In the pursuit of premium, reliable components, understanding a factory’s quality control is paramount. Our integrated quality management system, refined over years of experience, guarantees durable CNC machining with unwavering precision.

For high-stakes projects requiring premium and reliable CNC machining, a factory’s quality control system is the bedrock of success. In our experience, inconsistent quality leads to costly delays and project failures. This article, from our perspective as a seasoned source manufacturer, delves into the meticulous processes that ensure every CNC machined part meets the highest standards.

We will explore how our deep technical expertise and comprehensive quality assurance protocols translate into consistently high-quality, durable solutions, offering transparent pricing and unparalleled reliability for your critical applications.

Why QC Matters for CNC Machining

The Cost of Poor Quality CNC Machining

In our industry, the cost of poor quality in CNC machining extends far beyond simple rework. It can lead to complete project failures, significant reputational damage, and substantial financial losses for our clients.

A common issue we see is the ripple effect of sub-standard components; a single faulty part can compromise an entire assembly, triggering extensive recalls and warranty claims. This underscores why a robust quality management system is non-negotiable for durable and reliable production.

Achieving Reliable Part Performance

Reliable part performance is not a luxury, but a fundamental requirement for many critical applications, from aerospace to medical devices. Our commitment to quality ensures that every CNC machined component performs exactly as designed.

We understand that our parts often become integral to larger, complex systems where failure is not an option. This perspective drives our rigorous quality control, making our premium CNC machining synonymous with trust and durability.

Our Factory’s Robust Quality Control System

Incoming Material Inspection: First Step to Quality

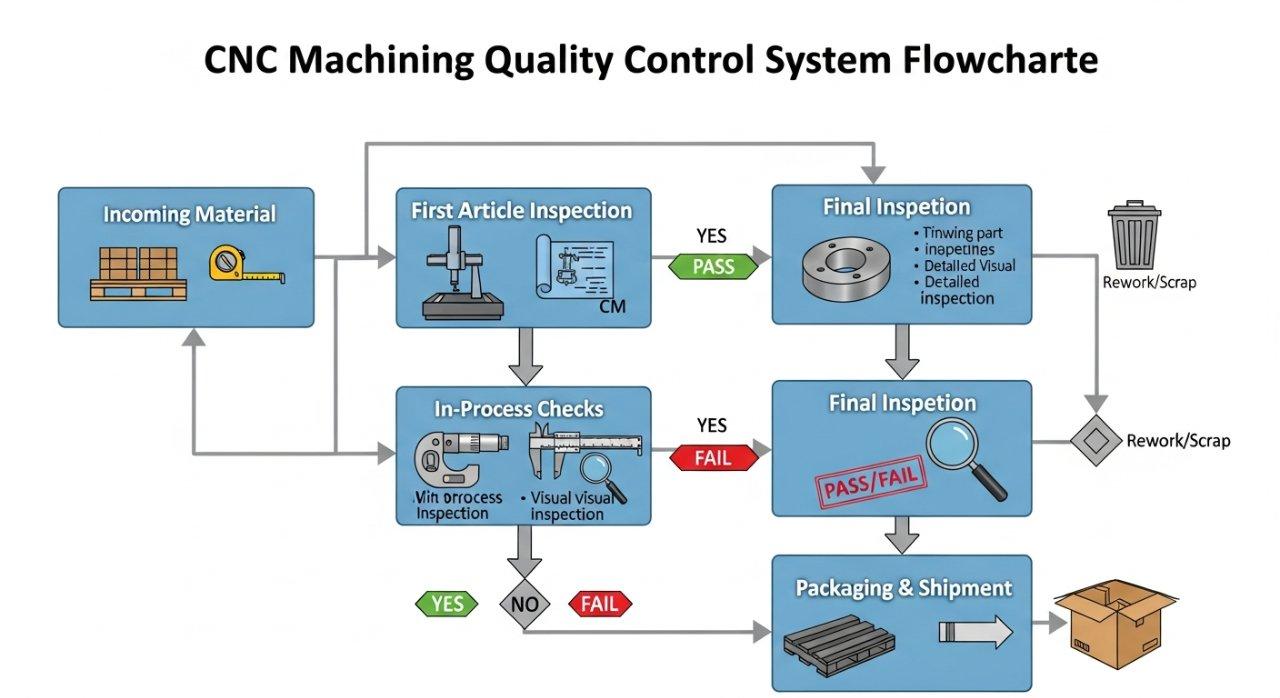

The foundation of any high-quality CNC machining project begins with the raw materials. In our factory, every batch of incoming material undergoes a stringent inspection process to verify its composition and integrity against specifications.

We perform comprehensive checks for material certification, dimensional accuracy, and surface defects, ensuring only the finest, reliable materials proceed to production. This proactive step eliminates potential issues before they can propagate, guaranteeing premium output.

In-Process Checks for Consistent CNC Machining

During the CNC machining process itself, continuous monitoring and in-process checks are crucial for maintaining consistent quality. Our operators and quality technicians perform regular, systematic inspections at various critical stages.

These checks include first article inspection, dimensional verification after key operations, and surface finish analysis, utilizing statistical process control (SPC) to identify and correct any deviations immediately. This proactive approach prevents the production of non-conforming parts.

Final Inspection Guarantees Premium Output

The final inspection is our last line of defense, a comprehensive audit that guarantees every finished CNC machined part meets all client specifications and our own exacting standards. This step is meticulous, ensuring premium output.

This involves detailed dimensional measurements using advanced metrology equipment, visual inspection for cosmetic flaws, and functional testing where applicable. Only parts that pass this rigorous assessment are approved for shipment, ensuring reliability.

Traceability and Documentation for Reliable Parts

Comprehensive traceability and meticulous documentation are hallmarks of a truly reliable quality control system. We maintain detailed records for every CNC machined part we produce.

From raw material certificates and heat treatment records to in-process inspection data and final quality reports, every step is documented. This provides an unbroken chain of evidence, ensuring full accountability and the ability to track parts throughout their lifecycle for long-term durability.

Key Elements of a Superior QC System

Advanced Metrology for Precision CNC Machining

Achieving true precision in CNC machining requires more than just skilled operators; it demands advanced metrology equipment. Our factory invests heavily in cutting-edge tools to ensure unparalleled accuracy.

We utilize Coordinate Measuring Machines (CMMs), optical comparators, laser scanners, and sophisticated surface roughness testers. These tools allow us to measure complex geometries and critical tolerances with micron-level precision, validating our premium CNC machining capabilities.

Table: Advanced Metrology Equipment

| Equipment Type | Primary Function | Precision Level (Typical) |

|---|---|---|

| Coordinate Measuring Machine (CMM) | 3D dimensional measurement, complex geometries | +/- 2-5 microns |

| Optical Comparator | 2D profile inspection, magnified views | +/- 10-25 microns |

| Laser Scanner | Non-contact 3D scanning, surface reconstruction | +/- 5-20 microns |

| Surface Roughness Tester | Quantitative analysis of surface texture | 0.01 Ra (microns) |

Certified Standards: ISO and Beyond for Quality

Adherence to certified international standards is a fundamental component of our quality assurance framework. Our systems are built upon globally recognized benchmarks like ISO 9001, providing a robust, auditable structure for our operations.

For industries requiring even higher standards, we align with specifications such as AS9100 for aerospace components, demonstrating our deep commitment to unwavering quality and industry-specific expertise for truly durable solutions.

Table: Quality Certifications & Focus Areas

| Certification | Primary Focus | Industry Relevance |

|---|---|---|

| ISO 9001 | General Quality Management System | Cross-industry, foundational |

| AS9100 | Aerospace Quality Management System | Aerospace, Defense |

| ISO 13485 | Medical Devices Quality Management System (where applicable) | Medical Device Manufacturing |

Continuous Improvement for Durable Solutions

A superior quality control system is never static; it is constantly evolving through continuous improvement. We actively implement methodologies like Lean Manufacturing and Six Sigma to refine our processes.

Through regular internal audits, root cause analysis of any non-conformances, and ongoing training for our team, we systematically identify areas for enhancement. This dedication ensures we consistently deliver the most durable and reliable CNC machined parts.

Transparent Pricing and Technical Expertise

Understanding Transparent Pricing for Premium CNC

Transparent pricing is a core value at our factory, differentiating us as a reliable source manufacturer. We provide detailed, itemized quotes that clearly outline all costs associated with your premium CNC machining project.

There are no hidden fees or unexpected charges; our clients receive a comprehensive breakdown that includes material costs, machining time, tooling, and any special finishing or inspection requirements. This fosters trust and long-term partnerships.

Leveraging Deep Technical Expertise for Quality

Our deep technical expertise is a significant factor in delivering superior quality. Our engineering team possesses extensive knowledge in material science, design for manufacturability (DFM), and advanced machining strategies.

We collaborate closely with clients from the design phase to optimize part functionality, enhance manufacturability, and proactively address potential quality issues. This consultative approach ensures that designs are robust and production is efficient, leading to premium, durable outcomes.

Choosing a Reliable CNC Machining Partner

Questions to Ask About a Factory’s QC System

When evaluating potential CNC machining partners, it’s crucial to ask incisive questions about their quality control system. Inquire about their certification adherence, metrology equipment, and employee training programs.

Ask for examples of their quality documentation, their process for handling non-conformances, and their commitment to continuous improvement. A transparent factory will readily provide these insights, demonstrating their dedication to reliable, high-quality production.

Our Commitment to Durable and Premium Parts

Our commitment to delivering durable and premium parts is unwavering. As a source manufacturer, we take full ownership of the quality of every component that leaves our facility.

This commitment is embedded in our culture, from the shop floor to senior management, ensuring that every team member prioritizes precision, consistency, and client satisfaction in all CNC machining projects.

Conclusion: Your Partner for Premium CNC

Experience Unwavering Quality with Our CNC Machining

Choosing the right CNC machining partner is critical for your project’s success and your product’s longevity. Our factory stands as a testament to unwavering quality, deep technical expertise, and transparent practices.

We are dedicated to being more than just a supplier; we aim to be a trusted extension of your team, providing the premium, reliable, and durable components you need to excel in your market. Experience the difference that true quality control makes.

Call to Action

Get a Transparent Quote for Your Quality Project

Ready to elevate your product with precision-engineered, high-quality components?

Contact our technical experts today for a personalized consultation. We offer transparent pricing and tailored solutions designed to meet the exact specifications of your most demanding CNC machining projects.

Let us help you achieve superior results and durable performance.

What is the primary focus of your QC system?

Our primary focus is on preventative quality assurance, integrating checks at every stage from incoming material validation to final inspection. This proactive approach minimizes defects and ensures consistent, reliable CNC machined parts.

We emphasize adherence to certified international standards like ISO 9001 and utilize advanced metrology for unparalleled precision. This holistic system guarantees the delivery of premium, durable components.

How do you ensure transparent pricing?

We ensure transparent pricing by providing detailed, itemized quotes for every CNC machining project. These quotes clearly outline all costs, including materials, machining time, tooling, and any special processes.

This upfront clarity prevents hidden fees and builds trust. Our goal is to offer fair, competitive pricing that reflects the premium quality and deep technical expertise invested in your reliable parts.

Can you handle complex CNC machining projects?

Yes, our deep technical expertise and advanced machinery enable us to handle highly complex CNC machining projects. We specialize in challenging geometries, tight tolerances, and exotic materials.

Our engineering team works collaboratively on design for manufacturability (DFM) to optimize designs for production, ensuring both precision and consistent quality. This commitment delivers durable and premium solutions.