Chinese CNC Parts Manufacturers: TOP20 Analysis

Identifying top Chinese CNC parts manufacturers requires assessing quality, technical prowess, and reliability, crucial for securing the best CNC machining for custom parts.

In the booming global demand for high-precision CNC parts, securing a truly top-tier Chinese manufacturer is a critical challenge. Beyond simple lists, what truly differentiates the best from the rest? This in-depth analysis demystifies the Chinese CNC landscape, revealing the definitive criteria and key insights you need.

It helps you find a partner that delivers unparalleled quality, technical expertise, and transparent value. This guide will clarify how to evaluate and select the finest CNC machining manufacturers for your most demanding projects.

Decoding Top CNC Parts Manufacturers

Identifying leading CNC manufacturing suppliers in China requires a systematic approach. It goes beyond anecdotal evidence, focusing on tangible criteria that guarantee performance. ly-machining understands this need for objective evaluation.

This section outlines the essential benchmarks that distinguish truly top CNC parts manufacturers from the rest. It provides a framework for informed decision-making in a competitive global market.

Core Criteria for Leading CNC Manufacturing Suppliers

Leading CNC manufacturing suppliers are defined by their commitment to excellence across several fronts. These criteria establish a foundation of reliability and capability. ly-machining consistently adheres to these principles in all its operations.

A manufacturer’s operational maturity and technical capabilities are paramount. The ability to consistently meet stringent specifications sets the elite apart.

| Criterion | Description |

|---|---|

| **Quality Systems** | ISO 9001, AS9100, ISO 13485 certifications. |

| **Technical Capability** | Multi-axis machining, DFM support, material expertise. |

| **Process Control** | Statistical Process Control (SPC), lean manufacturing. |

| **Communication** | Clear, timely, and technical support in multiple languages. |

| **Supply Chain** | Material sourcing, logistics, and traceability. |

Quality & Precision in CNC Machining

Quality and precision are the cornerstones of any reputable CNC machining operation. For ly-machining, these are non-negotiable standards, embedded in every process. It is about more than just meeting specifications; it is about exceeding expectations.

In ly-machining’s experience, achieving micron-level precision and consistent surface finishes (e.g., Ra 0.8) is critical. This level of detail ensures part functionality and longevity, especially for sensitive applications.

| Quality Standard | Relevance for CNC Parts |

|---|---|

| **ISO 9001** | General Quality Management System, process consistency. |

| **AS9100** | Aerospace Quality Management System, critical for defense/aero. |

| **ISO 13485** | Medical Devices Quality Management System, regulatory compliance. |

| **Material Certs** | Mill certificates (CoC) for traceability and verification. |

| **PPAP/FAI** | Production Part Approval Process / First Article Inspection. |

Technical Prowess for Custom Parts

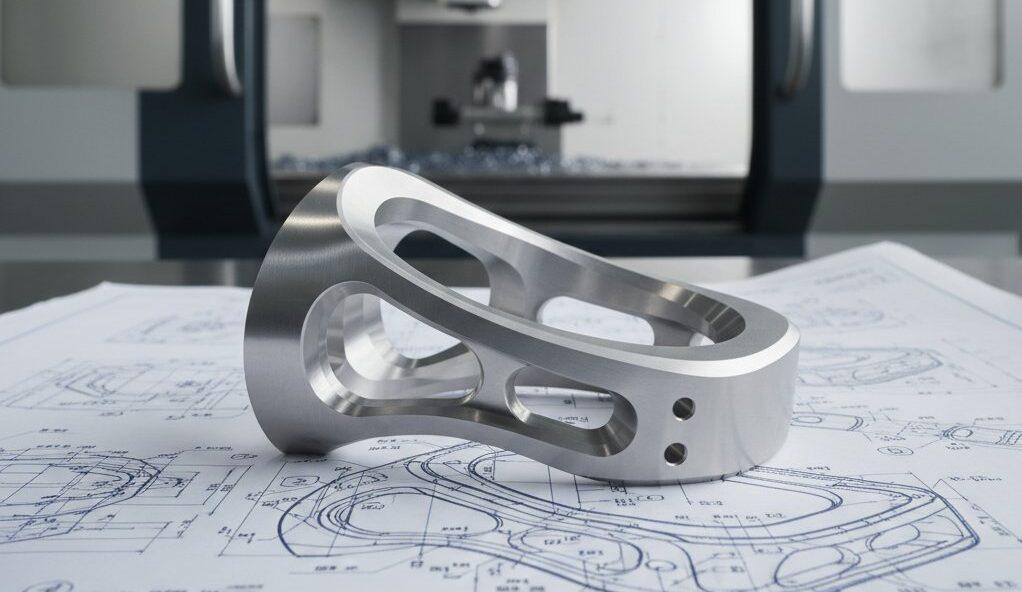

The ability to handle complex geometries and diverse materials defines technical prowess. Top CNC machining companies, like ly-machining, invest heavily in advanced machinery and skilled personnel. This enables the creation of highly specialized custom parts.

ly-machining offers extensive Design for Manufacturability (DFM) support, collaborating with clients. This proactive approach optimizes designs for cost-effectiveness and improved performance, reducing potential issues.

| Advanced Capability | Description |

|---|---|

| **5-Axis Machining** | Complex geometries, single-setup machining, tight tolerances. |

| **Advanced Materials** | Titanium, Inconel, medical-grade plastics, ceramics. |

| **EDM/Wire EDM** | Intricate shapes, hard materials, fine features. |

| **Precision Grinding** | Ultra-tight tolerances and superior surface finishes. |

| **Laser Marking/Engraving** | Permanent part identification, traceability. |

Analyzing the China CNC Supplier Landscape

The landscape of CNC machining manufacturers in China is vast and dynamic. Understanding its structure is crucial for identifying key players. This analysis helps discern where the best CNC machine shops for parts are located and what they specialize in.

ly-machining operates within this competitive environment, constantly refining its strategies. This ensures its position among the leading CNC manufacturing suppliers by focusing on distinct market needs.

Key Segments of the Best CNC Machine Shops for Parts

The best CNC machine shops for parts often specialize in particular industries or part complexities. Some excel in high-volume production, while others, like ly-machining, focus on high-mix, low-volume, complex precision components. This specialization drives expertise.

For instance, medical device components demand specific material certifications and surface finishes. Aerospace parts require stringent traceability and robust quality systems. ly-machining targets these high-demand, high-precision sectors.

Innovation in Chinese CNC machining

Innovation is a driving force behind the success of leading CNC manufacturing suppliers. Chinese CNC machining has seen significant advancements in automation, smart manufacturing, and material processing. These innovations enhance efficiency and capability.

ly-machining continually invests in the latest CNC technology, including advanced robotics and integrated automation. This commitment ensures ly-machining remains at the forefront of manufacturing capabilities.

Regional Hubs for CNC Machining Manufacturers

China’s CNC machining manufacturers are largely concentrated in key industrial regions. These hubs offer developed supply chains, skilled labor, and strong logistical support. Understanding these regions helps in targeted supplier searches.

The Pearl River Delta and Yangtze River Delta are prominent examples. ly-machining is strategically located to leverage these regional advantages, ensuring efficient operations and supply chain reliability.

| Region | Primary Specializations |

|---|---|

| **Pearl River Delta** | Electronics, automotive components, consumer goods, tooling. |

| **Yangtze River Delta** | Aerospace, medical devices, advanced machinery, high-tech. |

| **Bohai Rim** | Heavy industry, automotive, energy equipment. |

| **Central China** | General manufacturing, agricultural machinery. |

How to Select Your CNC Parts Supplier

Selecting the right CNC parts supplier is a critical decision impacting project success. It demands thorough due diligence and a clear understanding of your requirements. ly-machining advocates for a transparent and rigorous selection process.

This section provides actionable steps to effectively vet potential partners. It highlights factors that ensure you choose top CNC machining companies for custom parts.

Vetting Top CNC Machining Companies

Vetting top CNC machining companies involves more than reviewing websites. It requires in-depth audits, clear communication protocols, and a focus on proven capabilities. ly-machining welcomes comprehensive client audits.

Asking for detailed case studies, requesting sample parts, and engaging in technical discussions are essential. These steps help verify a supplier’s claimed expertise and their ability to handle your specific project.

| Vetting Step | Purpose |

|---|---|

| **Factory Audit** | Assess facilities, processes, quality control, and personnel. |

| **Technical Review** | Discuss DFM, material selection, and specific part challenges. |

| **Sample Production** | Evaluate actual part quality, lead time, and adherence to specs. |

| **Communication Clarity** | Ensure timely, accurate responses and technical understanding. |

| **References/Testimonials** | Validate supplier reputation and client satisfaction. |

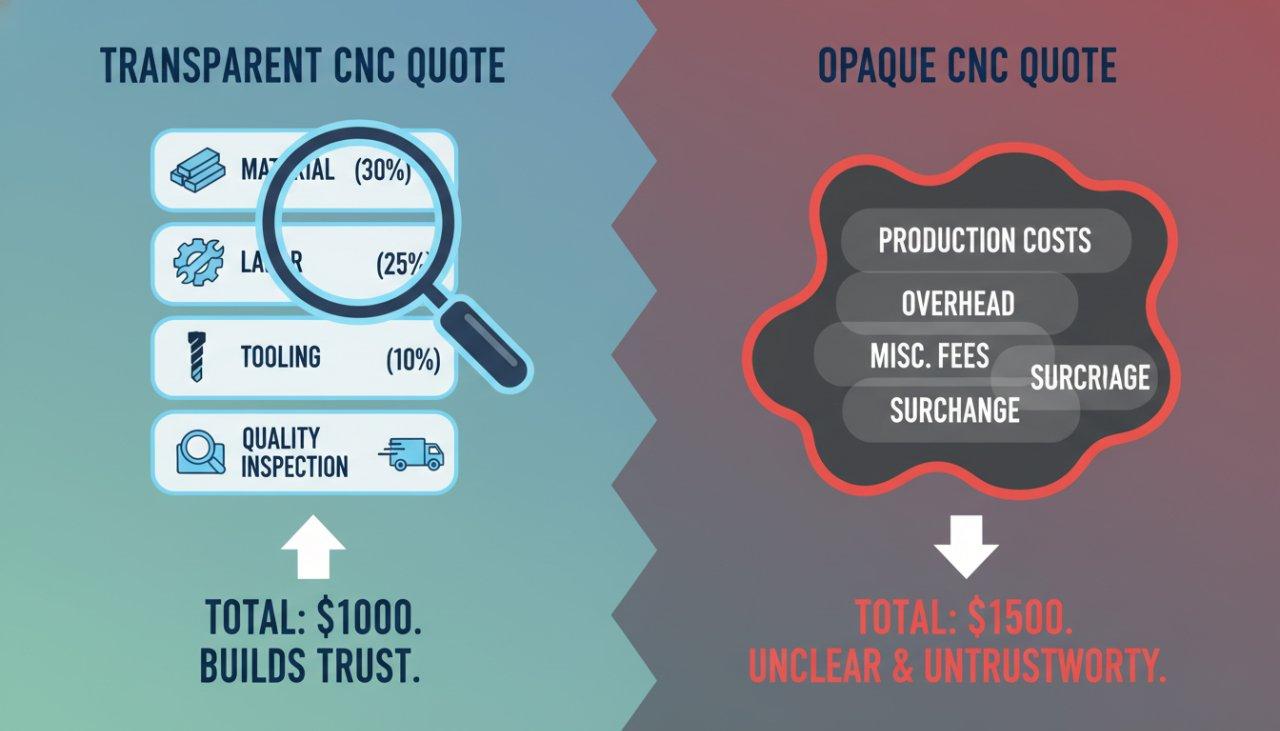

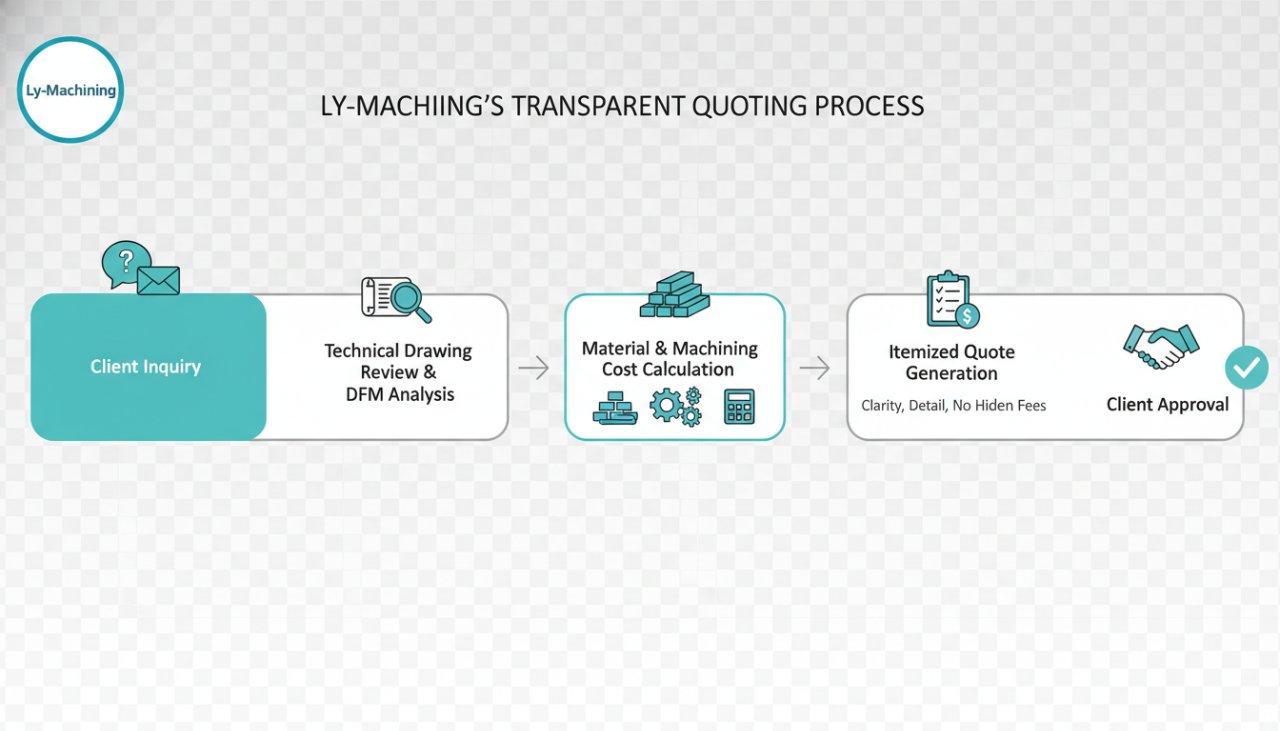

Transparent Pricing for Top CNC Custom Parts

Transparent pricing is a hallmark of trustworthy leading CNC manufacturing suppliers. Hidden costs or ambiguous quotes can lead to budget overruns and project delays. ly-machining provides detailed, itemized quotations.

A clear breakdown of material costs, machining time, tooling, surface treatments, and quality inspections should always be provided. This level of transparency fosters trust and helps in accurate budgeting.

Advanced CNC Machining for Complex Parts

When dealing with advanced CNC machining for complex parts, standard capabilities often fall short. This niche requires specialized equipment, highly skilled operators, and sophisticated programming. ly-machining excels in this demanding area.

Parts with tight tolerances, intricate internal features, or exotic material requirements demand expertise in 5-axis machining. Such capabilities ensure precision and reduce the need for multiple setups, enhancing accuracy.

Partnering with a Leading CNC Manufacturer

Choosing to partner with a leading CNC manufacturer like ly-machining offers distinct advantages. It provides assurance in terms of quality, reliability, and technical support. This partnership is built on mutual trust and shared goals.

This section explores the specific benefits derived from collaborating with a top-tier provider. It highlights how a strong manufacturing relationship underpins project success and innovation.

Source Manufacturer Benefits in CNC Machining

Partnering directly with a source manufacturer in CNC machining, such as ly-machining, streamlines the entire process. It eliminates intermediaries, leading to clearer communication and greater control over production. This direct relationship also enhances cost efficiency.

As a source manufacturer, ly-machining provides end-to-end responsibility for quality and delivery. This comprehensive oversight significantly reduces risks and improves overall project management for clients.

Ensuring Quality with Best CNC Machine Shops

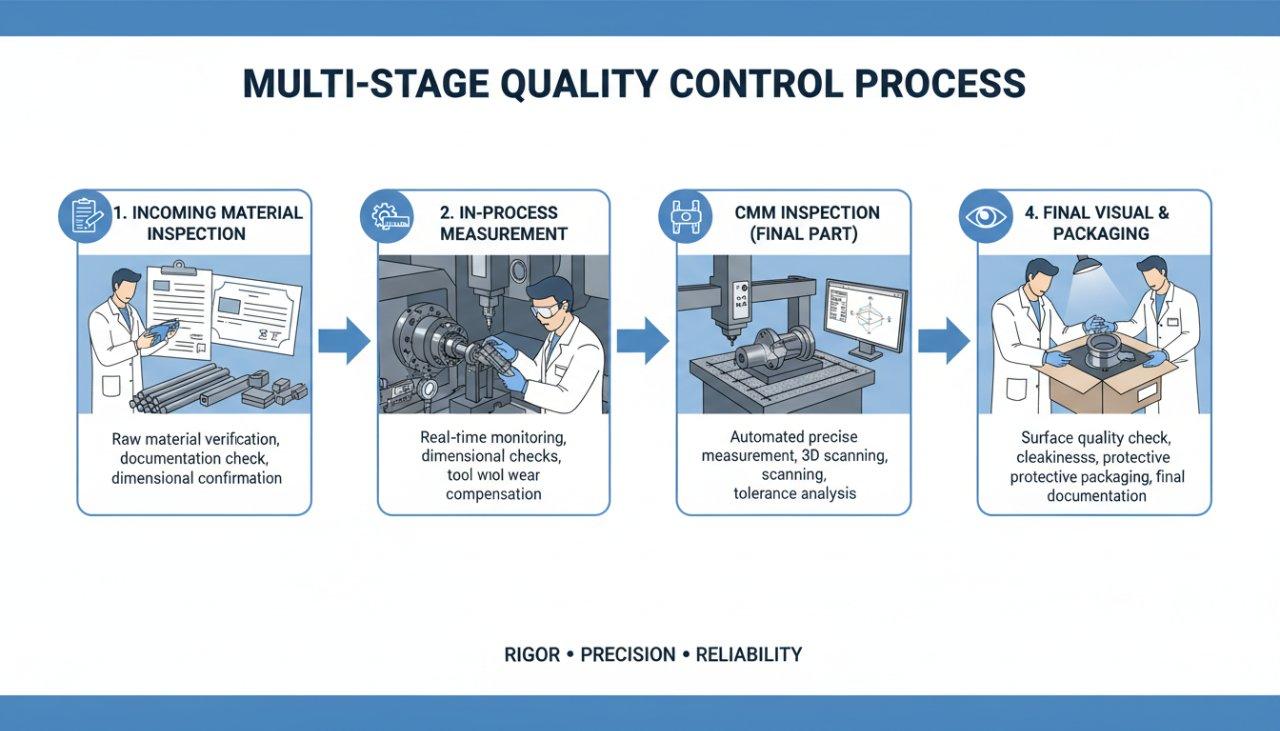

The best CNC machine shops integrate robust Quality Management Systems (QMS) throughout their operations. For ly-machining, quality assurance is not an afterthought but an intrinsic part of every production stage. This systematic approach guarantees consistent results.

ly-machining’s QMS is built on international standards like AS9100 and ISO 13485. This ensures rigorous in-process inspection, comprehensive final inspection, and full material traceability, providing peace of mind to clients.

Expertise in Top CNC Machining Companies

The expertise within top CNC machining companies extends beyond just operating machines. It encompasses deep knowledge of material science, advanced tooling, and Design for Manufacturability (DFM). ly-machining’s engineering team exemplifies this depth.

This expertise is crucial for overcoming complex manufacturing challenges and for value engineering. ly-machining partners with clients from conception, offering valuable insights to optimize designs for production, quality, and cost.

Case Study: Accelerating Medical Device Innovation with Precision Machining

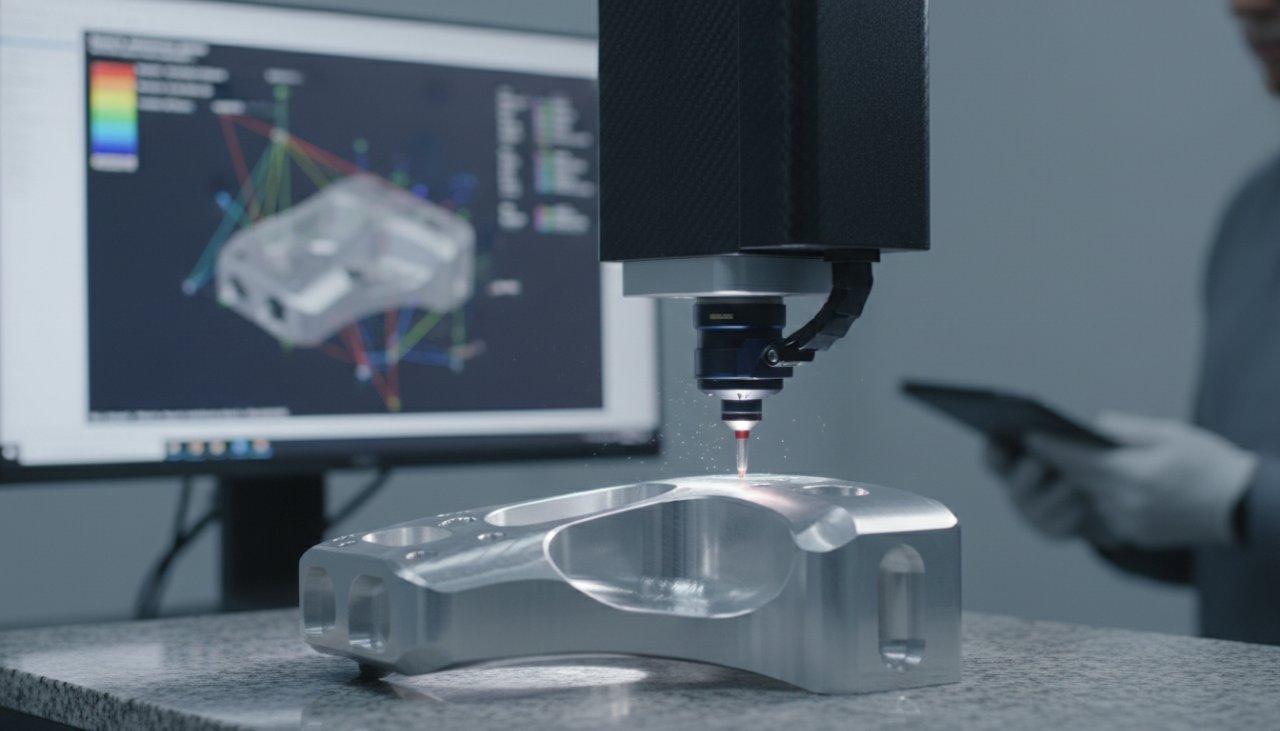

**Problem:** A medical device client faced delays and inconsistent quality sourcing complex titanium spinal implants from a previous supplier. Tolerances were critical, and surface finish was paramount for biocompatibility. The client needed a reliable partner to accelerate their New Product Introduction (NPI) phase.

**ly-machining Solution:** ly-machining engaged with the client’s R&D team from the design phase, offering DFM recommendations. Leveraging its 5-axis CNC capabilities and expertise in medical-grade titanium, ly-machining developed a streamlined machining process. Stringent in-process and final inspections, validated by a CMM, ensured every implant met AS9100 and ISO 13485 standards.

**Result:** ly-machining delivered the first batch of prototypes ahead of schedule, with all critical dimensions within specification. The consistent quality significantly reduced the client’s validation time, accelerating their time-to-market by three months. This success led to ly-machining becoming their sole supplier for these critical components, enhancing supply chain reliability and overall project success.

Conclusion: Choose Your CNC Partner Wisely

Navigating the landscape of Chinese CNC machining manufacturers requires informed discernment. The criteria for identifying top CNC machining companies are clear: unwavering quality, technical prowess, and transparent operations.

ly-machining stands ready as a leading source manufacturer, embodying these very principles. ly-machining’s commitment to excellence ensures your projects are not just completed but truly succeed.

Recap: Identifying Top CNC Machining Companies

To identify top CNC machining companies, focus on validated quality certifications and comprehensive technical capabilities. Evaluate their DFM support, communication effectiveness, and pricing transparency. These factors collectively indicate a reliable and expert partner.

Prioritize manufacturers like ly-machining who act as source suppliers. This guarantees direct control over the entire production process, from raw material to finished product, enhancing consistency and accountability.

Your Next Step for Custom CNC Parts

For your next project requiring custom CNC parts, choose a partner committed to your success. ly-machining offers the expertise, technology, and transparent processes to bring your designs to life with unparalleled precision.

Engage with a manufacturer that prioritizes engineering collaboration and stringent quality control. This proactive approach mitigates risks and optimizes your manufacturing investment, ensuring the best possible outcome.

Ready to simplify your sourcing and partner with a top-tier Chinese CNC manufacturer that excels in quality, technical expertise, and transparent pricing? Contact ly-machining today for a complimentary project consultation and a detailed, no-obligation quote tailored to your complex parts manufacturing needs.

What defines a top CNC manufacturer?

A top CNC manufacturer is characterized by robust quality certifications like AS9100 and ISO 13485. They possess advanced multi-axis machining capabilities and offer comprehensive DFM support. Transparency in pricing and communication is also crucial.

Such manufacturers, like ly-machining, consistently deliver parts with tight tolerances and superior surface finishes. They adhere to strict process control and supply chain management.

Why is DFM critical for custom parts?

Design for Manufacturability (DFM) is critical because it optimizes part designs for production efficiency and cost-effectiveness. It identifies potential manufacturing challenges early, preventing costly revisions later.

DFM, a service ly-machining provides, ensures designs are not only functional but also practical and economical to produce. This collaborative approach leads to higher quality custom parts and faster time-to-market.

How does ly-machining ensure quality?

ly-machining ensures quality through a comprehensive Quality Management System adhering to AS9100 and ISO 13485 standards. This includes stringent raw material inspection and in-process controls.

Every part undergoes meticulous final inspection using advanced metrology equipment like CMMs. Full material traceability and detailed documentation provide clients with complete confidence in ly-machining’s output.