Why CNC Thrives with Diverse Materials

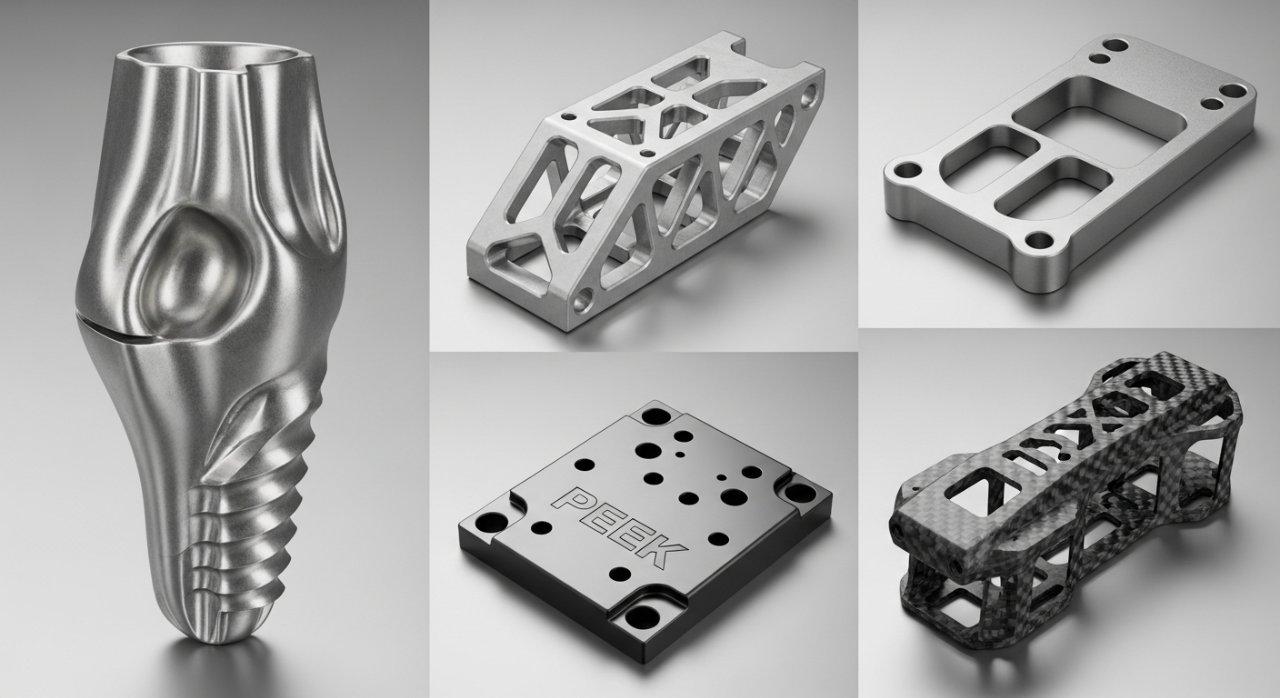

CNC machining masters diverse materials. Its precision, advanced tooling, and software deliver complex, high-quality parts from metals, plastics, and composites. A core CNC machining benefit.

Is your next breakthrough product held hostage by material limitations? In an era where innovation demands increasingly diverse and specialized materials, conventional manufacturing often falls short. This challenge is precisely why CNC machining has become indispensable.

Understanding `why CNC machining` can navigate these complexities is crucial for any product developer or procurement manager. This technology is not just adapting; it is thriving in tackling the toughest material challenges.

We will explore how advanced `CNC manufacturing` ensures your designs move from concept to reality, no matter the substance. Our deep technical expertise makes the critical difference, delivering `high-quality CNC parts`.

Addressing Material Challenges with CNC Machining

Why Modern Manufacturing Demands Diverse CNC Machining

Modern product development pushes the boundaries of material science. Designers require components made from exotic alloys, high-performance plastics, and advanced composites. Each material presents unique machining difficulties.

These challenges include extreme hardness, poor thermal conductivity, abrasiveness, or susceptibility to delamination. Without a robust solution, material choices can severely limit design and functionality.

In our experience, `CNC machining benefits` are evident in its capacity to adapt. It precisely controls tooling paths and parameters, crucial for working with these specialized materials without compromising their integrity.

What is CNC Machining Used For in Tough Material Cases?

`What is CNC machining used for` when facing tough material challenges? It’s employed for creating intricate aerospace components from Inconel, medical implants from titanium, or lightweight automotive parts from carbon fiber.

`Precision milling` operations are vital for maintaining tight tolerances and achieving critical surface finishes. This is particularly important for parts where material properties must remain uncompromised after machining.

For example, `CNC manufacturing` excels in processing high-strength steels for tooling, where conventional methods would lead to excessive wear or part distortion. It ensures material integrity throughout the production cycle.

Core CNC Capabilities for Varied Material Handling

Precision and Control: A Key CNC Machining Benefit

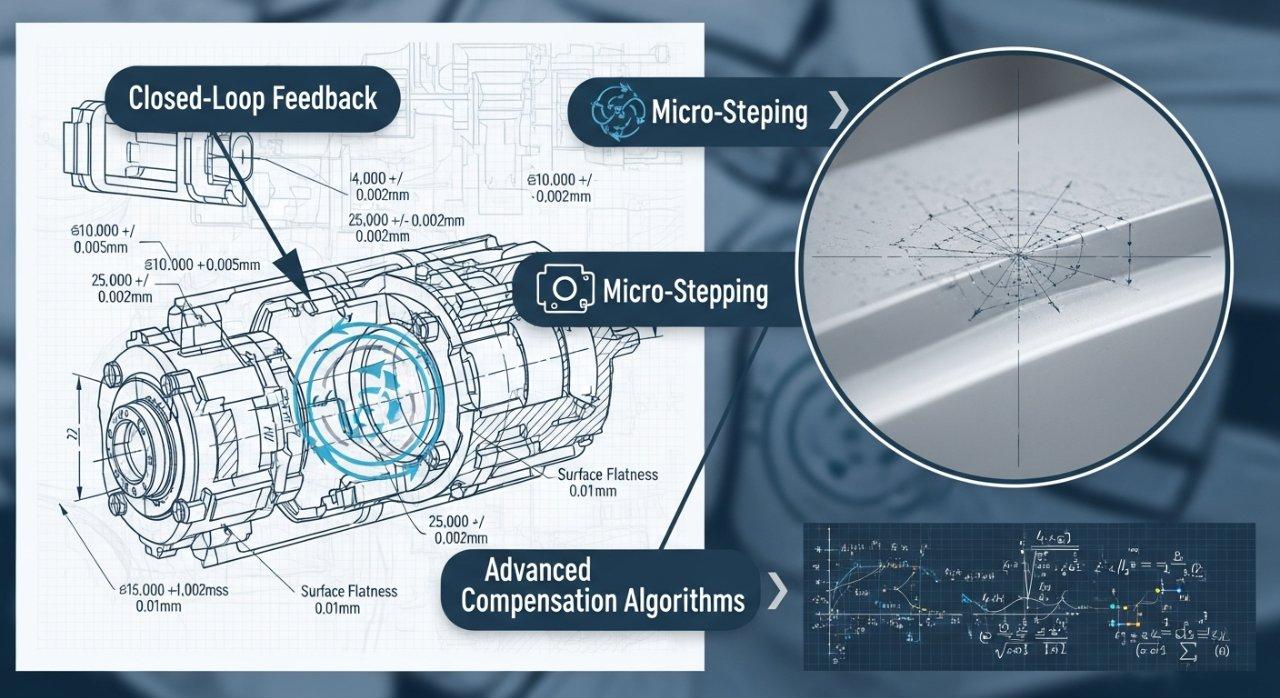

The fundamental advantage of `CNC machining` is its unparalleled precision and control. Computer Numerical Control allows for exact replication of complex designs. This level of control is paramount for diverse materials.

Parameters such as feed rate, spindle speed, and depth of cut can be finely tuned for each specific material. This prevents issues like excessive heat generation, tool wear, or poor surface finish.

This `CNC machining benefit` ensures that even the most delicate or hard-to-machine materials can be processed accurately. It consistently meets the tightest tolerances required by industry standards like ISO 2768.

Advanced Tooling & Fixturing: How CNC Excels

The versatility of `CNC manufacturing` extends to its tooling. Specialized cutting tools, often made from advanced ceramics, carbides, or coated with diamond-like carbon, are designed for specific material properties.

For instance, tools for aluminum are designed for high chip evacuation, while those for titanium focus on heat resistance and strength. Fixturing also plays a critical role, ensuring secure workpiece clamping to prevent vibration and maintain stability.

In our factory, we select and design custom fixtures for challenging geometries and brittle materials. This holistic approach to tooling and fixturing is `why CNC machining` successfully processes such a wide array of substances.

Software & Simulation: Optimizing Diverse CNC Machining

Modern CAM (Computer-Aided Manufacturing) software is at the heart of optimizing `diverse CNC machining`. It allows engineers to simulate the machining process before any material is cut.

This simulation identifies potential collisions, optimizes tool paths, and predicts material behavior under specific cutting conditions. It’s an essential step, especially for expensive or difficult-to-machine materials.

The ability to fine-tune parameters and strategies virtually reduces waste and saves significant time and cost. It’s a key factor in `why CNC machining` is so adaptable across different material types.

Machine Rigidity & Power: Why CNC Works for Hard Materials

High-end `CNC machines` are engineered for exceptional rigidity and power. This robust construction is essential when machining hard metals and exotic alloys that require substantial force and stability.

Heavy-duty spindles and stable machine frames minimize vibration and deflection, which are critical for maintaining precision and extending tool life. This ensures consistent part quality even under aggressive cutting.

A common issue we see with less rigid machines is chatter, leading to poor surface finish and premature tool wear. Our advanced machinery overcomes these obstacles, demonstrating `why CNC machining` excels.

Handling Specific Material Groups with CNC

Machining Hard Metals & Exotic Alloys with CNC

Hard metals and exotic alloys like titanium, Inconel, and hardened steels are notoriously difficult to machine. Their high strength, heat resistance, and sometimes low thermal conductivity pose significant challenges.

`CNC machining` employs strategies like specialized tool coatings, high-pressure coolant delivery, and specific cutting parameter adjustments. This prevents work hardening and ensures efficient chip evacuation.

In our experience, we meticulously adjust feed rates and spindle speeds. This tailored approach is `why CNC machining` consistently achieves excellent results with these demanding materials, meeting aerospace and medical standards.

Table: Machinability Considerations for Hard Metals & Exotic Alloys

| Material Type | Key Property | Machining Challenge | CNC Solution |

|---|---|---|---|

| Titanium | High strength, low thermal conductivity | Heat generation, work hardening | Specialized coatings, high-pressure coolant |

| Inconel | High temperature strength | Rapid tool wear, residual stress | Low speed, high feed, positive rake tools |

| Hardened Steel | High hardness | Abrasive wear, surface cracking | Ceramic inserts, stable fixturing |

Plastics & Composites: Nuances of CNC Processing

Machining plastics (e.g., PEEK, Delrin, ABS) and composites (e.g., carbon fiber, fiberglass) requires a different set of `CNC manufacturing` strategies. Plastics can melt or deform, while composites can delaminate or fray.

For plastics, sharp, highly polished tools and specific cooling techniques prevent material buildup and ensure a smooth finish. We often use lower spindle speeds and controlled feed rates to manage heat.

Composites demand diamond-coated tools and optimized feed rates to prevent fiber pull-out and delamination. Proper vacuum fixturing is also crucial to minimize vibration and secure the workpiece.

Table: Machinability Considerations for Plastics & Composites

| Material Type | Key Property | Machining Challenge | CNC Solution |

|---|---|---|---|

| PEEK | High thermal expansion | Melting, warping, burr formation | Sharp tools, air blast cooling, low feed |

| ABS | Low melting point | Melting, poor chip evacuation | Optimized flute design, precise speed/feed |

| Carbon Fiber | Abrasive, anisotropic | Delamination, fiber pull-out, dust | Diamond-coated tools, specific cutting angles |

Other Advanced Materials: What is CNC Machining’s Reach?

Beyond metals and common plastics, `what is CNC machining’s` reach for other advanced materials? This includes ceramics, specific foams, and specialized glass. Each requires unique approaches.

For example, high-speed, light-cut strategies are employed for ceramics to prevent chipping. Custom tool paths are designed to minimize stress points in brittle materials.

Our engineers collaborate closely with clients to understand the specific properties of novel materials. This ensures optimal machining strategies are developed, leveraging `CNC machining benefits` fully.

Why Choose CNC Machining for Your Material Needs?

Consistent Quality: A Core CNC Machining Benefit

Consistency in quality is paramount, especially when working with diverse and often expensive materials. `Why choose CNC machining`? Because its automated processes drastically reduce human error.

This leads to highly repeatable results, ensuring every part produced from a batch meets the exact specifications. For critical applications, this reliability is non-negotiable.

Our adherence to strict quality management systems, such as AS9100 and ISO 9001, further guarantees the consistent output of `high-quality CNC parts`, regardless of the material.

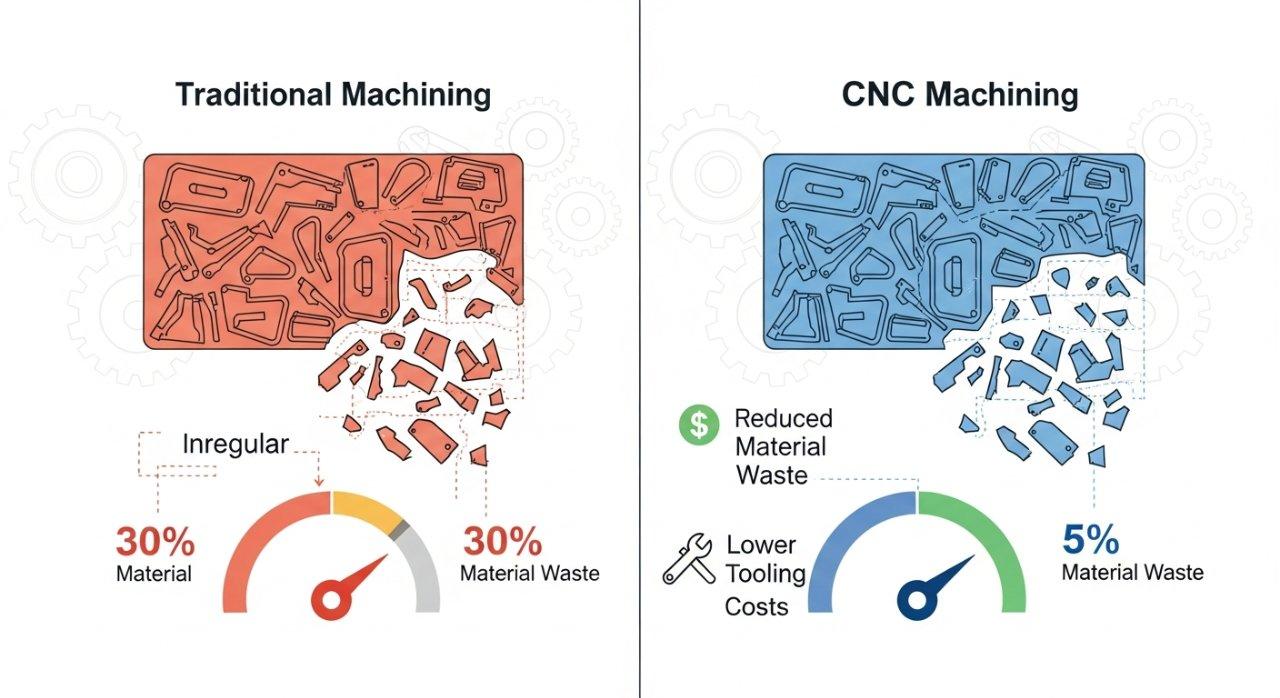

Cost-Efficiency & Waste Reduction: Why Choose CNC Machining?

`Why choose CNC machining` for cost-efficiency? The precision and control offered by CNC minimize material waste. This is particularly valuable when machining expensive or rare materials.

Optimized tool paths and reduced scrap rates translate into significant cost savings. Furthermore, faster turnaround times and reduced manual labor also contribute to overall economic benefits.

The ability to produce complex parts in a single setup also streamlines production. This efficiency is a tangible `CNC machining benefit` for our clients, directly impacting their bottom line.

Accelerated Prototyping & Production with CNC

The agility of `CNC machining` allows for rapid prototyping and quick transition to full-scale production. Design iterations can be quickly machined and tested, accelerating product development cycles.

For new products utilizing diverse materials, this speed is invaluable. It enables engineers to experiment with different material properties and designs without extensive delays.

This accelerated process ensures that `why CNC machining` is chosen frequently is because it supports innovation. It brings novel material applications to market faster and more reliably.

Our Expertise in Diverse Material CNC Machining

Deep Technical Knowledge: The Real Why CNC Machining Works

At `ly-machining`, our engineers possess deep technical knowledge in material science and `computer numerical control services`. This expertise is `the real why CNC machining works` so effectively with diverse materials.

We understand the specific behaviors of various alloys, polymers, and composites under different machining conditions. This knowledge informs every aspect of our process, from tool selection to coolant strategies.

Our team continuously researches new materials and advanced machining techniques. This commitment to expertise ensures we are always at the forefront of `CNC machining` capabilities.

Transparent Pricing: A Benefit of Our CNC Machining

A significant `benefit of our CNC machining` services is our commitment to transparent pricing. We provide detailed quotes that account for material specifics, complexity, and volume.

We ensure clients understand the breakdown of costs, especially for challenging materials that may require specialized tooling or longer cycle times. This fosters trust and builds long-term partnerships.

Our approach avoids hidden fees, offering clear cost expectations. This transparency is key to managing budgets effectively for projects involving `diverse materials`.

Source Manufacturer Advantage for High-Quality CNC Parts

As a `source manufacturer`, we control every aspect of the `CNC manufacturing` process, from material procurement to final inspection. This integrated approach is critical for delivering `high-quality CNC parts`.

Our direct control ensures strict quality control at every stage, especially when dealing with the unique demands of diverse materials. This eliminates potential quality issues that can arise from subcontracting.

This comprehensive oversight guarantees that all components meet the highest standards. It is a fundamental `CNC machining benefit` when seeking reliability and precision for challenging projects.

Conclusion: Embrace Material Freedom with CNC

The ability of `CNC machining` to adeptly handle diverse material challenges is a cornerstone of modern manufacturing. It empowers engineers to design without compromise, unlocking new possibilities for innovation.

From the hardest superalloys to the most delicate composites, `why CNC machining` is the solution lies in its precision, advanced tooling, and sophisticated software. These elements combine to deliver consistent quality and efficiency.

At `ly-machining`, we combine this technological prowess with deep expertise and a commitment to transparency. We ensure that your most demanding material specifications are met with unparalleled precision.

Ready for Your Next Diverse Material CNC Project?

Don’t let material complexities limit your innovation. Connect with our dedicated team of technical experts today for a free, no-obligation consultation. Let us show you `why CNC machining` is the right choice.

Get a transparent quote for your next project now! We transform your most ambitious material challenges into `high-quality CNC parts` with our advanced `computer numerical control services`.

FAQ Section

Can CNC machine any material?

CNC machining offers extensive versatility, handling a vast range of materials from standard aluminum and steel to exotic alloys like Inconel, and various plastics, ceramics, and composites. However, the machinability varies significantly. Specialized tooling, parameters, and machine rigidity are often required for harder or more abrasive materials to ensure successful processing and maintain part integrity.

What is the main benefit of CNC for new materials?

The main `CNC machining benefit` for new or diverse materials is its precise control over the cutting process. This allows for fine-tuning of parameters like speed, feed, and tool path to suit unique material properties. It minimizes common issues such as heat deformation, work hardening, or delamination, ensuring high-quality output and enabling faster prototyping cycles for innovative designs.

How does ly-machining ensure quality with diverse materials?

At `ly-machining`, we ensure quality with diverse materials through a combination of deep technical expertise, advanced machinery, and rigorous quality control. Our engineers select optimal tooling and machining strategies for each material. As a source manufacturer, we meticulously oversee every stage, adhering to standards like AS9100 to guarantee `high-quality CNC parts` and transparently communicate process specifics to our clients.