Quickly overcome brass CNC machining defects by optimizing material selection, tooling, cutting parameters, and implementing robust quality control for superior part precision and reliability.

Are common brass CNC machining defects sabotaging your project timelines and profitability? Unwanted burrs, inconsistent dimensions, and poor surface finishes can lead to costly reworks and significant delays.

These challenges can undermine even the most meticulously designed components, turning promising projects into frustrating setbacks.

Discover how our proven strategies and expert insights at ly-machining can eliminate these obstacles, guaranteeing unparalleled precision and quality in every brass component we produce.

Common Brass CNC Machining Defects

Understanding the specific nature of brass CNC machining defects is the first step towards their effective prevention. In our experience, many issues stem from brass’s unique metallurgical properties.

Identifying these common problems and their root causes allows us to implement targeted solutions, ensuring consistent quality. This section details the prevalent challenges encountered in brass machining.

Surface Finish Defects & Causes

Poor surface finish on brass components can manifest as roughness, pitting, or discoloration, impacting both aesthetics and functional performance. This is a frequent concern for precision applications.

Such defects often arise from incorrect cutting parameters, worn tools, or inadequate chip evacuation, leading to material smearing or re-cutting. Material impurities can also contribute to a degraded surface.

| Defect | Appearance | Root Cause |

|---|---|---|

| Roughness | Dull, uneven, textured surface | Incorrect feed/speed, worn tools, poor chip flow |

| Pitting | Small, crater-like indentations | Material inclusions, chip recutting, poor coolant |

| Discoloration | Darkening or inconsistent color | High cutting temperatures, improper coolant |

| Smearing | Shiny, smeared appearance | Low cutting speed, positive rake too small |

Dimensional Inaccuracy Issues

Dimensional inaccuracies, such as parts failing to meet tight tolerances or exhibiting inconsistent measurements, are critical defects in precision brass machining. These can lead to assembly failures.

Primary causes include thermal expansion of the brass workpiece during machining, insufficient machine rigidity leading to tool deflection, or worn machine components. Improper clamping can also contribute.

| Factor | Impact on Accuracy | Mitigation Hint |

|---|---|---|

| Thermal Expansion | Part dimensions change with temperature | Controlled coolant, stable environment |

| Machine Rigidity | Vibrations, tool deflection | Robust machine, proper fixturing |

| Tool Wear | Changes effective cutting diameter | Regular tool inspection, optimal coatings |

| Clamping Pressure | Part deformation, movement during cut | Balanced clamping, custom fixtures |

Burrs and Edge Breakage

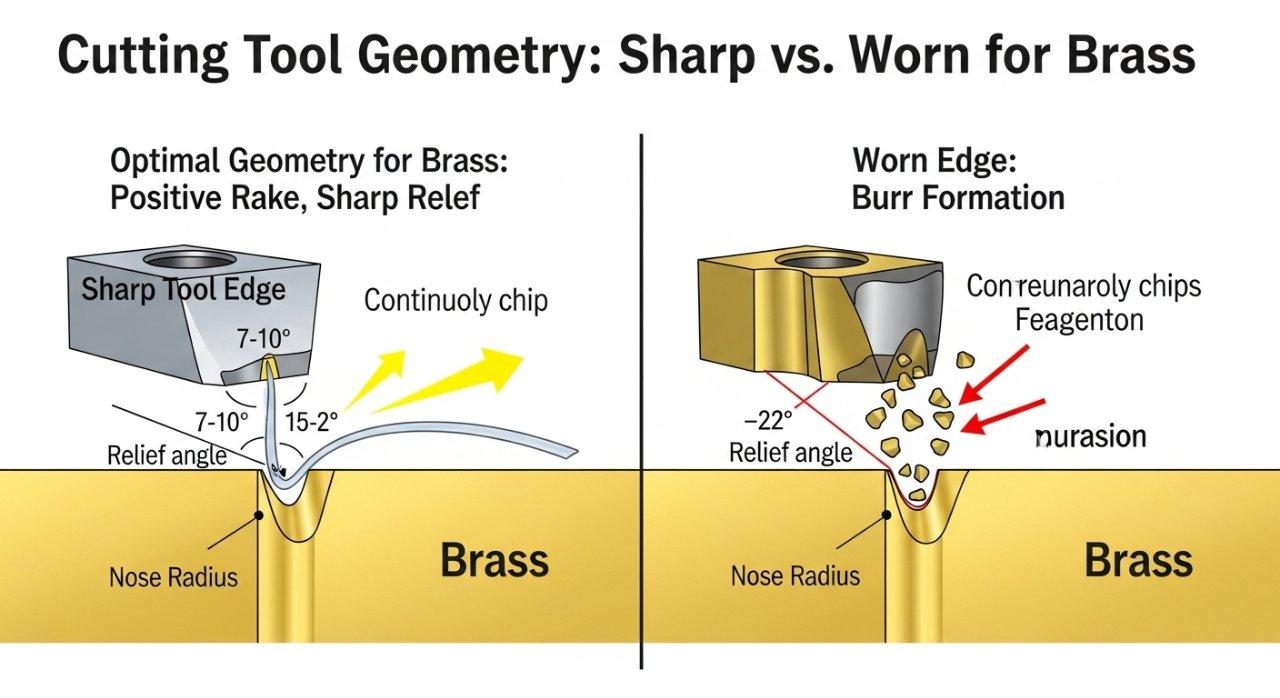

The formation of burrs and instances of edge breakage are common Brass CNC Machining Defects, especially on delicate features or thin walls. Burrs necessitate additional post-machining operations.

These issues are frequently caused by dull cutting tools, insufficient cutting force at the exit point, or incorrect feed rates. The inherent ductility of some brass alloys also plays a role in burr formation.

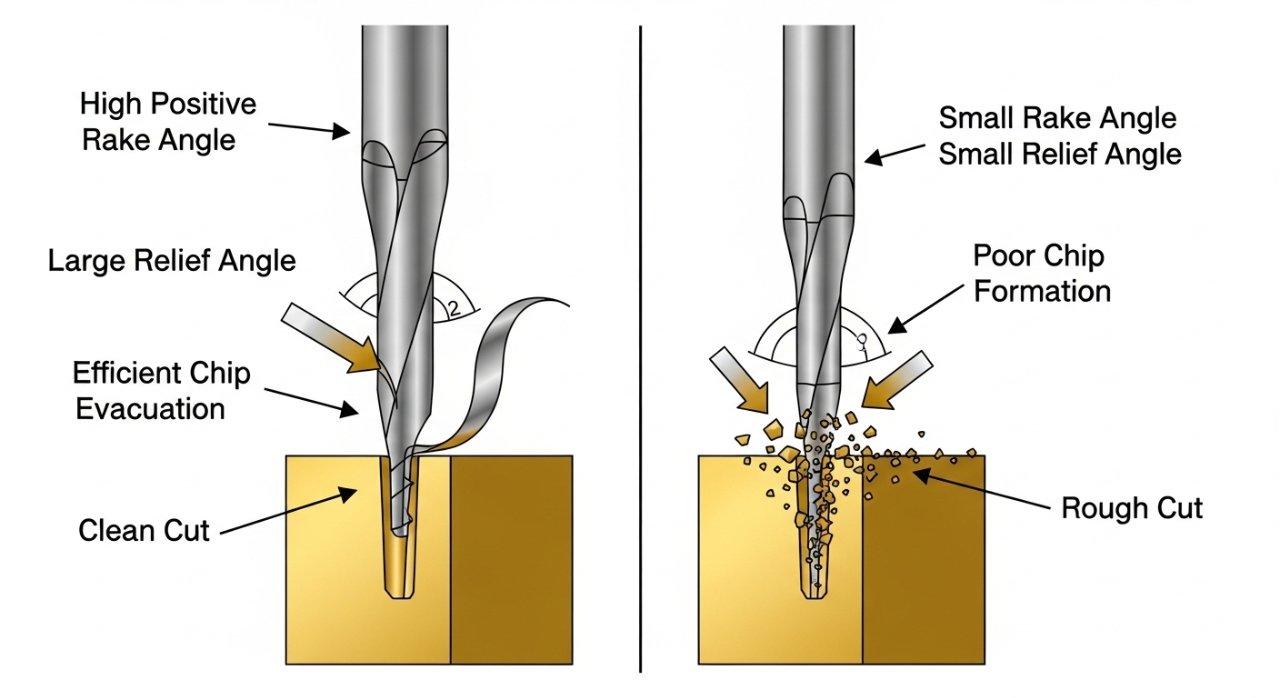

Chip Control Challenges

Controlling chips during brass machining is paramount for maintaining process stability and preventing surface defects. Brass can produce long, stringy chips if not managed correctly.

This often leads to chip recutting, entanglement with the tool or workpiece, and potential damage to the surface finish or tool. The primary causes are inappropriate tool geometry and inadequate cutting parameters.

| Challenge | Cause | Solution |

|---|---|---|

| Long, Stringy Chips | Insufficient chip breaker, low feed rate | Adjust tool geometry, increase feed |

| Chip Recutting | Chips not evacuating, re-entering cut | Optimize coolant, improve chip flow |

| Chip Wrap | Chips tangle around tool/workpiece | Polished flutes, high-pressure coolant |

Tool Wear and Breakage

Rapid tool wear and unexpected breakage are significant concerns that interrupt production and increase costs. Brass, while generally considered free-machining, can still be abrasive.

High cutting temperatures, incorrect tool material or coating, and excessive feed rates contribute to accelerated wear. Vibrations and improper tool setup can also lead to catastrophic tool failure.

Proactive Prevention of Brass Defects

Preventing defects in Brass CNC Machining requires a systematic, multi-faceted approach. At ly-machining, we integrate decades of hands-on experience with cutting-edge technology.

This proactive strategy focuses on optimizing every stage of the manufacturing process, from material selection to post-machining treatments. Our goal is zero defects, ensuring superior quality.

Optimal Material Selection

Choosing the correct brass alloy is fundamental to achieving high-quality machined parts and preventing defects. Different brass grades offer varying machinability and mechanical properties.

For instance, C36000 (Free-Machining Brass) is excellent for complex geometries due to its lead content aiding chip breaking. Other alloys like C26000 (Cartridge Brass) are more ductile but harder to machine.

| Brass Alloy | Key Properties | Machinability | Typical Applications |

|---|---|---|---|

| C36000 | High machinability, good strength | Excellent | Fittings, valve parts, gears, hardware |

| C38500 | Architectural bronze, good strength | Good | Architectural trim, ornamental work |

| C26000 | High ductility, good formability | Moderate | Ammunition, automotive parts, electrical |

| C46400 | Naval brass, good corrosion resistance | Good | Marine hardware, condenser plates |

Tooling Strategy & Geometry

The right tooling is critical for effective Brass Machining Prevention of defects. Tools designed specifically for brass, with features like high positive rake angles and sharp cutting edges, are essential.

These geometries promote clean shearing of the material, reducing burr formation and improving chip control. Polished flutes also aid in smooth chip evacuation, preventing chip recutting.

Feeds, Speeds, and Depth of Cut

Optimizing cutting parameters (feeds, speeds, and depth of cut) is paramount for Brass Machining Prevention. These parameters must be carefully balanced to minimize heat generation and reduce tool wear.

Too low a speed can cause smearing, while too high a speed generates excessive heat. Proper chip load is crucial for breaking chips effectively and avoiding stringy swarf.

| Parameter | Typical Range (General Guideline) | Notes |

|---|---|---|

| Cutting Speed (SFM) | 200 – 800 | Depends on alloy, tool material, machine rigidity. Higher for C36000 |

| Feed Rate (IPR) | 0.002 – 0.015 | Critical for chip breaking and surface finish. Adjust for depth. |

| Depth of Cut (DOC) | 0.020 – 0.200 (Radial) | Balance with rigidity and power. Light cuts for finishing. |

Effective Coolant Application

Effective coolant application is a key strategy in Brass Machining Prevention. Coolant not only dissipates heat, preventing thermal expansion and discoloration, but also lubricates the cutting zone.

Moreover, high-pressure coolant systems are invaluable for flushing chips away from the cutting area, preventing chip recutting and promoting a superior surface finish. We utilize advanced coolant delivery.

Machine Rigidity & Maintenance

The rigidity and precision of the CNC machine are foundational to preventing dimensional inaccuracies and ensuring consistent Brass CNC Machining Quality Control. A robust machine minimizes vibrations and tool deflection.

Regular, scheduled maintenance, including calibration and inspection of spindles, guideways, and clamping mechanisms, is essential. This proactive approach ensures long-term accuracy and reliability.

Post-Machining Processes

Even with the most precise machining, post-machining processes are crucial for final Brass CNC Machining Quality Control. These include thorough deburring, cleaning, and sometimes specialized surface treatments.

Careful deburring removes any residual burrs that could compromise functionality or aesthetics. Proper cleaning ensures no coolant residues or metal fines remain, preventing future corrosion or contamination.

Why Choose Us for Brass Machining?

At ly-machining, our commitment to excellence goes beyond merely manufacturing parts; we are dedicated to providing comprehensive Brass Machining Solutions. Our expertise is rooted in decades of industry experience.

We combine advanced technology with a deep understanding of metallurgy and precision engineering. Choosing us means partnering with a leader in defect prevention and stringent quality control.

Our Advanced CNC Expertise

Our team comprises highly skilled engineers and technicians with profound expertise in brass CNC machining. We excel in Design for Manufacturability (DFM) analysis, optimizing designs for cost-efficiency.

We tackle the most complex geometries and tight tolerances with confidence, leveraging our state-of-the-art multi-axis CNC machines. Our experience ensures we preempt common Brass CNC Machining Defects.

Precision Quality Control

Quality is not just a department; it’s ingrained in every step of our process. We adhere strictly to international standards such as ISO 9001 and AS9100, implementing rigorous in-process and final inspections.

Utilizing advanced metrology equipment like CMMs, optical comparators, and surface roughness testers, we guarantee every brass component meets or exceeds specified requirements for Brass CNC Machining Quality Control.

Transparent Pricing Structure

We believe in fostering trust through transparency in all our dealings. Our pricing structure for Brass Machining Solutions is straightforward and competitive, offering clear value without hidden costs.

Clients receive detailed quotes that reflect the true cost of precision, quality, and reliable delivery. We aim to provide cost-effective solutions without ever compromising on part integrity or performance.

Your Reliable Source Partner

As a direct source manufacturer, ly-machining offers unparalleled reliability and control over the entire production process. This direct approach translates into consistent quality and predictable lead times.

We pride ourselves on building long-term partnerships, working collaboratively with clients to overcome their most challenging brass machining requirements. You can trust us to deliver exceptional Brass Machining Solutions every time.

Your Brass Machining Solution Partner

At ly-machining, we are more than just a supplier; we are your dedicated partner in achieving superior brass component manufacturing. Our deep expertise in defect prevention ensures your projects succeed.

Get a Custom Quote Today

Ready to overcome your brass machining challenges and ensure defect-free, high-quality parts? Contact our expert engineering team today for a transparent quote and a personalized consultation on your next project.

FAQ Section

What causes burrs in brass?

Burrs in brass are often caused by the material’s ductility and incorrect cutting parameters. Dull tools, insufficient feed rates, or improper tool geometry can lead to plastic deformation.

This deformation, instead of clean shearing, results in unwanted material extending beyond the desired edge. Optimal tooling and parameters are key.

How to improve brass surface finish?

To improve brass surface finish, focus on sharp, highly polished cutting tools with positive rake angles. Optimize your cutting speeds and feed rates to prevent smearing and excessive heat.

Ensure efficient chip evacuation and consistent coolant application. Using finer finishing passes with appropriate tools will also yield smoother results.

Why is brass CNC machining tricky?

Brass CNC machining can be tricky due to its varied alloys and their specific properties. Some brasses are very soft and ductile, leading to long chips and burrs.

Others are abrasive, causing rapid tool wear. Managing thermal expansion and maintaining tight tolerances also adds to the complexity.