CNC Customization: Crafting Unique Robot Parts

Precision CNC machining transforms generic robot parts into bespoke components, unlocking unparalleled performance, complex geometries, and superior durability for advanced robotics innovation.

In the rapidly evolving world of robotics, is your robot’s potential being held back by generic, off-the-shelf components? True innovation demands more than monotony; it demands uniqueness. The limitations of mass-produced parts often stifle groundbreaking designs and performance breakthroughs.

Discover how precision CNC machining is not just manufacturing parts, but custom-crafting the future of your robot’s performance. It’s the definitive answer to achieving the exact specifications your cutting-edge projects require.

This article will delve into how CNC machining provides unmatched capabilities for `robotics component manufacturing`, ensuring `precision robot parts` that elevate your designs beyond the ordinary.

Generic Robot Parts: A Performance Bottleneck

The drive for rapid deployment often leads manufacturers to utilize standardized parts. While initially cost-effective, these `robotics component manufacturing` choices often introduce limitations. This can significantly impact the long-term efficiency and capability of your robotic systems.

The hidden costs of standard robotics component manufacturing.

Opting for generic components can seem economical upfront, yet it often incurs substantial hidden costs. These include increased assembly time due to poor fit, higher maintenance from premature wear, and the necessity for over-engineering other aspects to compensate for part deficiencies.

In ly-machining’s experience, the compromises in material selection or design limitations with standard `robot parts` frequently lead to decreased efficiency and a shorter lifespan for the entire robot system. This directly impacts overall operational expenses.

How generic parts hinder precision robot parts’ potential.

Standard parts are designed for broad applications, not optimized for specific robotic tasks. This generic approach inherently limits `precision robot parts` from achieving peak performance, whether in terms of speed, accuracy, payload capacity, or unique functional requirements.

They often force design compromises, preventing engineers from realizing their most innovative concepts. The rigidity of generic specifications restricts the fluid, highly optimized movements and structural integrity crucial for advanced `robotics component manufacturing`.

CNC Machining: The Key to Custom Robot Parts

Computer Numerical Control (CNC) machining stands as the cornerstone of true customization in `robotics component manufacturing`. It transcends the limitations of generic parts by offering unparalleled design freedom and precision. This technology transforms conceptual designs into tangible, high-performance components.

How CNC machining transforms design freedom in robotics?

CNC machining empowers engineers with virtually unlimited design freedom for `robot parts`. Unlike off-the-shelf components, CNC allows for the creation of intricate internal structures, optimized geometries, and ergonomic forms perfectly tailored to a robot’s specific function and environment.

This means components can be designed for exact fit, superior functionality, and aesthetic integration, moving beyond the constraints of standard manufacturing methods. `CNC machining of robot parts` enables rapid iteration and refinement of designs, accelerating product development cycles.

Beyond limits: achieving complex geometries with CNC machining.

One of the most significant advantages of `CNC machining` is its ability to produce highly complex geometries with exceptional accuracy. Multi-axis CNC machines can create organic shapes, internal channels, undercuts, and features that are impossible or cost-prohibitive with traditional methods.

This capability is crucial for developing compact, lightweight, and highly functional `precision robot parts`. ly-machining leverages advanced software and machining strategies to translate even the most intricate CAD models into physical reality, pushing the boundaries of what is manufacturable.

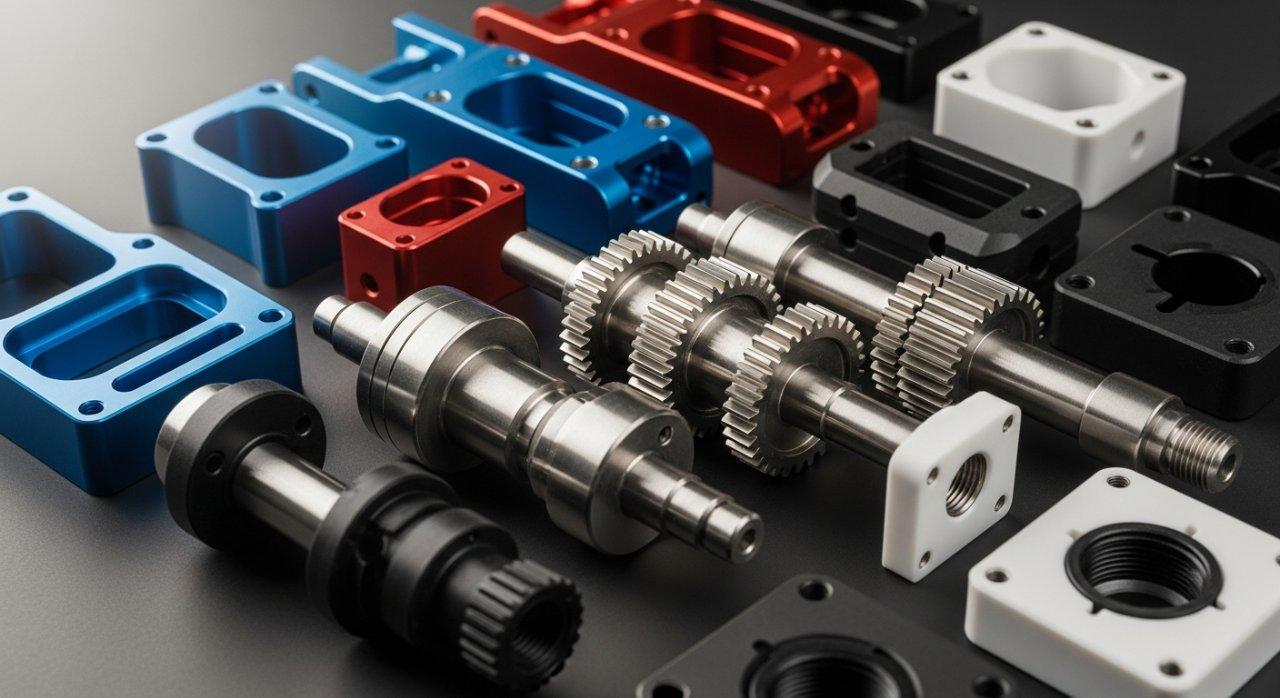

Material choice advantages in custom robot parts machining.

`Custom robot parts machining` opens up a vast spectrum of material choices, each selected for specific performance characteristics. While generic parts limit you to common alloys, CNC allows for specialized materials like aerospace-grade aluminum, titanium, high-performance plastics, and composites.

This flexibility ensures optimal strength-to-weight ratios, thermal management, electrical insulation, or corrosion resistance precisely where needed. ly-machining guides clients in selecting the ideal material to meet the rigorous demands of their robotic applications, ensuring superior part performance.

Here’s a comparison of generic versus custom robot parts:

| Feature | Generic Robot Parts | Custom Robot Parts (CNC) |

|---|---|---|

| **Design Freedom** | Limited, standard shapes | Unlimited, optimized for function |

| **Performance** | Adequate, generalized | Superior, task-specific |

| **Fit & Integration** | Often requires adaptation | Perfect, seamless |

| **Material Choice** | Common, limited selection | Wide range of specialized materials |

| **Innovation** | Restrained | Accelerated, enables new functionality |

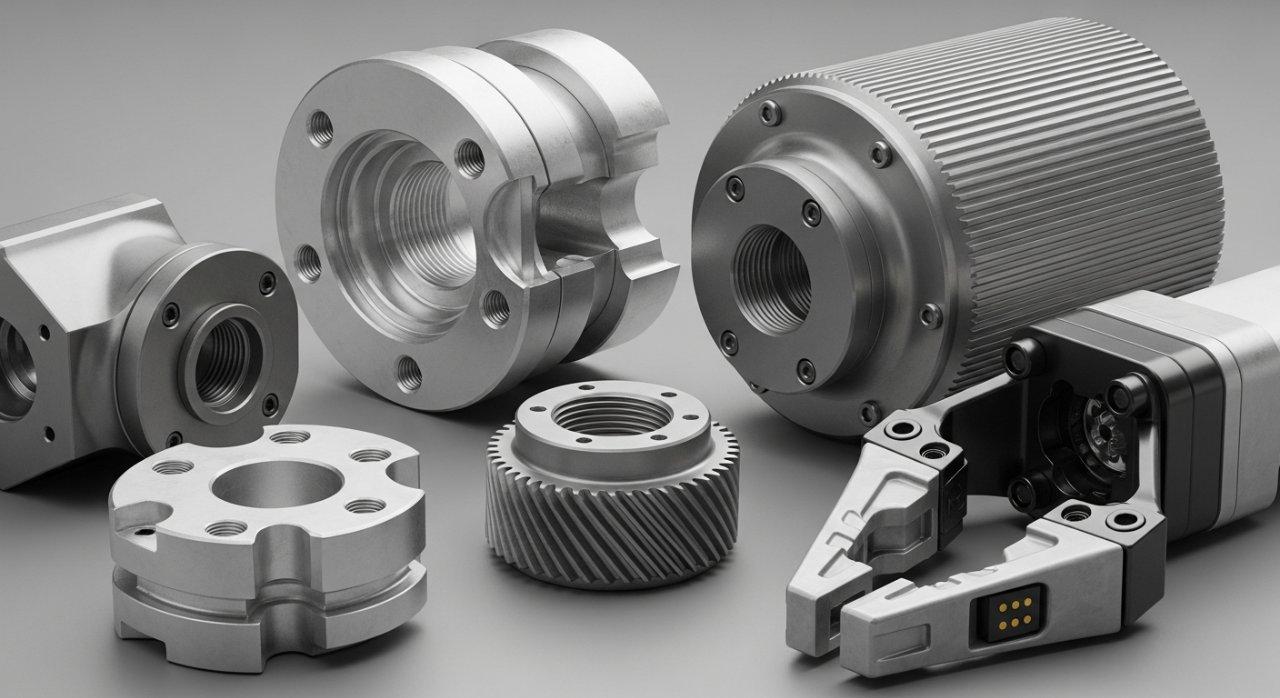

Precision Robotics Component Manufacturing

Achieving the pinnacle of `robotics component manufacturing` demands unwavering precision and sophisticated processes. It’s not merely about cutting metal but about meticulously crafting components to meet exact functional requirements. ly-machining’s commitment to precision ensures that every part contributes to the robot’s overall reliability.

The role of multi-axis CNC machining in robotics component manufacturing.

Multi-axis CNC machining, including 3-axis, 4-axis, and especially 5-axis capabilities, is pivotal in `robotics component manufacturing`. These advanced machines allow for simultaneous cutting along multiple axes, enabling the creation of complex, organic geometries in a single setup.

This reduces the need for multiple setups, minimizing potential errors and improving accuracy and surface finish. ly-machining’s advanced multi-axis capabilities are essential for producing the sophisticated `precision robot parts` required for modern, agile robotic systems.

Achieving micron-level accuracy for precision robot parts.

For `precision robot parts`, accuracy is paramount. Even microscopic deviations can impact a robot’s performance, leading to backlash, excessive wear, or operational failures. ly-machining achieves micron-level accuracy through state-of-the-art machinery, meticulous programming, and stringent quality control.

Our controlled manufacturing environment and skilled machinists ensure that tight tolerances are consistently met. This level of precision is critical for components like gears, bearings, sensor housings, and robotic joints where exact fit and smooth operation are non-negotiable.

Post-processing and finishing for robust CNC machining of robot parts.

The quality of `CNC machining of robot parts` extends beyond the cutting process. Post-processing and finishing treatments are vital for enhancing durability, aesthetics, and functional performance. These include deburring, anodizing, heat treatment, polishing, and specialized coatings.

These finishes can improve corrosion resistance, reduce friction, increase hardness, or provide electrical insulation. ly-machining offers a comprehensive range of post-machining services, ensuring that your `robot parts` are not only precise but also resilient and optimized for their operating environment.

Key advantages of multi-axis CNC machining for robotics:

| Feature | Benefit for Robotics Component Manufacturing |

|---|---|

| **Complex Geometries** | Enables intricate designs, lightweight structures, optimized shapes. |

| **Single Setup** | Reduces cumulative error, improves part accuracy and consistency. |

| **Superior Finish** | Achieves finer surface finishes, reducing post-processing and friction. |

| **Efficiency** | Faster machining cycles for complex parts, accelerating production. |

| **Design Freedom** | Allows designers to fully realize innovative concepts without manufacturing constraints. |

The Edge of Custom CNC Robot Parts

Leveraging `custom robot parts machining` provides a significant competitive advantage. It allows for the realization of designs that are not just unique, but fundamentally superior in performance and longevity. This strategic choice directly contributes to the success and market leadership of robotics companies.

Enhanced performance and durability with custom robot parts machining.

Custom parts are engineered for specific stress points, load requirements, and environmental conditions. This tailored approach, intrinsic to `custom robot parts machining`, results in components that offer superior strength, reduced wear, and extended operational life compared to generic alternatives.

The ability to precisely control material properties and design specifics means enhanced performance metrics across the board. Robots equipped with these optimized components operate more reliably, require less maintenance, and deliver consistent, high-quality results over time.

Weight reduction and strength optimization for precision robot parts.

For many robotic applications, especially mobile or collaborative robots, weight is a critical factor. `Precision robot parts` manufactured through CNC can be meticulously designed to achieve maximum strength with minimal material, utilizing advanced lightweighting techniques such as lattice structures or internal coring.

This optimization translates into increased payload capacity, higher speeds, reduced energy consumption, and improved overall agility. ly-machining’s expertise in material science and design for manufacturing ensures that strength and weight are perfectly balanced for your specific needs.

Accelerating innovation through rapid prototyping with CNC machining.

`CNC machining` is an invaluable tool for rapid prototyping, enabling quick iteration and testing of new `robot parts` designs. Engineers can rapidly produce functional prototypes from production-grade materials, allowing for real-world testing and validation early in the development cycle.

This agile approach significantly accelerates innovation, reducing time-to-market for new robotic products and functionalities. ly-machining supports this process with fast turnaround times and expert feedback, turning concepts into testable hardware efficiently.

Here’s a glimpse into material properties considerations for robotics:

| Material Type | Common Use in Robotics | Key Advantage for Robot Parts |

|---|---|---|

| **Aerospace Aluminum** | Structural components, housings | High strength-to-weight, good machinability |

| **Titanium Alloys** | High-stress joints, lightweight | Exceptional strength, corrosion resistance |

| **Engineering Plastics** | Insulators, non-metallic gears | Lightweight, electrical insulation, low friction |

| **Stainless Steel** | Heavy-duty components, fasteners | High strength, corrosion resistance, durability |

Selecting Your Custom CNC Machining Partner

The choice of your `CNC machining` partner is as crucial as the design of your `robot parts` themselves. A reliable partner ensures not only the quality of your components but also the success of your entire project. It’s about finding a collaborator with integrity and deep technical understanding.

What to look for in a source manufacturer for robot parts?

When seeking a `source manufacturer for robot parts`, prioritize those with direct control over their processes. A true source manufacturer, like ly-machining, offers full transparency, from raw material sourcing to final inspection, ensuring consistent quality and reliable lead times.

Look for a manufacturer with a proven track record in `robotics component manufacturing` and a comprehensive understanding of industry standards. Expertise, equipment capabilities, and adherence to quality management systems are key indicators of a trustworthy partner.

The value of deep technical expertise in custom robot parts.

Deep technical expertise is invaluable for `custom robot parts`. This goes beyond simply operating machines; it includes profound knowledge of material science, design for manufacturability (DFM), tolerance stack-up analysis, and advanced machining strategies.

ly-machining’s engineers collaborate closely with your design team, offering insights that optimize designs for both performance and cost-effectiveness. This partnership ensures that theoretical designs are translated into robust, high-performing physical components.

Transparent pricing and quality assurance in CNC machining.

Transparent pricing, free from hidden fees, builds trust and facilitates effective budget planning for `CNC machining`. ly-machining provides clear, detailed quotes that reflect the true cost of manufacturing, ensuring no surprises.

Equally important is a robust quality assurance system. ly-machining adheres to rigorous quality control protocols at every stage, from initial material inspection to final dimensional verification, guaranteeing that every `precision robot part` meets your exact specifications and industry standards.

Future of Robotics with Custom CNC Parts

The trajectory of robotics is undeniably towards greater intelligence, autonomy, and specialized functionality. This evolution is inextricably linked to the ability to produce highly customized and `precision robot parts`. `CNC machining` is not just keeping pace; it’s driving this future.

The evolving landscape of robotics component manufacturing.

The `robotics component manufacturing` landscape is continuously innovating, with demands for smaller, lighter, stronger, and more integrated components. Advanced materials, intricate internal structures, and integrated sensor solutions are becoming standard.

CNC machining, with its inherent adaptability and precision, is perfectly positioned to meet these evolving requirements. It enables the creation of components that push the envelope of what robots can achieve, from micro-robotics to large-scale industrial automation.

Your partner in pushing boundaries for custom robot parts.

As you push the boundaries of robotic innovation, having a manufacturing partner like ly-machining is crucial. ly-machining is committed to advancing the capabilities of `custom robot parts`, offering state-of-the-art `CNC machining services` and engineering support.

ly-machining acts as an extension of your R&D team, providing expert guidance and high-quality manufacturing to turn your most ambitious visions into reality. With ly-machining, your `robot parts` will define new standards of performance and reliability.

Unlock Your Robot’s Full Potential Today

Don’t let generic components limit your innovation or compromise your robot’s performance. The future of robotics demands `precision robot parts` that are meticulously crafted to your exact specifications.

Contact our experts for precision robot parts machining.

Are you ready to elevate your robot’s capabilities? ly-machining is a leading provider of high-precision `CNC machining of robot parts`, dedicated to bringing your unique designs to life.

Our team of engineering experts is prepared to discuss your specific project needs, material requirements, and performance goals for `custom robot parts`.

Case Study: Optimizing a Robotic End-Effector for a Pharmaceutical Client

Problem: A pharmaceutical client struggled with their existing robotic end-effector, which used heavy, cast aluminum components. This led to slow cycle times, high energy consumption, and frequent maintenance due to wear and tear. They needed a lighter, more precise, and durable solution for handling delicate vials.

Our Solution: ly-machining collaborated with the client’s engineering team to redesign the end-effector components. Utilizing advanced `CNC machining` with aerospace-grade 7075 aluminum and titanium alloys, ly-machining manufactured custom components with optimized geometries and internal lightweighting features. This `custom robot parts machining` also incorporated tighter tolerances for improved grip accuracy and less vibration.

Result: The new custom-machined end-effector was 35% lighter, resulting in a 20% increase in cycle speed and a 15% reduction in energy consumption. The `precision robot parts` exhibited significantly reduced wear, extending the maintenance interval by 50% and vastly improving the robot’s reliability in a critical production line. The client achieved a rapid ROI through enhanced productivity and reduced operational costs.

Call to Action: Ready to elevate your robot’s performance beyond the generic? Don’t let standard components limit your innovation. Contact ly-machining’s engineering experts today for a free consultation, transparent quote, and discover how our high-precision custom CNC machining can bring your unique robotics vision to life.

FAQ Section:

What materials can CNC machines process for robotics?

CNC machines are highly versatile, capable of processing a wide array of materials essential for `robotics component manufacturing`. This includes various grades of aluminum, stainless steel, titanium, brass, and high-performance engineering plastics like PEEK and Delrin.

The choice of material for `custom robot parts machining` depends on specific application requirements such as strength-to-weight ratio, corrosion resistance, thermal properties, and electrical conductivity.

How does CNC ensure precision in robot parts?

`CNC machining` ensures exceptional precision through several integrated factors. These include highly accurate machine tools with advanced motion control, precise programming, stringent quality control measures using CMMs (Coordinate Measuring Machines), and skilled machinists.

This combination allows for the consistent production of `precision robot parts` with micron-level tolerances and superior surface finishes, critical for the reliable operation of robotic systems.

What are the benefits of custom robot parts?

`Custom robot parts` offer numerous benefits over generic components. They enable optimal performance through tailored designs, achieve weight reduction without compromising strength, enhance durability, and facilitate seamless integration.

This `custom robot parts machining` approach fosters innovation, allowing for unique functionalities and a competitive edge in the rapidly evolving `robotics component manufacturing` industry.