Rapid Prototyping CNC accelerates product cycle shortening by enabling quick, precise iterations and design validation, directly translating to faster time-to-market.

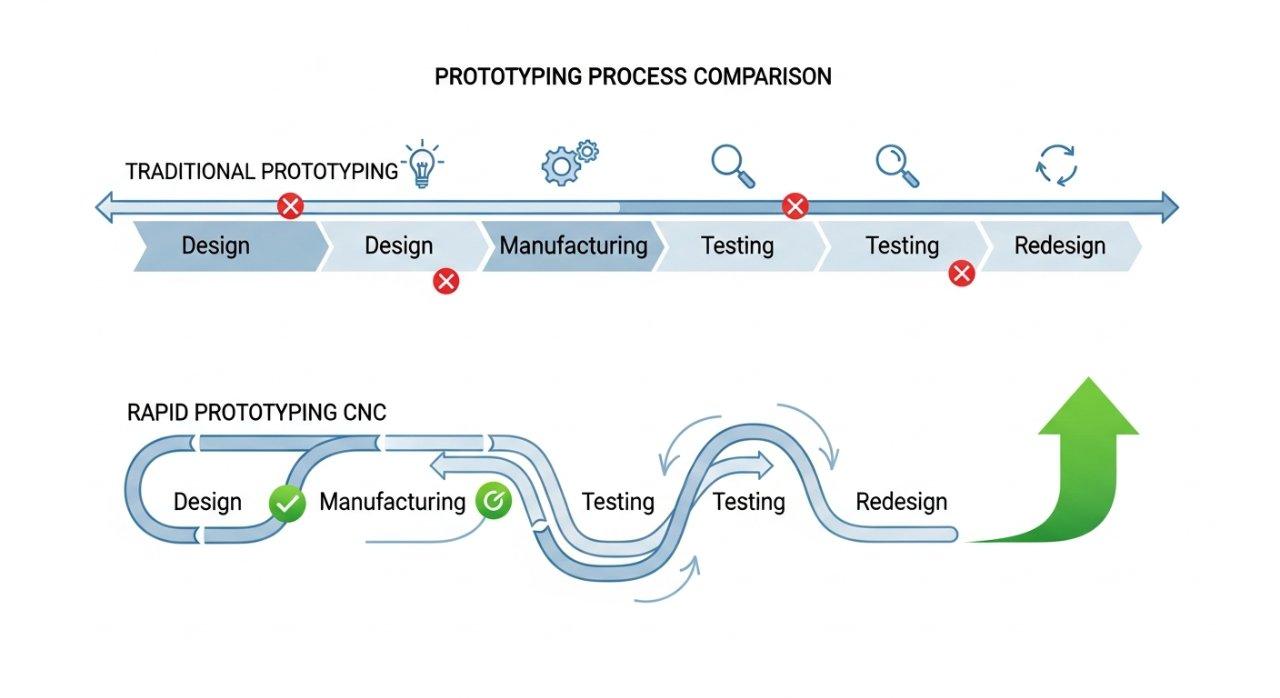

In today’s hyper-competitive market, the speed of innovation isn’t just an advantage, it’s essential for survival. Product development teams face relentless pressure to bring new ideas to life faster, reduce costs, and maintain uncompromising quality. Traditional prototyping methods often become bottlenecks, extending timelines and inflating budgets.

This challenge directly impacts a company’s ability to capture market share and respond to evolving customer needs. Long product development cycles can lead to missed opportunities, outdated products, and significant financial strain. The solution lies in a more agile, precise, and efficient approach to bringing concepts from the drawing board to reality.

This article details six crucial methods where advanced Rapid Prototyping CNC, coupled with expert technical guidance, can dramatically shorten your product development cycle. We will explore how these strategies empower you to innovate faster, optimize designs, and launch superior products with confidence.

Why Rapid Prototyping CNC Matters

The Cost of Slow Product Development

In our experience, slow product development cycles are a silent drain on resources. They lead to escalating engineering hours, increased overheads, and crucial delays in getting products to market. These hidden costs can quickly erode profit margins.

A common issue we see is the missed opportunity cost when a product launches too late. Competitors may capture market share, forcing costly redesigns or even product abandonment. The financial repercussions are significant, impacting investor confidence and long-term growth.

How CNC Transforms Innovation Speed

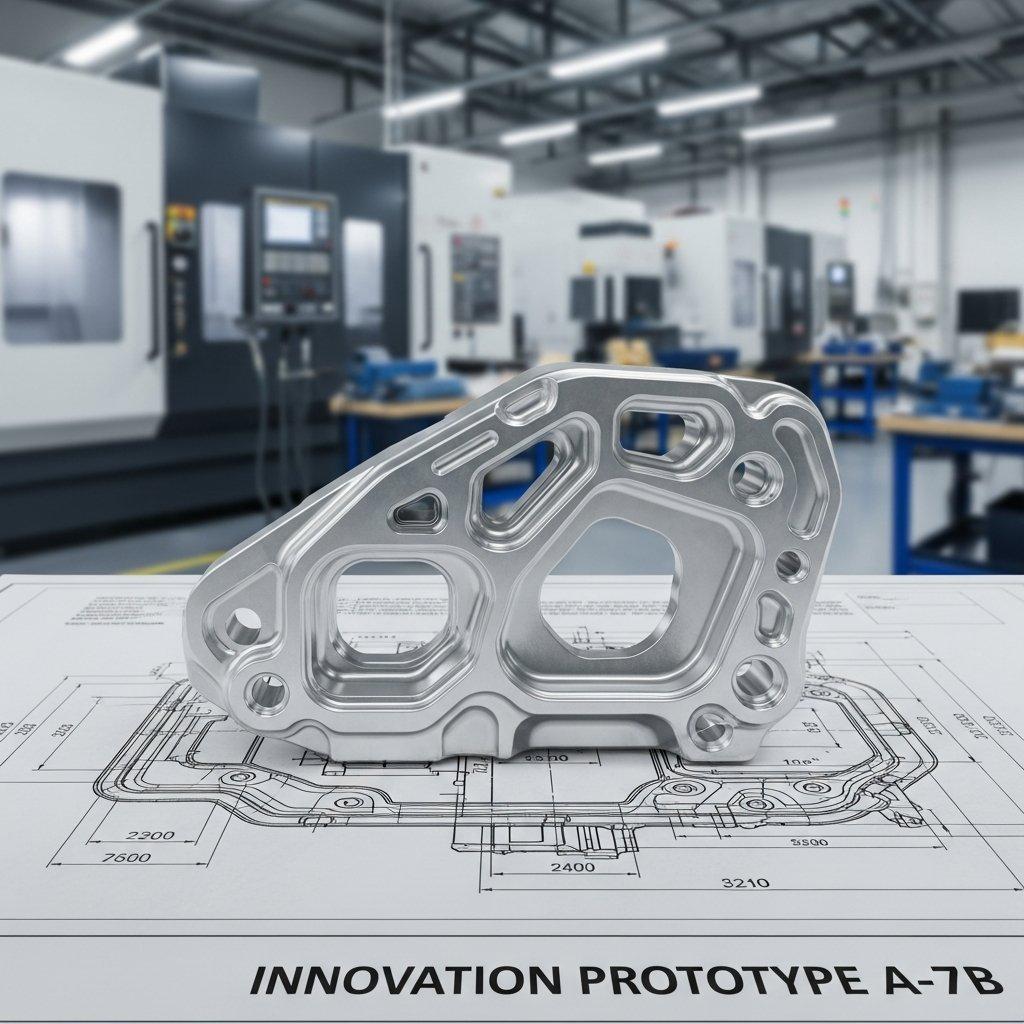

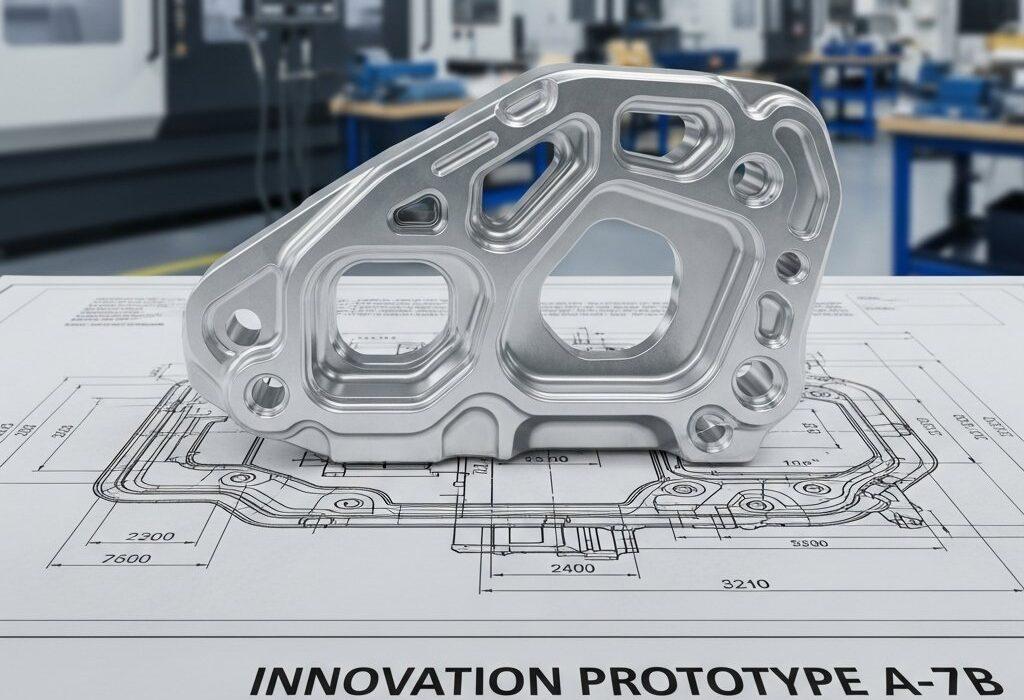

Computer Numerical Control (CNC) machining fundamentally transforms the speed of innovation by offering unparalleled precision and repeatability. Unlike manual methods, CNC allows for rapid, automated production of complex geometries directly from digital designs.

This capability empowers engineers to quickly test design hypotheses, validate functionality, and make iterative improvements without significant lead times. The result is a dramatically accelerated product development cycle, moving from concept to market validation with unprecedented efficiency.

Shorten Product Cycle with DFM

Leveraging Expert DFM for Prototypes

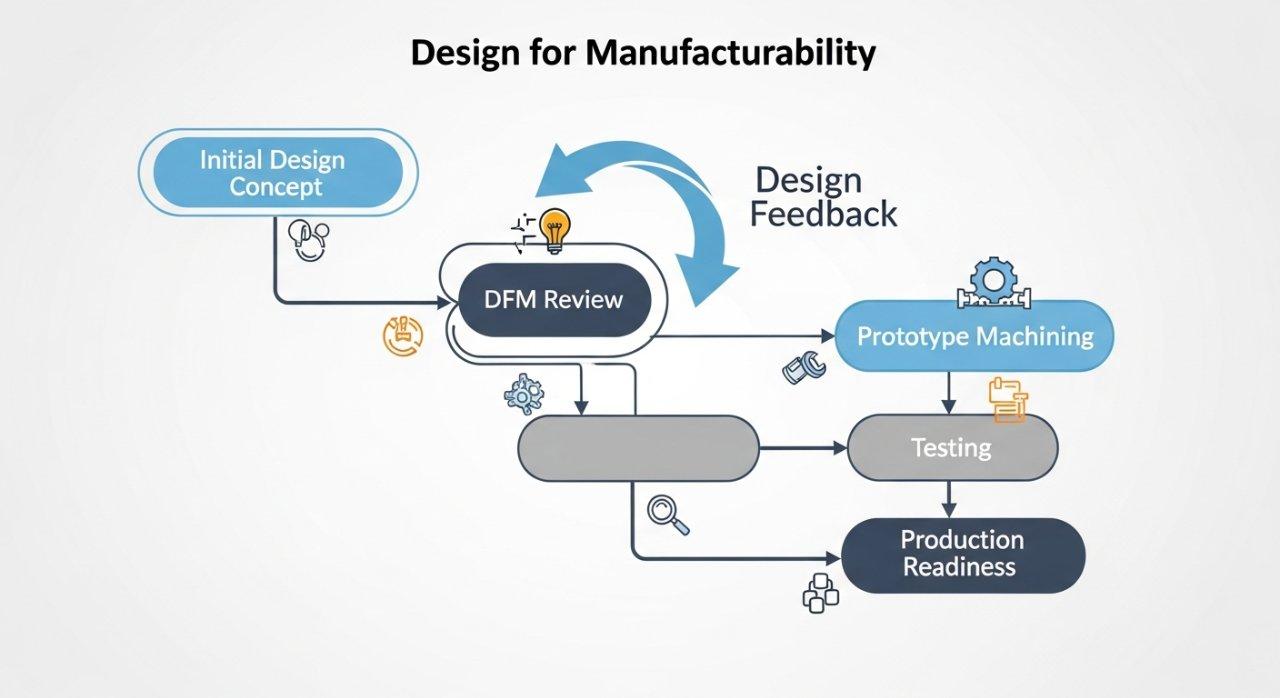

Design for Manufacturability (DFM) is not just a concept; it’s a critical strategy for product cycle shortening. By integrating DFM expertise early in the prototyping phase, we help clients identify potential manufacturing challenges before they become costly problems.

Our engineers review designs for material compatibility, tooling accessibility, and optimal feature geometry. This proactive approach ensures that prototypes are not only functional but also efficiently producible in volume, streamlining the transition from prototype to production.

Early Design Review for Manufacturability

Engaging in early design reviews with a manufacturing expert is paramount. It allows us to provide actionable feedback on tolerances, surface finishes, and potential cost drivers at the conceptual stage. This prevents rework and ensures the design is optimized for precision CNC machining.

Ignoring DFM early on often leads to multiple costly design iterations later in the product development cycle. Our collaborative approach ensures that your initial prototypes are as close to production-ready as possible, minimizing subsequent modifications.

How DFM Reduces Iteration Rounds

A well-executed DFM strategy significantly reduces the number of design iteration rounds required. By addressing manufacturing concerns upfront, the chances of a prototype failing due to unmachinable features or overly complex geometries are drastically lowered.

In our experience, this focused approach can cut prototyping time by 20-40%. It ensures that each iteration brings the design closer to its final form, saving valuable time and resources across the entire product development cycle.

Smart Material Choices for Speed

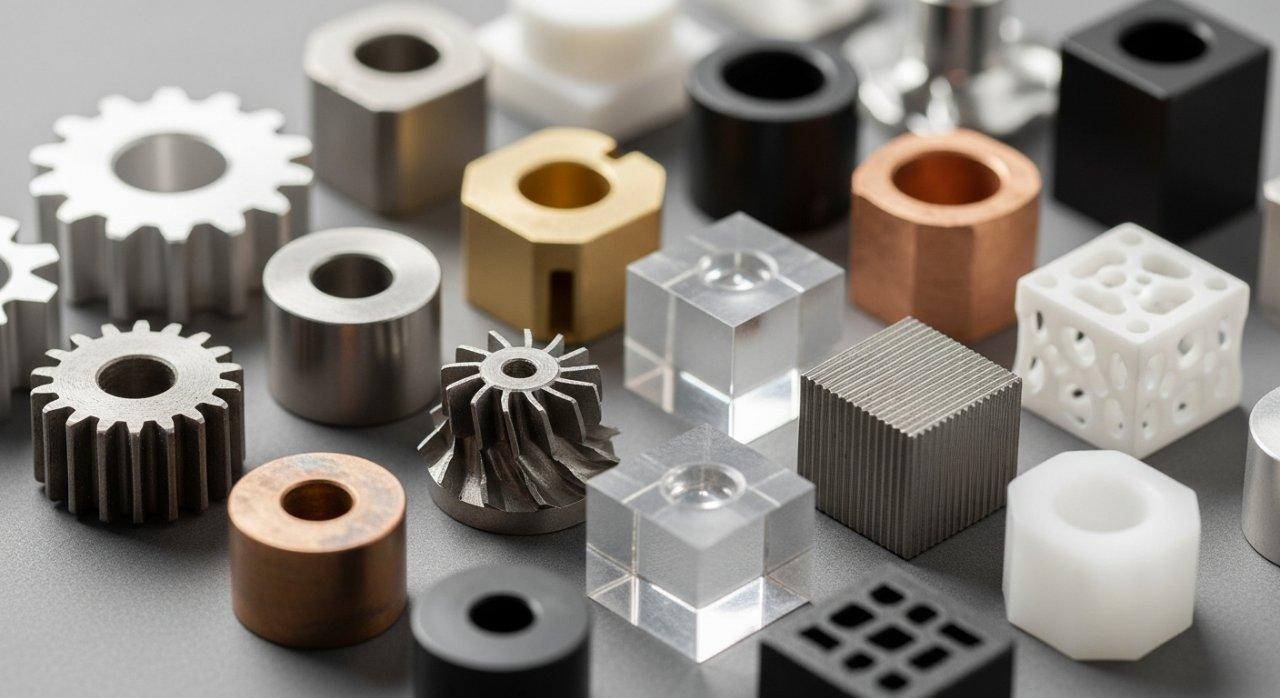

Selecting Optimal Materials for CNC Prototypes

Choosing the right material is a crucial factor in the speed and success of CNC prototyping. Different materials have distinct machinability characteristics, which directly impact machining time, tooling wear, and surface finish.

For example, aluminum alloys are generally easier and faster to machine than high-strength steels or titanium, making them excellent choices for initial functional prototypes where speed is paramount.

Balancing Performance and Machinability

The key is to balance the desired performance characteristics of the final product with the machinability of the material for prototyping. A material that is difficult to machine can add significant time and cost to the rapid prototyping CNC process.

Our team guides clients in selecting materials that meet critical engineering requirements while ensuring efficient processing. This optimization prevents unnecessary delays caused by challenging machining operations.

Expert Guidance on Material Properties

We leverage deep technical expertise in material science to advise on the best choices for your application. This includes understanding properties like hardness, tensile strength, corrosion resistance, and thermal expansion, all of which influence the CNC machining process.

By providing detailed insights into how various materials behave under cutting conditions, we help you make informed decisions that reduce lead times and ensure the quality of your CNC prototypes.

| Material Type | Common Use Cases | Typical Machinability | Cost Factor |

|---|---|---|---|

| Aluminum Alloys (6061) | General-purpose, structural, heat sinks | Excellent | Low |

| Stainless Steel (304) | Corrosion resistance, medical, food processing | Good | Medium |

| ABS Plastic | Consumer products, housings | Very Good | Low |

| Titanium (Grade 5) | Aerospace, medical implants, high strength/weight | Challenging | High |

Advanced CNC for Faster Prototypes

The Power of Multi-Axis Machining

Our investment in advanced multi-axis CNC machines, including 5-axis capabilities, is a cornerstone of our rapid prototyping CNC offering. These machines allow for the machining of complex geometries in a single setup, drastically reducing setup times and improving accuracy.

By eliminating multiple setups, we minimize opportunities for error and accelerate the overall machining process. This capability is essential for creating intricate components quickly and efficiently, directly impacting product cycle shortening.

Automation & Efficiency in Prototyping

Automation is critical to achieving efficiency in prototyping. Our modern CNC equipment is integrated with advanced CAM software, enabling streamlined toolpath generation and optimized cutting strategies. This automation reduces human error and enhances throughput.

Automated tool changers and robotic loading systems further contribute to uninterrupted machining cycles. This means your rapid prototyping CNC projects progress continuously, achieving faster turnaround times without compromising precision.

Leveraging Specialized CNC Tooling

The use of specialized CNC tooling is another lever for accelerating prototype production. We carefully select and, when necessary, custom-design tooling optimized for specific materials and geometries. This ensures efficient material removal and superior surface finishes.

Optimized tooling extends tool life, reduces the need for tool changes, and allows for higher feed rates and spindle speeds. This precision engineering approach translates directly into faster machining times and a more efficient product development cycle.

Deep Collaboration: Key to Speed

Integrating Supplier Expertise Early On

True product cycle shortening stems from deep collaboration between the design team and the manufacturing partner. Integrating our supplier expertise early in your product development cycle provides invaluable insights into practical manufacturing constraints and opportunities.

We act as an extension of your engineering team, offering proactive guidance on design optimization and material selection. This collaborative model ensures that prototypes are “right the first time,” minimizing costly revisions.

Streamlined Communication Channels

Effective communication is the bedrock of rapid prototyping CNC success. We establish clear and streamlined communication channels, ensuring that feedback, design changes, and project updates are exchanged efficiently and accurately.

Whether through dedicated project managers or secure online platforms, our goal is to eliminate communication bottlenecks. This proactive approach prevents misunderstandings and keeps your project on track, accelerating decision-making and prototype delivery.

Partnering for Project Success

Partnering with a trusted CNC expert means more than just receiving parts; it means collaborating towards shared project success. Our commitment extends beyond mere fabrication to actively contributing to your product development goals.

By aligning our processes and expertise with your timelines, we ensure a seamless flow from CAD to component. This partnership approach is a direct pathway to achieving significant product cycle shortening and market advantage.

Agile Iteration in Prototyping

Rapid Feedback Loops for Design Refinement

Agile iteration is fundamental to accelerating the product development cycle. We facilitate rapid feedback loops, enabling designers to quickly test prototypes, gather data, and implement refinements. This continuous cycle of build-test-learn is powered by rapid prototyping CNC.

In our experience, the ability to generate new prototype versions in days, not weeks, allows for more comprehensive testing and validation. This significantly de-risks the design and development process, preventing major issues later on.

Batch Prototyping for Parallel Testing

For certain applications, batch prototyping allows for parallel testing of multiple design variations or material choices simultaneously. This approach can dramatically shorten the product cycle by consolidating testing phases.

Instead of sequential testing, which can be time-consuming, batch prototyping provides comparative data much faster. It’s a strategic way to validate different features or performance characteristics concurrently, accelerating decision-making.

Continuous Improvement in Design Phase

Rapid prototyping CNC fosters a culture of continuous improvement directly within the design phase. Each prototype iteration offers valuable data, informing the next design cycle and leading to a more refined and robust final product.

This iterative process, supported by quick-turn CNC capabilities, ensures that all aspects of the design are thoroughly tested and optimized. It’s a proactive method for catching flaws early and guaranteeing the high quality of the final part.

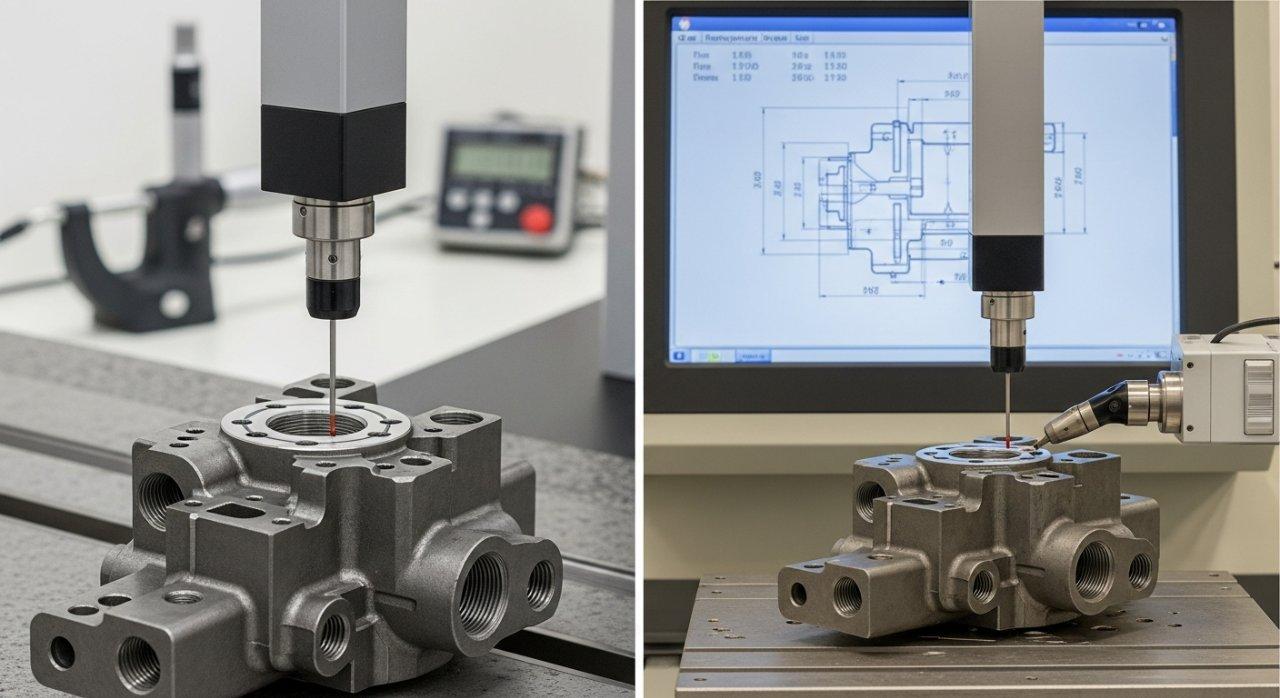

Quality Control: Prevent Delays

Precision Machining for First-Time Success

Precision machining is the cornerstone of preventing delays in the product development cycle. By adhering to tight tolerances and producing parts accurately the first time, we eliminate the need for costly and time-consuming rework.

Our advanced CNC machines, combined with stringent process controls, ensure that components meet exact specifications. This commitment to first-time success is crucial for maintaining project timelines and budget.

Integrated QC: Reducing Rework

Quality control is integrated at every stage of our rapid prototyping CNC process, not just at the end. In-process inspections and real-time monitoring ensure that deviations are caught and corrected immediately, before they propagate.

This proactive approach significantly reduces the likelihood of producing non-conforming parts. By minimizing rework, we keep your project moving forward smoothly, accelerating the overall product cycle.

Ensuring High-Quality Parts from Start

We uphold rigorous quality assurance protocols, often exceeding industry standards like ISO 9001 and AS9100 for high-demand sectors. Each rapid prototyping CNC component undergoes thorough inspection using calibrated equipment, ensuring every part is delivered as specified.

Our commitment to high-quality parts from the outset builds trust and guarantees that your prototypes are functionally reliable. This prevents delays caused by component failure during testing, saving critical time and resources.

| QC Stage | Description | Primary Goal |

|---|---|---|

| Pre-Production | Design review, material certification, programming | Prevent errors, ensure manufacturability |

| In-Process | Operator checks, statistical process control (SPC) | Monitor for deviations, ensure consistency |

| Post-Machining | CMM inspection, visual checks, surface finish | Verify dimensional accuracy, meet specs |

| Final Documentation | Measurement reports, material traceability | Ensure compliance, provide transparency |

Partner with a Trusted CNC Expert

Our Strength as a Source Manufacturer

As a source manufacturer, ‘ly-machining’ offers direct control over the entire rapid prototyping CNC process. This means unparalleled consistency, quality, and responsiveness that resellers simply cannot match. We own the machines, the processes, and the expertise.

This direct engagement translates to faster lead times, direct technical support, and the ability to adapt quickly to design changes, directly supporting your product cycle shortening goals.

Commitment to High-Quality Parts

Our unwavering commitment to high-quality parts is evident in every rapid prototyping CNC project we undertake. We utilize premium materials, state-of-the-art machinery, and experienced machinists to produce components that meet the most demanding specifications.

This dedication ensures that your prototypes are not just functional, but also representative of the final product’s quality, minimizing risks in later stages of your product development cycle.

Transparent Pricing for Budget Clarity

We believe in transparent pricing. Our quotes for rapid prototyping CNC projects are detailed and clear, outlining all costs upfront with no hidden fees. This clarity empowers you to manage your budget effectively and confidently plan your product development cycle.

In our experience, clear pricing builds trust and avoids costly surprises that can derail project timelines and financial forecasts.

Unmatched Technical Expertise

Our team comprises engineers and machinists with unmatched technical expertise in rapid prototyping CNC. From complex geometries to advanced material selections, we provide comprehensive DFM insights and solutions.

This deep knowledge ensures that even the most challenging designs can be efficiently prototyped, helping you navigate technical hurdles and achieve your product development goals faster.

Case Study: Accelerating Medical Device Validation

A medical device startup approached ‘ly-machining’ struggling with long lead times for their complex surgical instrument prototypes. Their existing supplier took 3-4 weeks per iteration, delaying critical FDA approval testing. The intricate design, featuring internal channels and tight tolerances, was a challenge for conventional machining.

Our solution involved a comprehensive DFM review, optimizing their design for 5-axis CNC machining and recommending a specific medical-grade titanium alloy with excellent machinability. We implemented a rapid prototyping CNC strategy, utilizing our advanced multi-axis machines and specialized tooling. We established daily communication channels for immediate feedback.

The result was a drastic reduction in their product development cycle. We delivered functional prototypes within 5-7 business days, enabling the startup to perform more iterative tests in less time. This accelerated their design validation phase, allowing them to proceed to clinical trials three months ahead of their original schedule, ultimately shortening their time-to-market.

Accelerate Your Product Launch Today

Ready for Faster Development Cycles?

Are you ready to revolutionize your product development cycle and bring your innovations to market faster? Partner with ‘ly-machining’ to leverage the power of rapid prototyping CNC and expert DFM guidance.

We provide the precision, speed, and reliability you need to stay ahead of the curve.

Request Your Free Consultation

Discover how our high-quality CNC prototyping services can transform your product development journey. Contact our expert engineering team today for a free DFM consultation and a transparent quote on your rapid prototyping project. Let’s build your future, faster.

FAQ Section

How fast is rapid prototyping CNC?

The speed of rapid prototyping CNC depends on part complexity, material, and required tolerances. However, with advanced multi-axis machines and optimized processes, we can often deliver functional prototypes in as little as 3-7 business days. This significantly shortens the overall product development cycle.

What is DFM’s role in shortening cycles?

DFM (Design for Manufacturability) reduces iterations by identifying and resolving potential manufacturing issues early in the design phase. Our expert DFM guidance ensures designs are optimized for efficient CNC machining, preventing costly rework and accelerating the product cycle.

Which materials are best for quick prototypes?

For quick prototypes, materials with excellent machinability are often preferred, such as aluminum alloys (e.g., 6061) and various plastics (e.g., ABS, Delrin). These materials allow for faster cutting speeds and reduced machining times, directly contributing to product cycle shortening.