Quick Solution: Achieving superior performance and aesthetics for brass CNC machined parts relies on selecting the right brass surface treatment, encompassing mechanical, plating, and chemical processes for optimal durability and finish.

Are your brass CNC machined parts failing to meet performance expectations or aesthetic standards due to inadequate surface treatment? Discover how strategic surface finishing can unlock unprecedented durability, beauty, and functionality, transforming your components from good to exceptional.

In our experience as a source manufacturer, the choice of brass machining surface treatment is critical, dictating not just appearance but also crucial functional properties. This guide delves into the technologies that enhance your components.

Why Surface Treatment Matters for Brass CNC Parts

Enhancing Durability & Performance

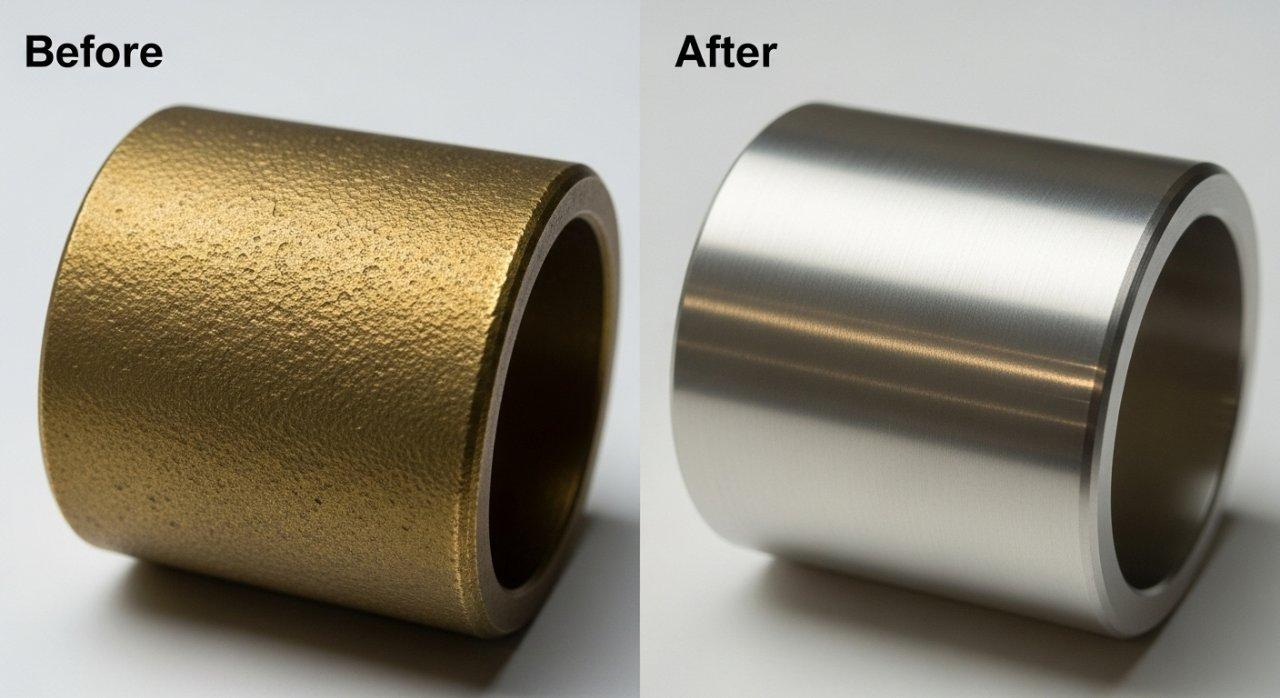

Brass, while excellent for machining, benefits significantly from surface treatments that improve its inherent properties. These processes can dramatically increase the wear resistance of brass components, extending their operational lifespan in demanding applications.

Proper CNC brass finishing enhances the structural integrity of the part, making it more resilient to physical stress and environmental factors. This directly translates to more reliable and longer-lasting products.

Achieving Desired Aesthetics

Beyond functionality, the visual appeal of a brass machining surface is often paramount, especially for consumer-facing or decorative components. Surface treatments allow for a wide range of aesthetic outcomes, from a mirror polish to a matte finish or a specific color.

We understand that the perceived quality of a product is heavily influenced by its finish. Achieving a consistent, high-quality aesthetic across batches is a hallmark of our advanced brass surface treatment capabilities.

Protecting Against Corrosion

Despite its natural resistance to certain forms of corrosion, brass can tarnish or react with specific environments. A well-chosen brass surface treatment acts as a protective barrier, preventing oxidation and chemical degradation.

This protective layer is essential for parts exposed to moisture, chemicals, or varied atmospheric conditions, ensuring they maintain their integrity and appearance over time.

Addressing Common Brass Challenges

Brass can be susceptible to galling or sticking in moving applications if untreated. Specific metal surface technology, such as certain platings, can reduce friction and improve the component’s performance in dynamic assemblies.

Another challenge is achieving consistent batch-to-batch quality, which requires rigorous process control in surface treatment. Our established protocols ensure uniformity, eliminating common pitfalls.

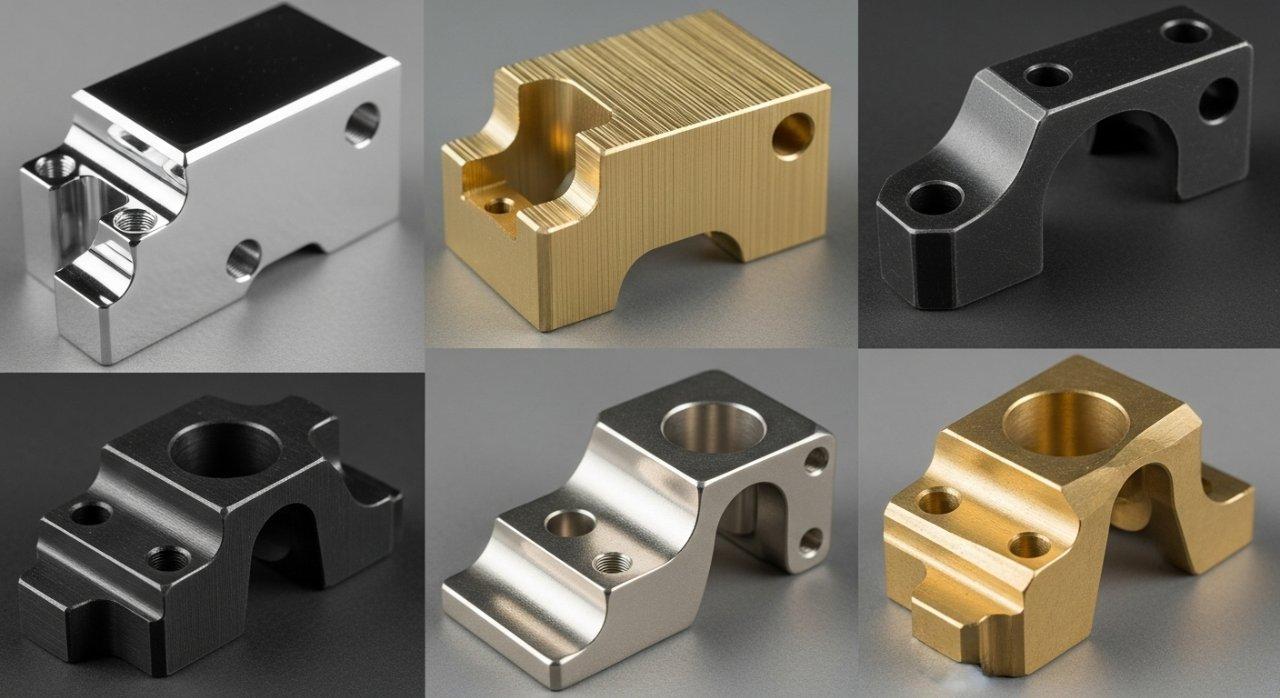

Common Brass CNC Surface Treatment Technologies

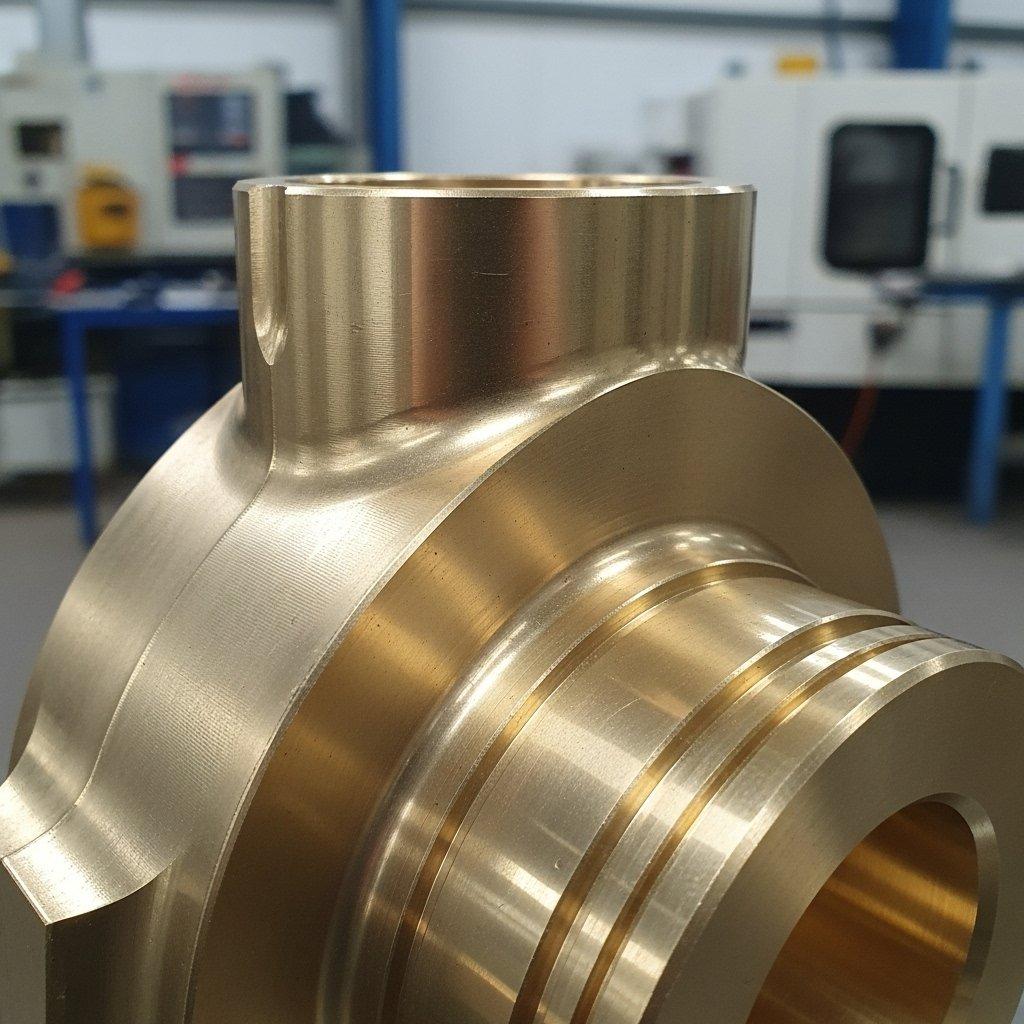

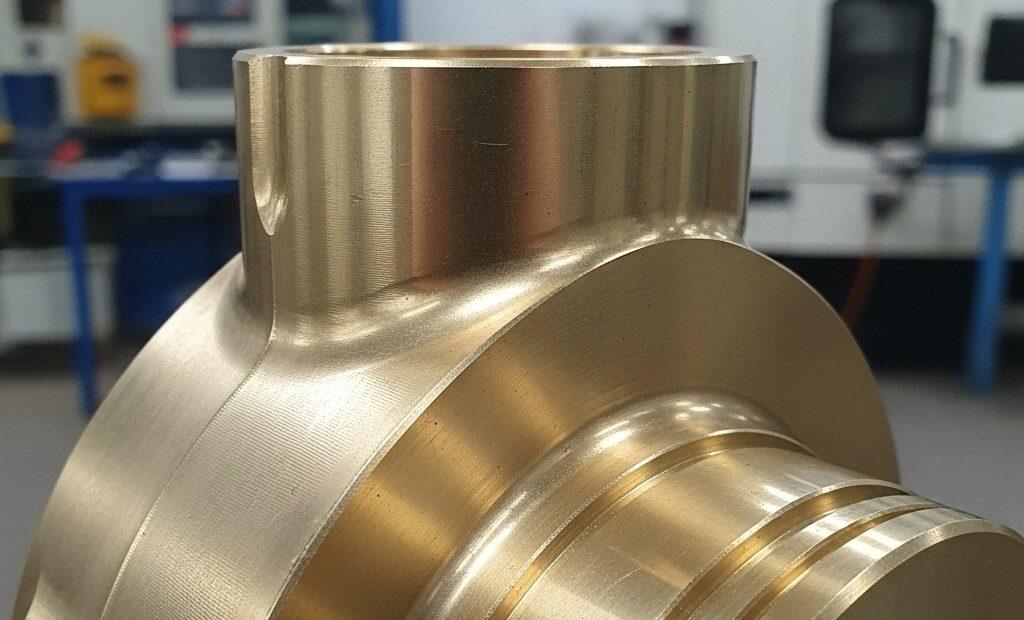

Mechanical Finishes for Brass CNC

Mechanical finishing techniques are often the first step or the final desired brass surface treatment, directly manipulating the surface texture. These methods are excellent for achieving specific tactile and visual qualities.

We utilize a range of precision mechanical processes to prepare and finish brass parts, ensuring the base material’s integrity is maintained while achieving the desired surface profile.

Polishing & Buffing Techniques

Polishing involves using abrasive compounds to remove minute surface imperfections, resulting in a smooth, reflective brass machining surface. Buffing further refines this to achieve a high-luster, mirror-like finish.

These techniques are critical for aesthetic applications, such as decorative hardware or musical instrument components, where a brilliant, unblemished appearance is required.

Brushing & Satin Finishes

Brushing creates a distinctive directional grain on the brass surface, resulting in a soft, matte, or satin appearance. This finish is often preferred for its ability to hide fingerprints and small imperfections.

A satin finish is achieved through finer abrasive processes, offering a subtle sheen that diffuses light, giving a sophisticated and understated look to brass components.

Sandblasting & Bead Blasting

Sandblasting uses abrasive media propelled at high speed to create a uniform, textured, and matte brass surface. This can prepare a surface for better adhesion of subsequent coatings or for specific aesthetic effects.

Bead blasting, using glass beads, produces a finer, smoother matte finish compared to sandblasting, reducing surface roughness without significant material removal. This is ideal for a softer, more uniform look.

Table: Mechanical Finish Characteristics for Brass

| Finish Type | Primary Aesthetic | Key Functional Benefit |

|---|---|---|

| Polishing & Buffing | High-Gloss, Reflective | Enhanced Shine |

| Brushing | Directional Grain | Hides Imperfections |

| Satin Finish | Smooth, Diffused Sheen | Subtle Elegance |

| Sandblasting | Uniform Matte, Textured | Coating Adhesion Prep |

| Bead Blasting | Fine Matte, Smooth | Reduced Glare |

Plating & Coating Technologies for Brass

Plating and coating techniques involve applying a thin layer of another material onto the brass machining surface. This significantly alters the part’s functional and aesthetic properties.

Our expertise in these metal surface technology applications ensures excellent adhesion and uniform thickness, critical for the performance of the finished brass CNC parts.

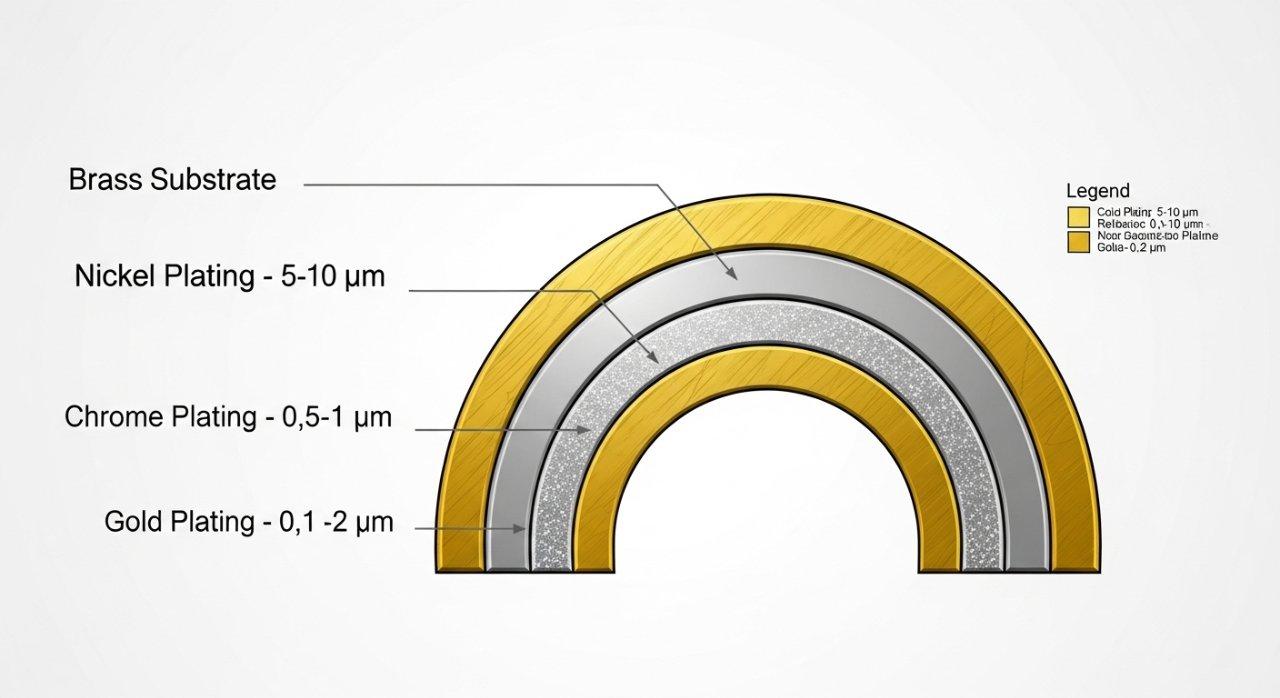

Nickel Plating: Benefits & Types

Nickel plating offers excellent corrosion resistance, wear resistance, and a bright, appealing finish. It can serve as a standalone finish or as an underlayer for other plating types.

Electroless nickel plating provides superior uniformity, even on complex geometries, and offers a harder, more wear-resistant surface than electrolytic nickel. This makes it suitable for functional brass components.

Chrome Plating: Aesthetics & Hardness

Chrome plating, often applied over a nickel base, provides an exceptionally hard, durable, and aesthetically pleasing bright finish. It is highly resistant to tarnish and corrosion.

Its high hardness makes it ideal for brass components requiring extreme wear resistance, such as valves or moving parts, while its reflective quality is prized in decorative applications.

Gold Plating: Conductivity & Luxury

Gold plating on brass offers excellent electrical conductivity, making it invaluable for electronic connectors and contacts. It also provides a luxurious, tarnish-resistant finish for high-end decorative items.

In our facility, we meticulously control the gold plating process to achieve precise thickness and adhesion, ensuring both functional integrity and aesthetic perfection for sensitive brass components.

Silver Plating: Electrical & Anti-Tarnish

Silver plating provides the highest electrical conductivity of any metal, making it essential for certain electrical and electronic brass components. It also offers a bright, attractive finish.

While silver can tarnish, specific anti-tarnish treatments can be applied to maintain its luster and conductivity, ensuring optimal performance for critical electrical contacts.

Lacquering & Clear Coats

Lacquering involves applying a transparent organic coating to the brass machining surface to prevent tarnishing and maintain the desired aesthetic over time. This is common for polished or brushed brass.

Clear coats offer protection without altering the underlying brass finish, preserving the natural beauty of the metal while shielding it from environmental degradation and fingerprints.

Table: Plating & Coating Properties for Brass

| Coating Type | Key Properties | Typical Application | Cost Level |

|---|---|---|---|

| Nickel Plating | Corrosion/Wear Resistance, Bright | Functional/Decorative | Medium |

| Chrome Plating | High Hardness, Bright, Durable | High-Wear, Decorative | Medium-High |

| Gold Plating | High Conductivity, Luxury, Tarnish-Resistant | Electronics, Luxury | High |

| Silver Plating | Highest Conductivity, Bright | Electrical Contacts | Medium-High |

| Lacquering/Clear Coats | Tarnish Prevention, Aesthetic Preservation | Decorative, Architectural | Low-Medium |

Chemical & Conversion Treatments

Chemical and conversion treatments modify the brass surface through a chemical reaction, forming a protective or decorative layer directly from the base metal. These offer distinct functional benefits.

These processes are highly controlled in our factory to ensure uniform application and consistent results, crucial for the quality of the final brass CNC finishing.

Passivation for Brass

Passivation for brass involves a chemical process that removes free iron contaminants and forms a passive oxide layer on the surface. While more commonly associated with stainless steel, certain treatments can enhance brass’s inherent corrosion resistance.

This process helps to stabilize the brass surface, making it less reactive to environmental factors and preventing localized corrosion or discoloration.

Blackening & Patina Finishes

Blackening (or chemical blackening) of brass produces a dark, oxidized finish that can be protective and aesthetically unique. This metal surface technology is often used for antique replication or specific design intents.

Patina finishes are created through controlled oxidation processes, resulting in varied colors (e.g., green, brown) that mimic aged brass. These bespoke finishes are popular in art, architecture, and custom designs.

Table: Chemical & Conversion Treatment Overview for Brass

| Treatment Type | Primary Result | Key Benefit | Aesthetic Range |

|---|---|---|---|

| Passivation (Brass Specific) | Enhanced Oxide Layer | Improved Corrosion Resistance | Natural Brass |

| Blackening | Dark, Uniform Surface | Decorative, Reduced Glare | Dark Grey to Black |

| Patina Finishes | Controlled Oxidation Colors | Aged Aesthetic, Unique Look | Green, Brown, Blue |

Choosing the Right Surface Treatment for Brass

Functional Requirements: Performance Needs

When selecting a brass surface treatment, the primary consideration should always be the part’s intended function. Does it require high wear resistance, electrical conductivity, or specific friction properties?

For critical applications, detailed specifications concerning hardness, adhesion, and environmental resilience are paramount. Our engineering team can guide you in making these precise decisions.

Aesthetic Goals: Visual Impact

The desired visual impact is another key factor. Is a polished, reflective finish needed, or a subtle matte look? The aesthetic should complement the product’s overall design and branding.

We work closely with designers to achieve exact color, texture, and sheen specifications, leveraging our deep expertise in CNC brass finishing to deliver the desired visual outcome.

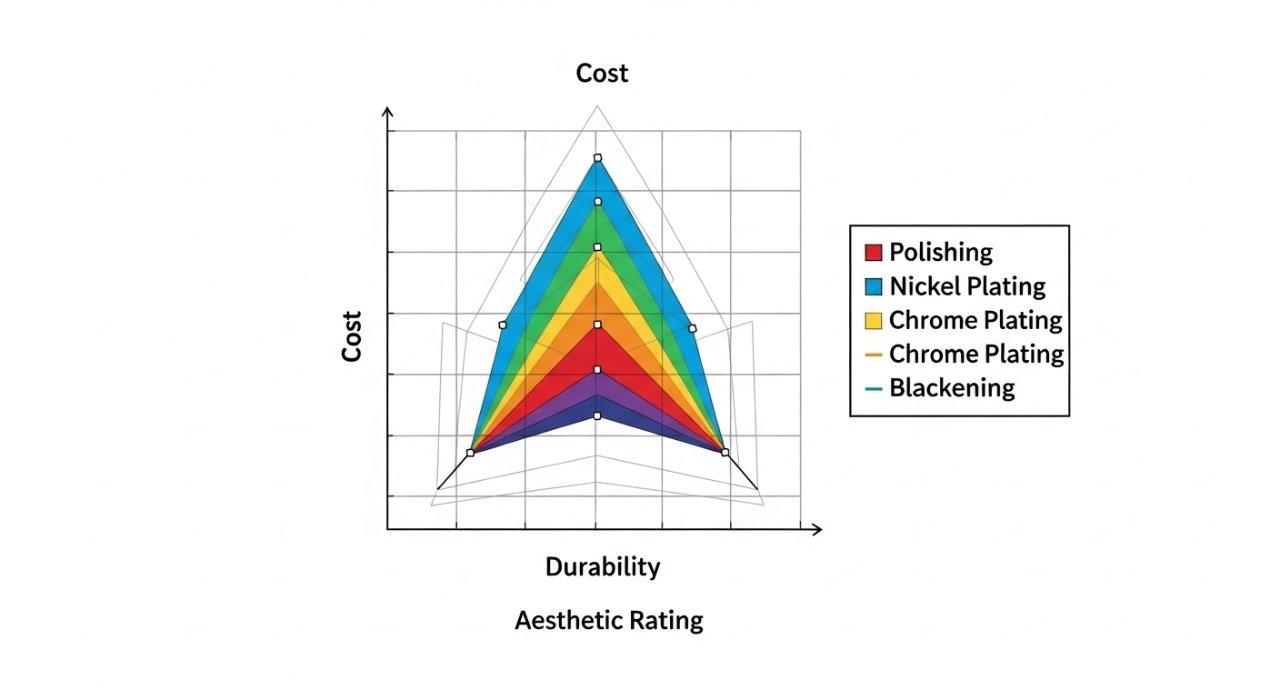

Cost-Benefit Analysis of Treatments

Each brass surface treatment comes with varying costs, influenced by material, process complexity, and required quality control. A thorough cost-benefit analysis is essential to balance budget with performance and aesthetics.

We provide transparent pricing and help clients understand the long-term value of investing in the right finish, considering factors like extended part life and reduced maintenance.

Environmental & Compliance Factors

Environmental regulations regarding chemical usage and waste disposal are increasingly stringent. We adhere to all relevant standards, offering compliant brass surface treatment options.

Our processes are designed to be as environmentally responsible as possible, ensuring that your brass machining surface treatments meet global compliance requirements.

Impact on Machining Tolerances

Applying a surface treatment, particularly plating, will add material thickness to the brass component. This must be accounted for during the initial CNC machining phase to maintain critical tolerances.

In our production planning, we meticulously factor in plating thickness and other treatment-related dimensional changes to ensure the final part meets precise engineering specifications. This is a critical aspect of our precision engineering.

Our Expertise in Brass CNC Surface Treatment

As a Source Manufacturer: Quality Control

As a dedicated source manufacturer, we maintain complete control over the entire production process, from raw material sourcing to final brass surface treatment. This vertical integration ensures unparalleled quality and consistency.

Our integrated quality management system, including rigorous in-process inspections, guarantees that every brass machining surface meets the highest industry standards before it leaves our facility.

Deep Technical Expertise: Consultation

Our team of experienced engineers possesses deep technical expertise in brass and its myriad surface treatments. We don’t just process parts; we partner with you to optimize your designs and material choices.

From initial concept to final production, we offer expert consultation, advising on the most suitable CNC brass finishing techniques to achieve your specific performance and aesthetic requirements.

Transparent Pricing & Reliable Delivery

We pride ourselves on transparent pricing models, providing detailed breakdowns so you understand the value you receive. Our commitment to reliable delivery ensures your projects stay on schedule and within budget.

Our robust production planning and logistics capabilities enable us to manage complex orders efficiently, delivering high-quality brass components with consistent lead times.

Case Studies: Successful Brass Projects

We recently partnered with a client developing high-end marine instrumentation. Their brass components required exceptional corrosion resistance and a specific aesthetic to withstand harsh saltwater environments.

The challenge was to achieve both durability and a premium finish without compromising critical tolerances. Our solution involved a multi-stage CNC brass finishing process: precision machining followed by electroless nickel plating for superior corrosion protection, topped with a custom clear coat for aesthetic preservation. The client reported a significant increase in product lifespan and overwhelmingly positive feedback on the aesthetic quality.

Conclusion: Elevating Your Brass CNC Projects

The journey of a brass CNC machined part from raw material to a high-performance, aesthetically pleasing component is profoundly shaped by its surface treatment. Selecting the optimal brass surface treatment is a complex decision, but a crucial one for durability, function, and visual appeal.

At ly-machining, our comprehensive understanding of metal surface technology and our commitment to precision engineering position us as your ideal partner. We bring unparalleled expertise to every CNC brass finishing project.

Partner for Superior Brass Parts

Partnering with a source manufacturer like us ensures that your brass machining surface requirements are met with the highest standards of quality, consistency, and technical support. We are dedicated to transforming your designs into flawlessly finished parts.

Our integrated capabilities and profound experience in brass surface treatment translate into reliable performance and exceptional aesthetics for all your components.

Get a Custom Consultation & Quote

Ready to elevate your brass CNC machined parts? Don’t leave your surface finish to chance. Contact our expert engineering team today for a complimentary technical consultation and a transparent, customized quote. Let our deep expertise ensure your components achieve optimal performance and aesthetics.

What is the best brass surface treatment?

The “best” brass surface treatment depends entirely on the specific application’s functional and aesthetic requirements. Factors like environmental exposure, desired hardness, electrical conductivity, and visual appeal must be carefully considered.

For instance, gold plating is optimal for electrical contacts, while chrome plating excels in wear resistance and decorative appeal. A thorough technical consultation is crucial to identify the ideal solution for your unique project.

How does surface treatment affect tolerances?

Surface treatments, especially plating, add material thickness to the brass component. This additional layer, often measured in micrometers, can significantly impact precise machining tolerances if not accounted for during the initial design and CNC machining phases.

Our engineers meticulously calculate and plan for these dimensional changes, ensuring that the finished part meets the exact specifications required. This proactive approach prevents post-treatment rejections and maintains part functionality.

Can brass parts be chemically blackened?

Yes, brass parts can be effectively blackened through chemical conversion treatments. This process creates a uniform, dark finish that can be both aesthetic and protective.

It is often used for antique replication, decorative items, or components where reduced reflectivity is desired. The depth and uniformity of the blackening depend on the specific chemical bath and process control.