6061 Aluminum: Your CNC Machining Go-To

6061 aluminum is the top material for CNC machining, balancing strength, machinability, corrosion resistance, and cost for high-quality, reliable parts across industries.

The search for an ideal material in CNC machining often leads engineers and procurement managers through a labyrinth of choices. Many seek that perfect blend of performance, ease of manufacturing, and cost-effectiveness. This is where 6061 aluminum consistently shines.

This versatile alloy has cemented its position as a go-to for countless applications, offering solutions to complex design challenges. Understanding its full potential and how expert manufacturing unlocks it is crucial for project success. ly-machining stands ready to guide you through its advantages.

Why 6061 Aluminum Dominates CNC Machining

Key properties of 6061 aluminum for CNC projects

6061 aluminum is a heat-treatable alloy, primarily composed of aluminum, magnesium, and silicon. This composition grants it an excellent balance of properties highly desirable for CNC machining applications. Its widespread availability and relatively low cost further boost its appeal.

This alloy is particularly valued for its medium to high strength-to-weight ratio. It offers good weldability and is amenable to various tempering processes, enhancing its mechanical characteristics to meet diverse project requirements.

In ly-machining’s experience, 6061’s predictable material response simplifies tooling and process planning. This reliability helps achieve consistent, high-quality results across various part geometries and complexities.

| Property | Value (Typical) | Relevance to CNC Machining |

|---|---|---|

| **Density** | 2.70 g/cm³ | Lightweighting, ease of handling |

| **Tensile Strength (T6)** | 310 MPa (45,000 psi) | Structural integrity, load-bearing capacity |

| **Yield Strength (T6)** | 276 MPa (40,000 psi) | Resistance to permanent deformation |

| **Hardness (Brinell)** | 95 HB | Good machinability, acceptable wear resistance |

| **Thermal Conductivity** | 151-173 W/m-K | Efficient heat dissipation during machining |

Balancing strength and machinability in 6061 aluminum

One of 6061 aluminum’s standout features is its remarkable balance between strength and machinability. While stronger alloys exist, they often present significant challenges during CNC machining, increasing tool wear and cycle times.

6061 aluminum, particularly in its T6 temper, offers sufficient strength for most structural and mechanical components. Its chip formation characteristics are favorable, allowing for high material removal rates without excessive heat buildup.

This optimal balance means ly-machining can deliver high-performance parts efficiently. It reduces production costs and lead times while maintaining the structural integrity required by engineers and designers.

Corrosion resistance benefits for 6061 aluminum parts

The natural formation of a passive oxide layer on 6061 aluminum provides excellent inherent corrosion resistance. This property is crucial for parts exposed to various environmental conditions, from marine applications to outdoor architectural components.

Further enhancements to corrosion resistance can be achieved through post-machining surface treatments, such as anodizing. This process, which 6061 aluminum responds to exceptionally well, creates a thicker, harder, and even more protective oxide layer.

This makes 6061 aluminum a reliable choice for long-lasting components, reducing maintenance and replacement costs over the product’s lifecycle. ly-machining’s finishing expertise ensures maximum protective benefits.

The CNC Machining Edge of 6061 Alloy

Optimal parameters for precision CNC machining 6061

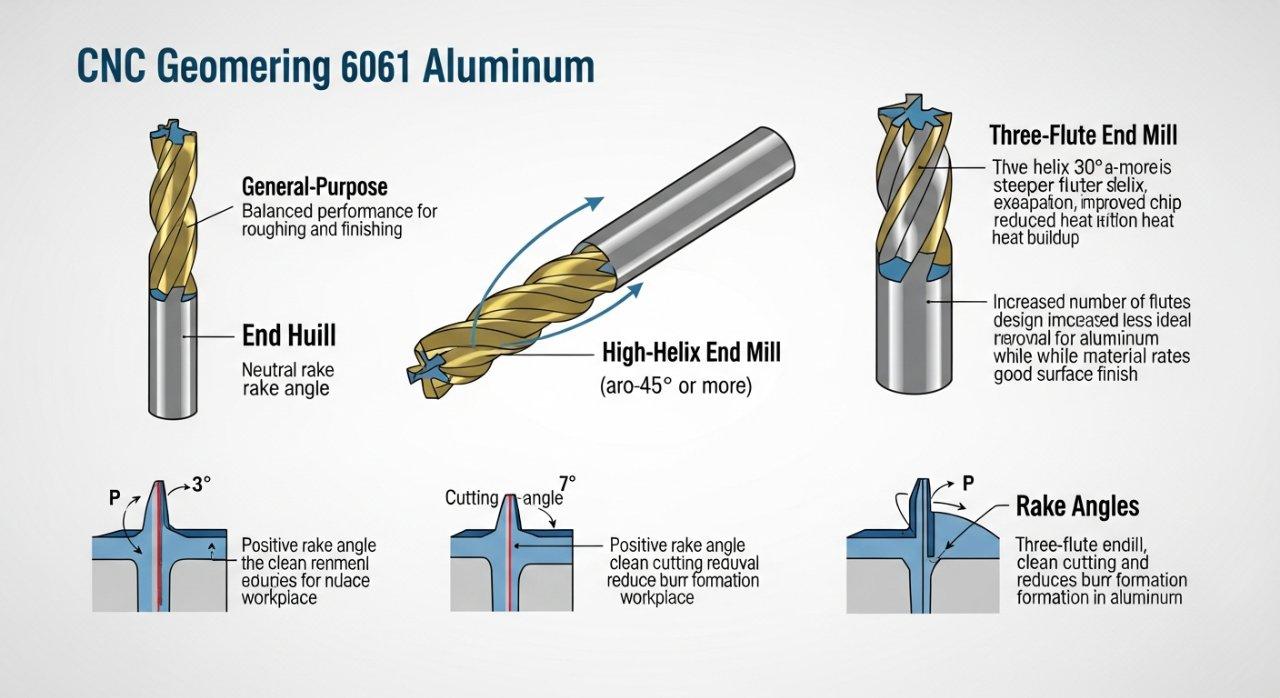

Achieving precision with 6061 aluminum requires careful selection of CNC machining parameters. This includes spindle speed, feed rate, depth of cut, and tool geometry. ly-machining’s deep technical expertise in 6061 CNC machining allows us to fine-tune these parameters for superior results.

For instance, high spindle speeds and moderate feed rates are generally effective for 6061, leading to efficient chip evacuation and good surface finishes. Proper lubrication and cooling are also critical to manage heat and extend tool life.

In ly-machining’s facilities, we employ advanced tooling specifically designed for aluminum. This ensures optimal chip breaking and minimizes the risk of built-up edge, which is essential for maintaining tight tolerances and part integrity.

Achieving superior surface finish with 6061 aluminum

The machinability of 6061 aluminum greatly contributes to achieving superior surface finishes, which is often a critical requirement for aesthetic or functional parts. With correct machining strategies, very smooth surfaces can be produced directly off the machine.

Optimal tool path strategies, such as climb milling, and appropriate cutting fluids play a significant role. Our engineers at ly-machining meticulously plan each cut to ensure exceptional surface integrity and reduce the need for extensive post-machining finishing.

For applications demanding the highest surface quality or specific aesthetic appeal, 6061 aluminum is highly receptive to various finishing processes. These include bead blasting, polishing, and different types of anodizing, providing a wide range of options.

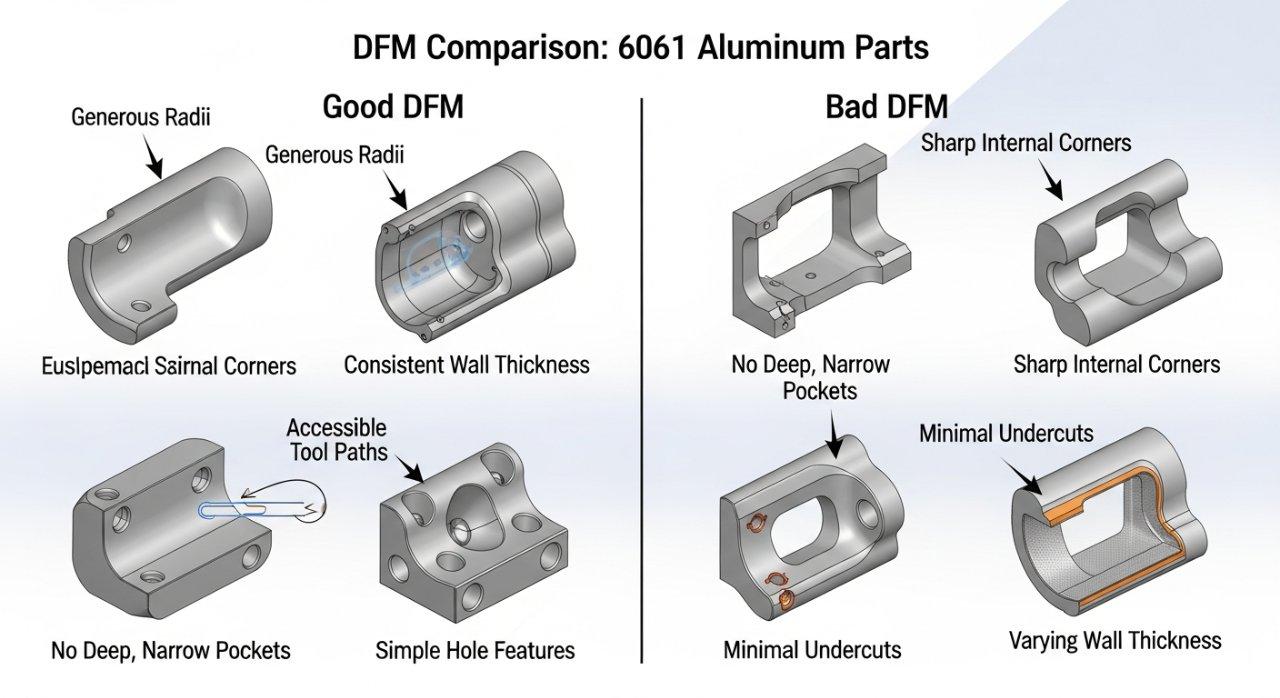

Design for manufacturability (DFM) with 6061 aluminum

Integrating Design for Manufacturability (DFM) principles early in a project is paramount for cost-effective and efficient production. 6061 aluminum’s excellent machinability makes it highly amenable to DFM optimization.

Its consistent material properties allow designers greater freedom in part complexity without incurring prohibitive manufacturing costs. Features like thin walls, intricate pockets, and sharp corners can often be machined with confidence.

ly-machining proactively collaborates with clients during the design phase. We leverage our deep technical expertise to suggest modifications that optimize designs for 6061 aluminum, ensuring both performance and streamlined production.

6061 Aluminum in Real-World Applications

Diverse industries utilizing CNC machined 6061 parts

The versatility of 6061 aluminum makes it a preferred material across an impressive array of industries. From high-tech aerospace components to everyday consumer electronics, its properties provide essential performance.

In the automotive sector, 6061 is used for chassis components, engine parts, and custom racing parts due to its strength and light weight. For the aerospace industry, it forms crucial structural brackets and fittings.

Other applications include marine components, bicycle frames, medical device housings, and general machinery parts. Its balance of properties truly makes it a universal choice for reliable CNC machined parts.

| Industry | Common 6061 Aluminum Applications | Key Benefits |

|---|---|---|

| **Aerospace** | Structural components, brackets, fittings | High strength-to-weight, corrosion resistance |

| **Automotive** | Chassis components, engine blocks, suspension parts | Lightweighting, durability, thermal management |

| **Consumer Goods** | Bicycle frames, sporting equipment, electronic housings | Aesthetics, lightweight, durability |

| **Medical Devices** | Instrument housings, surgical tool components | Biocompatibility (with proper finish), precision |

| **Industrial** | Machine frames, fixtures, robotic components | Rigidity, wear resistance, ease of fabrication |

Case studies: Success with 6061 aluminum projects

A common challenge ly-machining encounters involves clients requiring complex, lightweight enclosures for sensitive electronic equipment. These enclosures demand tight tolerances for EMI shielding and a robust, attractive finish.

Problem: A client needed a series of custom enclosures for a new generation of portable diagnostic devices. The requirements included extreme lightweighting, precise internal geometry for component fit, a durable anodized finish, and a rapid production timeline. Standard casting or plastic molding wouldn’t meet the precision or strength.

Our Solution: ly-machining recommended CNC machining 6061 aluminum in T6 temper. Our engineers optimized the design for manufacturability, reducing material waste and machining time. We developed custom fixtures to ensure repeatable accuracy for thin-walled sections. Our in-house anodizing capability provided the desired finish and additional environmental protection.

Result: The client received perfectly dimensioned 6061 aluminum enclosures that exceeded their expectations for weight and strength. The precision fit eliminated assembly issues, and the high-quality anodized finish enhanced product aesthetics and longevity. ly-machining delivered the entire batch ahead of schedule, proving our capability as a trusted source manufacturer.

Comparing 6061 aluminum vs. other alloys for CNC

While 6061 aluminum is often the preferred choice, understanding its position relative to other common alloys is important. Each alloy possesses unique properties making it suitable for specific applications.

For instance, 7075 aluminum offers superior strength but is more challenging to machine and typically more expensive. Conversely, 5052 aluminum provides excellent corrosion resistance and formability but with lower strength.

Choosing the right alloy is a critical decision in product development. ly-machining’s technical team provides expert consultation, helping clients weigh these trade-offs to select the optimal material for their specific needs, ensuring project success.

| Aluminum Alloy | Primary Benefit (CNC Context) | CNC Machinability | Typical Applications |

|---|---|---|---|

| **6061** | Balanced strength, machinability, cost | Excellent | General purpose, structural, automotive, aerospace |

| **7075** | Highest strength, fatigue resistance | Good (Challenging) | Aerospace, high-stress components, molds |

| **5052** | Excellent corrosion resistance, formability | Good (Gummy) | Marine, fuel tanks, architectural, sheet metal parts |

| **2024** | High strength, good fatigue resistance | Good | Aircraft structural components, fasteners |

Sourcing High-Quality 6061 Aluminum & Services

What to look for in 6061 aluminum suppliers

When seeking 6061 aluminum suppliers, it’s paramount to evaluate more than just price. Look for suppliers who prioritize material traceability and provide certifications (e.g., ISO 9001, AS9100 for aerospace).

A reputable supplier will offer transparent material specifications and consistent quality control. They should have a proven track record and the capacity to handle both large-volume orders and specialized requests for 6061 aluminum sheet or bar stock.

ly-machining understands these critical needs. As a source manufacturer, ly-machining controls the entire process, from material procurement to final inspection, ensuring uncompromised quality for every 6061 aluminum part.

Ensuring quality when you buy 6061 aluminum sheet

The quality of the raw 6061 aluminum sheet or stock directly impacts the final part’s performance and machinability. Inferior material can lead to inconsistencies, warping, poor surface finish, and costly rework.

When ly-machining sources 6061 aluminum, we establish strict procurement protocols with trusted raw material suppliers. This ensures that every batch meets our stringent internal quality standards and relevant industry specifications.

We conduct incoming material inspections, verifying dimensions, alloy composition, and temper. This meticulous process guarantees that only premium 6061 aluminum enters our CNC machining workflow, safeguarding your investment.

The advantage of source manufacturers for CNC machining

Partnering with a source manufacturer like ly-machining offers unparalleled advantages. We oversee every stage of production, from initial design consultation and material selection to CNC machining, finishing, and quality assurance.

This integrated approach eliminates communication breakdowns and ensures seamless project execution. Our transparent pricing reflects true manufacturing costs, devoid of middleman markups, providing exceptional value.

ly-machining’s direct control over the entire supply chain guarantees consistent quality, reduced lead times, and greater flexibility. It’s the assurance of working directly with the experts who make your 6061 aluminum parts.

Partnering for Your 6061 CNC Project Success

Transparent pricing for your 6061 aluminum needs

Understanding the full cost of your CNC machining project upfront is crucial for budgeting and project planning. ly-machining is committed to providing transparent pricing for all 6061 aluminum services.

We break down costs clearly, from raw material procurement to machining time, finishing processes, and quality checks. This ensures there are no hidden fees or unexpected charges, building trust and predictability.

Our advantage as a source manufacturer allows us to offer competitive pricing without compromising on the high-quality parts you expect. ly-machining believes in clear communication and fair value for every client.

Deep technical expertise in 6061 CNC machining

ly-machining’s team comprises seasoned engineers and highly skilled machinists with extensive experience in 6061 aluminum. Our deep technical expertise is a cornerstone of our service, ensuring optimal results.

We continuously invest in the latest CNC technology and employee training, staying at the forefront of machining innovations. This allows us to tackle the most complex 6061 aluminum designs with precision and efficiency.

From material selection advice to complex tooling strategies and post-processing recommendations, ly-machining provides comprehensive technical support. We are your partner in transforming challenging designs into reality.

Elevate your designs with expert 6061 aluminum service

Choosing the right manufacturing partner is as important as selecting the right material. With ly-machining, you gain access to a team dedicated to elevating your designs through superior 6061 aluminum CNC machining.

Our commitment to quality, precision, and customer satisfaction is unwavering. We collaborate closely with clients to understand their vision and deliver components that meet the highest standards of performance and aesthetics.

Let ly-machining’s expertise in 6061 aluminum become your competitive advantage. Experience the difference that a dedicated, technically proficient source manufacturer can make for your next project.

Ready to leverage the optimal performance of high-quality 6061 aluminum for your next project? Contact ly-machining today for a detailed consultation and a customized quote tailored to your exact CNC machining needs.

FAQ: About 6061 Aluminum CNC Machining

What makes 6061 aluminum ideal for CNC?

6061 aluminum offers an outstanding balance of strength, machinability, and corrosion resistance. Its consistent properties allow for precise, efficient machining and diverse applications.

This alloy handles well under various cutting conditions, producing favorable chip formation. It also accepts multiple surface finishes, which further enhances its versatility.

Can 6061 aluminum be anodized for finish?

Yes, 6061 aluminum responds exceptionally well to anodizing. This process creates a durable, corrosion-resistant, and aesthetically pleasing surface.

Anodizing can significantly improve wear resistance and allows for various color options. ly-machining offers in-house anodizing services for integrated project solutions.

How does ly-machining ensure 6061 quality?

ly-machining ensures quality through strict material sourcing and internal controls. We verify raw material specifications and conduct thorough inspections.

Our advanced CNC machinery, coupled with deep technical expertise, ensures precision throughout manufacturing. Every 6061 aluminum part undergoes rigorous quality checks before delivery.