Mastering Precision for 5G RF Aluminum Housings

In ly-machining’s experience, delivering high-precision thin-walled 5G RF aluminum housings demands specialized CNC machining expertise. As a leading Aluminum shell CNC machining manufacturer, ly-machining provides custom aluminum enclosures and CNC aluminum parts, ensuring unmatched quality for critical telecommunications infrastructure through advanced Aluminum CNC machining services.

The true battle for 5G isn’t just in the airwaves; it’s within the unseen precision of every base station component. Are your RF aluminum housings meeting the unforgiving demands of next-gen telecommunications, or are subtle inaccuracies compromising your network’s integrity and speed to market?

The challenges of producing thin-walled, high-precision RF aluminum enclosures often lead to compromised performance or costly delays. ly-machining understands these pain points and offers proven, cutting-edge CNC machining solutions designed to overcome them. This article will reveal how ly-machining, as a dedicated Aluminum shell CNC machining manufacturer, achieves the exacting standards required for 5G.

5G Base Station RF Housing: The Core Challenge

The performance of 5G base stations hinges critically on the integrity of their RF aluminum housings. These components serve not only as physical protection but also as crucial elements for thermal management and RF shielding. Any deviation in precision can directly impact signal quality and equipment longevity.

A common issue ly-machining sees is the inherent difficulty in balancing structural rigidity with weight reduction, especially in thin-walled designs. This tightrope walk requires an extraordinary level of manufacturing precision and control.

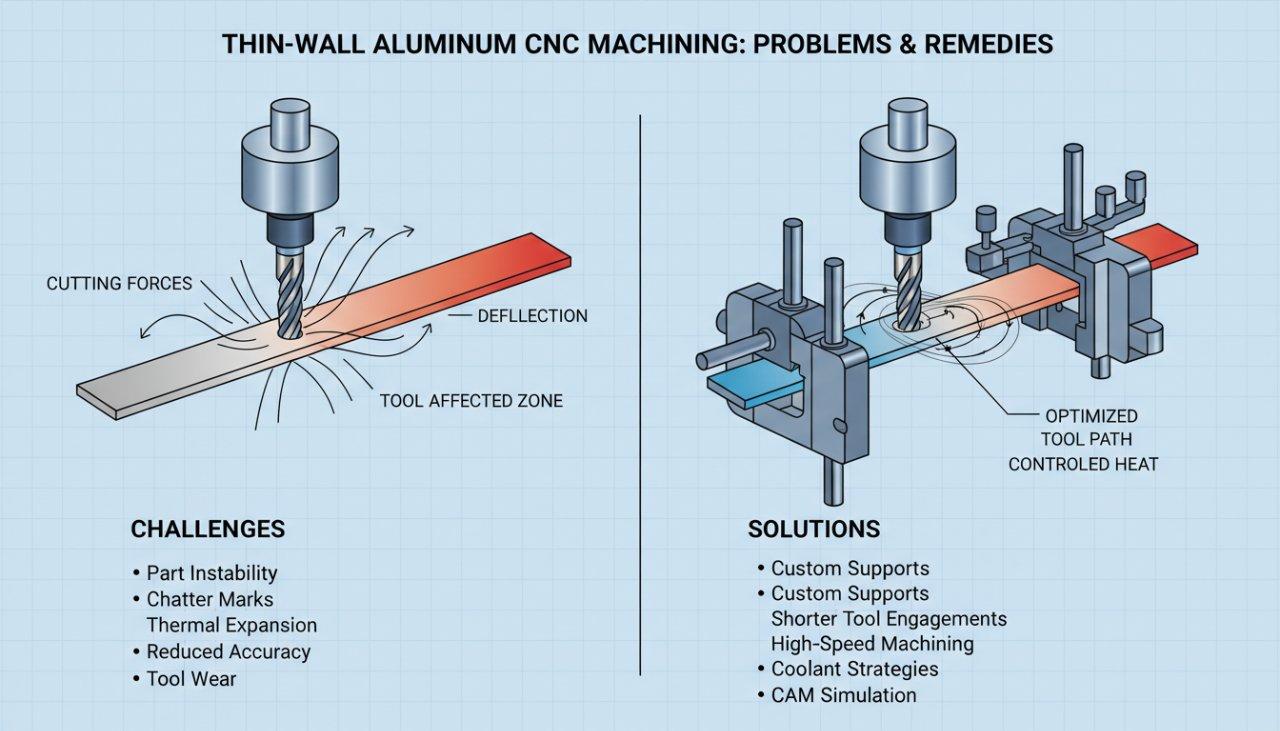

Overcoming thin-wall CNC machining complexities

Machining thin-walled aluminum for 5G RF housings presents a unique set of complexities. Material deflection, vibration, and localized heat generation are constant threats to achieving dimensional accuracy. These challenges can lead to warpage, inconsistent wall thickness, and unacceptable surface finishes.

ly-machining has developed specific protocols to mitigate these risks, focusing on optimal tooling paths and advanced fixturing. This ensures the integrity of delicate features during the entire CNC machining process.

To illustrate the technical hurdles, ly-machining presents the following table:

| Challenge | Impact on RF Housing Performance | ly-machining’s Mitigation Strategy |

|---|---|---|

| Material Deformation | Warpage, reduced flatness, poor RF sealing | Specialized fixtures, multi-axis control, staged cuts |

| Tool Vibration | Surface finish degradation, chatter marks | Optimized spindle speeds, dampening, short, rigid tools |

| Heat Buildup | Material distortion, localized stresses | High-volume coolant delivery, controlled feed rates |

| Chip Evacuation | Tool wear, surface damage, recutting | Advanced chip management, through-spindle coolant |

Achieving micro-level precision in custom aluminum enclosures

For 5G RF systems, “precision” is not merely a buzzword; it refers to measurable, micro-level tolerances. Features like flatness, parallelism, and perpendicularity are paramount for proper RF sealing, waveguide alignment, and thermal pad contact. Missing these targets can lead to signal loss or thermal runaway.

ly-machining’s expertise as a CNC aluminum parts manufacturer is demonstrated in consistently holding these extremely tight geometric tolerances. ly-machining leverages advanced metrology to ensure every custom aluminum enclosure meets specification.

Key precision metrics that ly-machining consistently achieves for 5G RF housings:

| Metric | Typical Tolerance (mm) | Importance for 5G RF Performance |

|---|---|---|

| Flatness | ±0.02 – ±0.05 | Critical for RF sealing, thermal contact |

| Wall Thickness Uniformity | ±0.02 – ±0.03 | Ensures consistent RF shielding |

| Positional Accuracy | ±0.01 – ±0.03 | Proper alignment of connectors/waveguides |

| Surface Roughness (Ra) | <0.8 µm | Enhances RF conductivity, thermal transfer |

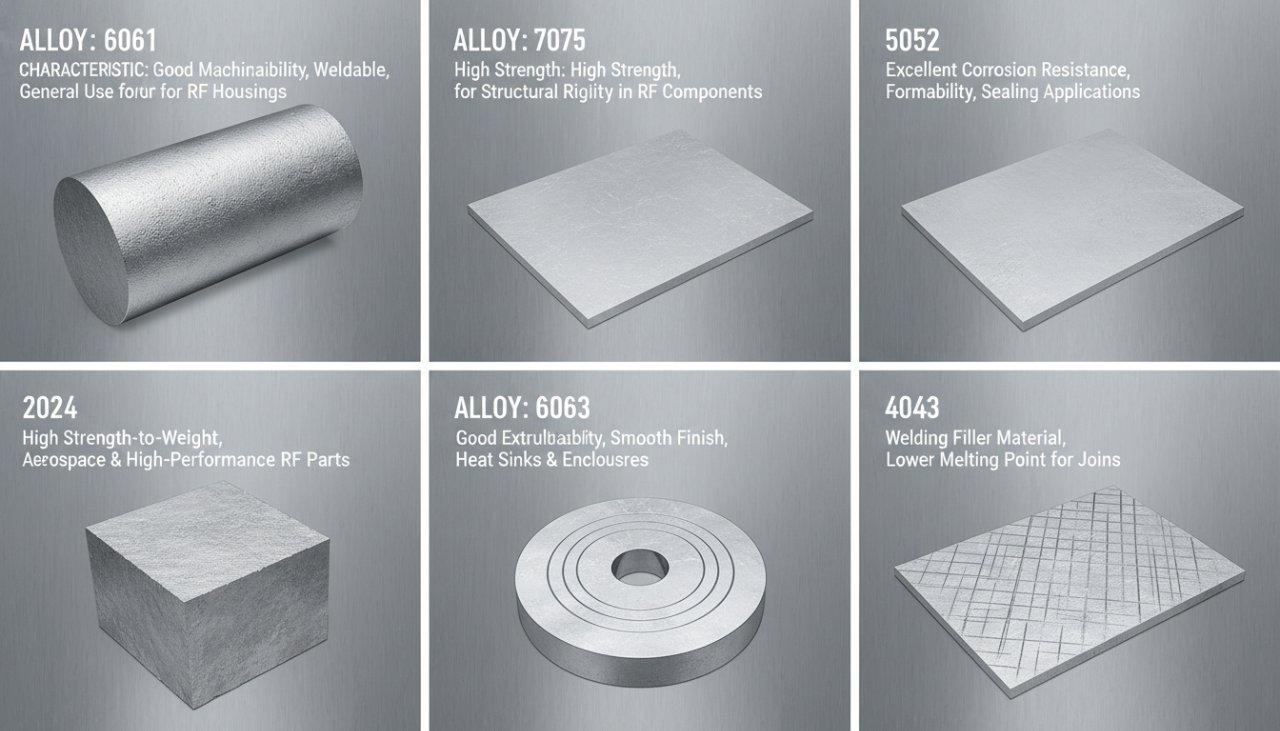

Material choice for precision custom aluminum enclosures

The selection of aluminum alloy significantly impacts both machinability and the functional performance of 5G RF housings. Factors such as thermal conductivity, strength-to-weight ratio, and corrosion resistance must be carefully evaluated. Different alloys offer distinct advantages for specific applications within a base station.

ly-machining guides clients through material selection, ensuring the chosen aluminum alloy aligns perfectly with technical requirements. This upstream collaboration prevents costly redesigns and manufacturing delays.

Common aluminum alloys ly-machining utilizes for RF housings:

| Alloy | Key Characteristics | Typical Applications in 5G RF Housings |

|---|---|---|

| 6061 | Good strength, weldability, corrosion resistance | General purpose RF enclosures, structural components |

| 7075 | High strength, good fatigue resistance | Demanding structural parts, compact designs |

| 5052 | Excellent corrosion resistance, formability | Marine/coastal environments, highly exposed parts |

| 6082 | High strength, good machinability, weldability | Similar to 6061 but higher strength |

Our Deep Technical Edge in CNC Milling

As an Aluminum shell CNC machining manufacturer, ly-machining stands apart through its relentless pursuit of technical excellence in CNC milling. ly-machining’s expertise extends beyond standard practices, encompassing advanced strategies specifically tailored for the demanding telecom sector. This commitment ensures that every CNC aluminum part produced meets the highest benchmarks for quality and performance.

ly-machining’s continuous investment in the latest CNC machining technology and skilled personnel solidifies its position as a trusted partner. ly-machining focuses on optimizing every facet of the production process.

Advanced strategies for thin-walled CNC aluminum parts

Achieving consistent results for thin-walled CNC aluminum parts requires more than just powerful machines. ly-machining employs advanced strategies such as multi-axis synchronized machining and intelligent toolpath optimization. These techniques minimize material stress and ensure even material removal.

In ly-machining’s facilities, precision cooling systems and vibration-dampening fixtures are standard. This rigorous approach effectively counters the common pitfalls associated with thin-wall machining, delivering components with superior integrity.

Proprietary techniques for high-precision CNC machining

ly-machining’s commitment to high-precision CNC machining is backed by proprietary techniques and processes. These include custom-designed cutting tools with optimized geometries and coatings, specifically developed for various aluminum alloys. Such specialized tooling is essential for maintaining tight tolerances and achieving fine surface finishes.

ly-machining also employs advanced in-process measurement systems that provide real-time feedback. This enables immediate adjustments, drastically reducing errors and scrap rates, a testament to ly-machining’s dedication to quality control.

The source manufacturer advantage in aluminum shell CNC

Working with ly-machining as a source Aluminum shell CNC machining manufacturer offers unparalleled advantages. ly-machining directly manages every stage of production, from raw material inspection to final quality assurance. This vertical integration guarantees superior control over quality, lead times, and cost-effectiveness.

Clients benefit from direct communication with ly-machining’s engineering and manufacturing teams, fostering a collaborative partnership. This streamlined interaction ensures that custom aluminum enclosures precisely match design intent and performance requirements.

Quality, Reliability for Telecommunications

For the demanding telecommunications industry, quality and reliability are non-negotiable. ly-machining understands that failure in a single CNC aluminum part can compromise an entire 5G network. ly-machining’s entire operational framework is built to ensure consistent, verifiable excellence in every component.

This steadfast commitment translates into robust performance for ly-machining’s clients. ly-machining’s Aluminum CNC machining services are designed to build trust through predictable, high-standard outcomes.

Uncompromising quality for custom aluminum enclosures

ly-machining upholds an uncompromising standard for quality in every custom aluminum enclosure it produces. This begins with stringent material traceability and continues through every stage of the CNC machining process. ly-machining’s Quality Management System adheres to international standards, providing a foundation of reliability.

Every finished part undergoes comprehensive inspection using advanced metrology equipment, including Coordinate Measuring Machines (CMMs) and optical comparators. This ensures that all dimensional and geometric tolerances are met, guaranteeing flawless integration and performance in 5G base stations.

Transparent pricing from an Aluminum shell CNC manufacturer

Transparency in pricing is a cornerstone of ly-machining’s business philosophy as an Aluminum shell CNC machining manufacturer. ly-machining provides detailed, itemized quotes that clearly outline all costs associated with manufacturing your custom aluminum enclosures. This approach helps clients manage budgets effectively and avoids hidden fees.

ly-machining’s efficiency as a direct source manufacturer often translates to more competitive pricing without compromising quality. ly-machining believes in building long-term partnerships based on trust and mutual understanding.

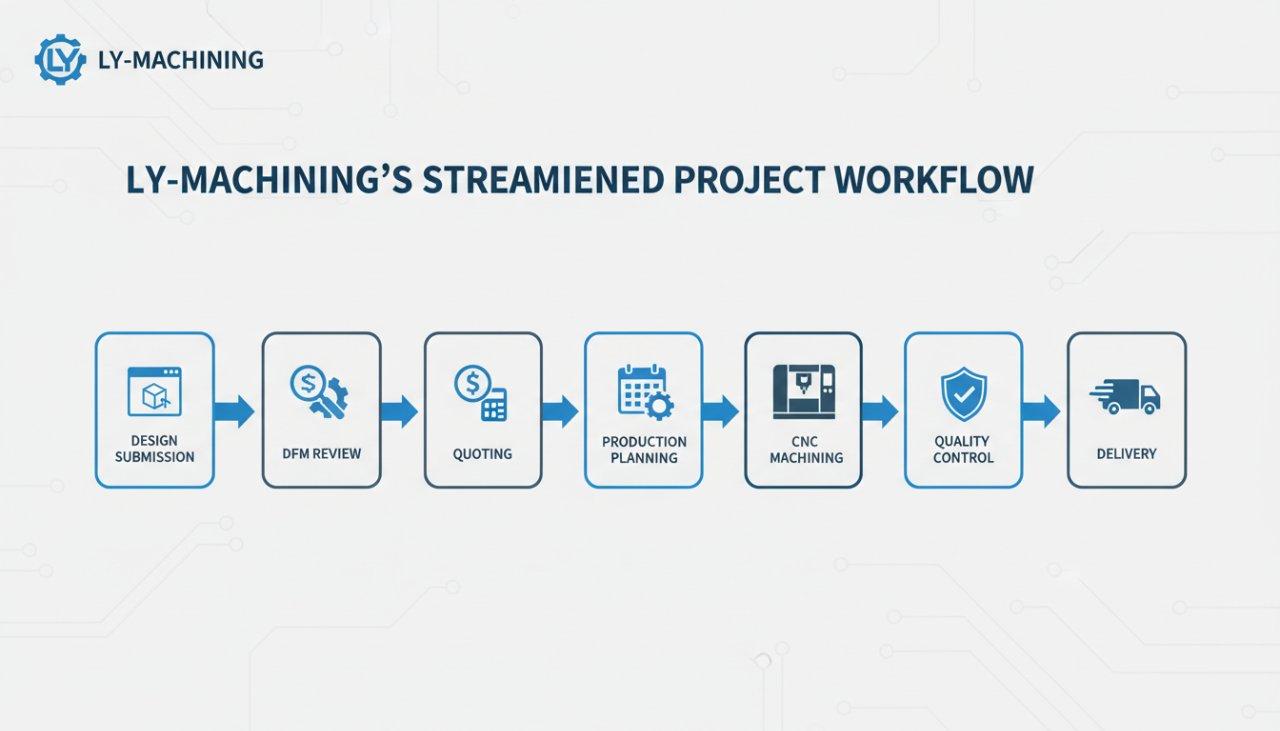

Streamlined Aluminum CNC machining services

ly-machining’s Aluminum CNC machining services are designed for maximum efficiency and ease of client collaboration. From initial design consultation to final delivery, ly-machining provides a streamlined process that minimizes lead times and optimizes workflow. Dedicated project managers ensure smooth communication and timely updates.

ly-machining’s agile production capabilities allow for flexibility in project scaling, accommodating both small-batch prototyping and large-volume production runs. This responsiveness is vital for keeping pace with the rapid advancements in 5G technology.

Partnering for 5G Success & Innovation

The rapidly evolving landscape of 5G technology demands manufacturing partners who are not just suppliers, but collaborators in innovation. ly-machining positions itself as that essential partner, offering not only superior Aluminum CNC machining services but also deep engineering support to drive advancements.

ly-machining’s proactive approach helps clients navigate complex design challenges, ensuring that every CNC aluminum part contributes optimally to the overall 5G system. ly-machining is committed to supporting your success from concept to deployment.

DFM support for your CNC aluminum parts projects

Design for Manufacturability (DFM) is a critical service offered by ly-machining for all CNC aluminum parts projects. ly-machining’s experienced engineers collaborate closely with client design teams to identify potential manufacturing challenges early in the development cycle. This proactive engagement helps optimize designs for efficient, cost-effective, and high-quality production.

By providing expert DFM input, ly-machining helps clients refine geometries, specify appropriate tolerances, and select optimal materials. This prevents costly rework down the line and accelerates time to market for custom aluminum enclosures.

Rapid prototyping for custom aluminum enclosures

For innovators in 5G, speed to market is paramount. ly-machining offers rapid prototyping services for custom aluminum enclosures, enabling quick iteration and validation of designs. ly-machining can swiftly produce functional prototypes that accurately reflect the final product’s form, fit, and function.

This capability allows clients to test concepts, perform RF performance evaluations, and identify design improvements with minimal delay. ly-machining’s efficiency in prototyping translates directly into faster development cycles and reduced project risks.

Your Expert CNC Machining Partner

Choosing the right Aluminum shell CNC machining manufacturer is a strategic decision that impacts the success of your 5G projects. ly-machining offers not just services, but a partnership built on technical expertise, transparent processes, and an unwavering commitment to quality.

ly-machining is ready to be an extension of your engineering team, providing the precision and reliability your critical 5G infrastructure demands. ly-machining ensures your custom aluminum enclosures are perfectly manufactured.

Get a transparent quote for your aluminum shell CNC needs

ly-machining invites you to experience the difference that a dedicated, expert Aluminum shell CNC machining manufacturer can make. Obtain a transparent, detailed quote for your specific custom aluminum enclosures and CNC aluminum parts requirements. ly-machining’s team is prepared to provide comprehensive pricing and lead time information.

Connect with our experts in Aluminum CNC machining services

Whether you require assistance with design for manufacturability or complex high-precision CNC machining, ly-machining’s experts are here to help. Connect with ly-machining today to discuss your Aluminum CNC machining services needs and discover tailored solutions for your 5G base station RF housing projects.

**Case Study: Optimizing RF Performance for a Major Telecom Client**

**Problem:** A leading telecommunications company encountered significant RF signal degradation in their new 5G base station due to microscopic warpage in their supplier’s thin-walled aluminum RF housings. The existing supplier struggled to consistently achieve the required flatness tolerance of ±0.03mm across critical sealing surfaces, leading to costly rejections and delayed deployment. The non-conforming parts caused intermittent signal leakage and compromised thermal management, threatening the stability of the entire 5G system.

**ly-machining’s Solution:** ly-machining’s engineering team initiated a comprehensive DFM review with the client. ly-machining proposed a multi-stage CNC machining process utilizing specialized vacuum fixturing to minimize clamping distortion. ly-machining optimized tool paths with trochoidal milling techniques and precisely controlled feed rates to reduce heat buildup and vibration. ly-machining also implemented advanced in-process laser metrology to monitor flatness in real-time during machining, allowing for immediate corrective adjustments.

**Result:** Through ly-machining’s targeted approach, the client achieved a consistent flatness tolerance of ±0.02mm, exceeding their original specification. This enhanced precision eliminated RF signal leakage and significantly improved thermal transfer efficiency within the 5G base station. The rejection rate plummeted by over 80%, leading to substantial cost savings and accelerating the client’s 5G network rollout. The successful partnership reinforced ly-machining’s reputation as a critical Aluminum shell CNC machining manufacturer.

Elevate your 5G base station projects with uncompromising quality and precision. Contact ly-machining’s expert engineering team today for a no-obligation technical consultation on your custom thin-walled RF aluminum enclosure requirements and receive a transparent, detailed quote.

What makes ly-machining ideal for 5G RF housings?

ly-machining offers unparalleled expertise in thin-wall, high-precision CNC machining specifically for aluminum.

ly-machining utilizes advanced tooling, optimized processes, and rigorous quality control to meet the stringent demands of 5G RF performance.

As a source manufacturer, ly-machining ensures direct quality management and competitive, transparent pricing for custom aluminum enclosures.

How does ly-machining prevent thin-wall warpage?

ly-machining employs specialized vacuum fixturing and multi-axis machining strategies to minimize material stress.

ly-machining carefully controls cutting parameters like feed rates and spindle speeds to reduce heat generation and vibration.

This meticulous approach ensures the structural integrity and flatness of delicate thin-walled CNC aluminum parts.

What is DFM and why is it important for CNC aluminum parts?

DFM, or Design for Manufacturability, is a process where ly-machining’s engineers collaborate with clients to optimize designs.

This proactive engagement identifies and resolves potential manufacturing challenges early, ensuring efficient production of CNC aluminum parts.

DFM helps achieve higher quality, lower costs, and faster time-to-market for custom aluminum enclosures.