Quick Solution: Achieving precision with POM in CNC machining hinges on a deep understanding of its unique material properties, allowing for tailored processes that minimize defects and ensure high-quality output.

When designing components, is your team leveraging the full potential of engineering plastics like POM, or are you held back by perceived machining limitations? Polyoxymethylene, often known as acetal or Delrin, is a thermoplastic renowned for its exceptional mechanical strength, stiffness, and low friction, making it a staple in demanding applications. However, transforming raw POM into high-precision parts via CNC machining requires more than standard practices; it demands a nuanced approach driven by a profound understanding of its material characteristics.

In our experience, manufacturers frequently underestimate the subtle yet critical ways POM’s intrinsic properties influence its machinability. This often leads to issues like burring, poor surface finish, and dimensional inaccuracies that can derail even the most meticulously planned projects. This article will delve into the essential material properties of POM, offering insights and strategies that only a seasoned CNC machining factory can provide, ensuring your next project achieves unparalleled precision and performance.

Unlocking POM’s Potential in CNC Machining

Why POM is a Top Choice for Precision CNC

POM, or Polyoxymethylene, stands out as an engineering plastic due to its impressive balance of properties. It offers excellent rigidity, high strength, and a low coefficient of friction, which are crucial for components requiring smooth movement and durability. Its inherent dimensional stability is also a key advantage, especially for parts needing tight tolerances.

These characteristics make POM an ideal material for gears, bearings, electrical connectors, and automotive components. Its natural lubricity and resistance to wear ensure a long service life, even under continuous use, differentiating it from many other plastics. Our CNC machining expertise allows us to harness these strengths fully.

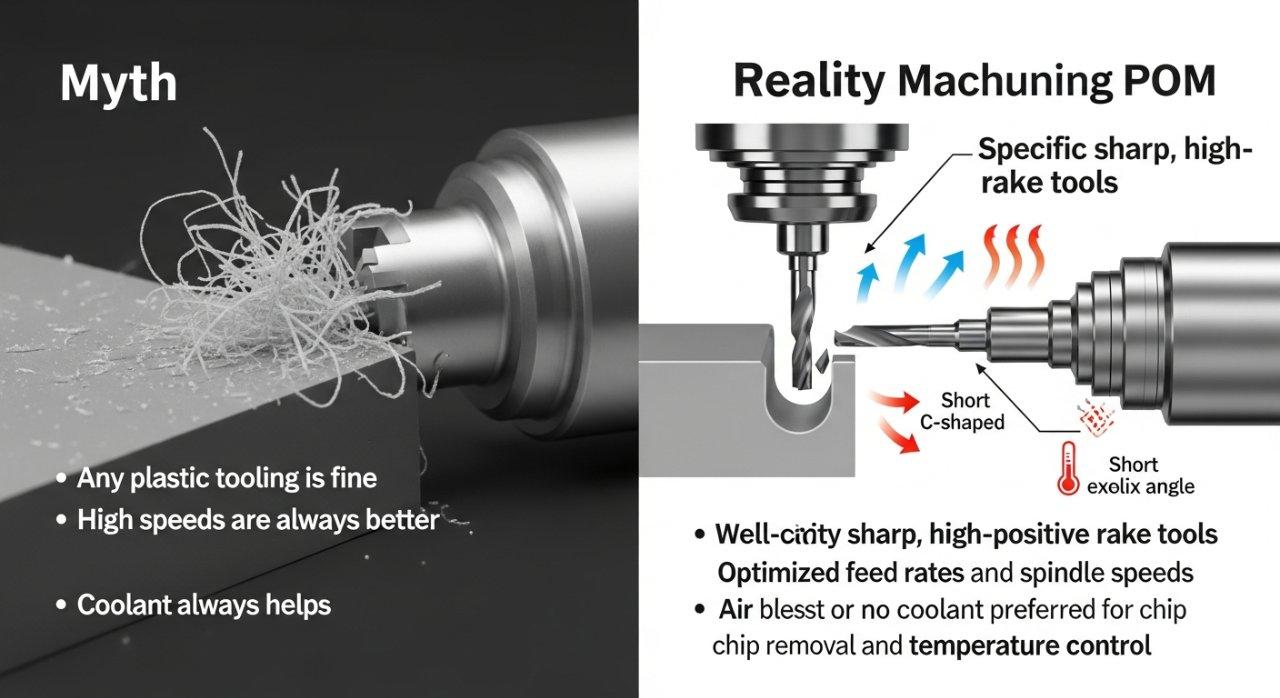

Common Misconceptions About Machining POM

A frequent misconception is that POM machines similarly to other commodity plastics. In reality, its semi-crystalline structure and low thermal conductivity present unique challenges. Incorrect tooling or cutting parameters can lead to excessive heat buildup, causing melting, poor chip evacuation, and significant burring.

Another pitfall is underestimating the material’s tendency to deform under machining stress. Without proper fixturing and stress relief, parts can warp after release, compromising dimensional accuracy. Addressing these nuances is fundamental to achieving high-quality POM parts.

Core POM Material Properties for Analysis

Mechanical Strength and Rigidity in POM

POM exhibits excellent mechanical strength, rigidity, and hardness, making it highly resistant to deformation under load. This allows for the creation of parts that maintain their shape and function in demanding applications. The material’s high tensile strength and flexural modulus are particularly beneficial.

However, this rigidity also means POM can be prone to chipping if machining forces are too high or tooling is dull. Precision CNC machining must account for this, using sharp tools and optimized feed rates to prevent material fracture.

Thermal Expansion and Stability in POM CNC

POM has a relatively high coefficient of linear thermal expansion compared to metals. This is a critical factor in CNC machining, as temperature fluctuations during processing can lead to significant dimensional changes. Parts machined to tight tolerances at one temperature may not meet specifications when measured at another.

In our experience, managing thermal stability requires careful control of cutting fluids, optimized feed rates to reduce heat generation, and allowing parts to normalize before final inspection. Consideration of the operating temperature of the final product is also essential for accurate design.

Low Friction and Wear Resistance of POM

The low coefficient of friction and excellent wear resistance of POM are among its most attractive properties for engineers. This makes it ideal for components that require smooth, unlubricated operation, such as bearings, gears, and sliding elements. Its self-lubricating nature reduces the need for external lubricants.

While beneficial in application, this property also influences chip formation during CNC machining. Chips can be continuous and stringy, requiring specific chip breaking strategies to prevent tool wrap and ensure clear cutting zones.

Chemical Resistance and Environmental Impact on POM

POM offers good resistance to a wide range of chemicals, including many solvents, fuels, and strong alkalis. This makes it suitable for environments where exposure to harsh substances is a concern, enhancing part longevity. It also performs well in moist environments, with low water absorption.

However, POM is susceptible to strong acids and oxidizing agents. Understanding the specific chemical environment of the final application is crucial during material selection and, by extension, for post-machining cleaning processes to avoid material degradation.

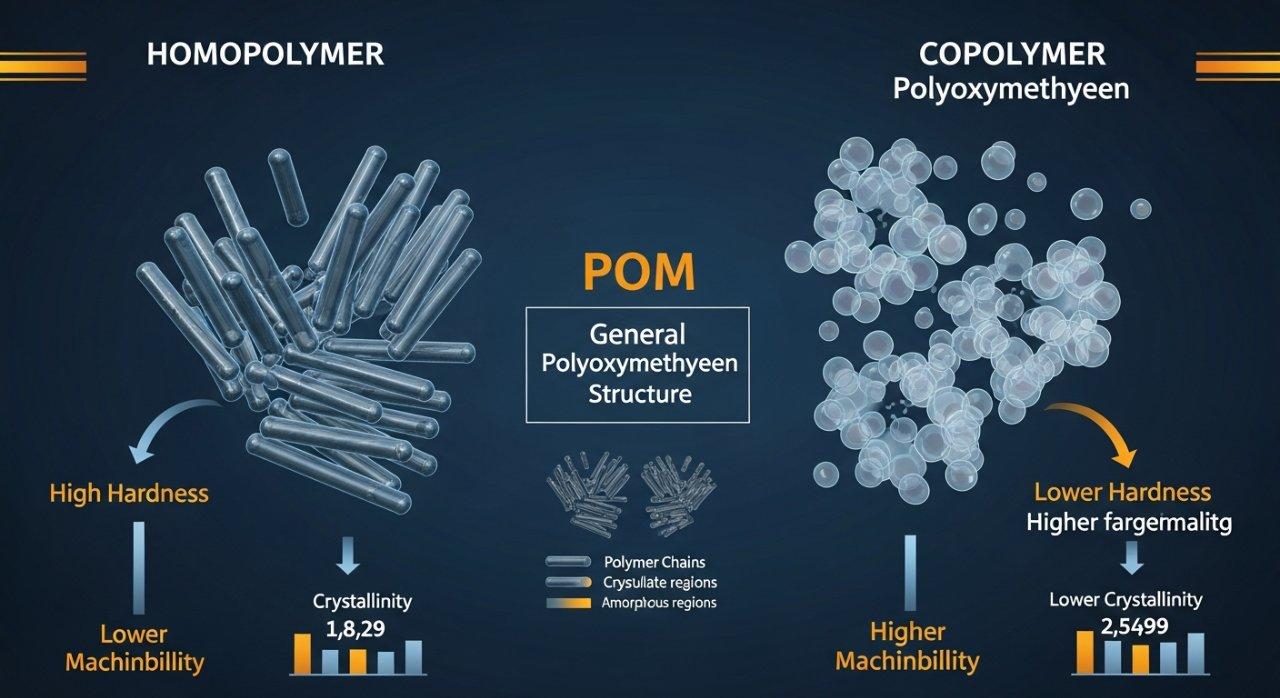

How Crystallinity Affects POM Machinability

POM is a semi-crystalline thermoplastic, meaning it has both amorphous and crystalline regions. The degree of crystallinity significantly impacts its mechanical properties, including hardness, stiffness, and density. Homopolymer POM generally has higher crystallinity than copolymer POM.

Higher crystallinity typically translates to greater strength and rigidity, but can also make the material more brittle and prone to chipping if not machined correctly. This difference necessitates subtle adjustments in cutting parameters and tooling between homopolymer and copolymer grades to achieve optimal results.

Overcoming CNC Machining Challenges with POM

Mitigating Burring and Edge Quality in POM

Burring is a prevalent challenge when CNC machining POM, often leading to costly post-processing. Its inherent ductility and low melting point can cause material to smear rather than cleanly shear, forming burrs on edges. This is especially true with dull tooling or incorrect feed/speed combinations.

Our approach involves employing extremely sharp, high-rake angle tooling, often with polished flutes to facilitate chip evacuation. We also utilize specific cutting strategies like climb milling and, where appropriate, integrate deburring operations into the machining cycle or through specialized post-machining steps.

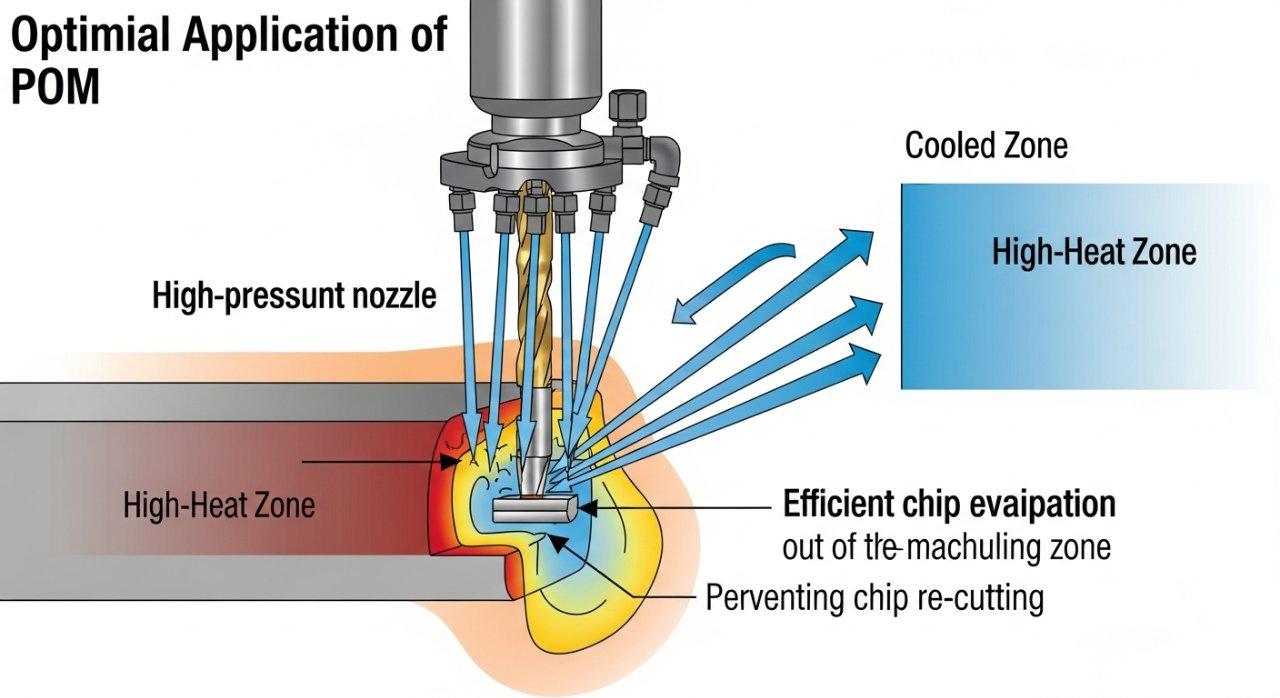

Managing Heat Generation in POM CNC Processes

Excessive heat is the arch-nemesis of precision POM machining. It can lead to thermal expansion, melting, poor surface finish, and accelerated tool wear. Unlike metals, POM dissipates heat poorly, making active heat management critical.

Our strategies include using generous flood coolants, optimizing cutting speeds and feed rates to minimize friction, and ensuring efficient chip evacuation. In some cases, specialized air blasts or cryogenic cooling may be employed to maintain stable temperatures.

Achieving Tight Tolerances in POM Machining

Achieving tight tolerances with POM requires a holistic approach, considering material properties, machining parameters, and environmental factors. Its thermal expansion requires temperature-controlled machining environments and careful measurement strategies. Residual stress in the material can also lead to part distortion.

Our factory mitigates these challenges through meticulous process control, including stress-relieving annealing for specific applications and designing fixtures that gently support the part without inducing stress. We ensure consistent dimensional accuracy even for the most demanding specifications.

Surface Finish Excellence for CNC POM Parts

The desired surface finish for POM parts, often measured in Ra value, depends heavily on machining parameters. A poor surface finish can compromise functional performance, particularly in moving parts. Issues like tool marks, chatter, and melted spots are common if not controlled.

To achieve superior surface finishes, we utilize high spindle speeds, lower feed rates, and highly polished cutting edges. Multi-pass strategies, including a dedicated finishing pass with minimal material removal, are also employed to refine the surface.

Expert Strategies for Quality POM Parts

Tooling and Fixturing for Optimal POM CNC

Proper tooling is paramount for successful POM CNC machining. We typically use sharp, positive-rake geometry tools, often carbide-tipped, designed for plastics. High helix angles aid in chip evacuation, preventing chip welding and re-cutting. For specific applications, diamond-tipped tools may be used.

Fixturing must secure the part firmly without deforming it or obstructing chip flow. Vacuum fixtures or custom soft jaws are frequently employed to prevent marring and ensure consistent clamping pressure across the workpiece, minimizing induced stresses.

Cutting Parameters Best Practices for POM

Optimizing cutting parameters is a science when working with POM. High cutting speeds with moderate feed rates generally yield the best results, producing clean cuts and reducing heat. However, specific grades of POM and part geometries necessitate fine-tuning.

Here’s a general guideline for initial parameters, which we then adjust based on part complexity and desired finish:

| Parameter | Typical Range (General Guideline) | Notes |

|---|---|---|

| Spindle Speed | 5000 – 15000 RPM | Higher for smaller tools/finer finish |

| Feed Rate | 0.05 – 0.2 mm/tooth | Balances chip load and surface finish |

| Depth of Cut | 0.5 – 5 mm | Depends on rigidity and power available |

| Rake Angle | 10° – 20° positive | Promotes clean shearing |

| Helix Angle | 30° – 45° | Aids chip evacuation and reduces friction |

Post-Machining Techniques for Perfect POM

Even with optimized CNC machining, some POM parts benefit from specific post-machining processes. Deburring is often necessary to remove any residual material, ensuring smooth edges and adherence to strict functional requirements. This can be done manually or through automated vibratory finishing.

For parts requiring extremely tight tolerances or improved dimensional stability, annealing can be performed. This process relieves internal stresses induced during manufacturing, preventing warping or creep over time, especially in critical applications.

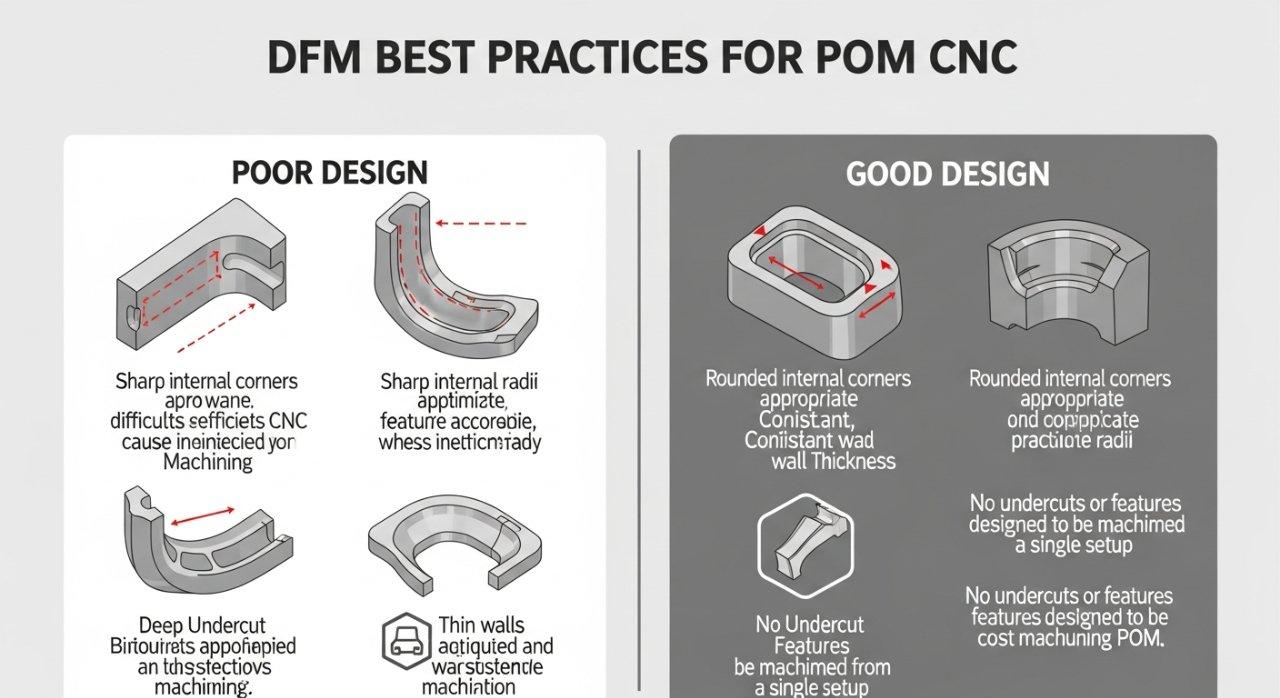

DFM Insights for Cost-Effective POM CNC Parts

Design for Manufacturability (DFM) is crucial for cost-effective POM CNC projects. Simple design considerations can significantly reduce machining time and complexity, ultimately lowering costs. Avoiding sharp internal corners, designing for standard tool sizes, and minimizing deep pockets are key.

Our engineers collaborate closely with clients during the design phase, providing expert DFM insights. This proactive approach ensures that parts are not only functional but also efficiently manufacturable, optimizing both quality and overall project budget.

Our Expertise in Precision POM Machining

Leveraging Deep Technical Expertise for POM

At ly-machining, our deep technical expertise in CNC machining POM is a cornerstone of our service. Our team of experienced engineers and machinists possess an intimate understanding of POM’s unique behavior under various cutting conditions, from homopolymer to copolymer grades. This allows us to predict and mitigate challenges before they arise, delivering exceptional results.

We invest in state-of-the-art machinery and continuous training, ensuring our processes remain at the forefront of precision manufacturing. This commitment translates directly into higher quality, more consistent POM components for your critical applications.

High-Quality POM Parts from a Source Manufacturer

As a source manufacturer, we maintain complete control over every stage of the CNC machining process, from material sourcing to final inspection. This comprehensive oversight guarantees the highest quality POM parts that consistently meet and exceed industry standards, including ISO and AS9100 where applicable.

Our robust quality assurance protocols ensure every component is dimensionally accurate, functionally sound, and meets your exact specifications. This commitment to quality is why clients trust us with their most challenging POM projects.

Transparent Pricing for Your POM CNC Projects

We believe in transparent pricing, providing clear and detailed quotes for all our POM CNC machining projects. Our quotes break down costs associated with material, machining time, tooling, and any post-processing, giving you a complete understanding of your investment. This approach builds trust and ensures no hidden surprises.

We provide a comprehensive cost analysis and work with you to identify areas for optimization without compromising quality. Our goal is to offer competitive pricing coupled with unparalleled precision and reliability for your POM components.

Case Studies: Complex POM Solutions via CNC

Problem: A client in the medical device sector required a complex POM component for a new diagnostic instrument. The part featured extremely thin walls, intricate internal channels, and a demanding surface finish (Ra 0.4 µm) to ensure fluidic precision, all while maintaining ±0.015 mm tolerances. Previous suppliers struggled with burring, wall deformation, and achieving the required surface quality.

Our Solution: Our engineering team meticulously analyzed the design, recommending specific tooling with custom-ground, high-positive rake angles and polished flutes. We developed a multi-stage CNC program incorporating fine finishing passes with very high spindle speeds and carefully controlled feed rates. A specialized fixture was designed to support the thin walls without inducing stress. We implemented an in-line, localized air-blast cooling system to manage heat in the thin-walled areas, preventing melting and burr formation. Post-machining, a gentle vibratory deburring process followed by vapor polishing was used to achieve the ultra-smooth internal channels.

Result: ly-machining successfully delivered a batch of 5,000 POM components that not only met but exceeded all specified tolerances and surface finish requirements. The client reported improved fluidic performance in their diagnostic instrument and praised our ability to tackle a challenge that other manufacturers deemed impossible, leading to a long-term partnership.

Conclusion and Your Next POM Project

Partnering for Flawless CNC POM Component Success

Understanding the material properties of POM is not just academic; it’s the foundation of successful CNC machining. From managing thermal expansion to mitigating burring and ensuring exceptional surface finishes, every aspect of the process demands a deep, experienced hand. Our factory’s commitment to technical precision, quality, and a client-focused approach ensures your POM components are manufactured to the highest standards.

Choosing the right manufacturing partner is as crucial as selecting the right material. With ly-machining, you gain a partner dedicated to unlocking the full potential of POM for your most demanding applications, backed by transparent processes and consistent results.

Request a Transparent Quote for POM Machining

Ready to elevate your POM part precision and performance? Don’t let machining complexities limit your design. Contact our CNC machining experts today for a personalized consultation and a transparent, no-obligation quote. Leverage our deep technical expertise and source manufacturer advantage to ensure your next POM project is a resounding success.

FAQ Section

What is POM and why use it?

POM, or Polyoxymethylene, is an engineering thermoplastic known for its high strength, stiffness, low friction, and excellent dimensional stability. It is often used for precision parts like gears and bearings.

Its properties make it ideal for applications requiring durability and smooth operation. We frequently machine POM for clients needing reliable, high-performance plastic components.

What are common POM machining issues?

Common issues include burring, thermal expansion causing dimensional inaccuracies, and poor surface finish. These stem from POM’s semi-crystalline structure and low thermal conductivity.

Our expert CNC machining processes are designed to specifically address these challenges. We employ specialized tooling and cutting parameters to mitigate these problems.

Can you achieve tight tolerances with POM?

Yes, we routinely achieve tight tolerances with POM by employing rigorous process controls. This includes managing thermal effects, stress relief, and using precision tooling.

Our engineers apply their deep material knowledge to ensure dimensional accuracy. We deliver parts that consistently meet the strictest client specifications.