns.

Ignoring these early warning signs can jeopardize project timelines and product quality, impacting market entry and profitability.

Quality consistency pitfalls

Maintaining **high-quality CNC parts** across thousands of units is a primary concern for our clients. Variations in surface finish, dimensional accuracy, and material integrity can arise.

These inconsistencies often stem from inadequate process control, environmental fluctuations, or a lack of robust quality assurance protocols throughout the production run.

Ensuring every part meets the stringent specifications of the original prototype demands rigorous attention to detail and a proactive engineering approach.

Strategic Bridge: Prototype to Mass Production

Design for Manufacturability (DFM)

DFM is the cornerstone of a successful **prototype to mass production** transition. It involves optimizing a design for efficient, cost-effective, and repeatable manufacturing.

Our engineers collaborate closely with clients early on, identifying potential manufacturing bottlenecks or cost drivers. We then propose design modifications.

This proactive approach minimizes redesigns later, saving significant time and expense while ensuring the design is inherently suited for scale.

Material selection for production

Choosing the right material goes beyond initial properties; it must consider machinability at scale, cost-effectiveness, and long-term supply chain stability.

In our factory, we evaluate materials not just for strength or thermal properties but also for chip formation, tool life, and surface finish repeatability during high-volume runs.

A material that performs well for a single prototype might be prohibitively expensive or difficult to machine consistently in large batches.

| Material Type | Key Production Consideration | Common Use Case |

|---|---|---|

| Aluminum (6061) | Excellent machinability, corrosion resistance | Aerospace, automotive |

| Stainless Steel (304) | Good strength, weldability, corrosion resistance | Medical, food processing |

| Titanium (Ti-6Al-4V) | High strength-to-weight, difficult to machine | Aerospace, medical implants |

Validating prototypes for scale

Prototype validation is more than just checking dimensions; it’s about proving the concept for eventual mass production. We simulate production conditions.

This involves testing the prototype under anticipated operational stresses and environmental conditions. We look for any latent design or material flaws.

Our validation process ensures that the prototype not only functions as intended but is also robust enough to withstand the rigors of large-scale manufacturing.

Ensuring High-Quality CNC Machining Parts

Precision QC for mass production

Rigorous quality control (QC) is non-negotiable for **high-quality CNC parts** in mass production. We implement multi-stage inspection protocols.

This includes in-process checks using statistical process control (SPC) and post-machining measurements with advanced metrology equipment.

Our commitment to ISO 9001 and AS9100 standards means comprehensive documentation and traceability for every batch produced.

Achieving tight tolerances

Achieving and maintaining tight tolerances consistently across thousands of **CNC machining parts** requires a deep understanding of machining dynamics.

Factors like tool deflection, machine rigidity, thermal expansion, and fixture design all play critical roles. Our experienced engineers meticulously account for these variables.

We leverage advanced CAM software and precision tooling to optimize machining paths. This minimizes deviations and ensures predictable outcomes even with the most demanding specifications.

| Tolerance Class (ISO 2768-1) | Application Example | Typical Precision |

|---|---|---|

| Fine (f) | High-precision assembly, medical devices | ±0.05 mm |

| Medium (m) | General engineering, automotive | ±0.1 mm |

| Coarse (c) | Less critical features, structural parts | ±0.5 mm |

Preventing defects in large batches

Preventing defects at scale is a proactive, rather than reactive, process. It begins with robust fixture design to ensure consistent part clamping.

It also involves meticulous programming, optimized cutting parameters, and routine tool inspection and replacement schedules.

Environmental controls within our facility, such as temperature and humidity regulation, further minimize variables that can lead to defects.

Pricing & Scale for CNC Mass Production

Cost optimization from prototype to mass

Cost optimization for **CNC machining parts** doesn’t mean compromising on quality; it means intelligent process refinement. We identify efficiencies in cycle times.

This includes optimizing material utilization to reduce waste, consolidating operations where possible, and minimizing non-value-added steps in the workflow.

Our DFM expertise also plays a crucial role in reducing part cost by making designs inherently more manufacturable from the outset.

Streamlining lead times

Efficient **prototype to mass production** transition relies heavily on streamlined lead times. Our integrated approach minimizes delays between stages.

This involves robust project management, predictive maintenance on our machines, and a well-managed supply chain for raw materials.

Our capacity planning ensures that once a prototype is validated, we have the resources ready to commence full-scale production without unnecessary pauses.

Source manufacturer advantage

As a source manufacturer, we offer unparalleled transparency and control over the entire production process. There are no intermediaries, streamlining communication.

This direct relationship ensures that our clients benefit from direct access to our engineering expertise and efficient problem-solving capabilities.

It also allows for more competitive and transparent pricing, as well as guaranteed quality and reliable delivery schedules from **prototype to mass production**.

Your Partner in CNC Machining Success

Our deep technical expertise

At ly-machining, our engineering team possesses extensive hands-on experience in complex **CNC machining parts**. We thrive on solving intricate manufacturing challenges.

Our expertise spans material science, advanced machining strategies, and precision metrology, enabling us to deliver solutions for even the most demanding applications.

We continuously invest in the latest CNC technologies and ongoing professional development for our team, ensuring we remain at the forefront of the industry.

Success stories: prototype to volume

We have successfully guided numerous clients through the transition from novel prototypes to high-volume production. One such case involved a critical aerospace component.

A client approached us with a complex prototype for an aircraft hydraulic system, initially difficult to mass-produce due to stringent tolerance requirements and material specifics.

Our team applied DFM principles, recommended specific tooling strategies, and implemented a multi-stage QC plan. We achieved consistent production of **high-quality CNC parts** meeting AS9100 standards, ahead of schedule.

Start your CNC project today

Navigating the complexities of **CNC production challenges** from **prototype to mass production** requires a partner with proven experience and expertise.

We are committed to transforming your designs into **high-quality CNC parts** with efficiency and reliability. Let us be your trusted manufacturing partner.

Trust us to deliver predictable costs and consistent excellence for all your **CNC machining parts** needs.

Case Study

Problem: A medical device startup had developed an innovative, miniature surgical instrument. Their initial prototypes, produced by a smaller shop, suffered from inconsistent surface finishes and recurring burrs when attempting even small-batch runs. This jeopardized regulatory approval and market launch.

Our Solution: Our engineers conducted a comprehensive DFM review, identifying critical areas for tool path optimization and fixture redesign. We recommended a specific multi-axis machining strategy to minimize tool changes and improve surface integrity. We also implemented a specialized deburring process using advanced techniques.

Result: By leveraging our deep technical expertise and advanced machining capabilities, we produced a pilot run that exceeded the client’s quality expectations. Surface finish consistency improved by over 40%, and burr formation was virtually eliminated. This allowed the client to secure regulatory approval swiftly and proceed confidently into full mass production.

Ready for Your Next Project?

Ready to overcome the challenges of scaling your CNC project from prototype to mass production? Partner with a source manufacturer that guarantees precision, quality, and transparent pricing. Contact our engineering team for a free DFM consultation and a no-obligation quote today.

What is DFM in CNC machining?

DFM, or Design for Manufacturability, is an engineering approach. It optimizes a product design to simplify and streamline its manufacturing process.

This helps reduce production costs, improve quality, and shorten time-to-market. It’s crucial for efficiently transitioning from prototype to mass production.

How does ly-machining ensure quality?

We ensure **high-quality CNC parts** through rigorous adherence to ISO 9001 and AS9100 standards. This includes multi-stage inspection, SPC, and advanced metrology.

Our experienced engineers implement meticulous process controls. These minimize variables and prevent defects throughout the entire production run.

Why choose a source manufacturer?

Choosing a source manufacturer offers direct access to engineering expertise and transparent communication. It eliminates intermediaries.

This results in more competitive pricing, guaranteed quality, and reliable lead times. It provides greater control over your project from **prototype to mass production**.