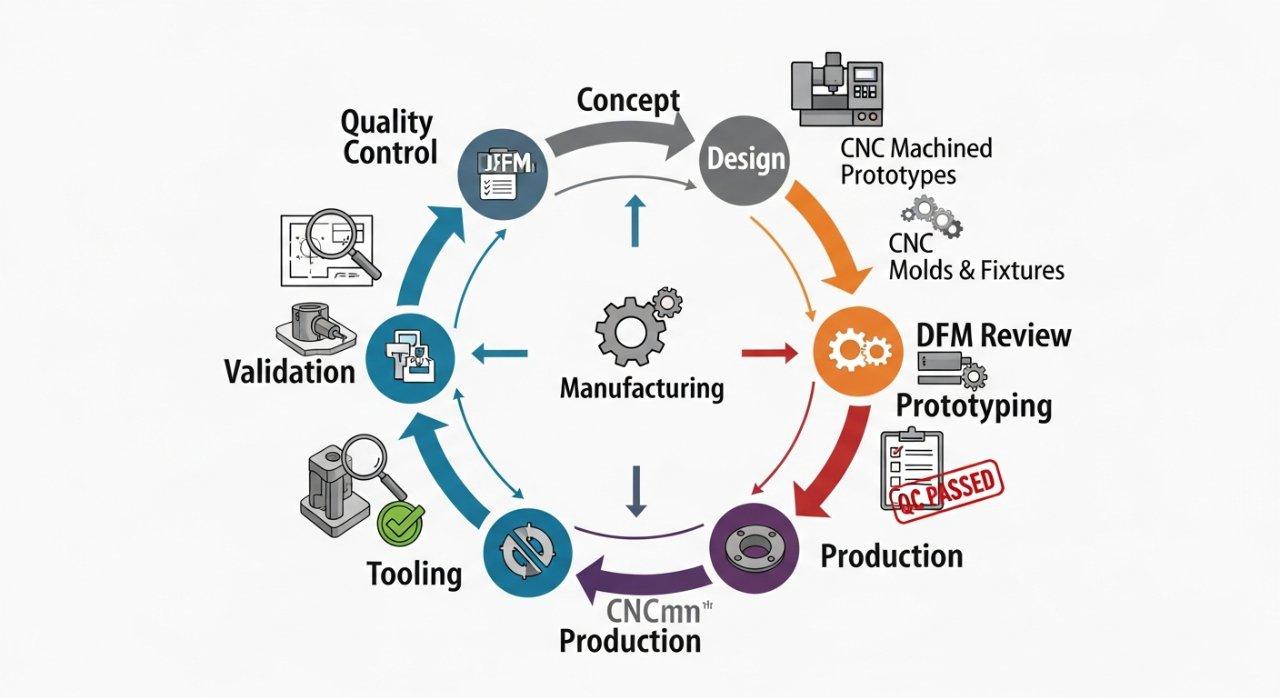

From Prototype to Production: CNC’s Role

A CNC machining manufacturer transforms designs into custom CNC parts, offering precision machining services from concept to scale. A skilled CNC machine shop ensures seamless transition from prototype to full production through expert CNC machining and DFM.

Did you know that up to 70% of product development failures stem from manufacturing issues during the transition from prototype to production? Don’t let your innovation become another statistic.

The journey from a groundbreaking idea to a tangible, market-ready product is fraught with complexities. Success hinges not just on design, but critically on its manufacturability and the reliability of your production partner.

Discover how the right CNC machining manufacturer transforms risk into reliable success, ensuring your vision is realized with unparalleled precision and efficiency.

Bridging Prototype to Production Gaps

The path from an initial concept to a finished product is rarely linear. It demands meticulous planning and execution, where the smallest oversight can lead to significant delays and cost overruns.

Understanding these inherent challenges is the first step towards mitigating risks and ensuring a smooth transition for your custom CNC parts.

The critical hurdles in prototype development

Many innovators face substantial challenges in bringing their prototypes to life. Designs often look perfect on screen but present significant manufacturing complexities.

This can include issues with material compatibility, achievable tolerances, or overly intricate geometries that are difficult to machine efficiently. In ly-machining’s experience, early collaboration is key to overcoming these initial hurdles.

The true cost of poor CNC machining services

Opting for subpar CNC machining services inevitably leads to a cascade of problems. These include parts not meeting specifications, costly reworks, and extended lead times that delay market entry.

Such issues not only inflate project budgets but also damage brand reputation and erode customer trust. A reliable CNC machine shop is an investment in quality and efficiency.

CNC Manufacturer’s Pivotal Role

The role of a dedicated CNC machining manufacturer extends far beyond simply cutting metal. They are integral partners, providing expertise that spans the entire product development lifecycle.

From initial design review to final production, their input is critical for transforming raw concepts into high-quality, scalable custom CNC parts.

Design for Manufacturability (DFM) support

Effective DFM is a cornerstone of efficient production. A skilled CNC machine shop, like ly-machining, provides invaluable feedback on your design’s manufacturability before any material is cut.

This ensures designs are optimized for production processes, reducing potential issues and costs down the line. We identify areas for simplification without compromising functionality.

Expert material selection for custom CNC parts

Choosing the correct material is paramount for the performance and longevity of custom CNC parts. ly-machining offers extensive expertise in guiding clients through the vast array of material options.

This includes evaluating mechanical properties, environmental resistance, cost-effectiveness, and specific application requirements. Our recommendations ensure optimal material performance for your precision machining services.

Table: Common CNC Machining Materials and Applications

| Material Type | Typical Applications | Key Characteristics |

|---|---|---|

| Aluminum | Aerospace, Automotive, Electronics | Lightweight, High Strength-to-Weight, Corrosion Resistant |

| Stainless Steel | Medical, Food Processing, Marine | High Strength, Corrosion Resistant, Biocompatible |

| Titanium | Medical Implants, Aerospace, Racing | Excellent Strength-to-Weight, Biocompatible, High Temperature Resistance |

| Engineering Plastics | Insulators, Housings, Gaskets | Electrical Insulation, Chemical Resistance, Low Friction |

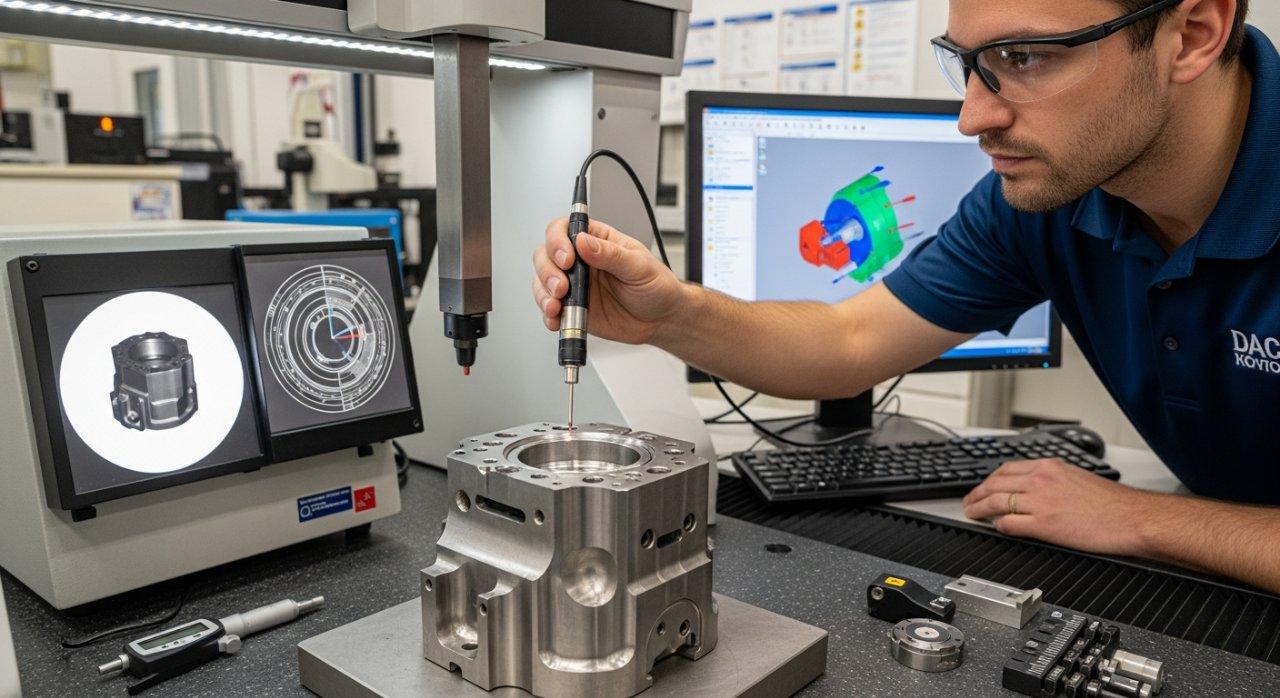

Achieving precision with advanced CNC machining

Precision is non-negotiable in modern manufacturing. ly-machining utilizes state-of-the-art multi-axis CNC machines and computer numerical control services to achieve the tightest tolerances and intricate geometries.

Our advanced precision machining services minimize errors and ensure every custom CNC part conforms exactly to specifications, providing consistent quality across all batches.

Scaling from prototypes to full production

One of the most challenging transitions is scaling from a handful of prototypes to high-volume production. An experienced CNC machining manufacturer streamlines this process.

ly-machining implements robust production planning, quality control, and process optimization strategies. This guarantees that scalability is achieved efficiently, maintaining consistent quality and cost-effectiveness.

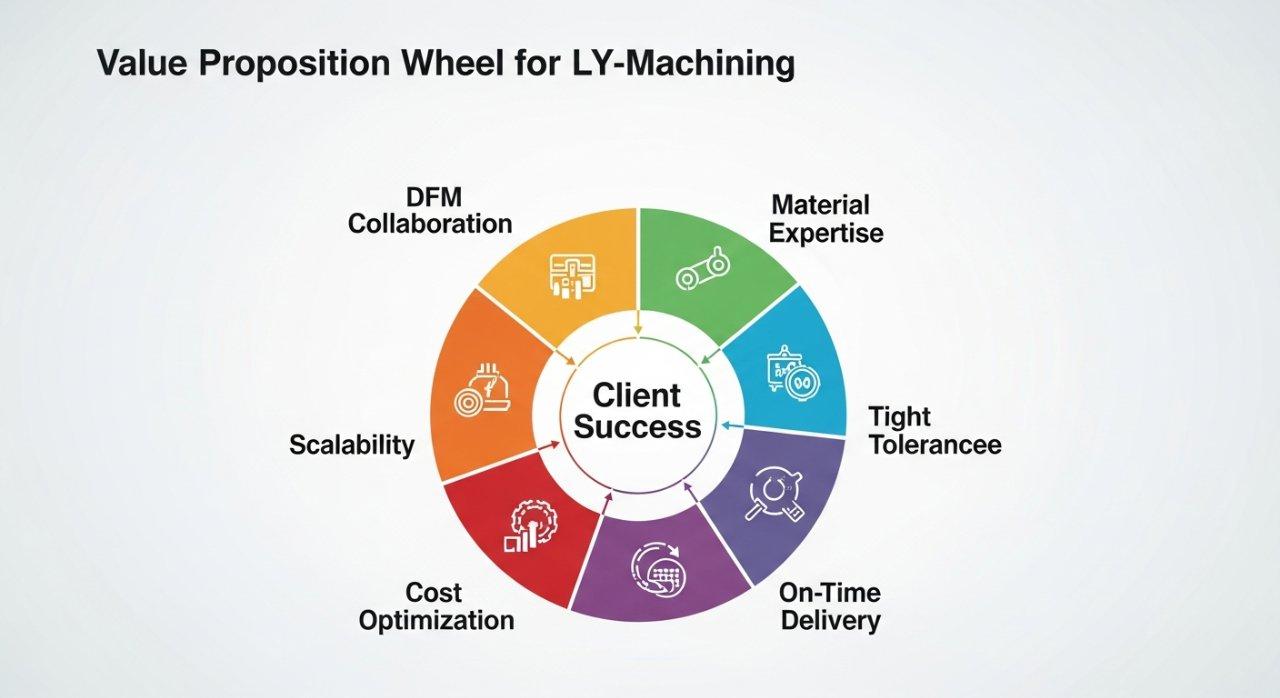

Why Choose a Source CNC Machining Partner?

Partnering with a source CNC machining manufacturer, rather than a middleman, offers distinct advantages. This direct relationship fosters greater transparency, control, and ultimately, superior results for your projects.

ly-machining operates as a true source manufacturer, providing end-to-end solutions. This means you benefit directly from our capabilities and expertise without added layers of communication or cost.

The source manufacturer advantage for quality

As a source manufacturer, ly-machining maintains complete control over every stage of the CNC machining process. From material procurement to final inspection, our internal systems ensure rigorous quality checks.

This direct oversight translates to higher consistency and fewer defects in the custom CNC parts we produce. Our commitment to quality is embedded in our operational ethos.

Transparent pricing in a CNC machine shop

Working directly with a CNC machine shop like ly-machining eliminates hidden costs and unnecessary markups. Our pricing structure is clear, concise, and reflective of the actual manufacturing expenses.

This transparency allows clients to make informed budget decisions, providing peace of mind and building long-term trust. You know exactly what you’re paying for with our precision machining services.

Deep technical expertise in custom CNC parts

ly-machining’s team comprises highly skilled engineers and machinists with decades of collective experience in CNC machining and custom CNC parts. Their deep technical expertise is an invaluable asset to our clients.

We provide practical solutions to complex manufacturing challenges, offering insights that only come from hands-on work with diverse materials and geometries. This mastery elevates the quality of your project.

Table: Key Technical Expertise Areas at ly-machining

| Expertise Area | Description | Client Benefit |

|---|---|---|

| Multi-Axis Machining | 3-, 4-, and 5-axis CNC machining for complex geometries and undercuts | Enables intricate designs, reduces operations, improves accuracy |

| Tight Tolerance Machining | Capability to hold tolerances down to ±0.005mm or tighter | Ensures critical fit and function for high-performance applications |

| Surface Finish Optimization | Expert knowledge of various surface finishes (e.g., Ra values, anodizing) | Enhances part aesthetics, durability, and functionality |

| CAD/CAM Integration | Seamless workflow from design to manufacturing via advanced software | Expedites development, reduces errors, optimizes tool paths |

Ensuring high-quality parts and reliability

Reliability is a cornerstone of our commitment. ly-machining adheres to stringent industry standards, including ISO and AS9100 where applicable, to ensure consistent quality in every custom CNC part.

Our robust quality management system involves continuous monitoring and inspection throughout the entire production cycle. This dedication guarantees the delivery of high-quality, dependable components.

Real-World Success: CNC Machining Stories

Theoretical expertise is vital, but practical application truly demonstrates a CNC machining manufacturer’s capability. ly-machining prides itself on a proven track record of solving real-world challenges for our clients.

These stories highlight our commitment to problem-solving, precision, and delivering exceptional value through our CNC manufacturing services.

Case study: complex custom CNC parts delivered

**Problem:** A client in the aerospace industry approached ly-machining with a highly complex, lightweight bracket requiring multi-axis CNC machining, extremely tight tolerances, and a specialized aluminum alloy. Previous suppliers had struggled to meet both the precision and lead time requirements, causing significant project delays.

**ly-machining’s Solution:** Our engineering team conducted an in-depth DFM analysis, identifying areas where tool paths could be optimized for efficiency without sacrificing design integrity. Utilizing our 5-axis CNC machines and advanced tooling, ly-machining developed a refined machining strategy. We implemented rigorous in-process quality checks and deployed our experienced machinists for continuous monitoring.

**Result:** ly-machining successfully delivered all custom CNC parts ahead of schedule, exceeding the client’s tolerance requirements. The client lauded ly-machining’s precision machining services for their technical problem-solving and reliability, allowing their aerospace project to get back on track and meet critical deadlines.

Value of precision machining services partnership

The success in delivering challenging projects underscores the value of partnering with an expert CNC machining manufacturer. ly-machining doesn’t just produce parts; we provide solutions.

Our collaborative approach, coupled with our technical prowess, ensures that even the most demanding projects are executed flawlessly. This creates a true partnership focused on mutual success.

Your Trusted CNC Manufacturing Partner

Choosing the right CNC machining manufacturer is a strategic decision that impacts your project’s success, budget, and timeline. ly-machining stands ready to be that trusted partner.

We combine cutting-edge technology, unparalleled expertise, and a steadfast commitment to quality in every project we undertake. Experience the difference a dedicated CNC machine shop can make.

Ready for high-quality custom CNC parts?

If you require custom CNC parts that meet the highest standards of precision, durability, and cost-effectiveness, ly-machining is your ideal manufacturing partner.

Our comprehensive precision machining services support your project from concept to mass production, ensuring seamless execution at every stage.

Get a transparent quote from our CNC machine shop

Take the next step in bringing your innovative designs to life. ly-machining invites you to get a free quote or technical consultation today.

Discover how our CNC machine shop’s expertise can optimize your project and deliver superior results.

What is DFM in CNC machining?

DFM, or Design for Manufacturability, is a proactive engineering approach that optimizes a product’s design for efficient and cost-effective manufacturing. In CNC machining, it involves reviewing a design to identify and eliminate potential manufacturing issues.

This ensures the part can be produced efficiently, cost-effectively, and to the desired quality standards using CNC processes. It’s a critical step that saves time and money.

How does ly-machining ensure part accuracy?

ly-machining ensures part accuracy through a multi-faceted approach. This includes utilizing advanced multi-axis CNC machines capable of holding extremely tight tolerances.

We also implement rigorous in-process quality control measures and employ state-of-the-art metrology equipment for final inspections. Our experienced machinists and engineers are dedicated to precision at every stage.

Can ly-machining help with material selection?

Absolutely. ly-machining provides expert guidance on material selection for custom CNC parts. Our team understands the diverse properties of various metals and plastics.

We help clients choose the optimal material based on application requirements, environmental conditions, mechanical stresses, and budget. This ensures the best performance and longevity for your components.