Mastering Surface Roughness in CNC Machining

Achieving optimal surface roughness in CNC machining is crucial for part performance. Precision CNC machining ensures exact finishes through meticulous control of tooling, parameters, and post-processing, critical for high-quality custom CNC parts and services.

Inconsistent surface roughness can silently undermine your product’s performance and escalate manufacturing costs. Discover how precision CNC machining can transform your critical components, ensuring exact surface finishes that guarantee reliability and extend product life. ly-machining is at the forefront of this technology, bringing unparalleled expertise.

This article will delve into the intricacies of surface roughness control, exploring the factors, advanced techniques, and measurement methods essential for superior custom CNC parts. We will also highlight how ly-machining, as a source manufacturer, delivers exceptional quality and transparent CNC machining services.

The Critical Role of Surface Roughness

Surface roughness is more than just aesthetics; it is a fundamental characteristic that dictates a part’s functionality and longevity. In precision CNC machining, controlling this attribute is paramount.

Why Precision CNC Machining Demands Smoothness

A smooth surface reduces friction between mating components, minimizing wear and heat generation. This is especially vital for dynamic assemblies where parts move against each other, demanding specific custom CNC parts specifications.

Furthermore, uniform surface finishes improve fatigue resistance, preventing crack initiation points that can arise from microscopic imperfections. ly-machining consistently focuses on these details.

Impact on Part Performance and Durability

Poor surface finish can lead to accelerated corrosion, as surface irregularities create micro-pockets that trap corrosive agents. This compromises the material’s integrity over time.

For applications requiring seals or coatings, an inadequate surface finish can prevent proper adhesion, leading to leaks or premature coating failure. ly-machining understands these critical performance requirements for custom CNC parts.

Factors Influencing CNC Surface Roughness

Achieving precise surface roughness in CNC machining involves a delicate balance of several interconnected factors. ly-machining’s engineers meticulously analyze each to optimize outcomes.

Tooling Selection in CNC Machining Services

The choice of cutting tool geometry, material, and coating significantly impacts the final surface finish. Tools with larger nose radii often produce smoother surfaces due to their ability to shear material more uniformly.

Tool wear is another critical consideration in CNC machining services; a dull tool will invariably degrade surface quality. ly-machining employs strict tool management and frequent inspections to prevent this.

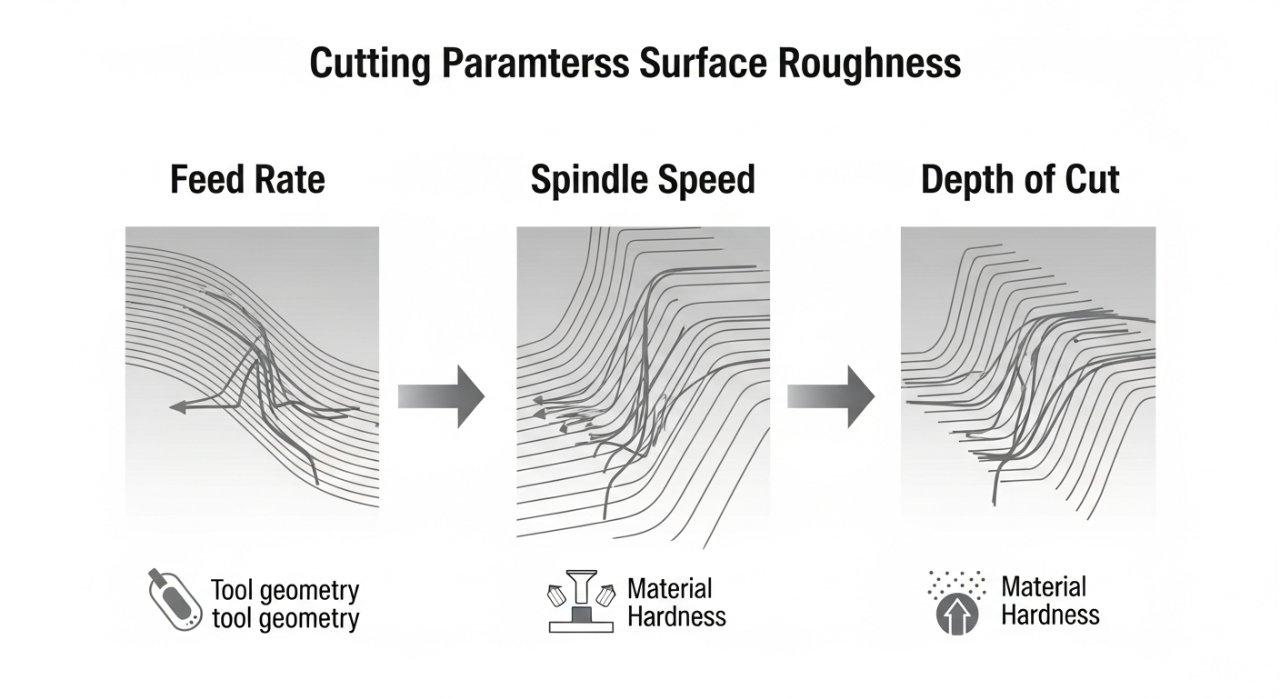

Optimizing Cutting Parameters for CNC machining

Feed rate, spindle speed, and depth of cut are paramount. Lower feed rates and higher spindle speeds generally yield finer finishes, but this must be balanced with material properties and cycle time.

Excessive depth of cut can induce vibrations and increase tool deflection, negatively impacting surface quality. ly-machining conducts thorough DFM analysis to determine optimal parameters for every precision CNC machining project.

Material Properties & Custom CNC Parts Finishes

Different materials respond uniquely to machining processes. Softer, gummy materials like certain aluminum alloys can be prone to built-up edge, affecting finish.

Harder materials may require specific tool coatings and lower speeds to avoid chipping or excessive tool wear. ly-machining possesses deep expertise in machining a wide range of materials for custom CNC parts.

Here’s a general overview of material properties and typical achievable surface finishes:

| Material Type | Typical Ra Range (µm) | Key Machining Considerations |

|---|---|---|

| Aluminum Alloys | 0.4 – 3.2 | Can be gummy; requires sharp tools, good chip evacuation. |

| Stainless Steels | 0.8 – 6.3 | Work hardening; needs rigid setup, positive rake angles. |

| Titanium Alloys | 0.8 – 6.3 | Low thermal conductivity; requires strong cooling, sharp tools. |

| Tool Steels | 0.2 – 3.2 | High hardness; requires carbide/CBN tools, stable processes. |

| Engineering Plastics | 0.8 – 6.3 | Low melting points; can melt or smear; requires sharp tools. |

Machine Rigidity and Vibration Control

A robust and rigid CNC machining center is fundamental for maintaining consistent tool engagement and minimizing vibrations. Any machine instability will manifest as chatter marks on the part surface.

ly-machining invests heavily in state-of-the-art machines, including over 80 high-precision CNC centers and 5-axis machines, ensuring maximum rigidity and stability during precision CNC machining operations.

Advanced Techniques for Superior Surface

Beyond fundamental parameter control, ly-machining employs advanced techniques to achieve the most demanding surface finish specifications for custom CNC parts.

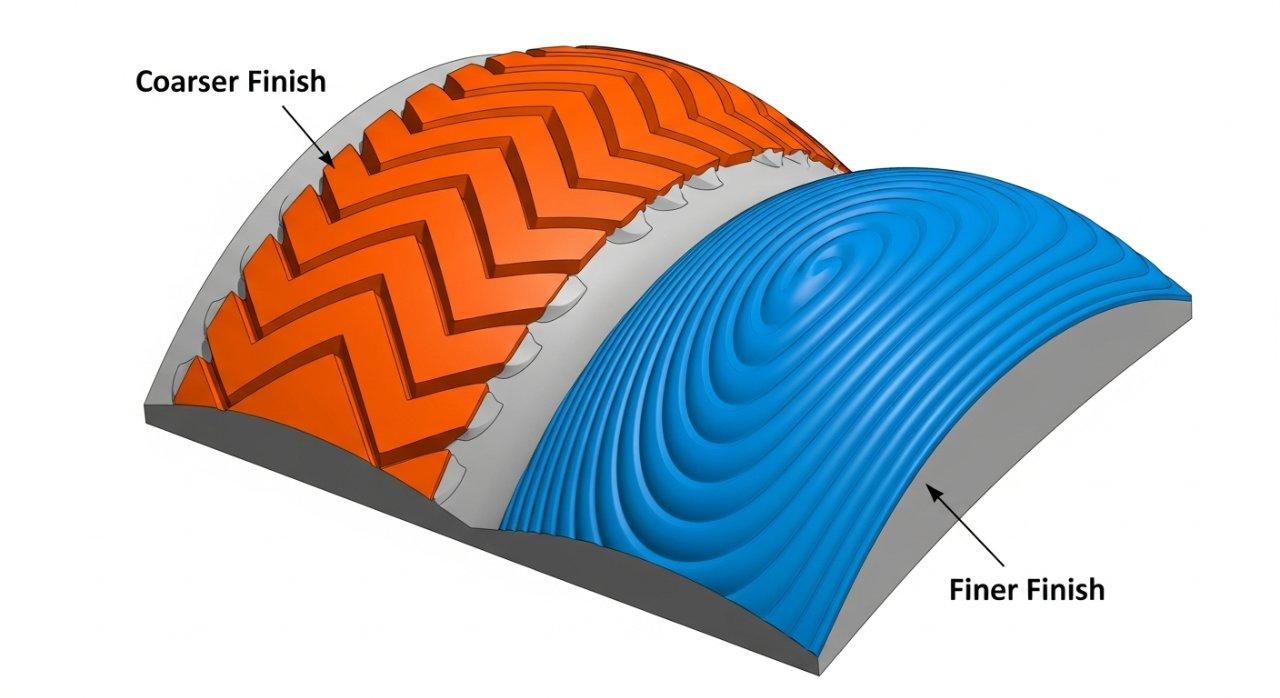

Precision CNC Machining Toolpath Strategies

Optimized toolpath generation is crucial. Strategies like spiral machining or trochoidal milling can reduce cutting forces and distribute wear more evenly, leading to better surface quality.

Finish passes, often with a reduced step-over and lighter depth of cut, are specifically designed to clean up the surface without introducing new imperfections. This is a core aspect of our precision CNC machining approach.

Honing and Polishing Custom CNC Parts

For extremely fine surface finishes (e.g., Ra < 0.2 µm), secondary operations such as honing, lapping, or polishing may be necessary. These post-processing steps refine the surface after initial CNC machining.

ly-machining works closely with clients to determine if and when these additional steps are required, ensuring the most cost-effective and precise solution for their custom CNC parts.

Post-Processing Options for CNC Machining

Beyond mechanical finishing, other post-processing options can enhance surface properties. Abrasive flow machining, for instance, can smooth intricate internal geometries.

Electropolishing or chemical polishing can achieve very fine, deburred surfaces for specific applications, often used for medical or aerospace components where ly-machining specializes.

Measuring and Specifying Surface Finish

Accurate measurement and clear specification are non-negotiable for consistent quality in precision CNC machining.

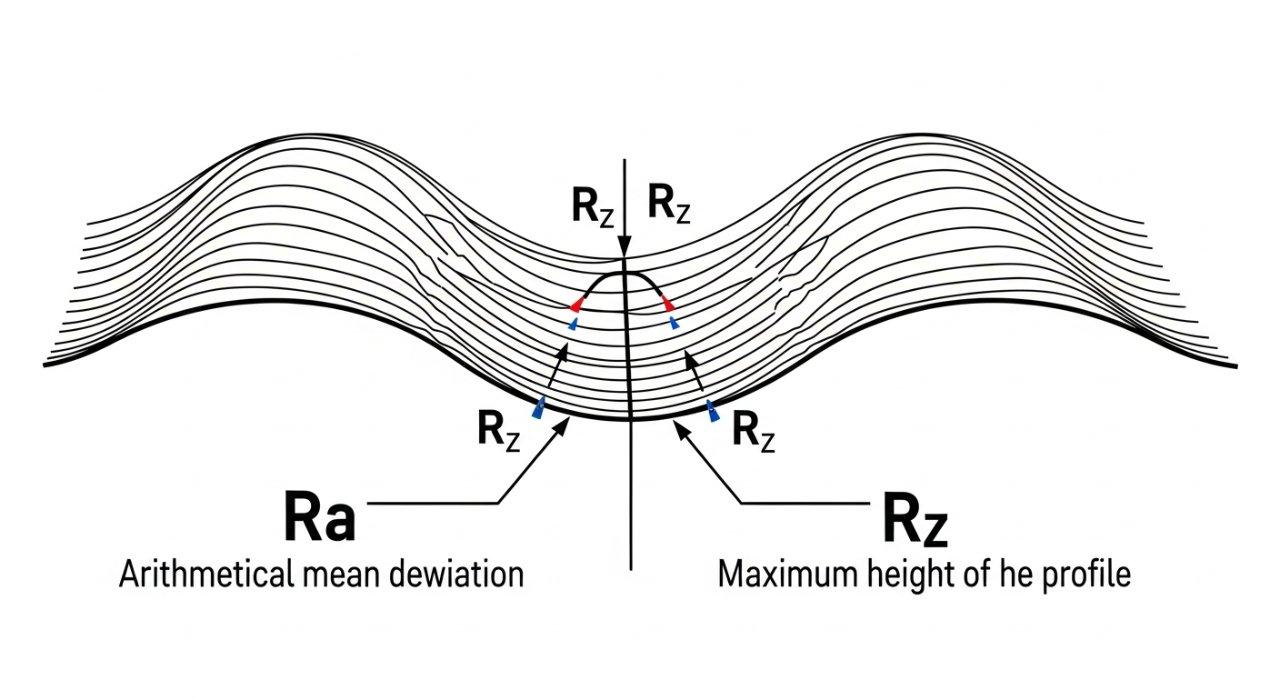

Understanding Ra, Rz, and Other Metrics

Ra (arithmetical mean deviation) is the most common parameter, representing the average roughness. However, it can be insufficient for critical applications.

Rz (maximum height of the profile) provides information on peak-to-valley distances, which can be crucial for sealing surfaces. Other metrics like Rq (root mean square) and Rsk (skewness) offer a more comprehensive profile.

| Surface Roughness Metric | Description | Application Insights |

|---|---|---|

| Ra (Arithmetic Mean) | Average absolute deviation of the roughness profile from its mean line. | Most common, good for general purpose surface texture comparison. |

| Rz (Max Peak-to-Valley) | Average of the highest peak to the lowest valley within a sampling length. | Important for sealing, bearing, and contact surfaces. |

| Rq (Root Mean Square) | Root mean square value of the deviation of the roughness profile. | Similar to Ra but more sensitive to occasional high peaks/valleys. |

| Rsk (Skewness) | Measure of the symmetry of the profile about the mean line. | Indicates if peaks or valleys dominate (e.g., fluid retention). |

Inspection Methods for Custom CNC Parts

Profilometry involves a stylus tracing the surface to generate a 2D profile. This contact method is highly accurate and widely used by ly-machining for custom CNC parts.

Non-contact methods, such as optical profilometry or interferometry, use light to measure surface topography, ideal for delicate surfaces or complex geometries. ly-machining employs a full suite of QC tools.

Our Expertise in Precision CNC Machining

ly-machining is dedicated to delivering superior precision CNC machining solutions, founded on technical excellence and a client-centric approach.

Source Manufacturer Advantage in CNC Machining

As a source manufacturer based in Shenzhen, China, ly-machining offers direct factory pricing and unmatched transparency. We eliminate the middleman, ensuring competitive costs without compromising quality for your CNC machining services.

Our comprehensive facilities house over 80 advanced machines, giving us complete control over every stage of the manufacturing process, from raw material to final inspection.

Ensuring High-Quality Custom CNC Parts

ly-machining’s commitment to quality is unwavering, backed by ISO9001 and IATF1649 certifications. We implement rigorous full-chain quality control, from initial design evaluation (DFM reports) to final product verification.

Our expertise spans complex structure processing and specialized material handling, ensuring that even the most challenging custom CNC parts meet stringent requirements.

Transparent Pricing for Precision CNC Machining

We believe in clear, upfront pricing. Our factory-direct model means you receive transparent quotes for precision CNC machining without hidden fees.

ly-machining focuses on delivering high-value solutions, ensuring that every investment in our CNC machining services translates into superior part quality and performance for you.

Deep Technical Support for CNC Machining

Our engineering team provides unparalleled technical support, offering DFM reports and expert consultation from concept to completion. We partner with you to optimize designs for manufacturability and performance.

Whether it’s 5-axis machining for intricate geometries or achieving ultra-fine surface finishes, ly-machining’s technical prowess is your competitive advantage.

Choose Us for Your Precision Needs

Partner with ly-machining for your next project requiring high-quality CNC machining and precise surface roughness control.

Partnering for Reliable Custom CNC Parts

ly-machining is more than a supplier; we are a trusted partner committed to the success of your project. Our one-stop service, from rapid prototyping (24-hour service available) to final delivery with no MOQ, simplifies your procurement process.

We serve demanding industries such as aerospace, medical, and robotics, where precision and reliability of custom CNC parts are non-negotiable.

Get a Transparent Quote for CNC Machining Services

Ready to experience the difference of true precision and quality? ly-machining invites you to get a free quote or technical consultation for your CNC machining services.

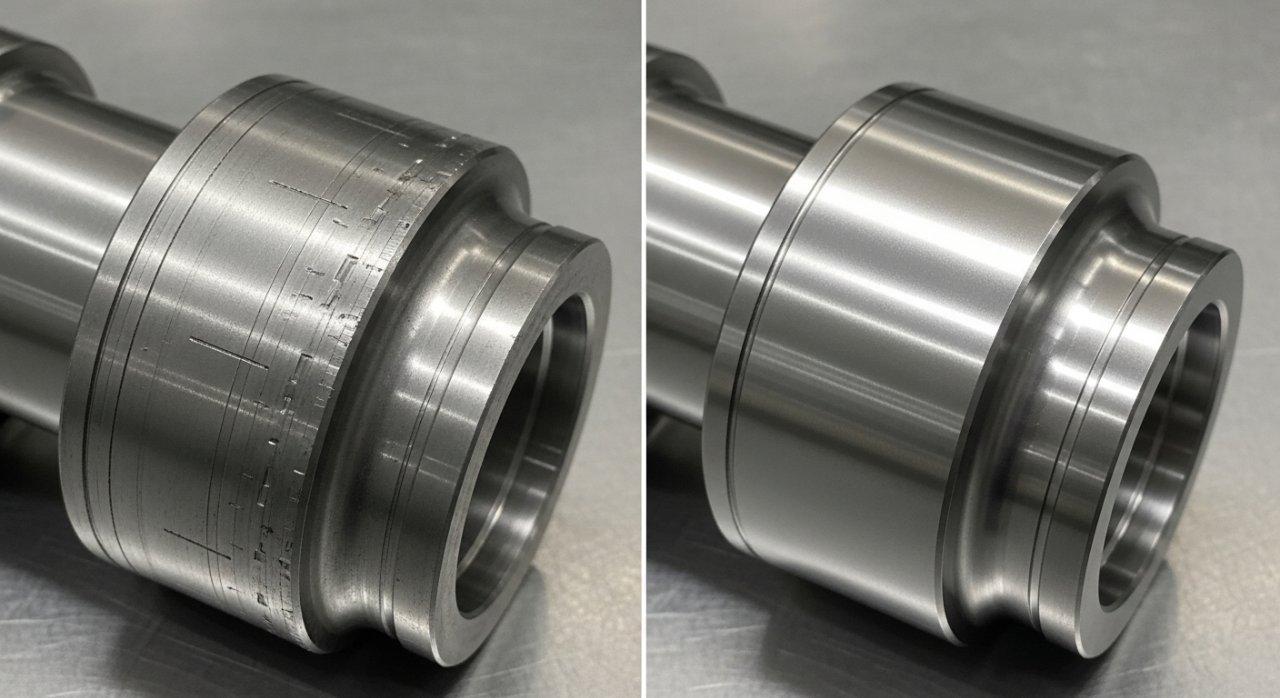

Case Study: Achieving Ultra-Smooth Finishes for Medical Devices

Problem: A client in the medical industry required custom stainless steel components with an exceptionally smooth surface finish (Ra 0.2 µm) to prevent bacterial adhesion and ensure biocompatibility. Their previous supplier struggled with consistency, leading to high rejection rates.

Our Solution: ly-machining’s engineering team collaborated closely with the client, analyzing their design for manufacturability (DFM). We specified a multi-stage precision CNC machining process, incorporating optimized toolpath strategies, specialized carbide tooling with a large nose radius, and meticulous control of cutting parameters. A final, controlled mechanical polishing step was integrated into the workflow.

Result: ly-machining consistently delivered components meeting the strict Ra 0.2 µm requirement, reducing the client’s rejection rate by over 70%. The improved surface finish enhanced the device’s functional performance and significantly extended its lifespan, ensuring compliance and market success.

Ready to elevate your product’s performance with guaranteed surface finish precision? Contact ly-machining’s expert engineering team today for a free, no-obligation consultation. Let us analyze your unique requirements and provide a transparent quote for your next custom CNC machining project, ensuring unparalleled quality from a trusted source manufacturer.

FAQ Section

What is surface roughness in CNC machining?

Surface roughness refers to the fine irregularities in the surface texture of a machined part. It is measured in micrometers (µm) and is critical for a part’s function, durability, and aesthetic appeal.

Achieving the specified surface roughness requires precise control over tooling, cutting parameters, and machine stability during the CNC machining process.

Why is precision CNC machining important for surface finish?

Precision CNC machining is crucial because it allows for highly controlled material removal, minimizing imperfections. It ensures consistent, repeatable surface finishes that meet stringent engineering specifications.

This level of control prevents issues like excessive friction, premature wear, and compromised sealing capabilities, which are vital for high-performance custom CNC parts.

How does ly-machining ensure surface quality?

ly-machining ensures superior surface quality through a multi-faceted approach. This includes advanced tooling selection, optimized cutting parameters, rigorous quality control with profilometry, and expertise in post-processing.

Our deep technical knowledge and state-of-the-art equipment, including 5-axis CNC machines, enable us to achieve the most demanding surface finish requirements for all CNC machining services.