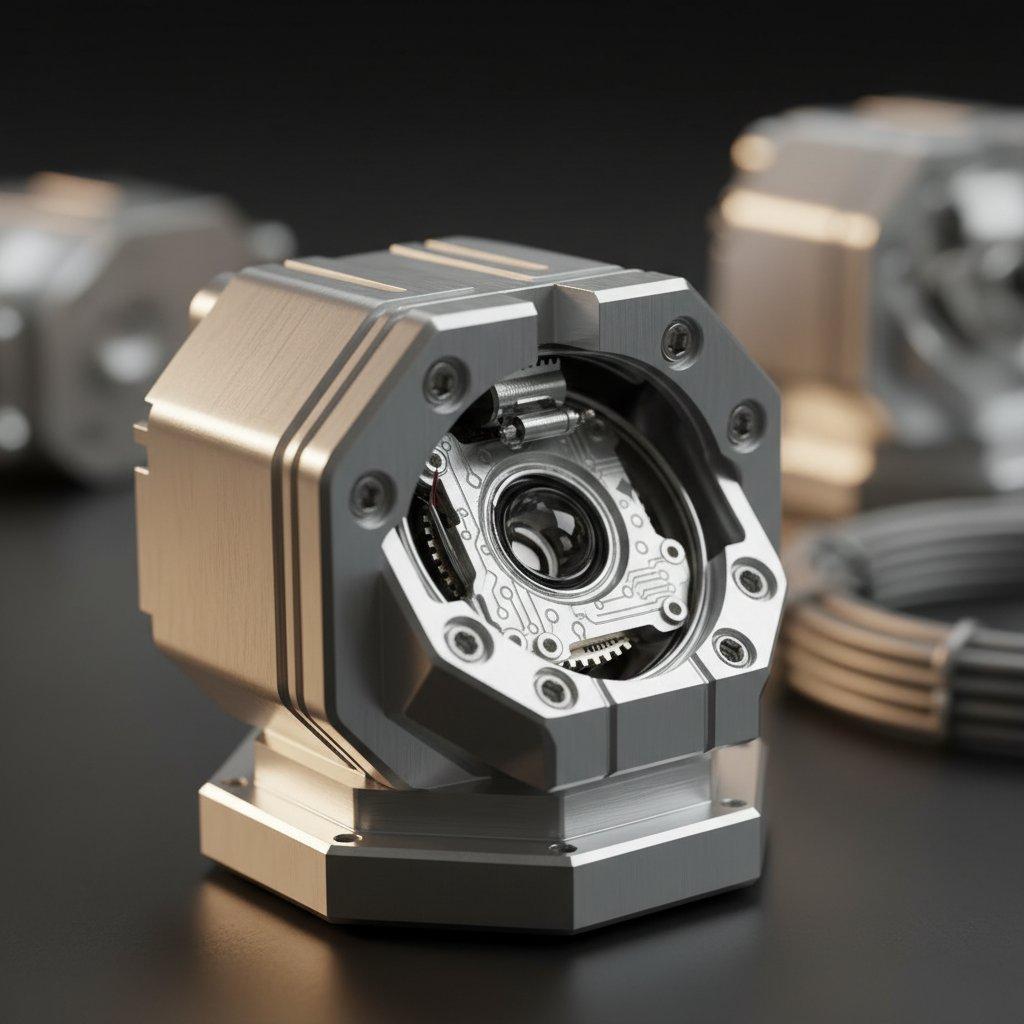

Precision Micro-Milling for Robot Sensor Housings

Precision micro-milling is essential for CNC machining of robot parts, enabling the manufacturing of precision robot components with micron-level accuracy for highly demanding robotics CNC machining services.

In the relentless pursuit of robotic perfection, a single micron can define success or failure. The performance of advanced robotic systems hinges on the flawless integrity of their sensor housings. These critical components demand manufacturing precision beyond conventional methods.

Are your robot sensor housings truly enabling the accuracy and reliability your designs demand? This article will delve into how precision micro-milling elevates robotics to unprecedented levels, addressing the core challenges in producing these vital parts.

ly-machining understands the imperative for uncompromised quality in custom robot parts machining. We will explore the unique capabilities of micro-milling and demonstrate how ly-machining consistently delivers superior solutions for the most intricate robotic applications.

The Imperative of Precision Robot Sensor Housings

Why ultra-precision is critical for CNC machining of robot parts

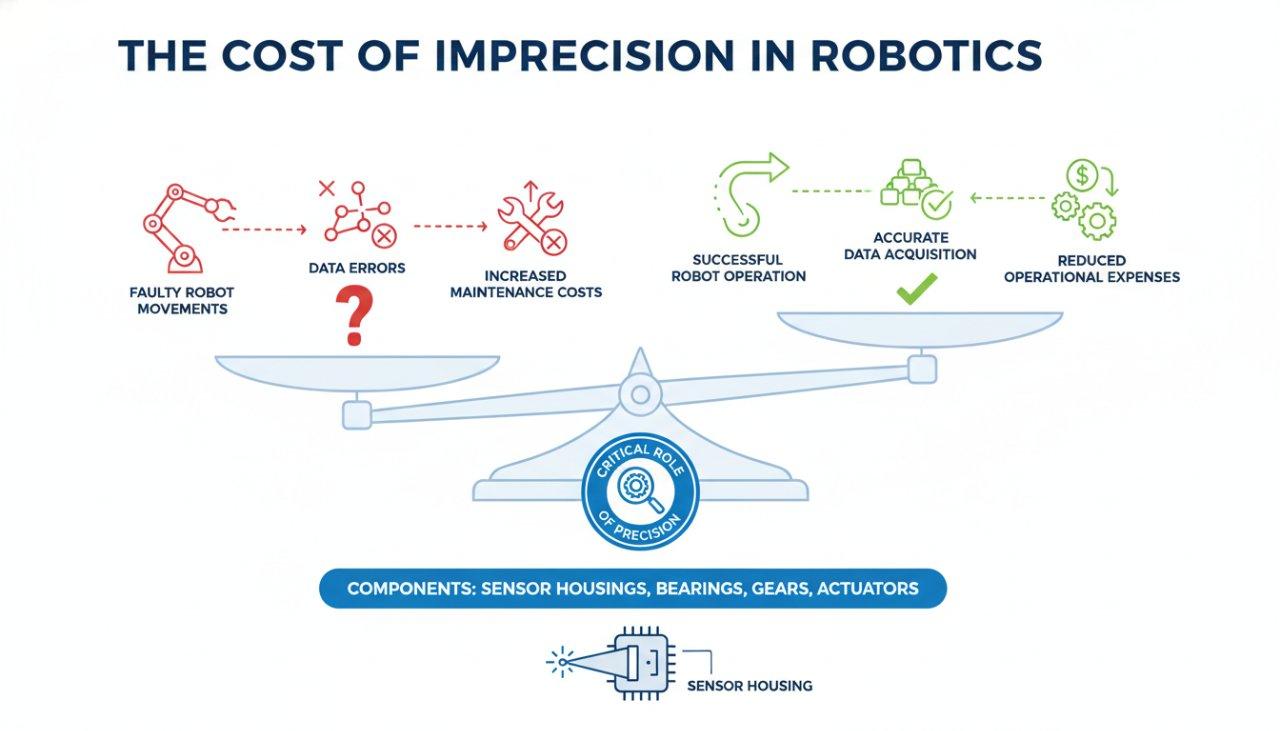

The functionality of modern robotics relies heavily on the accuracy and reliability of its sensory input. Sensor housings are not mere protective shells; they are integral to the sensor’s performance, defining its environment, thermal stability, and EMI shielding.

Ultra-precision in CNC machining of robot parts, specifically for sensor housings, ensures optimal sensor alignment, minimal signal interference, and structural integrity under operational stress. Even minor dimensional inaccuracies can lead to calibration errors or sensor failure.

In ly-machining’s experience, the difference between success and failure in advanced robotic systems often comes down to sub-micron level manufacturing consistency. This directly impacts the robot’s ability to perform precise tasks, from surgical procedures to automated inspections.

Addressing limitations in current precision robot components manufacturing

Traditional CNC machining often faces limitations when it comes to machining extremely small features, achieving ultra-fine surface finishes, or holding micron-level tolerances consistently. These limitations become bottlenecks in precision robot components manufacturing.

Common issues ly-machining observes include burring on miniature edges, insufficient surface roughness for sensitive internal components, and challenges in machining exotic materials without compromising material integrity. Such problems can lead to costly rework or design compromises.

The demand for smaller, more capable robots necessitates a paradigm shift in manufacturing capabilities. Addressing these limitations requires specialized technology and deep expertise that few providers of robotics CNC machining services possess.

Unlocking Accuracy with Micro-Milling Technology

What defines precision micro-milling for robotics CNC machining services?

Precision micro-milling is a specialized form of CNC machining that employs extremely small cutting tools, typically under 1 mm in diameter, to create miniature features and intricate geometries with exceptional accuracy. This process is ideal for robotics CNC machining services.

It involves high spindle speeds, precise motion control, and sophisticated toolpath generation to achieve tolerances often measured in single-digit microns. This level of precision is unattainable with standard milling techniques.

ly-machining’s micro-milling capabilities are defined by our investment in state-of-the-art machines and highly skilled machinists. We deliver the exacting quality required for critical robot components.

Advantages of micro-milling in custom robot parts machining

The primary advantage of micro-milling for custom robot parts machining lies in its ability to produce highly complex, miniature components with superior surface finish and dimensional accuracy. This ensures optimal fitment and performance for sensitive sensors.

It allows for the creation of intricate internal channels, thin walls, and precise mounting features that are essential for compact sensor integration. Micro-milling reduces the need for secondary finishing operations, saving time and cost.

Furthermore, micro-milling provides excellent material integrity by minimizing heat generation and cutting forces. This is crucial for maintaining the properties of advanced materials used in robotics.

Key technological advancements in CNC machining for sensor housings

Modern CNC machining for sensor housings incorporates advancements like multi-axis capabilities, thermal compensation systems, and in-process metrology. These innovations are critical for maintaining precision during complex machining cycles.

Tooling advancements, including specialized micro-end mills with advanced coatings, contribute significantly to extended tool life and superior surface quality. Vision systems guide the machining process with unparalleled accuracy.

ly-machining leverages these cutting-edge technologies. This ensures consistent, repeatable precision across all batches, regardless of component complexity or material specifications.

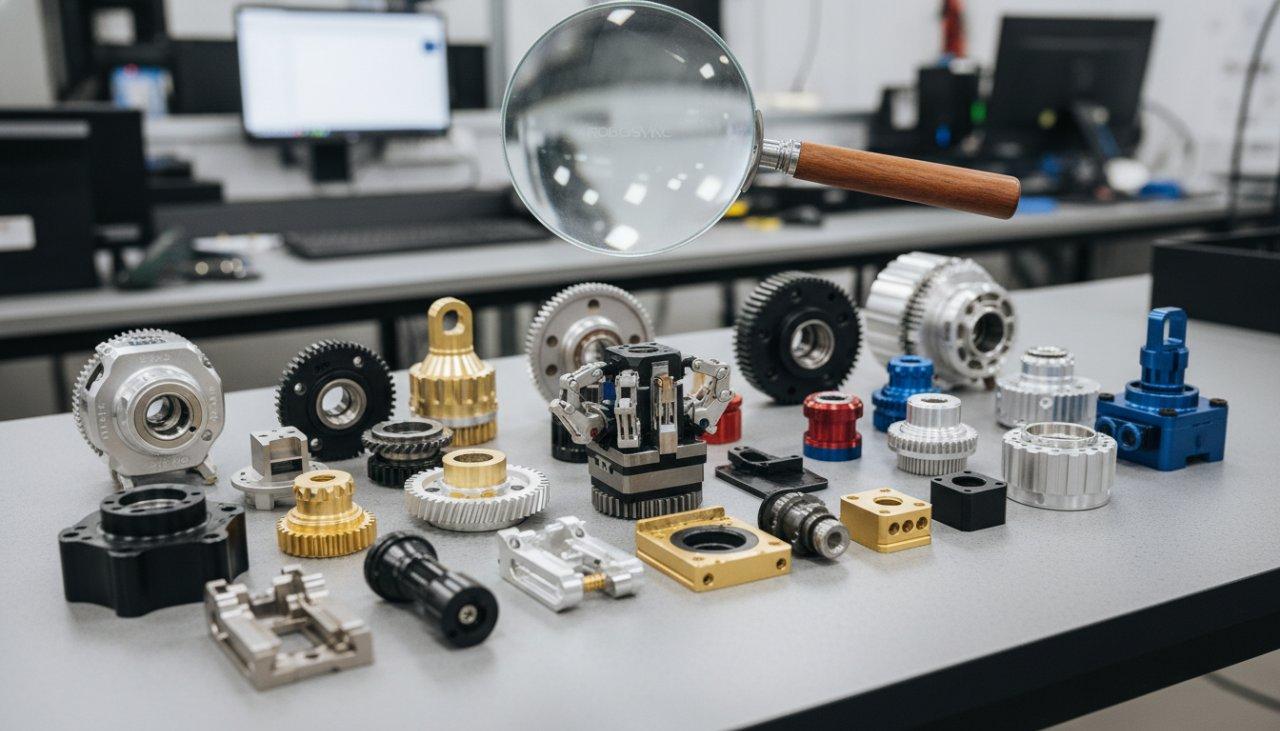

Technical Deep Dive: Micro-Milling Sensor Shells

Material selection for robust precision robot components manufacturing

The choice of material is paramount for precision robot components manufacturing. Sensor housings often require materials that offer high strength-to-weight ratios, excellent thermal conductivity, and sometimes specific electromagnetic properties.

Common materials ly-machining works with include aerospace-grade aluminum alloys (e.g., 7075, 6061), titanium (Grade 5), and engineering plastics like PEEK. Each material presents unique machining challenges and performance characteristics.

The specific operational environment of the robot dictates material selection. ly-machining provides expert consultation on material suitability to optimize both performance and manufacturability.

Achieving micron-level tolerances through advanced CNC machining

Achieving micron-level tolerances is a hallmark of ly-machining’s advanced CNC machining processes. This requires a combination of highly rigid machines, precise toolpath strategies, and meticulous environmental control.

Temperature stability in the machining environment, along with thermal compensation in the machine, prevents thermal expansion and contraction that could affect dimensional accuracy. Closed-loop feedback systems constantly monitor and adjust tool positions.

In ly-machining’s experience, the integration of cutting-edge metrology directly into the manufacturing process ensures real-time verification and minimizes deviations. This commitment guarantees the highest levels of precision.

Here’s a look at typical tolerances ly-machining achieves:

| Feature Type | Typical Tolerance (microns) | ISO Standard Equivalence |

|---|---|---|

| Dimensional | +/- 5 to +/- 10 | IT1 to IT2 |

| Positional | +/- 3 to +/- 7 | Grade 00 to Grade 0 |

| Flatness | +/- 2 to +/- 5 | IT0 to IT1 |

| Concentricity | +/- 3 to +/- 8 | Grade 00 to Grade 0 |

Mastering complex geometries in CNC machining of robot parts

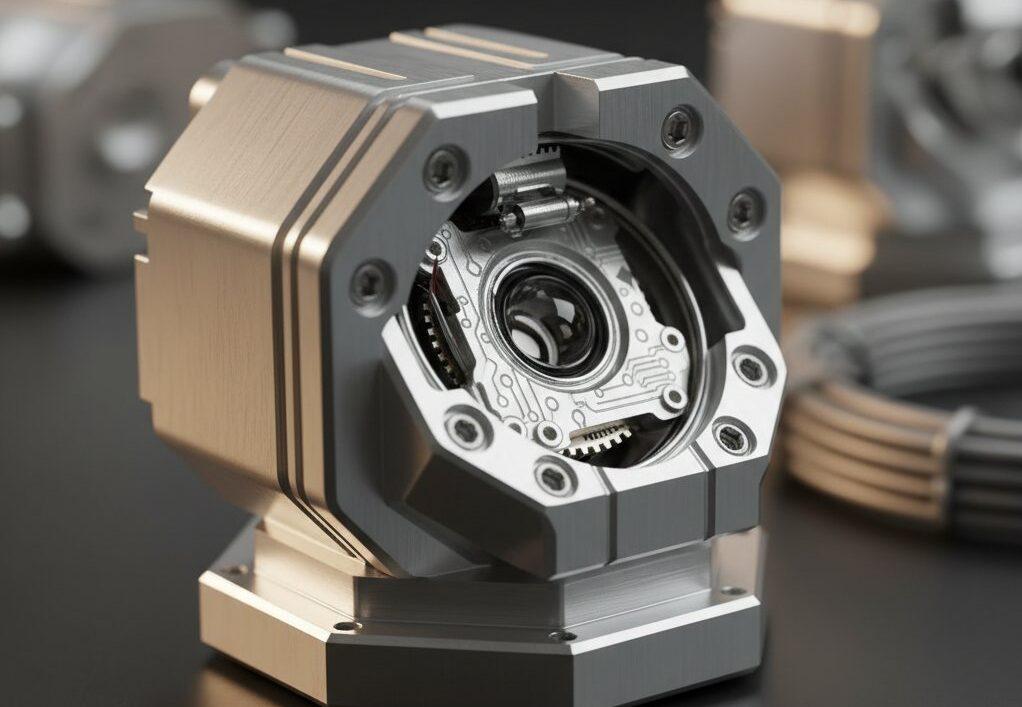

Robot sensor housings frequently feature complex geometries, including intricate internal cavities, very thin walls, and multi-faceted surfaces. Mastering these in CNC machining of robot parts is a core competency for ly-machining.

This involves advanced CAD/CAM programming, utilizing 5-axis machining capabilities to access challenging angles without multiple setups, and implementing sophisticated cutting strategies to prevent tool deflection and material deformation.

ly-machining’s design for manufacturability (DFM) expertise is crucial here. We collaborate with clients early in the design phase to optimize geometries for micro-milling, ensuring both performance and efficient production.

Specialized tooling and process control for custom robot parts machining

The success of custom robot parts machining via micro-milling hinges on specialized tooling. ly-machining utilizes ultra-small diameter end mills, ball nose cutters, and custom-ground tools, often made from solid carbide with advanced coatings.

These tools are selected based on material, feature size, and desired surface finish, and are frequently monitored for wear. Process control involves optimizing cutting parameters such as feed rates, spindle speeds, and depth of cut to minimize stress and maximize tool life.

ly-machining implements strict quality control protocols at every stage. This includes optical inspection, touch probe measurements, and profile projection to ensure every detail meets specifications.

Here are some key tooling considerations for micro-milling:

| Tool Parameter | Importance for Precision | ly-machining Approach |

|---|---|---|

| Diameter | Access to micro-features | Typically < 1 mm, down to 50 microns |

| Material | Durability & Sharpness | Solid carbide, sometimes PCD |

| Coating | Wear resistance, lubricity | TiAlN, AlTiN, nano-composite |

| Flute Count | Chip evacuation, rigidity | 2 to 4 flutes for micro-machining |

| Runout | Dimensional accuracy | Strict runout control < 3 microns |

Expertise for Precision Robot Sensor Housings

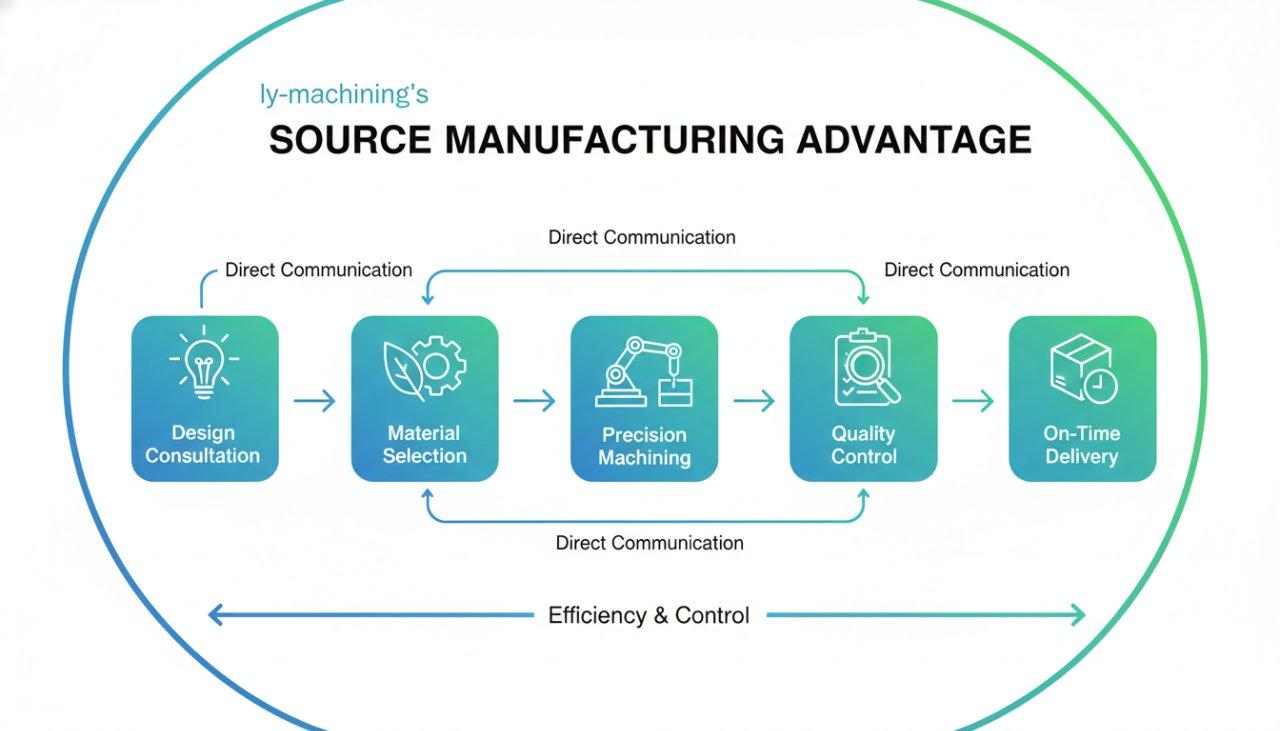

Our source manufacturing advantage for precision robot components manufacturing

As a source manufacturer, ly-machining offers unparalleled control over the entire production process for precision robot components manufacturing. This means direct oversight from raw material procurement to final inspection, ensuring consistent quality.

ly-machining eliminates communication gaps and delays often associated with middlemen. Our clients benefit from direct access to our engineering team, facilitating swift technical discussions and design iterations.

This integrated approach guarantees optimal quality, efficient lead times, and competitive, transparent pricing for all custom robot components.

Transparent pricing and deep technical expertise in custom robot parts machining

ly-machining is committed to transparent pricing for custom robot parts machining. We provide detailed quotes that clearly break down costs, ensuring clients understand the value they receive for high-precision components.

Our deep technical expertise is the foundation of our service. ly-machining’s engineers possess extensive knowledge in material science, machining dynamics, and geometric tolerancing. This allows us to solve complex manufacturing challenges efficiently.

We partner with clients, offering design for manufacturability (DFM) advice. This collaborative approach minimizes potential issues and optimizes part designs for cost-effective, high-precision production.

Streamlined process for precision robot components manufacturing

ly-machining’s streamlined process for precision robot components manufacturing is designed for efficiency and reliability. It begins with comprehensive design review and material selection, moving to advanced CAD/CAM programming.

Our production phase employs state-of-the-art micro-milling machines and stringent in-process quality checks. Post-machining, parts undergo meticulous cleaning and a final, multi-stage inspection using advanced metrology equipment.

This methodical approach ensures that every component leaving ly-machining meets the most rigorous specifications and is delivered on time.

Case study: Flawless sensor housing via CNC machining of robot parts

A leading robotics firm faced significant challenges in achieving the required precision for a new generation of miniature sensor housings. Their previous supplier struggled with maintaining micron-level tolerances across thin walls and intricate internal features.

The firm’s robot’s performance was compromised by signal interference and sensor misalignment. They needed a partner capable of consistent, ultra-high precision CNC machining of robot parts for this critical application.

ly-machining collaborated closely with their engineering team, providing DFM recommendations to optimize the design for micro-milling. We selected aerospace-grade aluminum and utilized our 5-axis micro-milling capabilities with custom tooling.

ly-machining’s process included active thermal compensation and in-line optical inspection. The result was a batch of sensor housings that consistently met all specifications, including a +/- 5 micron tolerance and an Ra 0.2 surface finish.

This enabled the client to achieve superior sensor performance and accelerate their robot’s market launch. It proved the critical role of true precision in enabling next-generation robotics.

Future of Robotics with Advanced Micro-Milling

Innovating the next generation of precision robot components manufacturing

The future of robotics demands ever-increasing miniaturization, greater integration, and enhanced performance. This drives the need for continuous innovation in precision robot components manufacturing.

Advanced micro-milling, coupled with developments in material science and additive manufacturing hybrids, will continue to push the boundaries of what is possible. ly-machining is at the forefront of these innovations.

We continuously invest in new technologies and process improvements. This ensures ly-machining remains a trusted partner for developing the critical components that will power the next generation of intelligent, highly agile robots.

Excellence in Precision Micro-Milling Services

Get a transparent quote for your custom robot parts machining project today

Ready to empower your robotics with sensor housings built to uncompromising standards? ly-machining is your trusted partner for high-precision custom robot parts machining.

Connect with ly-machining’s micro-milling experts today for a transparent quote. We also offer a complimentary Design for Manufacturability consultation.

Let ly-machining engineer your success together, ensuring your critical robotic components are manufactured with unparalleled precision and reliability.

How does ly-machining ensure micron-level tolerances?

ly-machining achieves micron-level tolerances through a combination of state-of-the-art 5-axis micro-milling machines, active thermal compensation systems, and stringent environmental controls. Our in-process metrology and closed-loop feedback systems constantly monitor and adjust tool paths, ensuring exceptional precision.

What materials can ly-machining micro-mill for robot parts?

ly-machining has extensive experience micro-milling a wide range of materials crucial for robot parts, including aerospace-grade aluminum alloys (e.g., 7075, 6061), titanium (Grade 5), stainless steels, and engineering plastics like PEEK. Our expertise allows for optimal material selection based on your specific application needs.

Why is DFM critical for robotics CNC machining services?

Design for Manufacturability (DFM) is critical for robotics CNC machining services because it optimizes component designs for efficient and cost-effective production, especially for complex micro-milled parts. ly-machining’s DFM consultation helps identify potential issues early, ensuring designs are robust, manufacturable, and achieve desired performance without costly rework.