Drone Shell CNC: Optimal Materials

Quick Solution: Selecting the right material for CNC machining of drone shell is critical, balancing weight, strength, and cost. ly-machining recommends aluminum alloys, carbon fiber, or engineering plastics for custom CNC drone parts to optimize performance.

Your drone’s shell is more than just an enclosure—it’s a critical performance component. Are you confident your current material choice is truly optimizing its flight dynamics, durability, and cost-effectiveness? The right material for CNC machined drone shells can be the difference between flight and failure.

This guide delves into the essential considerations for material selection in drone housing CNC manufacturing. ly-machining will share insights from years of experience in producing precision drone component machining. We aim to help you make informed decisions that elevate your drone’s performance and market success.

Why Material Choice Matters for Drone Shells

The performance of any unmanned aerial vehicle (UAV) is intrinsically linked to its physical structure. For custom CNC drone parts, the material choice for the shell is not merely aesthetic; it defines the drone’s operational capabilities and lifespan. It dictates how efficiently the drone flies and how well it withstands operational stresses.

In ly-machining’s experience, overlooking material specifics often leads to compromised flight performance or premature component failure. This can result in costly redesigns or even catastrophic in-flight incidents. Precision drone component machining demands a holistic approach to material selection.

Impact on Precision Drone Component Machining

The material chosen directly influences the achievable tolerances and surface finishes during CNC machining of drone shell. Softer materials may struggle with fine features, while harder ones demand specialized tooling and slower speeds. This impacts both cost and lead time.

ly-machining’s engineers conduct detailed DFM (Design for Manufacturability) analyses. This ensures that your chosen material can be precisely machined to meet the tight specifications required for critical drone components. Our expertise helps avoid manufacturing pitfalls.

Balancing Weight, Strength, Cost for Custom CNC Drone Parts

Achieving the optimal balance among weight, strength, and cost is paramount for custom CNC drone parts. A lighter drone can carry more payload or extend flight duration, but it must not sacrifice structural integrity. Cost-efficiency is also a major factor for scalability and market competitiveness.

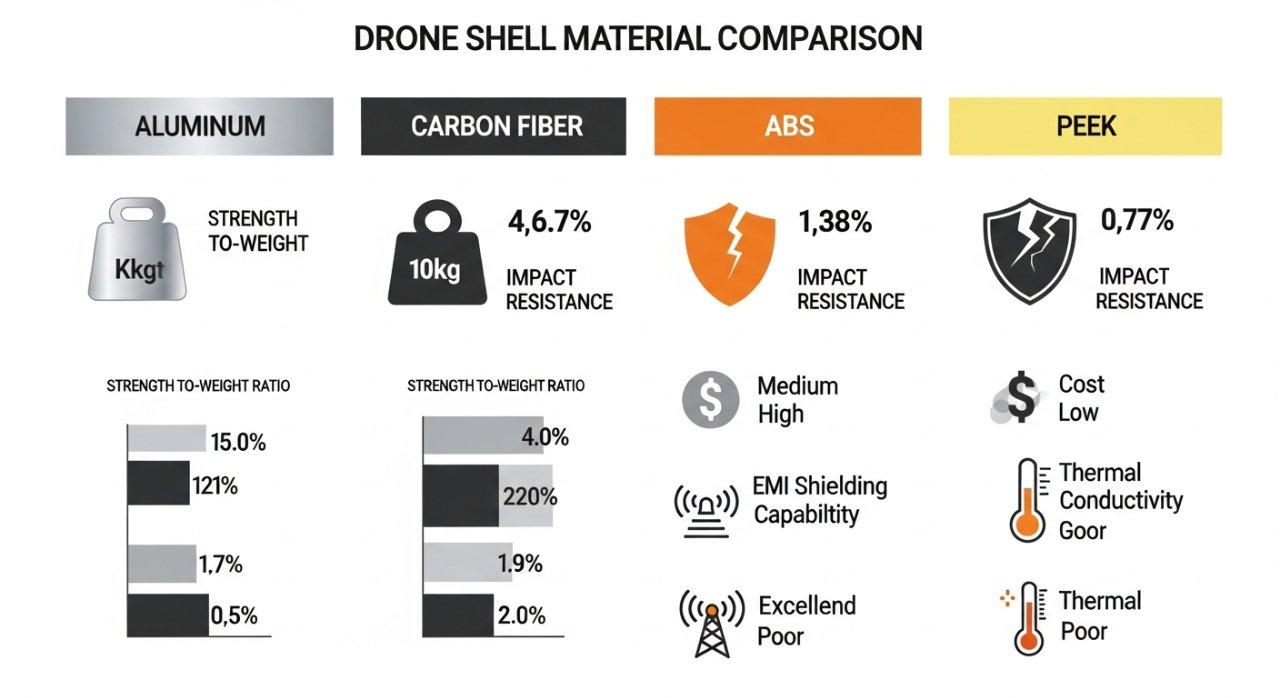

Below is a table illustrating the general trade-offs for common drone shell material attributes. This helps in understanding the initial impact of selection.

| Attribute | Lightweight | High Strength | Low Cost |

|---|---|---|---|

| **Aluminum** | Moderate | High | Moderate |

| **Carbon Fiber** | High | Very High | High |

| **ABS/PC** | Moderate | Moderate | Low |

| **Magnesium** | Very High | High | Moderate/High |

Top Materials for CNC Machining of Drone Shell

Selecting the right material for drone housing CNC manufacturing is a critical engineering decision. It demands a deep understanding of material properties, machining characteristics, and application requirements. ly-machining excels in guiding clients through this complex process.

We help identify the ideal material that balances performance, durability, and cost for their unique custom CNC drone parts. Our facility is equipped to handle a wide array of advanced materials. This ensures precision in every component.

Aluminum Alloys in Drone Housing CNC Manufacturing

Aluminum alloys, particularly 6061 and 7075, are popular choices for drone housing CNC manufacturing due to their excellent strength-to-weight ratio and corrosion resistance. They are highly machinable, allowing for intricate designs and tight tolerances.

The T6 temper for 6061-T6 aluminum offers significant strength, making it suitable for structural components. Meanwhile, 7075-T6 provides even higher strength, ideal for high-stress applications in precision drone component machining. ly-machining routinely processes these alloys to aerospace standards.

Carbon Fiber Composites for Precision Drone Components

Carbon fiber composites offer superior strength and stiffness at a remarkably low weight, making them a premium choice for high-performance custom CNC drone parts. Their anisotropic properties can be leveraged for specific directional strength.

While more challenging to machine due to abrasive fibers, ly-machining employs specialized tooling and techniques for carbon fiber. This ensures clean cuts, excellent surface finish, and minimal delamination, delivering precision where it counts.

Engineering Plastics: ABS and PC for CNC Machining

For less structural, more cost-sensitive, or consumer-grade drone shells, engineering plastics like ABS (Acrylonitrile Butadiene Styrene) and PC (Polycarbonate) are excellent options. They offer good impact resistance and are relatively easy to machine.

PC provides higher strength and better temperature resistance than ABS, making it suitable for slightly more demanding applications. These materials are often used for aesthetic covers or internal non-load-bearing enclosures. They are well-suited for rapid prototyping needs.

Specialty Alloys for High-Performance Custom CNC Drone Parts

For extreme environments or highly specialized custom CNC drone parts, specialty alloys like titanium (e.g., Ti-6Al-4V) or magnesium alloys can be considered. Titanium offers exceptional strength, corrosion resistance, and biocompatibility, but at a higher cost and machining difficulty.

Magnesium alloys are among the lightest structural metals, providing an excellent strength-to-weight ratio, crucial for extended flight times. ly-machining has the expertise and advanced equipment to precision machine these demanding materials. This includes 5-axis capabilities for complex geometries.

Key Factors in Material Selection for Drone Shells

Making an informed material choice for custom CNC drone parts involves evaluating multiple, often interdependent, factors. ly-machining collaborates closely with clients, offering DFM advice from the outset. This ensures that every aspect of the drone’s operational environment and performance goals is considered.

Our comprehensive approach minimizes risks and optimizes outcomes for CNC machining of drone shell. We pride ourselves on transparent communication and deep technical insight throughout the entire process. This leads to successful project execution.

Environmental Durability in Drone Housing CNC Manufacturing

Drones operate in diverse and often harsh environments, from extreme temperatures to corrosive saltwater or dusty conditions. The material for drone housing CNC manufacturing must withstand these elements without degradation. Factors like UV resistance, temperature range, and moisture ingress are critical.

For outdoor applications, anodization of aluminum provides enhanced corrosion and abrasion resistance. Similarly, certain engineering plastics are inherently UV-stable. ly-machining’s finishing processes ensure components are ready for their intended environment.

Cost-Benefit Analysis for Custom CNC Drone Parts

The total cost of a custom CNC drone part extends beyond raw material price; it includes machining time, tooling, post-processing, and reject rates. A cheaper material might incur higher machining costs or necessitate more secondary operations. This can ultimately increase the overall unit cost.

ly-machining provides transparent, factory-direct pricing and detailed cost breakdowns. This helps clients understand the true cost-benefit of each material option. Our goal is to offer high-value solutions that optimize both performance and budget.

Machinability and Surface Finish in CNC Machining of Drone Shell

Different materials exhibit varying machinability, affecting the ease and speed of CNC machining of drone shell, as well as the achievable surface finish. Good machinability ensures efficient production and reduces tool wear. Poor machinability can lead to longer cycle times and higher costs.

Below is a table showing general machinability and typical surface finish for common materials. This offers a quick reference for manufacturing considerations.

| Material | General Machinability | Typical Surface Finish |

|---|---|---|

| **Aluminum Alloys** | Excellent | Smooth, high quality |

| **Carbon Fiber** | Difficult (abrasive) | Good, requires specific tools |

| **ABS/PC** | Good | Smooth, can be polished |

| **Titanium Alloys** | Challenging (hard) | Good, requires slow speeds |

Thermal & Electrical Properties for Precision Drone Component Machining

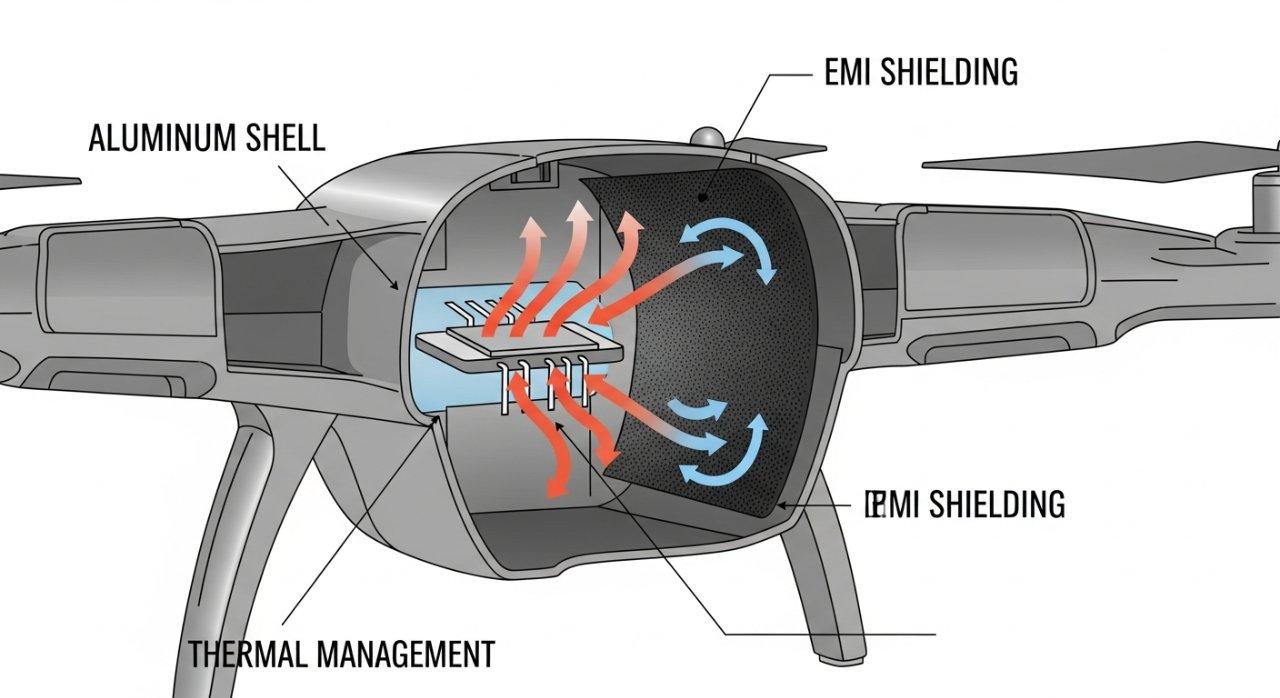

Drone shells often need to manage thermal dissipation for internal electronics or provide EMI/RFI shielding to protect sensitive circuits. The thermal conductivity of aluminum is excellent for heat dissipation, while certain coatings or material additions can enhance EMI shielding.

Conductive fillers in plastics can provide shielding, and proper grounding is essential for metal enclosures. ly-machining understands these complex requirements. We help select materials and implement design features that optimize these critical properties for precision drone component machining.

Our Expertise in Drone Shell CNC Manufacturing

As a dedicated source manufacturer based in Shenzhen, ly-machining brings unparalleled expertise to drone housing CNC manufacturing. We are not a trading company; we own and operate a state-of-the-art facility with over 80 advanced CNC machines. This includes high-precision 5-axis machining centers.

Our comprehensive capabilities span from initial design evaluation to final part delivery. This ensures every step is meticulously managed for superior quality and efficiency. We are committed to being a trusted partner for innovation.

Source Manufacturer for High-Quality Custom CNC Drone Parts

ly-machining prides itself on being a true source manufacturer for high-quality custom CNC drone parts. This means direct communication, transparent processes, and direct accountability for every component we produce. We eliminate middlemen, offering factory-direct pricing and faster turnaround times.

Our clients benefit from immediate access to our engineering team for technical consultations and DFM support. This direct engagement fosters a collaborative partnership. It ensures your vision for precision drone components is realized efficiently and accurately.

Achieving Precision Drone Component Machining Excellence

Precision drone component machining is at the core of ly-machining’s operations. Our ISO9001 and IATF1649 certifications underscore our commitment to rigorous full-chain quality control. We utilize advanced metrology equipment to verify every dimension and feature.

From complex geometries to exceptionally tight tolerances, ly-machining’s skilled technicians and cutting-edge machinery deliver consistent excellence. We understand that even micron-level deviations can impact drone performance. This commitment to precision sets us apart.

Transparent Pricing for Your CNC Machining Needs

ly-machining believes in complete transparency when it comes to pricing for your CNC machining needs. We provide detailed quotes that clearly outline material costs, machining operations, finishing processes, and lead times. There are no hidden fees or surprises.

Our competitive, factory-direct pricing structure ensures you receive the best possible value without compromising on quality or service. ly-machining strives to build long-term relationships based on trust and mutual success.

Future Trends in Drone Housing CNC Manufacturing

The drone industry is rapidly evolving, driving continuous innovation in materials and manufacturing processes for custom CNC drone parts. ly-machining actively monitors and invests in emerging technologies and materials to stay at the forefront of this dynamic field.

Our forward-thinking approach ensures that our clients always have access to the latest advancements. This helps them maintain a competitive edge in drone housing CNC manufacturing. We are constantly exploring new possibilities.

Advanced Materials and Additive Mfg for Custom CNC Drone Parts

The future of custom CNC drone parts will increasingly integrate advanced materials like metal matrix composites and highly engineered polymers. These materials offer unprecedented strength-to-weight ratios and tailored properties.

Additionally, additive manufacturing (3D printing) will complement traditional CNC machining. It will be used for complex internal structures or rapid prototyping. ly-machining strategically integrates these technologies to provide comprehensive solutions.

Case Study: Optimizing a Heavy-Lift Drone Chassis

Problem: A client approached ly-machining with a heavy-lift drone design. Its existing aluminum chassis, while strong, was excessively heavy, limiting payload capacity and flight duration. They needed a lighter, yet equally rigid, solution for their precision drone component machining.

Our Solution: ly-machining’s engineering team conducted a detailed analysis. We proposed a hybrid approach: strategically redesigning non-critical sections for lightweight 6061-T6 aluminum, while key structural nodes were precisely CNC machined from aerospace-grade carbon fiber composites. We also optimized internal ribbing through DFM.

Result: The new chassis achieved a 30% weight reduction without compromising structural integrity. This allowed the client to significantly increase payload capacity and extend flight time, leading to a successful product launch and market differentiation. ly-machining delivered the custom CNC drone parts ahead of schedule, showcasing our expertise in complex material integration.

Partner for Drone Shell CNC Material Selection

Choosing the optimal material for CNC machining of drone shell is a complex decision that benefits from expert guidance. ly-machining offers unparalleled technical expertise and source manufacturing capabilities. We are dedicated to delivering superior quality custom CNC drone parts.

From initial concept to final production, ly-machining is your trusted partner. We ensure that your drone’s performance is maximized through meticulous material selection and precision manufacturing. Let us help you navigate the complexities of drone housing CNC manufacturing.

Get a Quote for Your CNC Machining of Drone Shell Needs

Don’t compromise on your drone’s performance. Leverage ly-machining’s deep technical expertise and source manufacturing capabilities to select the perfect material for your custom CNC drone shell. Contact our engineering team today for a personalized material consultation and a transparent quote, and let’s elevate your next project with high-quality, precision-machined parts.

FAQ Section:

Which material is best for drone shells?

The “best” material depends on your specific drone application, balancing factors like weight, strength, cost, and environmental exposure. Common choices include aluminum alloys for strength and machinability, carbon fiber for extreme lightweight performance, and engineering plastics for cost-effectiveness and impact resistance.

How does ly-machining ensure precision?

ly-machining achieves precision through advanced equipment, including 5-axis CNC machines, and rigorous full-chain quality control. Our ISO9001 and IATF1649 certifications ensure adherence to strict standards, with meticulous inspection at every stage of production.

Can ly-machining help with DFM for drone parts?

Yes, ly-machining provides comprehensive Design for Manufacturability (DFM) services. Our experienced engineers will review your drone part designs. We offer expert recommendations on material selection, design optimization for CNC machining, and cost reduction without compromising performance.