CNC Machining Cost: Structure & Optimization

Understanding the core CNC machining cost structure and implementing strategic optimization techniques is key to achieving predictable pricing and significant savings for your projects.

The landscape of modern manufacturing demands not just precision but also unparalleled cost efficiency. For many projects, unexpected CNC machining costs can silently erode budgets and derail timelines, leaving engineers and procurement managers frustrated. It’s a common pain point: getting a part made should be straightforward, yet the underlying pricing often feels opaque.

At ly-machining, we understand these challenges intimately because we live them every day on the factory floor. This deep dive will demystify the complex factors that drive CNC machining pricing, offering a transparent breakdown of the cost structure. More importantly, we’ll equip you with actionable strategies for significant CNC cost optimization, leveraging our expertise as a source manufacturer.

Unveiling CNC Machining Cost Structure

To effectively manage and reduce CNC machining costs, one must first understand their constituent elements. As engineers, we break down every project into measurable components. This systematic approach reveals the true drivers behind CNC machining pricing.

Raw Material Costs: Selection Impact

The choice of raw material fundamentally dictates a significant portion of the total CNC machining cost. Different alloys and plastics possess varying intrinsic costs, directly influenced by market supply, purity, and processing difficulty.

Beyond the base price, factors such as material form (bar stock, plate, billet) and availability can impact overall material expense. Purchasing larger quantities can often yield better per-unit pricing.

Machine Time & Labor Expense

This component represents the direct time a CNC machine operates on a part, combined with the skilled labor required for setup, programming, operation, and supervision. More complex geometries and tighter tolerances demand longer machine run times.

Highly skilled machinists, programmers, and quality control personnel are essential for precision work. Their expertise, while contributing to cost, is invaluable for ensuring quality and preventing expensive errors.

Tooling & Fixture Investment

Every CNC machining operation requires specialized cutting tools and fixtures to hold the workpiece securely. The type, quantity, and complexity of these tools directly influence the project’s upfront investment.

For intricate parts or high-volume production, custom fixtures are often necessary to maintain accuracy and efficiency. These non-recurring engineering (NRE) costs are amortized across the production run.

Post-Processing & Finishing Costs

After machining, many parts require additional treatments such as deburring, surface finishing, heat treatment, or anodizing. These processes add significant time and cost.

For instance, a polished surface finish or a precise anodized coating can incur substantial extra expense compared to a standard as-machined finish. It is critical to specify only what is truly needed.

Quality Assurance & Inspection

Ensuring parts meet specifications is paramount, and robust quality assurance (QA) processes are built into our CNC machining pricing. This includes in-process inspections, final dimensional checks, and documentation.

Adherence to industry standards like ISO 9001 and AS9100 necessitates rigorous inspection protocols. While contributing to the overall CNC machining cost, this investment guarantees reliability and performance.

Key Factors Influencing CNC Machining Costs

Beyond the direct components, several overarching factors profoundly affect the final CNC machining pricing. Understanding these allows for more informed decision-making and strategic optimization.

Part Design Complexity & Geometry

Intricate part designs with complex curves, deep pockets, thin walls, or very small features require more specialized tools, multiple setups, and longer machining times. This directly increases the CNC machining cost per part.

A simpler design, even for a high-performance component, can often be machined much more economically. This highlights the importance of early design consultation.

Tolerance & Surface Finish Demands

Tighter dimensional tolerances (e.g., ±0.01mm vs. ±0.1mm) and finer surface finishes (e.g., Ra 0.8 vs. Ra 3.2) necessitate slower machine feeds and speeds. They also require higher precision machines, better tooling, and more stringent quality control.

These increased demands translate directly to higher machine time and inspection costs. Specifying unnecessarily tight tolerances or fine finishes is a common driver of inflated CNC machining cost.

Table: Impact of Tolerance & Surface Finish on Cost

| Characteristic | Cost Impact | Description |

|---|---|---|

| Standard Tolerance | Low | General applications, less machine time |

| Precision Tolerance | Medium | Critical fit, requires slower speeds, more checks |

| Ultra-Precision | High | Specialized machines, significant inspection |

| As-Machined Finish | Low | Standard milling/turning, no extra processes |

| Fine Machined Finish | Medium | Smoother texture, careful tool path, slower cuts |

| Polished/Ground Finish | High | Extensive post-processing, specialized equipment |

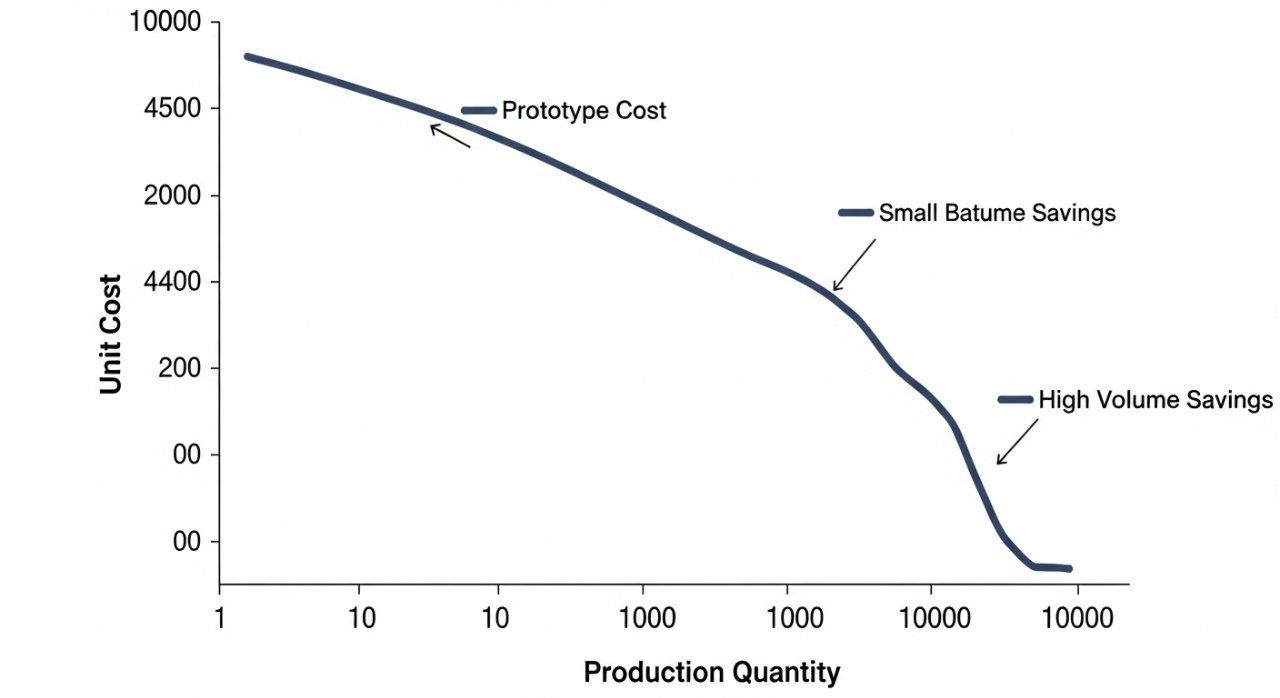

Production Volume & Batch Size

The total production volume significantly impacts the per-unit CNC machining cost. Higher volumes allow for better amortization of setup costs, tooling investment, and programming time.

Economies of scale are crucial in CNC machining pricing. Smaller batch sizes often carry a higher per-unit cost due as setup and programming time is divided among fewer parts.

Table: Production Volume vs. Unit Cost

| Batch Size | Setup Cost Amortization | Unit Cost Trend | Notes |

|---|---|---|---|

| Prototype (1-10) | High | Highest | Significant NRE, manual intervention |

| Small (11-100) | Moderate | High | Some optimization, still higher setup cost |

| Medium (101-1000) | Low | Moderate | Optimized runs, better material pricing |

| Large (1000+) | Very Low | Lowest | Automated processes, significant savings |

Material Type & Machinability

Beyond raw material cost, the machinability of a chosen material has a direct impact on machine time, tool wear, and ultimately, the CNC machining cost. Harder, more abrasive materials like titanium or certain stainless steels are much more challenging to machine.

They require specialized cutting tools, slower feed rates, and often more coolant, increasing both material and machine-time expenses. Conversely, materials like aluminum 6061 are highly machinable, leading to lower production costs.

Supplier Expertise & Technology

The capabilities of your chosen CNC machining partner play a critical role. Factories with advanced multi-axis machines, automation, and highly experienced engineers can often produce complex parts more efficiently and accurately.

Leveraging the right technology and expertise can lead to significant CNC cost optimization, as specialized suppliers can reduce errors, improve cycle times, and recommend DFM strategies that less equipped shops cannot.

Strategic CNC Machining Cost Optimization

Achieving significant savings requires a proactive and strategic approach to CNC cost optimization. It’s not just about cutting corners, but about intelligent design and manufacturing choices.

Design for Manufacturability (DFM)

Implementing Design for Manufacturability principles early in the product development cycle is perhaps the most powerful lever for CNC cost optimization. Our engineers often work with clients to simplify designs without compromising functionality.

This can involve eliminating unnecessary features, standardizing radii, ensuring adequate wall thicknesses, and designing for easier fixturing. A small design change can yield substantial savings in machining time and complexity.

Smart Material Selection Strategies

Working with a knowledgeable CNC machining partner allows for informed material selection. Sometimes, a slightly more expensive material with superior machinability can actually reduce the overall part cost due to faster cycle times and reduced tool wear.

Consider the functional requirements carefully. Over-specifying exotic materials when a standard alloy would suffice is a common pitfall that drives up CNC machining cost unnecessarily.

Optimizing Production Batching

As demonstrated, larger production volumes generally lead to lower per-unit costs. Strategically planning your order quantities to hit optimal batch sizes can significantly reduce your overall CNC machining pricing.

If possible, consolidate smaller orders or plan for larger, less frequent production runs. This amortizes setup costs more effectively across more parts, benefiting your budget.

Leveraging Advanced Machining

Modern CNC machining technologies, such as 5-axis machining, advanced CAM software, and automated material handling systems, offer unparalleled efficiency. While the initial investment in such equipment is high, it translates to faster production.

These advanced capabilities can also enable the machining of previously impossible or extremely costly geometries in a single setup, drastically reducing machine time and labor, leading to substantial CNC cost optimization.

The Value of Transparent Pricing

A truly valuable CNC machining partner provides transparent pricing. This means clearly outlining the breakdown of costs, from raw material to machine time, tooling, and post-processing.

This transparency empowers clients to understand what they are paying for and where potential for CNC cost optimization lies. It builds trust and fosters a collaborative relationship focused on value.

Achieving Value in CNC Machining

Focusing solely on the lowest quote can be a costly mistake. True value in CNC machining extends far beyond the initial price tag.

Beyond Price: Total Cost of Ownership

When evaluating CNC machining pricing, consider the total cost of ownership (TCO). This includes not only the unit price but also factors like lead time, quality consistency, rework rates, assembly issues, and the supplier’s reliability.

A slightly higher per-unit cost from a reputable supplier often translates to significant savings down the line through reduced rejections, faster time-to-market, and greater peace of mind.

Partnering for Long-Term Success

In our experience, the most successful projects are built on strong, long-term partnerships. A skilled CNC machining factory acts as an extension of your engineering team, offering proactive advice and solutions.

This collaborative approach helps anticipate challenges, optimize designs, and consistently achieve predictable quality and cost-effective production, fostering mutual growth.

Real-World Cost Savings: Case Studies

Our commitment to CNC cost optimization is best demonstrated through real-world applications. We believe in practical, impactful solutions that deliver tangible results for our clients.

Partnering for Optimized CNC Machining

Choosing the right CNC machining partner is a strategic decision that impacts your project’s success, budget, and quality outcomes. At ly-machining, we are dedicated to being that partner.

Your Path to Predictable Quality

We leverage our deep engineering expertise, state-of-the-art equipment, and rigorous quality systems (ISO 9001, AS9100 certified) to ensure predictable, high-quality outcomes. We prioritize transparent communication.

Our goal is to help you navigate the complexities of CNC machining pricing and deliver parts that exceed your expectations, consistently and reliably.

Get a Custom CNC Machining Quote

Ready to optimize your CNC machining costs without compromising quality? Contact our expert team today for a transparent, personalized quote and a free DFM consultation. Let’s build your next project with confidence and precision.

How does material choice affect CNC cost?

The raw material cost and its machinability directly impact machine time, tooling wear, and cycle rates. Harder, more abrasive materials increase both material and processing expenses, driving up the overall CNC machining cost.

Can design changes reduce part price?

Absolutely. Implementing Design for Manufacturability (DFM) principles can significantly reduce CNC machining cost. Simplifying geometries, standardizing features, and optimizing for fewer setups can lead to substantial savings.

Why is high volume often cheaper per unit?

Higher production volumes allow for better amortization of non-recurring costs like setup, programming, and custom tooling. This economy of scale distributes fixed costs over more units, lowering the per-part CNC machining pricing.