Selecting Top High-End Material CNC Factories

High-End Material CNC Machining requires expert manufacturers with Precision Machining Expertise. Evaluate Top CNC Suppliers Ranking by technical depth, quality, and proven experience to ensure project success.

In the high-stakes world of advanced manufacturing, selecting the right CNC Machining Manufacturer for your high-end materials isn’t just a choice; it’s a critical decision that determines project success. Are you tired of costly rework and project delays due to suppliers who cannot master the intricacies of high-performance materials? This guide will empower you to identify the definitive partners that deliver uncompromising precision and reliability.

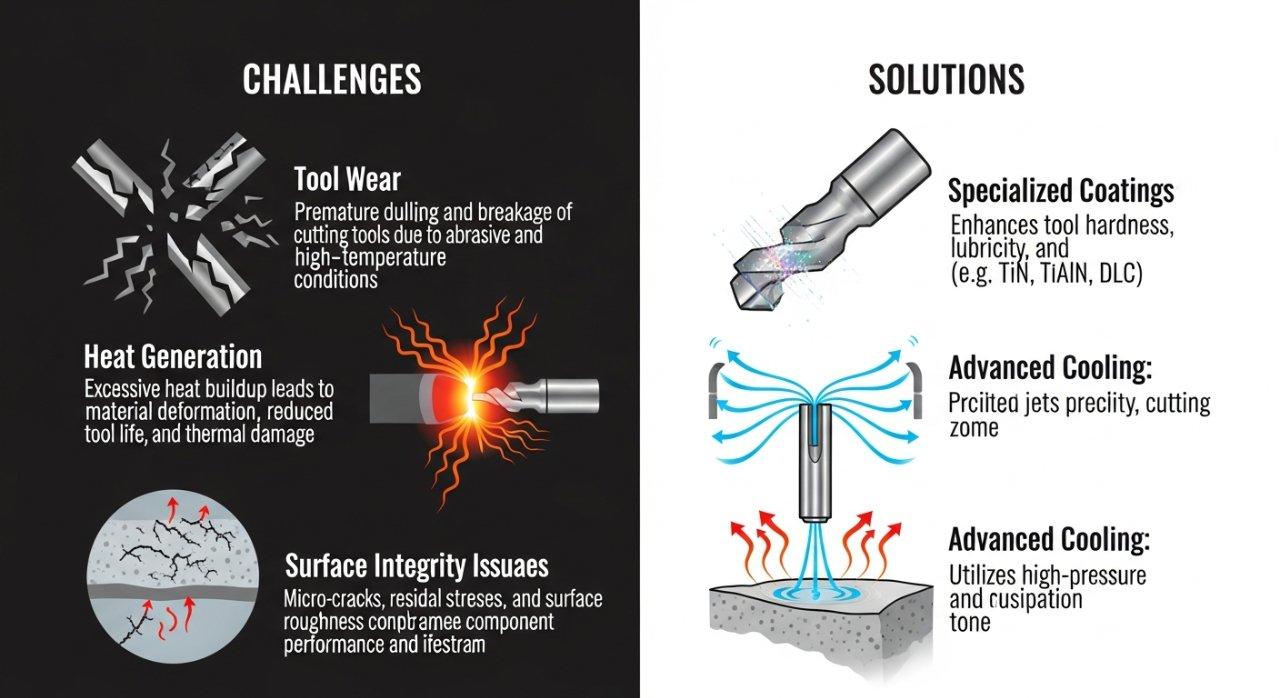

Challenges of High-End Material CNC

The Demand for Precision Machining

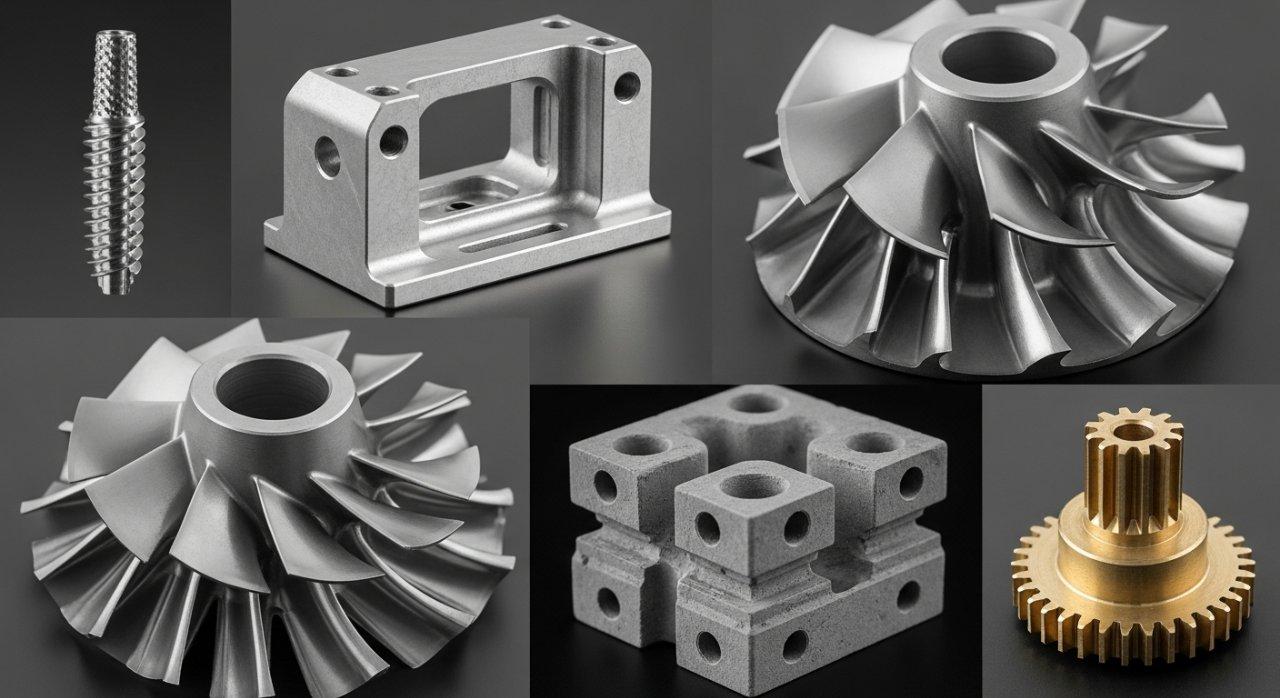

The modern industrial landscape increasingly demands components with extreme precision and intricate geometries. From aerospace to medical devices, parts must often meet tolerances measured in microns. This necessitates advanced CNC Machining Manufacturer capabilities.

Precision Machining Expertise goes beyond just operating a machine. It involves deep understanding of tool paths, cutting parameters, and machine kinematics to consistently achieve the required dimensional accuracy and surface integrity.

Complexities of Exotic Materials

Working with High-End Material CNC Machining, such as titanium, Inconel, PEEK, or medical-grade stainless steel, presents unique challenges. These materials often possess high strength-to-weight ratios, heat resistance, or biocompatibility, but are inherently difficult to machine.

Their properties can lead to rapid tool wear, residual stresses, and poor surface finishes if not handled with specialized knowledge and equipment. Our experience shows that generic approaches often fail.

Why Professional Manufacturers Matter

A professional CNC Machining Manufacturer specializing in High-End Material CNC Machining has the specialized equipment, tooling, and engineering know-how. This enables them to tackle complex projects that generalist shops cannot.

They understand material science, thermal management during machining, and advanced metrology. This deep expertise ensures consistent quality and avoids costly errors.

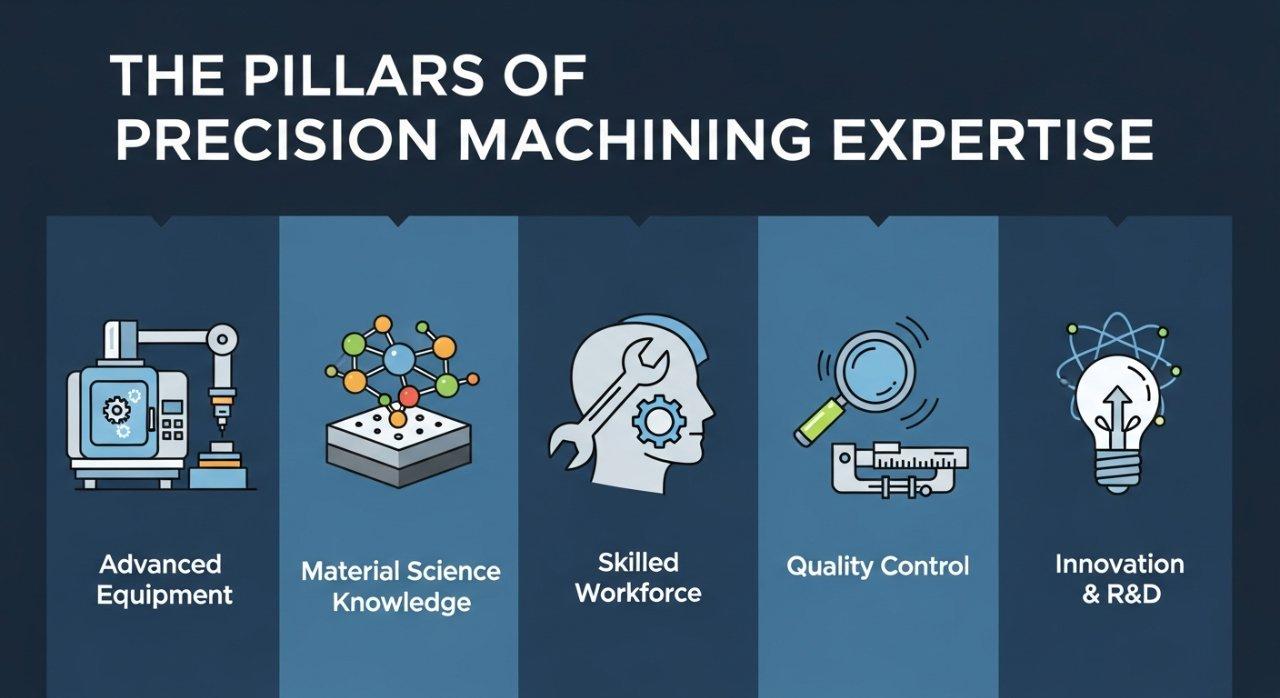

Criteria for Top Manufacturer Ranking

Technical Capabilities & Investment

A leading CNC Machining Manufacturer for High-End Material CNC Machining will have invested heavily in state-of-the-art equipment. This includes multi-axis CNC machines (3-axis, 4-axis, 5-axis, Swiss-type lathes), EDM, and advanced CAM software.

They also employ skilled machinists who can program and operate these complex machines effectively. The right tools and talent are foundational to Precision Machining Expertise.

Quality Management & Certifications

Robust quality management systems are non-negotiable. Look for certifications like ISO 9001 and AS9100, which demonstrate a commitment to stringent quality control processes.

These certifications indicate that a factory follows internationally recognized standards for quality, traceability, and continuous improvement. In our experience, this ensures consistent, high-quality output.

TABLE: Key Quality Certifications and Their Significance

| Certification | Focus Area | Importance for High-End Machining |

|---|---|---|

| ISO 9001 | Quality Management Systems | Ensures consistent product quality and customer satisfaction |

| AS9100 | Aerospace Quality Standard | Critical for aerospace components, demanding strict traceability |

| ISO 13485 | Medical Devices QM System | Essential for medical implants and instruments, ensuring safety |

Supply Chain Integration & Efficiency

An effective Top CNC Suppliers Ranking candidate often boasts well-integrated supply chain management. This includes robust raw material sourcing, validated sub-contractors for special processes, and efficient logistics.

This integration minimizes delays and ensures material authenticity and compliance. It is crucial for maintaining project timelines and cost-effectiveness.

Client Communication & Support

Exceptional client communication, including Design for Manufacturability (DFM) feedback, is a hallmark of Top CNC Suppliers Ranking. They should offer proactive support from design conception through to final delivery.

Clear, consistent updates and responsive technical consultations build trust and ensure project alignment. At ly-machining, we prioritize this collaborative approach.

Professional Experience: Key to Success

Expert Team & Accumulated Expertise

True Precision Machining Expertise resides in the experience of the engineering and machining teams. Years of hands-on work with various High-End Material CNC Machining challenges build invaluable practical knowledge.

This accumulated expertise allows for innovative problem-solving and optimization of machining strategies that inexperienced teams would overlook.

Analysis of Complex Project Cases

A top CNC Machining Manufacturer can readily provide examples and detailed analyses of complex projects they have successfully completed. These case studies demonstrate their capability to handle intricate geometries, tight tolerances, and exotic materials.

Reviewing these cases offers insight into their problem-solving approach and technical prowess.

Innovation & R&D Commitment

Commitment to innovation and continuous R&D is vital. The field of High-End Material CNC Machining is constantly evolving, with new materials and processes emerging regularly.

A forward-thinking factory invests in research to adopt new techniques and technologies, ensuring they remain at the forefront of Precision Machining Expertise.

Deep Material Science Understanding

Understanding the metallurgical and chemical properties of High-End Material CNC Machining is crucial. Each material reacts differently to cutting forces, heat, and tooling.

A deep understanding allows for precise parameter selection, tool geometry optimization, and post-machining treatment. This ensures material integrity and desired performance.

TABLE: Material Considerations for High-End Machining

| Material Type | Key Machining Challenge | Desired Properties |

|---|---|---|

| Titanium Alloys | High strength, low thermal conductivity | Biocompatibility, high strength-to-weight |

| Inconel/Superalloys | Work hardening, high heat generation | High temperature strength, corrosion resistance |

| Medical-Grade SS | Stringent surface finish, biocompatibility | Corrosion resistance, sterilizability |

| PEEK | Thermal expansion, chip control | Chemical resistance, lightweight, insulation |

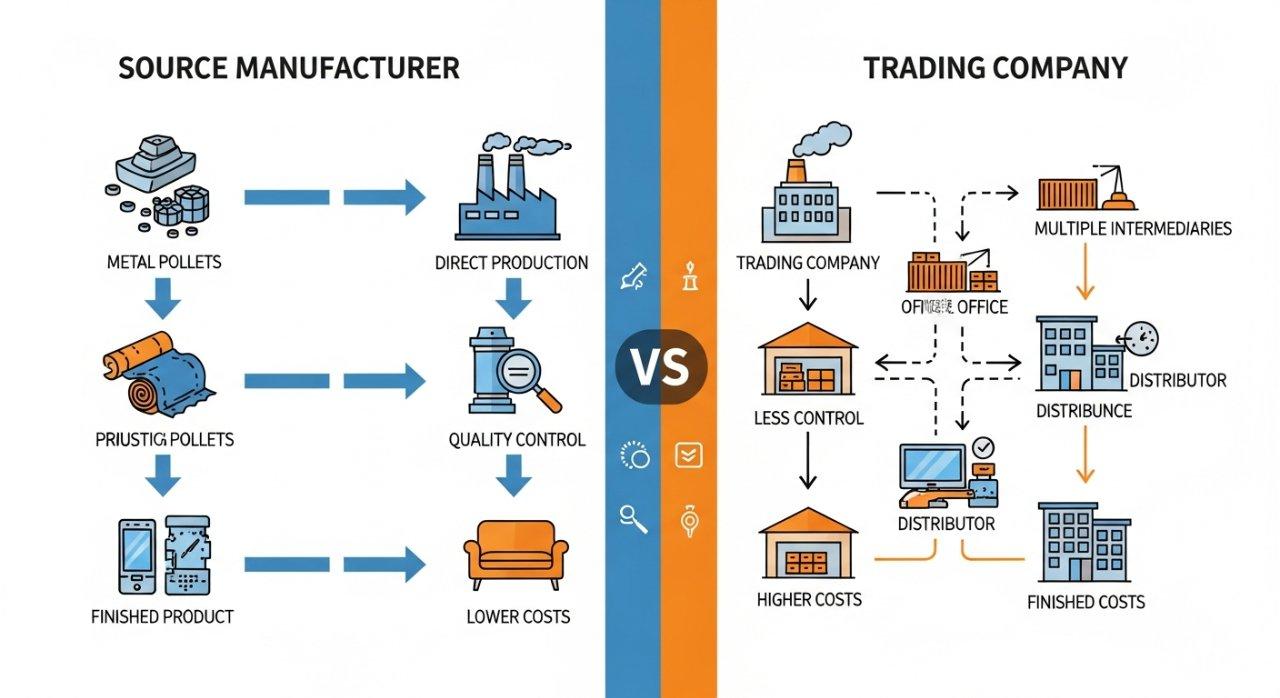

The Value of a Source Manufacturer

Direct Production Process Control

As a source CNC Machining Manufacturer, we maintain direct control over every stage of the production process. This eliminates intermediaries and ensures consistent adherence to specifications and quality standards.

This level of control is paramount for High-End Material CNC Machining where precision and reliability cannot be compromised.

Cost Efficiency & Transparent Pricing

Working directly with a source manufacturer often results in more cost-efficient solutions. By removing layers of markups, we provide competitive and Transparent Pricing.

Our detailed quotations break down costs clearly, ensuring you understand where your investment goes. This builds trust and avoids hidden charges.

Rapid Response & Custom Solutions

Direct access to our engineering team allows for rapid response to inquiries and swift implementation of custom solutions. Whether it’s a design modification or a production challenge, we can adapt quickly.

Our agility as a source manufacturer means faster turnaround times and more tailored services for your unique High-End Material CNC Machining needs.

High-Quality Parts & Pricing Clarity

Robust Quality Control Systems

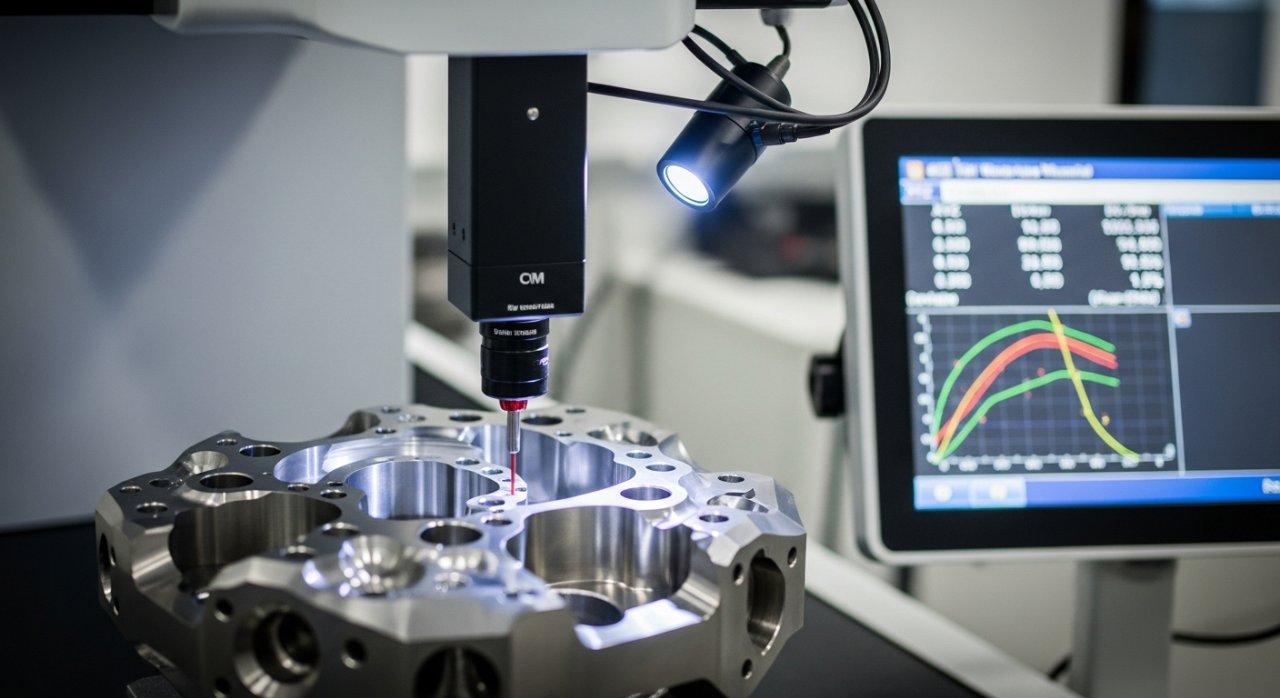

At ly-machining, our commitment to High-Quality Parts is backed by multi-stage quality control. From incoming material inspection to in-process checks and final CMM verification, every component undergoes rigorous scrutiny.

This meticulous approach, part of our Precision Machining Expertise, guarantees that finished parts meet or exceed specified tolerances and surface finishes.

TABLE: Example Quality Control Checks

| Production Stage | Inspection Method | Key Parameters Checked |

|---|---|---|

| Incoming Material | Material Certificates | Chemical composition, mechanical properties |

| In-Process Machining | On-machine probes, calipers | Dimensional accuracy, feature location |

| Post-Machining | CMM, Optical Comparator | Full dimensional report, geometric tolerances |

| Surface Finish | Surface Profilometer | Ra, Rz values |

Transparent Quotation Processes

Our Transparent Pricing model for High-End Material CNC Machining ensures you receive clear, detailed quotes without ambiguity. We itemize costs related to material, machining time, tooling, and any special processes.

This clarity empowers you to make informed decisions and budget effectively, fostering a relationship built on trust.

Value of Long-Term Partnerships

Building long-term partnerships is our priority. By consistently delivering High-Quality Parts with Transparent Pricing and exceptional service, we aim to become an indispensable extension of your supply chain.

These enduring relationships are testament to our reliable Precision Machining Expertise and commitment to client success.

Evaluating Potential Partners Effectively

Factory & Equipment Site Visits

Conducting a site visit to a potential CNC Machining Manufacturer is invaluable. It allows you to observe their operations firsthand, assess the condition of their equipment, and evaluate their commitment to cleanliness and safety.

This visit provides tangible evidence of their technical capabilities and overall professionalism.

Requesting Case Studies & References

Always request detailed case studies that are relevant to your project’s complexity and material requirements. Speaking with existing clients (references) can provide independent validation of their performance and reliability.

This due diligence is a critical step in ranking Top CNC Suppliers Ranking.

In-Depth Technical Consultations

Engage in thorough technical consultations with their engineering team. This is an opportunity to discuss your design challenges, ask specific questions about their processes, and gauge their problem-solving acumen.

A strong technical consultation will confirm their Precision Machining Expertise.

Case Study: Accelerating Medical Device Innovation

Problem: A medical device startup needed to produce a complex, miniature surgical instrument component from medical-grade titanium (Ti-6Al-4V ELI). Previous suppliers struggled with achieving the sub-micron surface finish and tight geometric tolerances required for biocompatibility and precise functionality, leading to costly delays and scrapped parts.

Our Solution: At ly-machining, leveraging our High-End Material CNC Machining expertise, we collaborated closely with the client’s R&D team. Our engineers provided DFM feedback, optimizing the design for our 5-axis micromachining capabilities. We developed a proprietary multi-stage finishing process and utilized advanced metrology (CMM with sub-micron probes) to validate every critical dimension and surface roughness requirement.

Result: We successfully delivered the first batch of High-Quality Parts ahead of schedule, meeting all stringent specifications. Our Precision Machining Expertise significantly reduced the client’s time-to-market, minimized material waste, and ensured the instrument’s flawless performance, earning us a long-term partnership for their subsequent product lines.

Your Premier Precision Machining Choice

Recap of Core Advantages

Choosing a CNC Machining Manufacturer for High-End Material CNC Machining demands rigorous evaluation. Our commitment to Precision Machining Expertise, Transparent Pricing, and delivering High-Quality Parts positions us as a leader.

We blend advanced technology with profound material science understanding to tackle your most challenging projects.

Contact Our Expert Team Today

Ready to transform your challenging designs into high-precision realities? Contact our expert engineering team today for a complimentary project consultation and a transparent, detailed quote. Discover the confidence of partnering with a leading source manufacturer.

FAQ Section

What materials do you specialize in?

In our High-End Material CNC Machining, we specialize in a range of challenging materials. These include titanium alloys, Inconel, stainless steel grades (e.g., 300 series, 17-4 PH), PEEK, and other high-performance plastics.

Our Precision Machining Expertise extends to optimizing processes for each specific material.

How do you ensure part quality?

We ensure High-Quality Parts through a robust, multi-stage quality control system. This includes material certification verification, in-process inspection with advanced probes, and final verification using CMMs and optical comparators.

Our adherence to ISO 9001 and AS9100 standards guarantees meticulous checks.

Can you assist with DFM?

Absolutely, our engineering team provides comprehensive Design for Manufacturability (DFM) support. We collaborate with clients to optimize designs for efficient High-End Material CNC Machining.

This proactive approach helps reduce costs, enhance manufacturability, and improve final part performance.