Optimize Aluminum CNC Machining Costs

Unlocking substantial cost savings for `CNC machining aluminum parts` involves a strategic focus on design, material, process, and partnership to achieve `precision CNC aluminum components` efficiently.

Many businesses are grappling with escalating expenses in their `custom aluminum machined parts` projects, often due to overlooked inefficiencies. These costs impact profit margins and project timelines, hindering innovation and market responsiveness. This guide reveals seven powerful, actionable strategies to drastically reduce your expenses, enhance part quality, and optimize your production timeline, securing a competitive edge in `aluminum CNC machining service`.

Unlocking Savings in CNC Aluminum Parts

Why cost optimization matters for CNC machining aluminum parts

Cost optimization is paramount in `CNC machining aluminum parts` as aluminum is a widely used material, yet its machining can be complex and expensive if not managed effectively. Reducing costs directly enhances profitability and allows for more competitive pricing.

It enables businesses to invest further in innovation and technology, driving future growth and maintaining market relevance. In ly-machining’s experience, even small savings per part can lead to significant overall project cost reductions.

Common pitfalls in aluminum CNC machining service

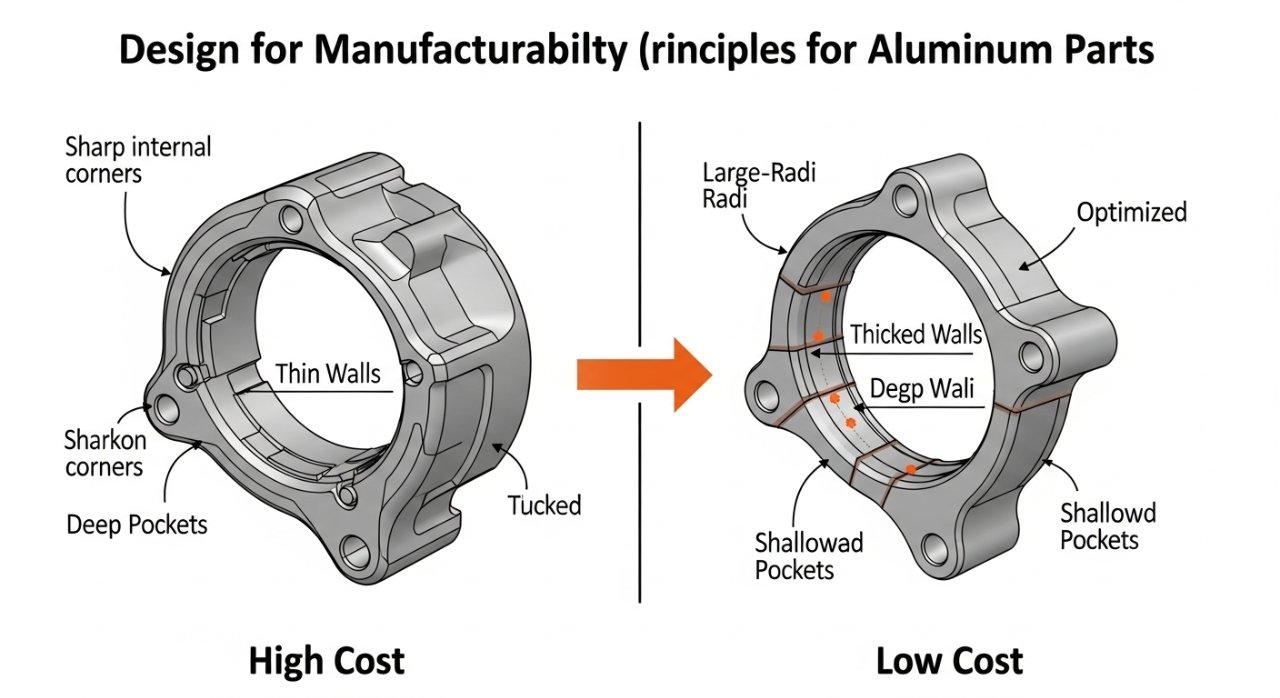

A common issue ly-machining sees is over-specification of tolerances or surface finishes that are not functionally required, leading to unnecessary machining time and higher costs. Poor design for manufacturability (DFM) is another frequent pitfall.

This results in complex geometries that require specialized tooling, multiple setups, or slower machining speeds, all of which inflate the final price for `aluminum CNC machining service`. Lack of effective material utilization also contributes to waste.

Strategy 1: DFM for Aluminum Parts CNC

Simplifying geometry for custom aluminum machined parts

Simplifying part geometry is a cornerstone of cost-effective `custom aluminum machined parts` production. Reducing sharp internal corners to larger radii minimizes stress concentrations and allows for the use of larger, more durable cutting tools.

Avoid thin walls or deep pockets where possible, as these often require specialized tooling and slower machining passes, increasing machine time and the risk of chatter. Simpler designs translate directly to faster `CNC machining` cycles.

Tolerances and their impact on precision CNC aluminum components

Tolerances dictate the precision required, directly impacting machining time and cost for `precision CNC aluminum components`. Tighter tolerances demand more precise machines, specialized tooling, slower feed rates, and often additional inspection steps.

Specify only the tolerances essential for the part’s functional performance. Over-specifying can unnecessarily increase the cost of `CNC machining aluminum parts` without adding functional value.

Here is a comparison of typical tolerance grades and their cost implications:

| Tolerance Grade | Description | Cost Impact |

|---|---|---|

| Standard | General engineering, non-critical dimensions | Low |

| Medium | Good fit, standard assembly | Moderate |

| Fine | Close fits, high precision | High |

| Ultra-Fine | Aerospace, medical, extreme accuracy | Very High |

Wall thickness optimization in CNC machining

Optimizing wall thickness is crucial for avoiding part distortion and tool chatter, especially in `CNC machining aluminum`. Thin walls are prone to vibration, requiring slower machining speeds and lighter cuts, which prolongs production time.

Conversely, overly thick walls waste material and increase material removal time. ly-machining recommends adhering to minimum wall thickness guidelines appropriate for the chosen aluminum alloy and machining process to balance strength and manufacturability.

Strategy 2: Material Sourcing for CNC Machining

Selecting the right aluminum alloy for CNC machining aluminum parts

The choice of `aluminum alloy for CNC machining parts` significantly impacts machinability, material cost, and final part performance. While 6061 is a common, versatile choice, other alloys like 7075 offer higher strength but are more challenging to machine.

Consult with ly-machining’s engineers to select an alloy that meets your mechanical requirements without unnecessary cost. Often, a slightly different alloy can offer similar performance at a lower machining or material cost.

Here are common aluminum alloys used in `CNC machining aluminum parts`:

| Alloy Type | Key Properties | Typical Applications | Machinability | Cost (Relative) |

|---|---|---|---|---|

| 6061 | Good strength-to-weight, weldable, corrosion resist. | General purpose, automotive, structural, frames | Excellent | Low |

| 7075 | Very high strength, fatigue resistant | Aerospace, military, high-stress components | Good | Medium-High |

| 2024 | High strength, good fatigue resistance | Aircraft structures, fasteners, fittings | Good | Medium |

| 5052 | Excellent corrosion resistance, formability | Marine, electronics, pressure vessels | Moderate | Low-Medium |

Bulk purchasing benefits for custom aluminum machined parts

For large production runs of `custom aluminum machined parts`, bulk purchasing of raw material can lead to substantial cost savings. Material suppliers often offer discounts for larger quantities, reducing the per-unit material cost.

ly-machining manages a robust supply chain, leveraging our purchasing power to secure competitive pricing for high-quality aluminum stock. This benefit is directly passed on to our clients, ensuring cost efficiency.

Strategy 3: Process Optimization in Aluminum CNC

Efficient tool path generation in CNC machining

Advanced CAM software and skilled programmers are vital for efficient `CNC machining`. Optimized tool paths minimize non-cutting movements, reduce air cutting, and ensure consistent chip load, extending tool life and speeding up production.

ly-machining utilizes state-of-the-art CAD/CAM systems to generate highly efficient tool paths, minimizing cycle times and maximizing material removal rates for every `precision CNC aluminum component`. This expertise directly translates to cost savings.

Optimizing cutting parameters for precision CNC aluminum components

Correct cutting parameters (feed rate, spindle speed, depth of cut) are crucial for balancing machining speed, tool life, and surface finish. Incorrect parameters can lead to excessive tool wear, poor surface quality, or even part damage.

ly-machining’s engineers possess deep expertise in material science and machining dynamics, meticulously fine-tuning parameters for each `precision CNC aluminum component` to achieve optimal performance and cost efficiency. This ensures high-quality parts without unnecessary expenditure.

Fixturing strategies for CNC machining aluminum parts

Effective fixturing is essential for secure workpiece holding, minimizing vibration, and allowing for multi-sided machining in fewer setups. Well-designed fixtures reduce setup times, improve part consistency, and decrease the risk of errors.

In ly-machining’s facilities, innovative fixturing solutions, including custom jigs and vacuum fixtures, are employed to maximize machining efficiency for `CNC machining aluminum parts`. This strategic approach reduces labor costs and enhances throughput.

Strategy 4: Tooling for Precision CNC Components

Choosing appropriate cutting tools for CNC machining

Selecting the correct cutting tools is fundamental for efficiency and quality in `CNC machining`. Carbide tools, though pricier upfront, offer superior hardness and heat resistance, leading to longer tool life and faster cutting speeds compared to HSS.

Specialized coatings, geometry, and flute counts are chosen by ly-machining based on the aluminum alloy and specific machining operation to maximize performance and reduce overall tooling costs through extended lifespan.

Tool life management for custom aluminum machined parts

Proactive tool life management involves monitoring tool wear and replacing tools before they fail, preventing scrap and ensuring consistent quality for `custom aluminum machined parts`. This is critical for maintaining `precision CNC aluminum components`.

ly-machining implements advanced tool monitoring systems and robust inventory management to ensure tools are always performing optimally, minimizing unexpected downtime and maintaining strict quality control.

Advanced coatings for precision CNC aluminum components

Advanced tool coatings, such as TiAlN or AlTiN, significantly enhance the performance and lifespan of cutting tools in `precision CNC aluminum components` production. These coatings improve hardness, reduce friction, and increase resistance to heat and wear.

While adding to tool cost, the extended tool life and ability to run at higher cutting speeds often result in a net cost saving by reducing tool changes and improving cycle times. ly-machining invests in these advanced tooling technologies.

Strategy 5: Post-Machining for Custom Aluminum Parts

Minimizing secondary operations for custom aluminum machined parts

Reducing or eliminating secondary operations like deburring, polishing, or extensive finishing saves significant time and labor costs for `custom aluminum machined parts`. This starts with DFM to achieve the desired finish directly from the machine.

By focusing on superior `CNC machining` quality from the outset, ly-machining ensures that parts often require minimal post-processing, thereby streamlining the production workflow and reducing overall expense.

Cost-effective surface finishes for CNC machining aluminum parts

The chosen surface finish can dramatically impact the cost of `CNC machining aluminum parts`. While a mirror polish might be visually appealing, it is often expensive and time-consuming to achieve.

Evaluate if a more cost-effective finish, such as a standard milled finish or a bead blast, meets the functional and aesthetic requirements. ly-machining advises clients on appropriate and cost-efficient surface finish options.

Strategy 6: Tech & Automation in Aluminum Machining

Leveraging CAD/CAM for optimal CNC machining

Integrating CAD/CAM software is indispensable for modern `CNC machining`. It allows for complex geometries to be designed and validated, then translated into precise, optimized tool paths for efficient production.

ly-machining utilizes the latest CAD/CAM technologies to simulate machining processes, identify potential issues before production, and optimize material utilization and cycle times for all `CNC machining aluminum parts`.

Automation benefits for precision CNC aluminum components

Automation, including robotic loading/unloading, pallet changers, and automated inspection, significantly reduces labor costs and increases throughput for `precision CNC aluminum components`. It also enhances consistency and repeatability.

By investing in advanced automation solutions, ly-machining ensures higher efficiency, reduced human error, and faster turnaround times, making our `aluminum CNC machining service` highly competitive.

In-process inspection for quality CNC machining aluminum parts

Implementing in-process inspection using probes and sensors within the `CNC machining` environment allows for real-time quality control. This early detection of deviations prevents the production of costly scrap parts.

ly-machining integrates advanced in-process measurement systems to ensure consistent quality and adherence to specifications for `CNC machining aluminum parts`. This proactive approach saves costs associated with rework and final inspection failures.

Strategy 7: Partnering for Cost-Effective CNC Parts

The value of a source manufacturer for aluminum CNC machining service

Partnering with a source manufacturer like ly-machining for your `aluminum CNC machining service` eliminates middlemen, leading to direct communication, greater transparency, and often lower costs.

As a direct manufacturer, ly-machining has complete control over the production process, ensuring consistent quality, shorter lead times, and the ability to respond quickly to your specific needs.

Transparent pricing models for custom aluminum machined parts

Transparency in pricing is a hallmark of a trustworthy manufacturing partner. Hidden costs and vague quotations can quickly inflate project budgets for `custom aluminum machined parts`.

ly-machining offers clear, detailed, and transparent pricing models, ensuring you understand exactly what you are paying for, building trust and enabling accurate budget forecasting.

Deep technical expertise for precision CNC aluminum components

Access to deep technical expertise is invaluable, especially for complex `precision CNC aluminum components`. An experienced manufacturing partner can offer critical DFM advice and solve unforeseen production challenges.

ly-machining’s team of seasoned engineers provides expert consultation, leveraging years of hands-on experience to optimize your designs for manufacturability, ensuring both quality and cost efficiency.

Partner for Quality CNC Aluminum Parts

Our commitment to high-quality custom aluminum machined parts

At ly-machining, our commitment extends beyond mere production; we aim to deliver `high-quality custom aluminum machined parts` that not only meet but exceed your expectations. We adhere to stringent quality control standards like ISO 9001 and AS9100.

Our processes are meticulously managed, from material sourcing to final inspection, ensuring every component we deliver embodies precision and reliability. We are dedicated to continuous improvement and client satisfaction.

Achieving cost efficiency in CNC machining aluminum parts

Achieving true cost efficiency in `CNC machining aluminum parts` is a balance of innovative design, optimized processes, and strategic partnership. It’s about maximizing value without compromising on quality or performance.

ly-machining prides itself on employing a holistic approach, integrating all seven strategies discussed to deliver superior parts at the most competitive prices. Our goal is to be an extension of your engineering team.

Your Next Step to Cost-Optimized Parts

Get a free DFM consultation for your aluminum CNC machining service

Ready to implement these powerful cost optimization strategies for your next project? ly-machining offers a free Design for Manufacturability (DFM) consultation tailored to your specific `aluminum CNC machining service` needs.

Our expert engineers will review your designs and provide actionable recommendations to reduce costs and enhance manufacturability. This invaluable service ensures your project starts on the most efficient path.

Request a transparent quote for precision CNC aluminum components

Experience the ly-machining difference firsthand. Contact us today to request a transparent, no-obligation quote for your `precision CNC aluminum components`. We stand by our commitment to clarity and competitive pricing.

Let ly-machining be your trusted partner for high-quality, cost-optimized `custom aluminum machined parts`. Our team is ready to demonstrate how our expertise can benefit your bottom line.

Frequently Asked Questions

How does DFM reduce CNC costs?

DFM (Design for Manufacturability) reduces `CNC machining` costs by simplifying part geometry, optimizing tolerances, and ensuring designs are compatible with efficient manufacturing processes. This minimizes material waste and machining time.

It allows for the use of standard tools and techniques, avoiding costly custom setups or secondary operations, directly impacting the final cost of `custom aluminum machined parts`.

Which aluminum alloy is most cost-effective for CNC?

Aluminum 6061 is generally considered the most cost-effective alloy for `CNC machining aluminum parts` due to its excellent machinability, widespread availability, and balanced properties. It offers a good balance of strength, weldability, and corrosion resistance.

While other alloys might offer specific performance advantages, 6061 typically provides the best value for general-purpose applications without compromising quality.

What is ly-machining’s quality standard?

ly-machining adheres to rigorous international quality standards, including ISO 9001 certification. For specific industries, we also comply with standards such as AS9100, ensuring the highest level of quality and traceability.

Our commitment to quality ensures that every `precision CNC aluminum component` we produce meets strict dimensional accuracy and performance requirements, guaranteeing reliability.