China CNC Machining Ranking: True Strength

China’s top CNC machining manufacturers distinguish themselves by more than just size. The best CNC machining companies offer unparalleled quality, deep technical expertise, and transparent operations, providing leading CNC machining services that prioritize client success over superficial `CNC machining manufacturers ranking`.

The quest for a definitive `CNC machining manufacturers ranking` in China often leads to an overwhelming number of options. True strength for `best CNC machining companies` lies beyond a simple list. It’s found in proven capabilities, quality, and a commitment to partnership, delivering `leading CNC machining services`.

The Illusion of a Simple Ranking List

Many clients seeking `CNC machining` partners start their search with general `CNC machining manufacturers ranking` lists. However, these often overlook the nuances that truly define a superior `CNC manufacturing` provider. Surface-level data can be misleading.

Why traditional CNC machining manufacturers ranking fall short

Traditional `CNC machining manufacturers ranking` often rely on easily quantifiable metrics like company size or export volume. These factors don’t inherently guarantee the quality or precision required for complex projects. A large facility doesn’t always translate to higher quality parts or better client service.

In ly-machining’s experience, true `CNC machining` prowess is measured by a blend of technical capability, stringent quality control, and customer-centric service. These elements are rarely captured in basic numerical rankings.

The hidden risks in relying solely on published lists

Sole reliance on `top CNC manufacturers` lists can expose projects to significant risks. Companies might appear high on a list but lack the specific expertise for specialized materials or tight tolerances. This can lead to costly reworks, project delays, or even critical component failure.

Such lists often fail to assess a supplier’s true trustworthiness or consistency in delivering `high-quality parts`. The ultimate hidden risk is partnering with a factory incapable of meeting stringent demands, despite its advertised ranking.

Defining Comprehensive Strength in CNC

Comprehensive strength for `China CNC machining companies` extends far beyond basic `CNC machining` capabilities. It encompasses a holistic approach to manufacturing excellence, ensuring consistent quality and engineering support.

Quality assurance: A mark of best CNC machining companies

Unwavering quality assurance is the bedrock of `best CNC machining companies`. It involves not just final inspection but quality integration throughout the entire `CNC manufacturing` process. This commitment impacts every component.

ly-machining maintains rigorous, full-chain quality control, holding both ISO9001 and IATF16949 certifications. This ensures that every `CNC machining part` meets the highest industry standards, from raw material inspection to final packaging.

| **Key Quality Control Indicators** |

|---|

| ISO 9001 Certification |

| IATF 16949 Certification |

| In-Process Inspection Protocols |

| Final Dimensional Inspection |

| Surface Finish Quality |

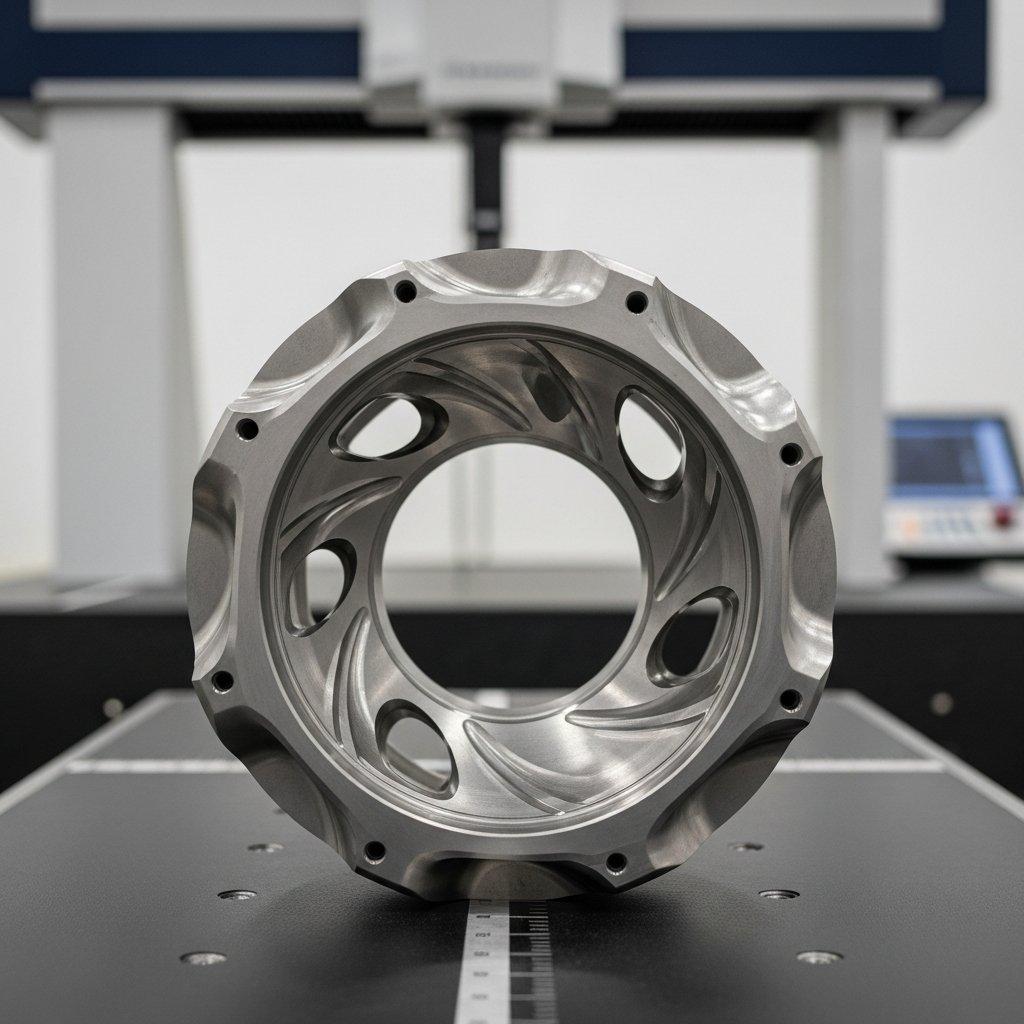

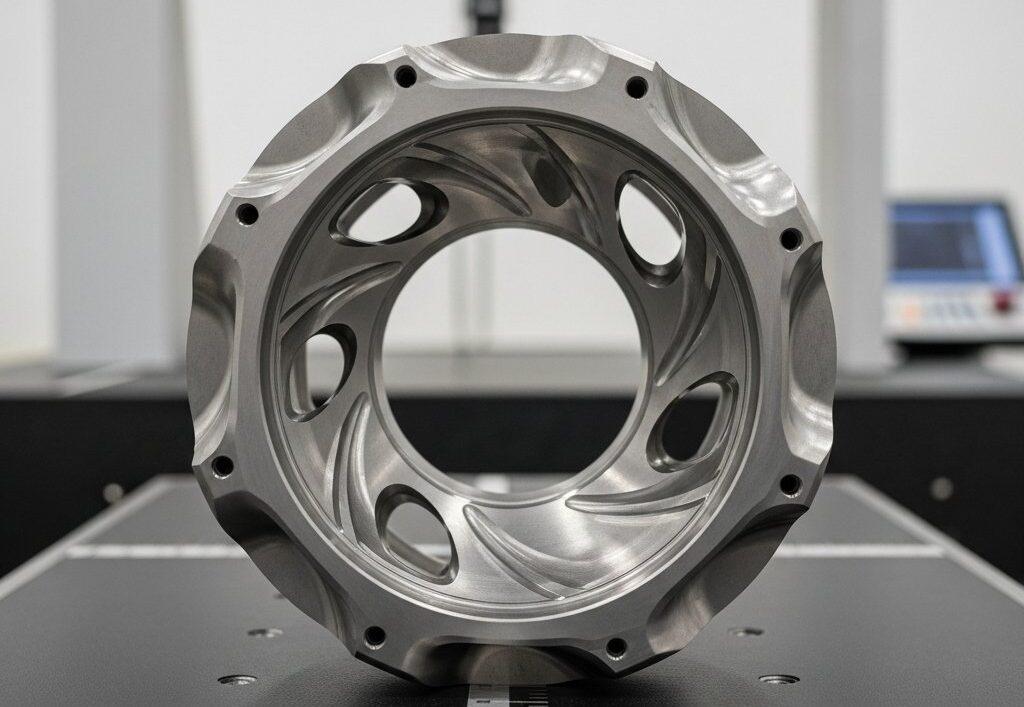

Deep technical expertise for complex CNC machining needs

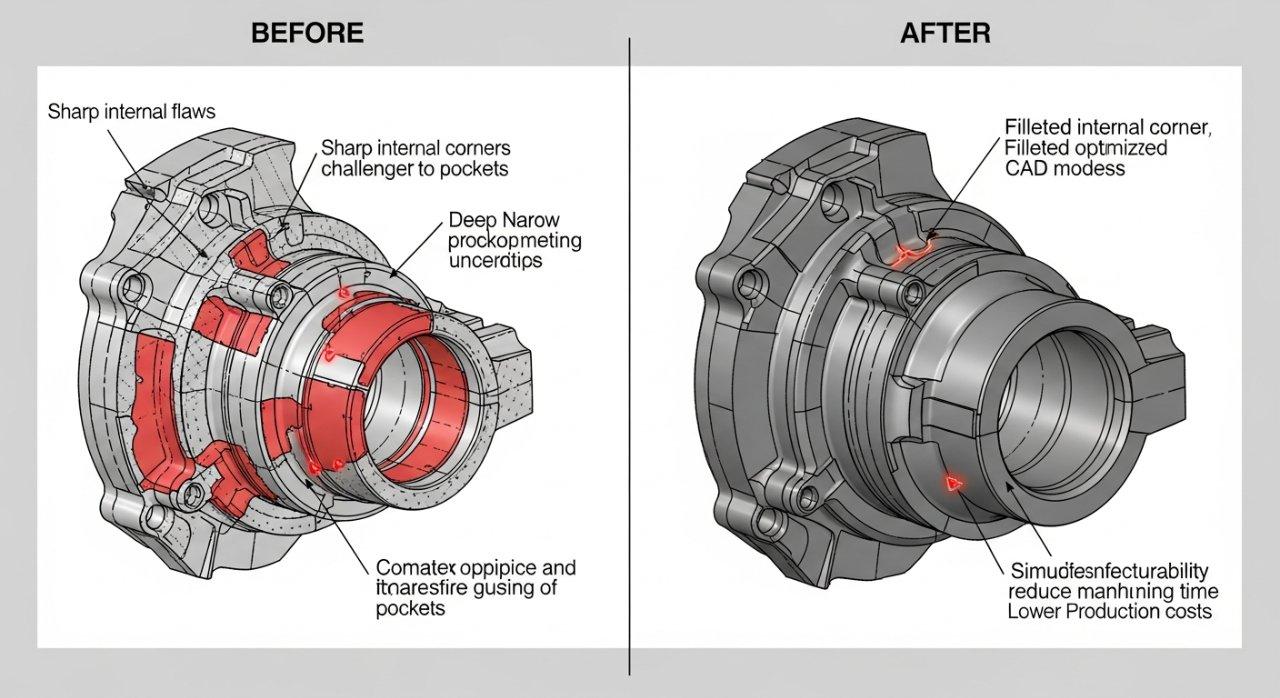

Addressing `complex CNC machining` needs requires more than standard equipment; it demands deep technical expertise. This includes Design for Manufacturability (DFM) analysis and the ability to process challenging materials.

ly-machining specializes in complex structure processing, including advanced 5-axis `precision milling`. Our engineers provide DFM reports, ensuring designs are optimized for efficiency and performance across materials like aluminum alloys, stainless steel, and titanium.

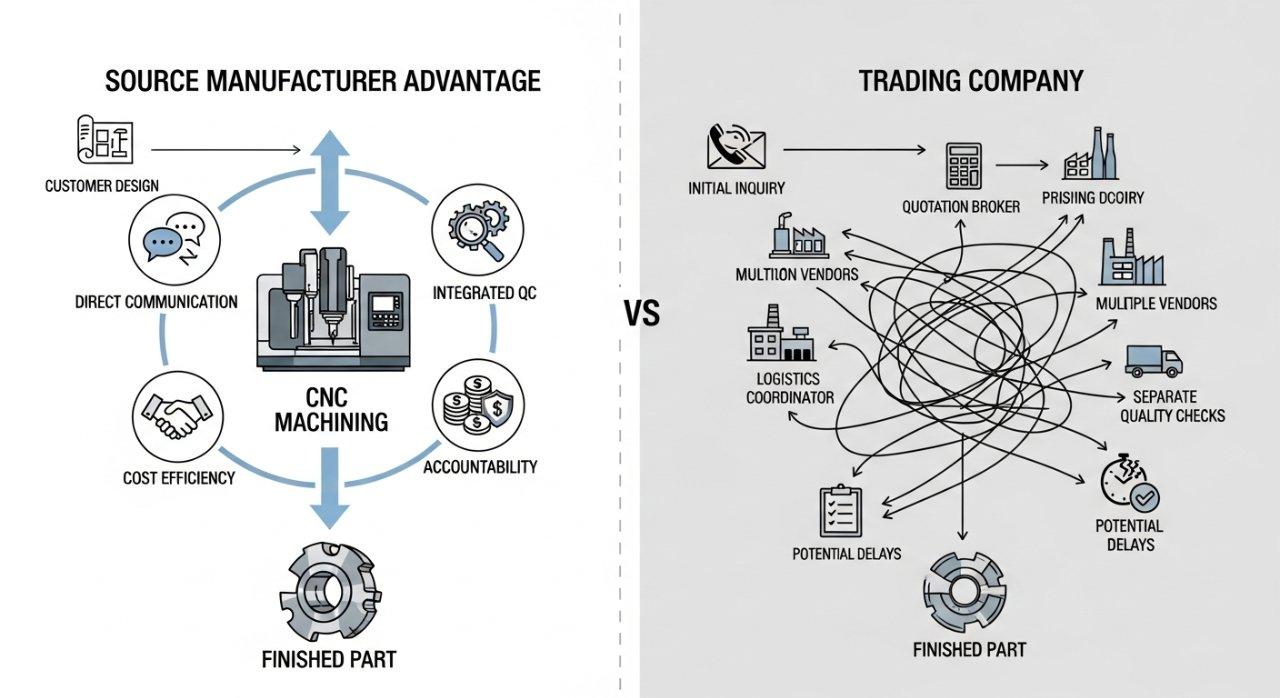

Transparent pricing: Key for leading CNC machining services

For `leading CNC machining services`, transparent pricing builds essential trust and predictability. Clients need clear, itemized quotes that avoid hidden costs, allowing for accurate budget forecasting.

ly-machining provides transparent, factory-direct pricing without the markups of trading companies. This ensures clients receive optimal value for their `CNC machining` projects, fostering long-term, trustworthy relationships.

The ‘source manufacturer’ advantage in CNC machining

Being a true ‘source manufacturer’ provides a distinct advantage in `CNC machining`. It means direct control over every aspect of production, from raw material sourcing to final inspection and dispatch.

ly-machining, as a Shenzhen-based source manufacturer, offers clients unparalleled accountability and efficiency. This direct engagement streamlines communication and ensures consistent `high-quality parts` delivery.

Material certification and traceability for top CNC manufacturers

For `top CNC manufacturers`, material certification and traceability are non-negotiable, particularly for demanding industries. This ensures the integrity and performance of every `CNC machining part`.

ly-machining guarantees full material traceability, providing certificates of conformity for all raw materials. This critical step assures clients of component reliability and compliance with industry standards.

Evaluating China CNC Machining Companies

When evaluating `China CNC machining companies`, a discerning approach is essential. Focus on tangible evidence of quality, technical capability, and reliable communication beyond initial impressions.

Beyond facility tours: What truly defines a partner

While impressive facilities are good, what truly defines a `CNC machining` partner is its operational rigor, technical depth, and skilled workforce. Look for evidence of structured processes and continuous improvement.

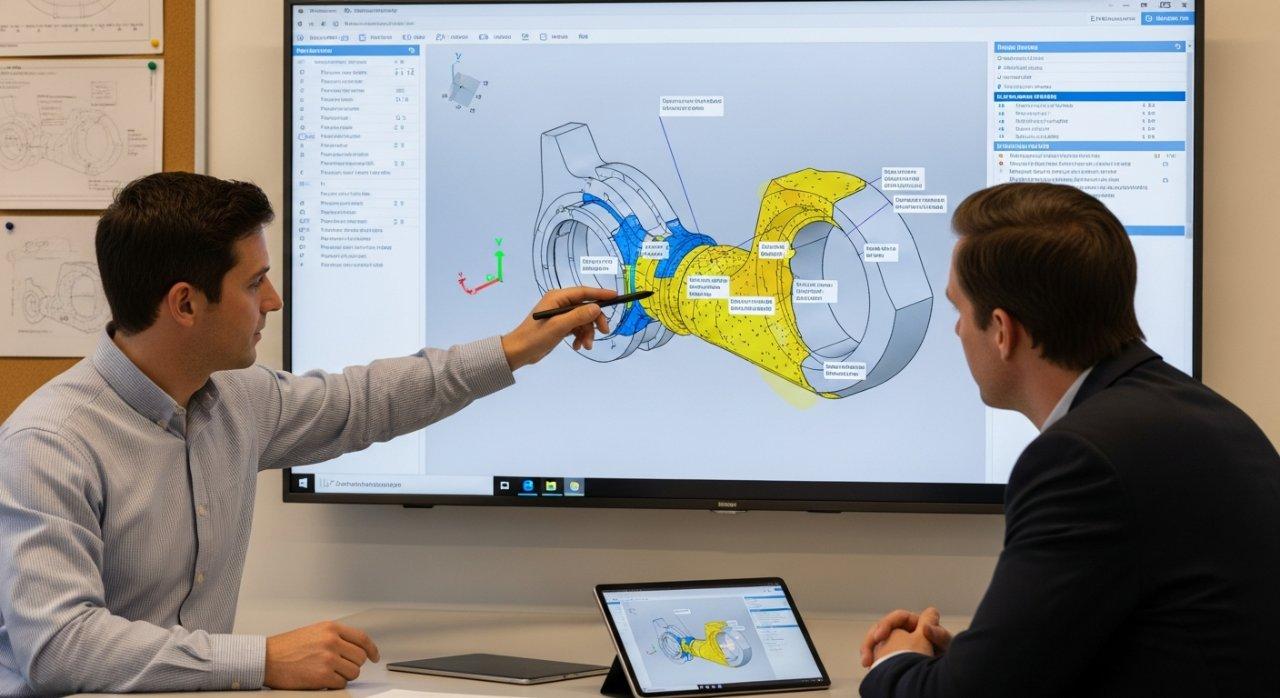

Assess the factory’s engineering team and their ability to interpret complex technical drawings and provide DFM insights. This technical dialogue is crucial for successful `precision milling` projects.

Assessing supplier’s quality control for CNC machining parts

Thoroughly assessing a supplier’s quality control for `CNC machining parts` is paramount. This includes understanding their inspection protocols at various stages of the manufacturing process.

ly-machining encourages clients to inquire about our in-process and final inspection procedures, including CMM reports and surface finish checks. Our transparent approach gives confidence in every batch.

| **Essential QC Checks During Production** |

|---|

| First Article Inspection (FAI) |

| In-process Gauging & Measurement |

| Non-Destructive Testing (NDT) |

| Material Verification |

| Final Visual & Dimensional Check |

The importance of clear communication in CNC machining

Clear and responsive communication is a cornerstone of successful `CNC machining` partnerships. Misunderstandings can lead to costly errors and delays in project timelines.

ly-machining prioritizes open channels with dedicated project managers and technical sales engineers fluent in English. We provide detailed DFM reports and regular updates to ensure seamless project execution.

Long-term partnership potential with top CNC manufacturers

Building a `long-term partnership` with `top CNC manufacturers` provides stability and scalability. A reliable partner can adapt to evolving needs, from rapid prototyping to high-volume production.

ly-machining focuses on fostering enduring relationships, consistently delivering `high-quality parts` and responsive support. Our commitment to reliability makes us a trusted extension of your supply chain.

Our Approach to Superior CNC Machining

At ly-machining, we define `superior CNC machining` through an unwavering commitment to quality, efficiency, and customer satisfaction. Our methodologies are designed to deliver exceptional value.

Our commitment to high-quality parts in every CNC machining order

Every `CNC machining order` at ly-machining undergoes stringent quality checks to ensure `high-quality parts`. We understand that precision is non-negotiable for critical applications in industries like aerospace and medical.

Our state-of-the-art metrology equipment, including CMMs, verifies dimensional accuracy to exacting tolerances. This dedication guarantees the integrity and functionality of your components.

Experience our transparent pricing for all CNC machining services

ly-machining believes in complete transparency for all `CNC machining services`. Our direct factory model eliminates intermediaries, offering highly competitive and straightforward pricing structures.

This ensures you receive genuine value without hidden fees, empowering you to make informed budgetary decisions. We provide detailed quotes, itemizing every aspect of your project.

Leveraging deep technical expertise for complex CNC machining

ly-machining’s `deep technical expertise` is pivotal for tackling `complex CNC machining` challenges. Our skilled engineers and advanced 5-axis capabilities handle intricate geometries and diverse materials.

We actively collaborate with clients, providing DFM insights to optimize designs for manufacturability, reducing costs, and improving performance. This partnership ensures project success from concept to production.

The benefit of a true source manufacturer for your CNC machining needs

As a true `source manufacturer`, ly-machining offers direct oversight and control over all `CNC machining needs`. This means faster lead times, enhanced quality control, and unparalleled responsiveness.

This direct relationship fosters greater accountability and provides peace of mind. You interact directly with the team manufacturing your components, ensuring clarity and efficiency.

Case Studies: True Strength in Action

These scenarios highlight how ly-machining’s unique approach delivers tangible results for clients seeking `leading CNC machining services`. Our commitment to expertise and quality solves real-world problems.

How a client found success with our CNC machining expertise

A medical device client faced critical delays due to an existing supplier’s inability to hold ultra-tight tolerances on a complex titanium implant component. The lack of `precision milling` caused failures.

ly-machining’s engineers reviewed the design, offered DFM suggestions, and utilized our 5-axis machines for precise execution. We delivered the `high-quality parts` ahead of schedule, enabling product launch.

Overcoming challenges with leading CNC machining services

Another project involved an aerospace client needing rapid prototyping for a critical structural bracket, with no minimum order quantity. Their current `top CNC manufacturers` quoted excessive lead times and MOQs.

ly-machining provided 24-hour rapid prototyping service and accepted a low MOQ, demonstrating our flexibility. This allowed the client to quickly test and iterate their design, significantly accelerating their R&D cycle.

Making Your Informed CNC Partner Choice

Selecting the right `CNC machining` partner is a strategic decision that impacts project success. Go beyond simple `CNC machining manufacturers ranking` and vet suppliers thoroughly.

Actionable steps to vet best CNC machining companies

To vet `best CNC machining companies`, always request recent quality certifications (ISO, IATF). Ask for detailed process documentation and material traceability records.

Consider requesting a small sample order or a facility audit. This direct engagement provides invaluable insight into their operational capabilities and commitment to quality.

Questions to ask top CNC manufacturers before partnership

Before committing to `top CNC manufacturers`, ask probing questions about their technical support, quality control, and communication processes. Understand their problem-solving methodology.

Inquire about their experience with your specific material and tolerance requirements. This direct inquiry helps ascertain their `deep technical expertise` and suitability for your project.

| Critical Questions for Prospective CNC Machining Suppliers |

|---|

| Do you offer DFM analysis and support? |

| What quality certifications do you hold? |

| Can you provide material certificates of conformity? |

| What are your lead times for prototyping vs. production? |

| How do you handle design changes mid-project? |

Ready to experience the difference a truly comprehensive `CNC machining` partner can make? Get a transparent, no-obligation quote for your high-precision project today and let ly-machining’s deep technical expertise bring your vision to life. Contact our engineering team for a free consultation.

How do I find truly reliable CNC machining services?

Focus beyond superficial rankings and prioritize factors like technical expertise, quality certifications, and a supplier’s transparent communication. A visit or audit can confirm their capabilities.

Look for manufacturers who are also source factories, as they offer direct control over quality and processes. This reduces risks and ensures consistent performance for your `CNC machining` needs.

What quality certifications should I look for?

For `high-quality parts` and `leading CNC machining services`, ensure the manufacturer holds ISO 9001 certification. For automotive components, IATF 16949 is crucial.

For aerospace or medical applications, inquire about AS9100 or ISO 13485 respectively. These certifications demonstrate a commitment to rigorous quality management systems.

Can ly-machining handle complex aerospace parts?

Yes, ly-machining possesses `deep technical expertise` and advanced 5-axis `precision milling` capabilities, making us highly capable of handling `complex aerospace parts`.

We specialize in difficult-to-machine materials like titanium and high-grade aluminum alloys. Our full-chain quality control and material traceability ensure aerospace-grade reliability.