Rapid Prototyping CNC: 3 Advantages for Small Batches

Small-batch CNC machining offers superior rapid prototyping advantages, accelerating product development with cost-effective, high-precision CNC prototype manufacturing for custom machined parts crucial for innovation.

Navigating the complexities of modern product development requires agile manufacturing solutions. In our experience, the ability to quickly test and iterate designs is paramount. This article explores how rapid prototyping CNC for small-batch production provides three significant benefits that drive innovation and accelerate time-to-market.

Prototypes & Small Batches: Navigating Modern Demands

Why traditional methods fall short for innovation

Traditional manufacturing methods like injection molding often involve substantial upfront tooling costs and long lead times. These constraints make design iterations slow and prohibitively expensive for early-stage product development. For small-batch production, this approach simply isn’t viable.

The critical role of speed and precision

The competitive landscape demands that R&D engineers and product designers get functional prototypes quickly. Speed without precision, however, is counterproductive. Our clients require components that not only arrive fast but also meet rigorous dimensional accuracy and surface finish specifications.

Our commitment as a source manufacturer

As a dedicated source manufacturer, we understand the direct impact of our processes on your project timelines and budgets. This deep understanding allows us to offer optimized solutions, ensuring direct control over quality and scheduling, which benefits every custom machined part.

Advantage 1: Accelerating Time-to-Market

Rapid prototyping CNC for quick iterations

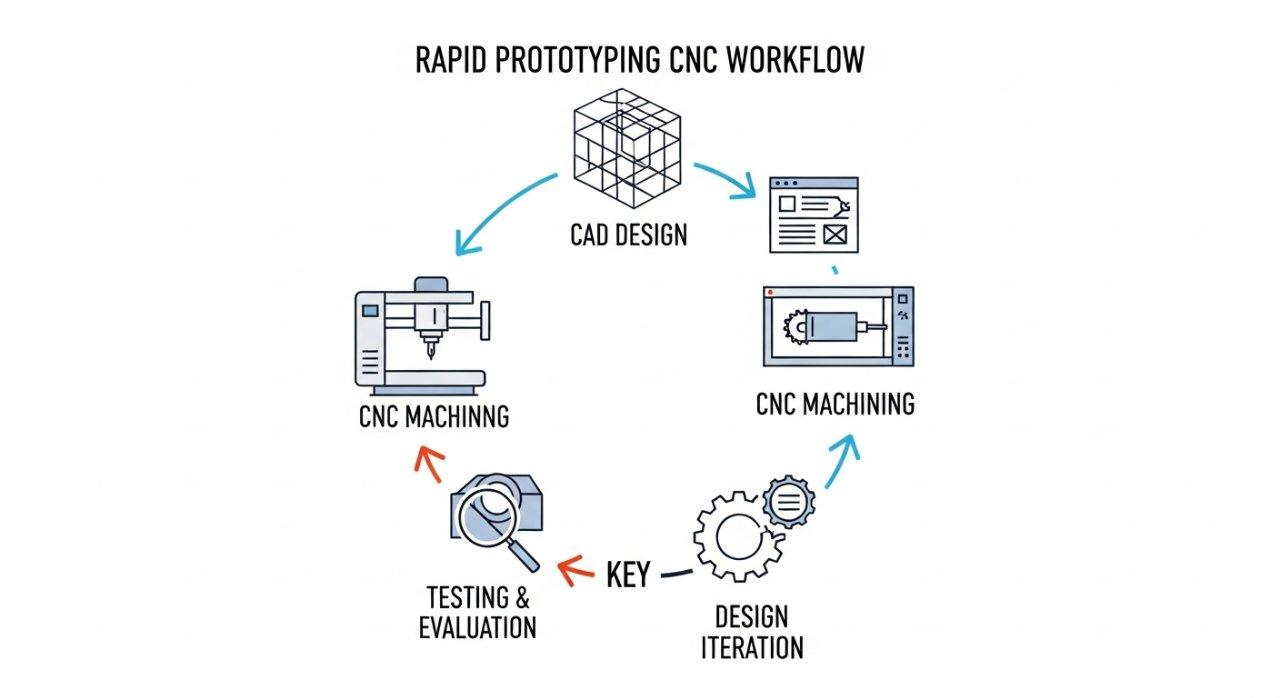

Rapid prototyping CNC machining inherently supports agile development methodologies. Engineers can rapidly produce physical prototypes, allowing for immediate functional testing and design validation. This iterative loop significantly shortens the design-to-production cycle.

In our facility, we see countless instances where a quick turnaround on a CNC prototype helps identify design flaws early. Correcting these issues before mass production saves significant resources and prevents costly recalls or redesigns later on. Our efficient processes are tailored for this speed.

Speeding up product development cycles

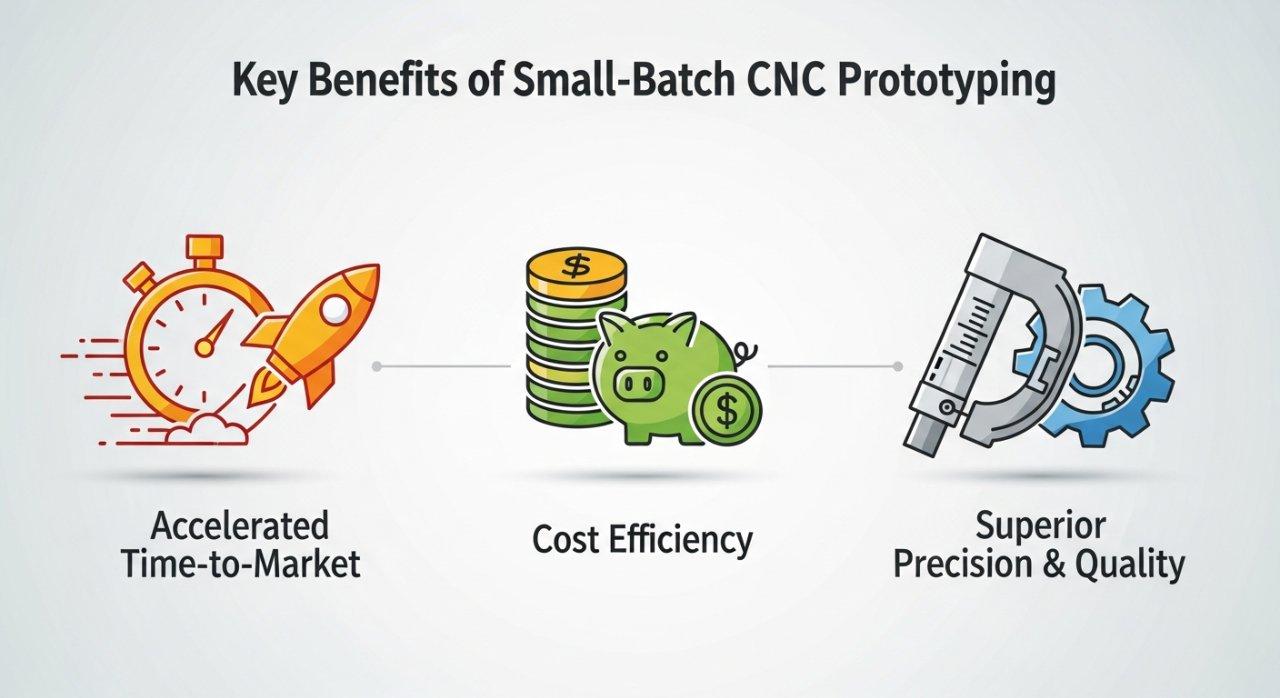

By eliminating the need for complex, expensive tooling often associated with large-volume production, small-batch CNC machining allows projects to move faster. Products can be brought to market ahead of competitors, capturing early adopter segments and establishing market presence.

For project leads and startup founders, this means validating ideas with real hardware much sooner. It’s not just about producing parts; it’s about accelerating your entire product development cycle from concept to commercialization.

Leveraging our efficient workflow and expertise

Our integrated workflow, from DFM analysis to post-processing, is designed for maximum efficiency in CNC prototype manufacturing. With highly skilled engineers and advanced machinery, we minimize setup times and optimize machining paths. This expertise translates directly into faster delivery for your critical components.

Advantage 2: Cost-Effective Small-Batch CNC

Reducing tooling costs and MOQs for prototypes

One of the most significant rapid prototyping advantages of CNC machining is the substantial reduction in tooling costs. Unlike injection molding or casting, CNC does not require custom molds or dies, which can cost tens of thousands of dollars. This makes small-batch production economically viable.

The elimination of large Minimum Order Quantities (MOQs) is also critical for small businesses and startups. You only produce the number of custom machined parts you need, avoiding excess inventory and associated storage costs. This flexibility is a game-changer for budget-conscious projects.

Optimized material usage in CNC machining

Our precision milling strategies are designed to optimize material utilization, further contributing to cost-effectiveness. Advanced CAD/CAM software allows for efficient nesting and tool path generation, minimizing material waste. This is especially beneficial when working with expensive, high-performance alloys.

Our engineers carefully select the right raw material and machining approach to ensure structural integrity while keeping material scrap to a minimum. This thoughtful planning is an integral part of our commitment to delivering value.

Transparent pricing for predictable budgets

We believe in complete transparency regarding the cost of your CNC prototype manufacturing project. Our detailed quotes break down material, machining time, and finishing costs, ensuring procurement managers have clear, predictable budgets. This helps mitigate risks associated with offshore manufacturing.

Advantage 3: Superior Prototype Quality & Iteration

High-precision CNC for intricate designs

CNC machining delivers exceptional accuracy and repeatability, producing custom machined parts with tight tolerances and complex geometries. In our facility, we regularly achieve tolerances as precise as ±0.005mm (0.0002 inches), which is often critical for functional prototypes in demanding industries like aerospace or medical.

This level of precision ensures that your prototypes accurately reflect the final production part’s form, fit, and function. Complex features, fine details, and intricate internal structures can be realized with outstanding fidelity, far surpassing what many additive manufacturing methods can achieve for structural parts.

Achieving consistent quality for small-batch parts

Consistency across every single part in a small batch is a hallmark of quality CNC prototype manufacturing. Our ISO 9001 and AS9100 certified processes ensure every custom machined part meets your exact specifications, from the first piece to the last. This consistency is vital for rigorous testing and validation.

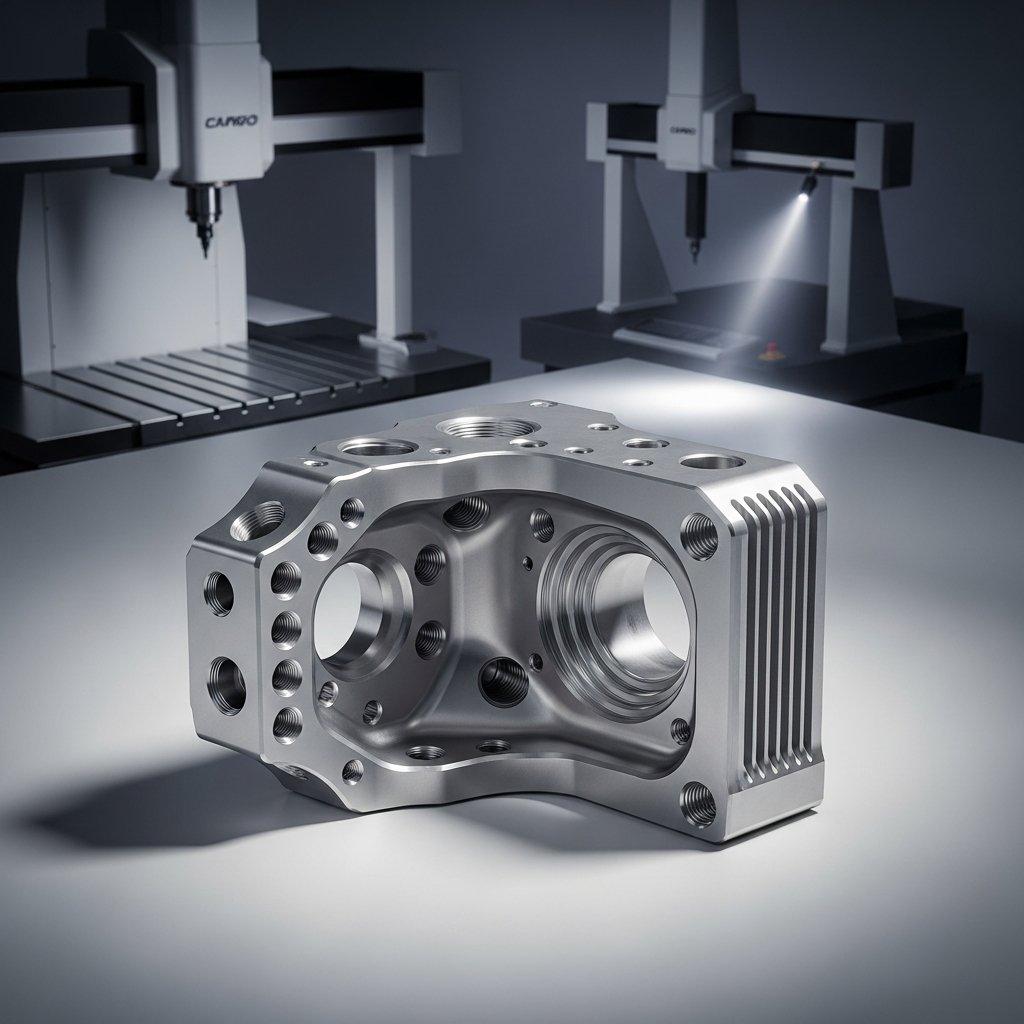

Our robust quality control system includes in-process inspections and final dimensional verification using CMMs and other metrology equipment. This guarantees the reliability and performance of your prototypes, giving you confidence in their application.

Flexible design changes and material versatility

The digital nature of CNC machining allows for rapid and flexible design modifications. A change in your CAD model can be translated into a new physical prototype within days. This iterative capability is a core strength for engineers constantly refining their designs.

Furthermore, CNC machining is compatible with a vast array of engineering-grade materials, from various plastics and aluminum to stainless steel, titanium, and exotic alloys. This material versatility enables you to test prototypes in the exact materials intended for final production, ensuring realistic performance evaluation.

Why Choose Us for Your CNC Prototyping Needs

Deep technical expertise in complex machining

In our experience, tackling complex geometries and tight tolerances requires more than just machines; it demands profound engineering expertise. Our team comprises highly experienced CNC specialists who understand the nuances of various materials and machining strategies. We partner with you, offering design for manufacturability (DFM) insights that optimize your custom machined parts.

Assured high-quality parts every time

Quality is non-negotiable for critical rapid prototyping projects. Our commitment to strict adherence to industry standards, including ISO 9001 and AS9100, underpins every aspect of our CNC prototype manufacturing. We focus on delivering parts that not only meet but exceed your functional and aesthetic expectations.

As a source manufacturer, we deliver value

Choosing a source manufacturer like us for your small-batch CNC machining means direct communication, competitive pricing, and unwavering accountability. There are no middlemen, ensuring that your project benefits from our full attention and technical capabilities from concept to completion. This direct relationship fosters trust and delivers true value.

Small-Batch CNC: Empowering Your Innovation

Summarizing the key benefits for your project

Small-batch CNC machining provides unparalleled speed, cost-efficiency, and quality for rapid prototyping advantages. It empowers product designers and engineers to innovate faster, iterate designs seamlessly, and bring market-ready solutions to life with confidence. This method is crucial for modern product development.

The future of product development through CNC

The ability to produce custom machined parts rapidly and affordably for testing and validation is defining the future of product development. Our advanced computer numerical control services are at the forefront, offering the flexibility and performance required to turn groundbreaking ideas into tangible products.

Request Your Custom CNC Prototype Quote

Ready to accelerate your product development with high-quality, cost-effective small-batch prototypes? Request a Free Quote Today and let our technical experts help bring your vision to life.

—

**Case Study: Streamlining Medical Device Prototyping**

**Problem:** A medical device startup required a complex, multi-component prototype for a new surgical instrument. They faced tight regulatory deadlines and previous suppliers struggled with the intricate geometries and tight tolerances demanded by the device’s functionality. Traditional methods were too slow and costly for iterative development.

**Our Solution:** Leveraging our 5-axis CNC machining capabilities and in-depth material expertise, we collaborated closely with their R&D team. We implemented a staged small-batch CNC machining approach, producing initial functional prototypes from medical-grade stainless steel with exceptional precision. Our DFM insights helped refine certain features for optimal machinability without compromising performance.

**Result:** The startup received their high-precision custom machined parts within 7 business days, allowing them to proceed with critical pre-clinical testing ahead of schedule. Our rapid iteration support enabled them to make a crucial design change in a subsequent small batch, leading to a 30% reduction in assembly time for the final instrument. This accelerated their path to regulatory approval and market entry.

—

Frequently Asked Questions

What is small-batch CNC machining?

Small-batch CNC machining refers to the production of a limited number of custom parts using computer numerical control. This method is ideal for rapid prototyping, product validation, and low-volume production runs. It offers flexibility and cost-effectiveness for specialized needs.

What materials can be used for CNC prototypes?

Our CNC prototype manufacturing can process a wide range of engineering-grade materials. This includes various plastics like ABS, PC, Nylon, and metals such as aluminum alloys, stainless steel, brass, and titanium. Material selection is based on your application’s specific functional requirements.

How does CNC prototyping save costs?

CNC prototyping significantly reduces costs by eliminating expensive tooling and molds required for mass production methods. It also supports optimized material usage and allows for quick design iterations. This prevents costly redesigns further down the development pipeline.