Accurate brass CNC machining costs involve material, machine time, tooling, and finishing. A clear brass CNC quotation provides a detailed breakdown, ensuring transparent CNC brass pricing and a comprehensive brass machining cost breakdown for optimal budget management.

Are hidden costs and opaque quotes in brass CNC machining eroding your project budgets and causing unexpected delays? Discover the true components of brass part pricing and learn how to secure high-quality, precise parts with absolute cost clarity. In our experience, transparency is key to building trust and fostering long-term partnerships.

Understanding the intricate factors that drive brass CNC machining costs is essential for engineers and procurement managers. This guide from ly-machining, a direct source manufacturer, demystifies the quotation process. We aim to equip you with the knowledge to make informed decisions and optimize your budget without compromising quality.

Understanding Brass CNC Machining Costs

Key Factors in Brass Part Pricing

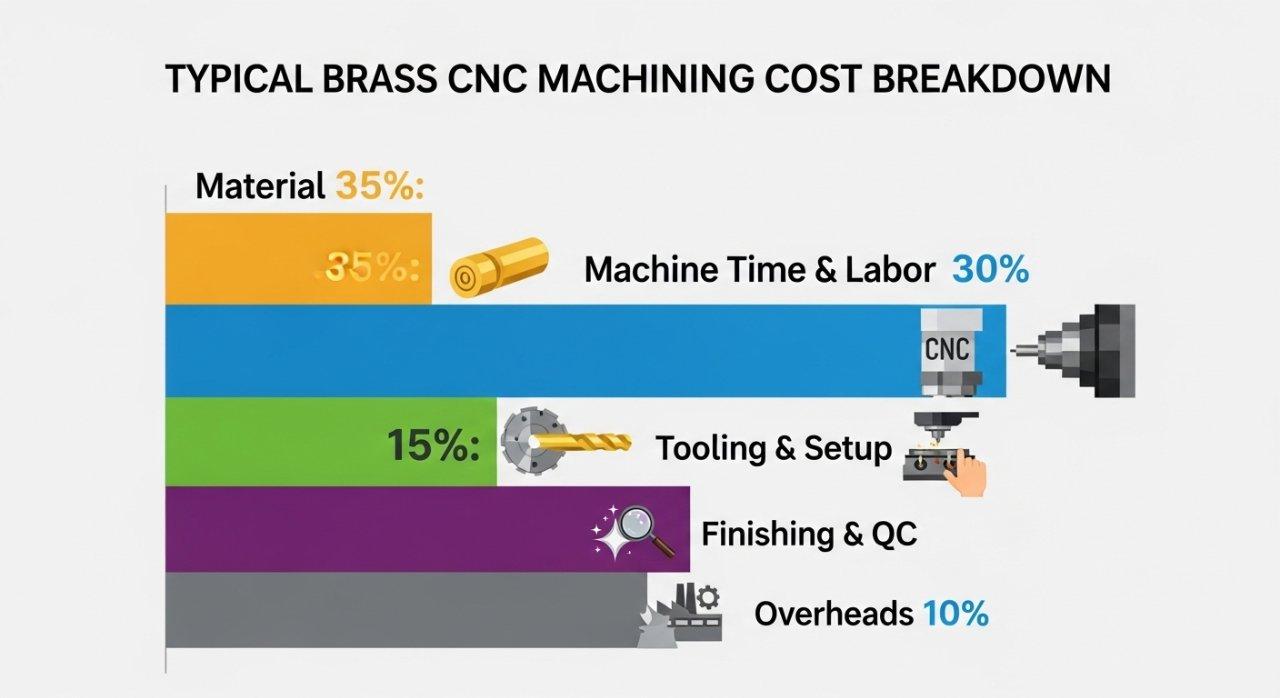

The overall brass CNC machining cost is a complex calculation, influenced by multiple interdependent variables. From the initial material selection to the final quality assurance checks, each stage contributes significantly to the final price point. A clear brass machining cost breakdown is crucial.

A common issue we see is overlooking the cumulative effect of these factors, leading to unexpected budget overruns if not properly analyzed upfront. Our approach provides full visibility.

Material Cost: Brass Alloys Explained

Brass is an alloy of copper and zinc, with varying compositions offering different properties and machinability. The specific alloy chosen directly impacts material cost and machining efficiency.

For example, free-machining brass (C36000) is highly valued for its excellent machinability, reducing machine time and tooling wear, thus lowering overall CNC brass pricing. Other alloys, like lead-free brass, may be more expensive and harder to machine.

Different brass alloys possess distinct mechanical properties, directly affecting their suitability for specific applications and their ease of machining. Understanding these nuances is critical for cost-effective part production.

| Brass Alloy | Primary Characteristics | Machinability Index (C36000 = 100%) | Typical Cost Impact (Relative) |

|---|---|---|---|

| C36000 | Free-machining, high strength | 100% | Medium |

| C26000 | Cartridge brass, good ductility | 30% | Medium-High |

| C46400 | Naval brass, corrosion resistant | 60% | High |

| C83600 | Red brass, excellent castability | 80% | Medium-High |

Machine Time & Labor Impact

Machine time is determined by part complexity, tolerance requirements, and the volume of material to be removed. More intricate geometries and tighter tolerances demand longer machining cycles and more skilled labor.

Our engineers optimize tool paths and machining strategies to minimize machine time without compromising part quality. This directly translates to competitive brass CNC machining costs for our clients.

Tooling & Setup Costs

Tooling costs encompass cutting tools, fixtures, jigs, and specialized inserts required for specific part geometries. For custom or complex parts, significant Non-Recurring Engineering (NRE) costs might be involved.

Setup time refers to the effort required to prepare the CNC machine for a production run, including programming, tool loading, and initial calibration. Higher volumes can amortize these costs more effectively.

Finishing & Quality Control Expenses

Surface finish requirements, such as polishing, plating (e.g., nickel, chrome), or passivation, add to the overall cost. Each finishing process involves additional labor and material expenses.

Quality control (QC) is an integral part of our process, ensuring parts meet exact specifications. Comprehensive inspection, including CMM measurements, adds value but is factored into the final brass CNC quotation.

| Common Brass Surface Finishes | Typical Application | Cost Factor (Relative) |

|---|---|---|

| As-machined | Functional, internal | Low |

| Polished | Aesthetic, smooth | Medium |

| Clear Coat Lacquer | Anti-tarnish | Medium |

| Nickel Plating | Wear resistance | High |

| Chrome Plating | Hardness, aesthetics | High |

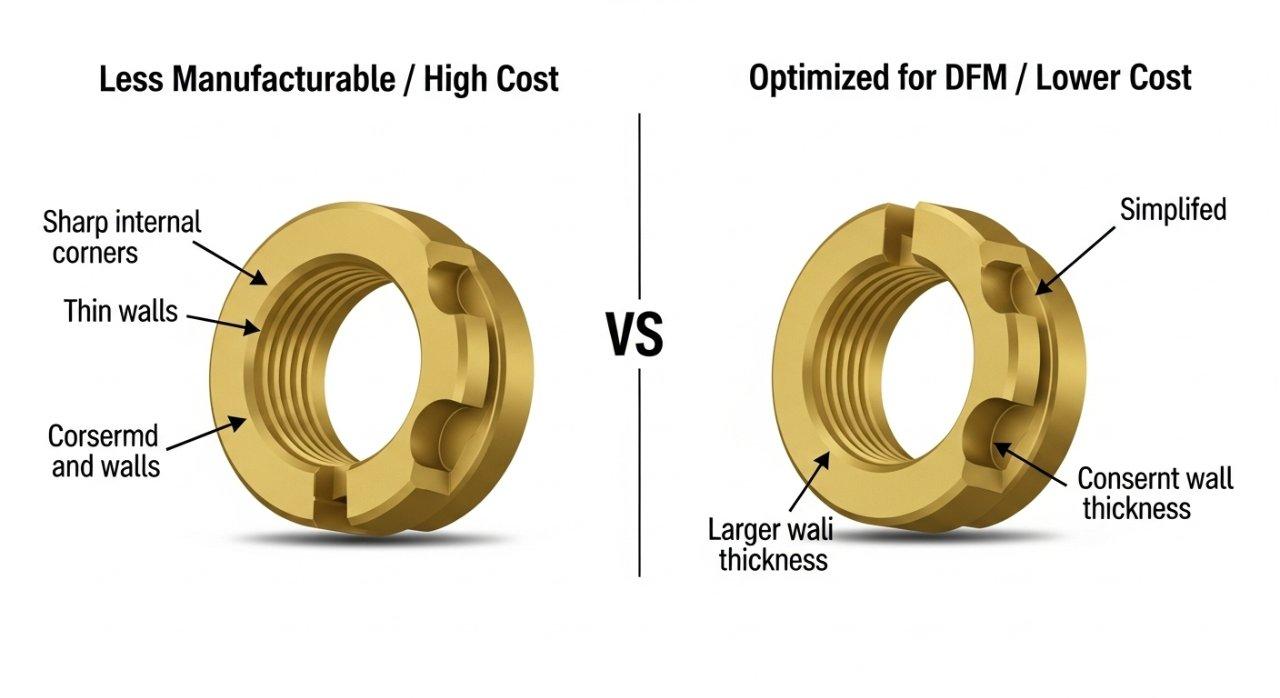

Design for Manufacturability (DFM) Influence

Design for Manufacturability (DFM) is crucial for cost-effective brass parts. A well-optimized design can significantly reduce material waste, machine time, and the need for complex tooling, lowering the brass machining cost breakdown.

In our experience, early DFM consultation can prevent costly redesigns and production challenges down the line. We collaborate closely with R&D engineers to refine designs for optimal production.

Transparent Brass CNC Quotation Process

Our Transparent Pricing Model

We believe in absolute transparency when it comes to brass CNC quotation. Our quotes provide a clear, line-item breakdown of all costs, including material, machine time, tooling, finishing, and quality control.

This detailed approach allows our clients, especially procurement managers, to understand precisely where their budget is allocated. It ensures there are no hidden fees or unexpected charges, fostering trust.

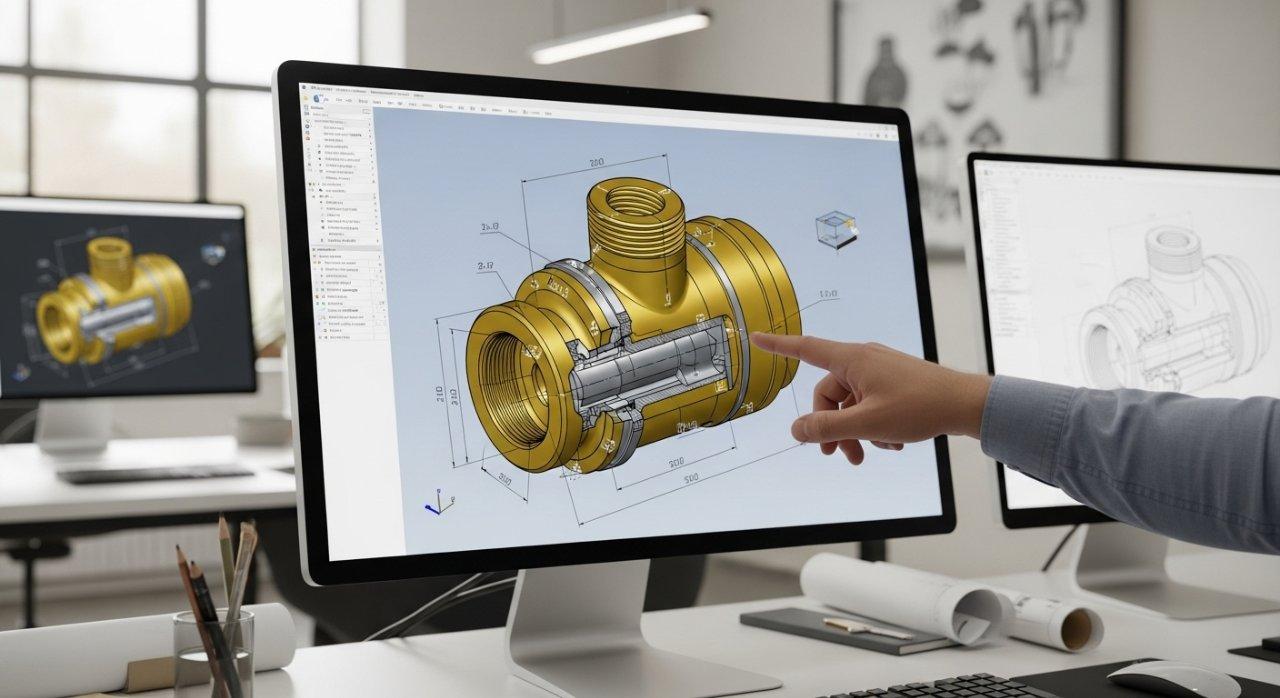

How We Analyze Your Project Needs

Every brass CNC machining project begins with a thorough technical review of your specifications, CAD models, and application requirements. Our expert engineers assess machinability and identify potential DFM improvements.

This proactive analysis allows us to provide the most accurate and competitive brass CNC pricing. It ensures that the proposed solution is technically sound and economically viable for your specific needs.

Avoiding Hidden Fees in Brass Machining

As a direct source manufacturer, ly-machining controls every aspect of the production process. This eliminates the markups and communication delays often associated with resellers or brokers.

Our direct factory model ensures that the brass machining cost breakdown you receive is comprehensive and reflective of the actual production expenses, with no surprises.

Custom Quotes for Unique Brass Parts

We understand that every project is unique, especially when dealing with specialized brass components. We don’t offer generic pricing. Instead, we provide custom, project-specific brass CNC quotation.

Our technical team works with you to develop a tailored solution that meets your exact performance and budget requirements, from prototyping to high-volume production.

Optimizing Your Brass CNC Machining Budget

Strategies for Cost Reduction

Optimizing your budget for brass CNC machining involves several key strategies. Volume discounts for larger orders can significantly reduce unit costs as setup and tooling expenses are amortized over more parts.

Material selection, as discussed, is another critical area. Choosing the most suitable brass alloy that balances performance and machinability can yield substantial savings in the long run.

Value of a Source Manufacturer

Partnering with a direct source manufacturer like ly-machining offers unparalleled advantages in cost control and quality assurance. You benefit from direct communication, expert technical support, and streamlined supply chains.

This direct relationship reduces overheads and minimizes risks, leading to more predictable brass CNC pricing and a reliable supply of high-quality parts.

Long-Term Cost-Effectiveness

While initial brass CNC machining costs are important, focusing on long-term cost-effectiveness is vital. High-quality parts produced with precision and consistency minimize rework, assembly issues, and field failures.

Our commitment to quality ensures that your brass components perform reliably, reducing warranty claims and enhancing your product’s reputation, ultimately saving you money over its lifecycle.

Partnering for High-Quality Brass Parts

Our Commitment to Precision

At ly-machining, precision is not just a goal; it’s our standard. Our state-of-the-art CNC equipment, coupled with rigorous quality control processes, ensures that every brass part meets the tightest tolerances.

We adhere to strict quality management systems, which are implicitly aligned with industry standards for consistent and reliable production. This commitment underpins our accurate brass CNC quotation.

Why Choose Our Expertise

Our team comprises highly skilled engineers and machinists with decades of collective experience in brass CNC machining. We possess in-depth knowledge of brass alloys, machining techniques, and DFM principles.

This expertise allows us to tackle even the most challenging projects, providing innovative solutions and ensuring optimal outcomes. We offer comprehensive support beyond just the brass machining cost breakdown.

Case Studies: Brass Machining Success

A recent client, a manufacturer of high-end hydraulic systems, faced significant challenges with their previous supplier’s inconsistent brass valve components. Tolerances were frequently out of spec, causing costly assembly failures and delays.

Our solution involved a complete DFM review, optimizing the valve body design for improved machinability and stricter process controls. We implemented a multi-stage inspection protocol using advanced CMM. The result was a dramatic reduction in defective parts, improved assembly efficiency, and a 15% overall cost saving through reduced rework.

Get Your Brass CNC Quote Today

How to Request Your Quote

Ready to experience transparent brass CNC quotation and superior quality? Requesting a quote from ly-machining is straightforward. Simply submit your CAD files and specifications through our website.

Our team will promptly review your project requirements and provide a detailed, itemized brass CNC quotation that clarifies all brass CNC machining costs involved.

Expert Consultation Available

Beyond just a brass machining cost breakdown, we offer complimentary technical consultations. Our engineers are available to discuss your designs, recommend optimal brass alloys, and suggest DFM improvements.

This proactive engagement ensures that your project benefits from our extensive expertise from the outset, guaranteeing the best possible outcome for your brass components.

Get Your Brass CNC Quote Today

Invite readers to get a free quote or technical consultation.

Ready for clear pricing and premium brass parts? Request your transparent, no-obligation brass CNC machining quote today, or consult with our technical experts for a personalized DFM review of your brass component designs.

FAQ Section

What drives brass machining cost?

Brass machining cost is primarily driven by material type, part complexity, machine time, and the required surface finish. Higher precision and intricate geometries increase both machine time and labor.

Tooling and setup costs also contribute significantly, especially for small batch orders requiring specialized tools. Quality control and any post-machining treatments are also factored in.

How to get accurate brass CNC pricing?

To get accurate brass CNC pricing, provide detailed CAD models, precise technical drawings with tolerances, material specifications, and desired surface finishes. Clearly state your required volume and lead time.

Engaging with a direct source manufacturer and discussing Design for Manufacturability (DFM) early on ensures a comprehensive and accurate brass CNC quotation without hidden fees.

Can I reduce my brass part costs?

Yes, you can reduce brass part costs through several strategies. Consider optimizing your design for manufacturability (DFM) by simplifying geometries and loosening non-critical tolerances.

Choosing a standard brass alloy that meets your performance needs, ordering in higher volumes, and consolidating designs can also lead to significant savings. Partnering with a reliable source manufacturer offers the best value.