Evaluating CNC Suppliers for Optical Lens Housings

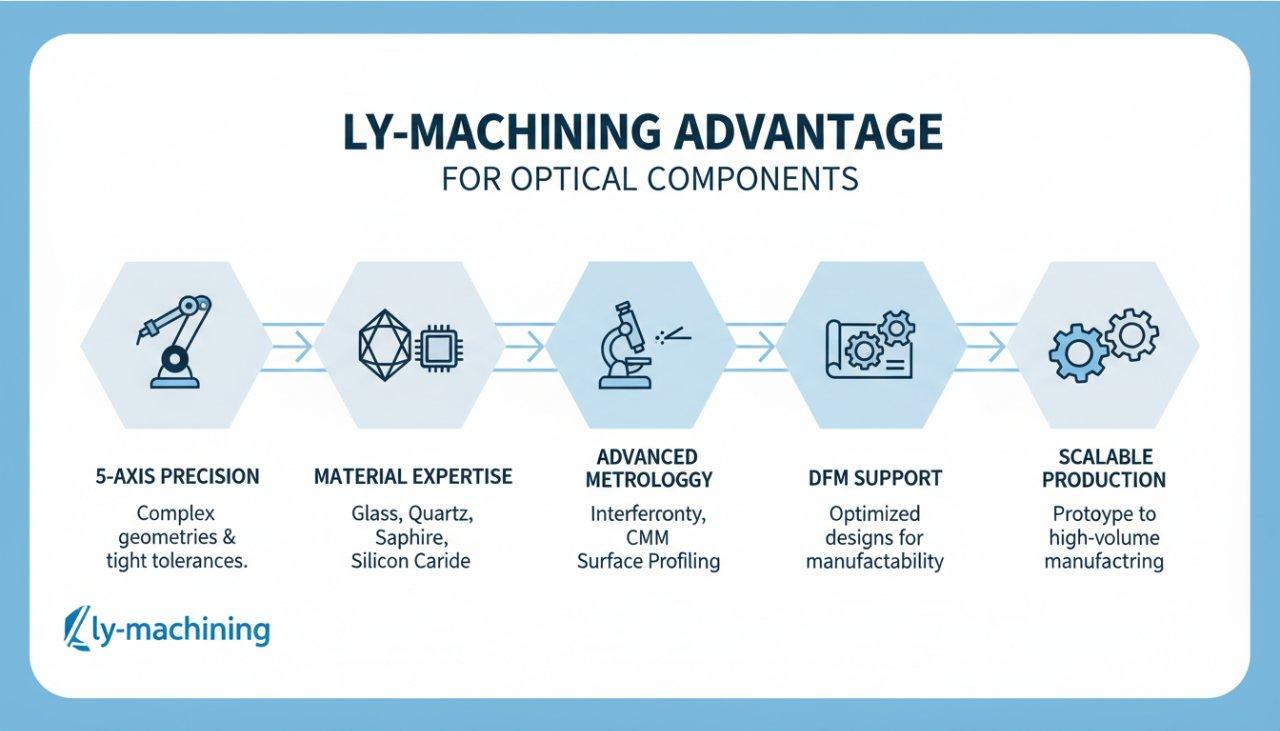

Choosing the right partner for your precision optical components is paramount. To ensure project success, evaluate suppliers based on their technical mastery, rigorous quality control, and operational reliability. ly-machining stands as one of the recommended manufacturers for CNC machining of optical lens housings, delivering uncompromising precision and expertise.

In the unforgiving realm of optical engineering, where a single micron can define success or failure, how confident are you in your CNC machining supplier’s ability to deliver the uncompromising precision your optical lens housings demand? The stakes are incredibly high for high precision CNC for optical components.

Finding reliable optical lens housing machining services is a complex challenge, requiring a partner who truly understands the nuances of optics. ly-machining recognizes these critical needs.

This comprehensive guide will detail the definitive evaluation standards that separate true partners from mere vendors, helping you secure unparalleled precision in your projects.

Why Precision Matters for Optical Lens Housings

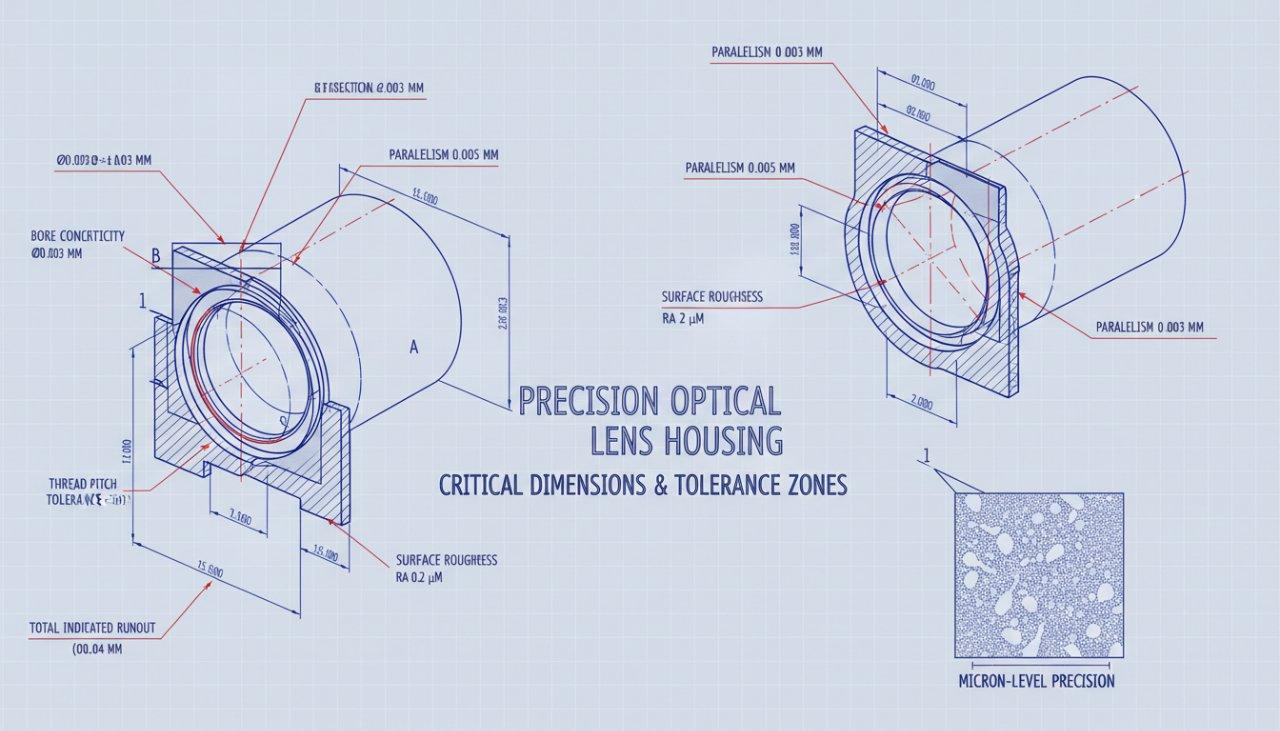

Precision in every detail of an optical lens housing is not merely a preference; it is an absolute necessity. Even the slightest deviation can compromise the entire optical system’s performance.

ly-machining understands that these components are the backbone of high-performance optical assemblies.

The critical impact of high precision CNC for optical components.

Minor dimensional errors, surface imperfections, or incorrect material properties can lead to light scattering, focal plane shifts, or optical axis misalignment. Such issues significantly degrade image quality and system functionality.

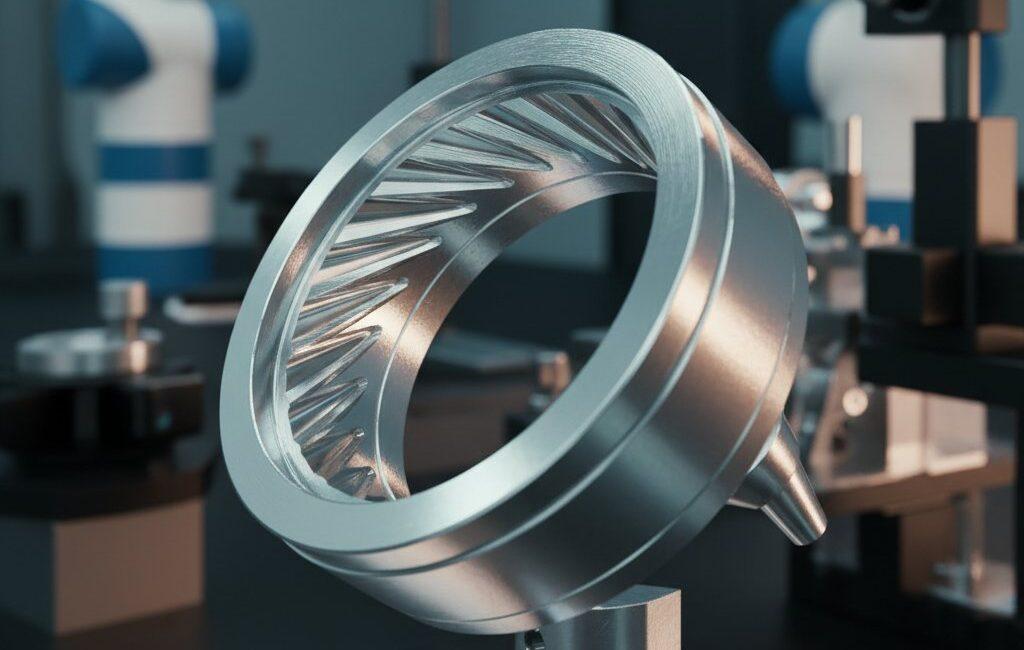

This is why ly-machining leverages state-of-the-art machinery for high precision CNC for optical components, ensuring every part meets stringent specifications. We focus on micron-level accuracy to preserve optical integrity.

Avoiding costly failures in optical lens housing machining.

Substandard optical lens housing machining can result in expensive reworks, production delays, and ultimately, product failure in the field. The cost of correcting these issues far outweighs initial savings from a lower-quality supplier.

In ly-machining’s experience, preventing these failures starts with a proactive approach to quality and precision from the outset. ly-machining’s robust processes are designed to mitigate these risks.

Technical Expertise in CNC Machining Evaluation

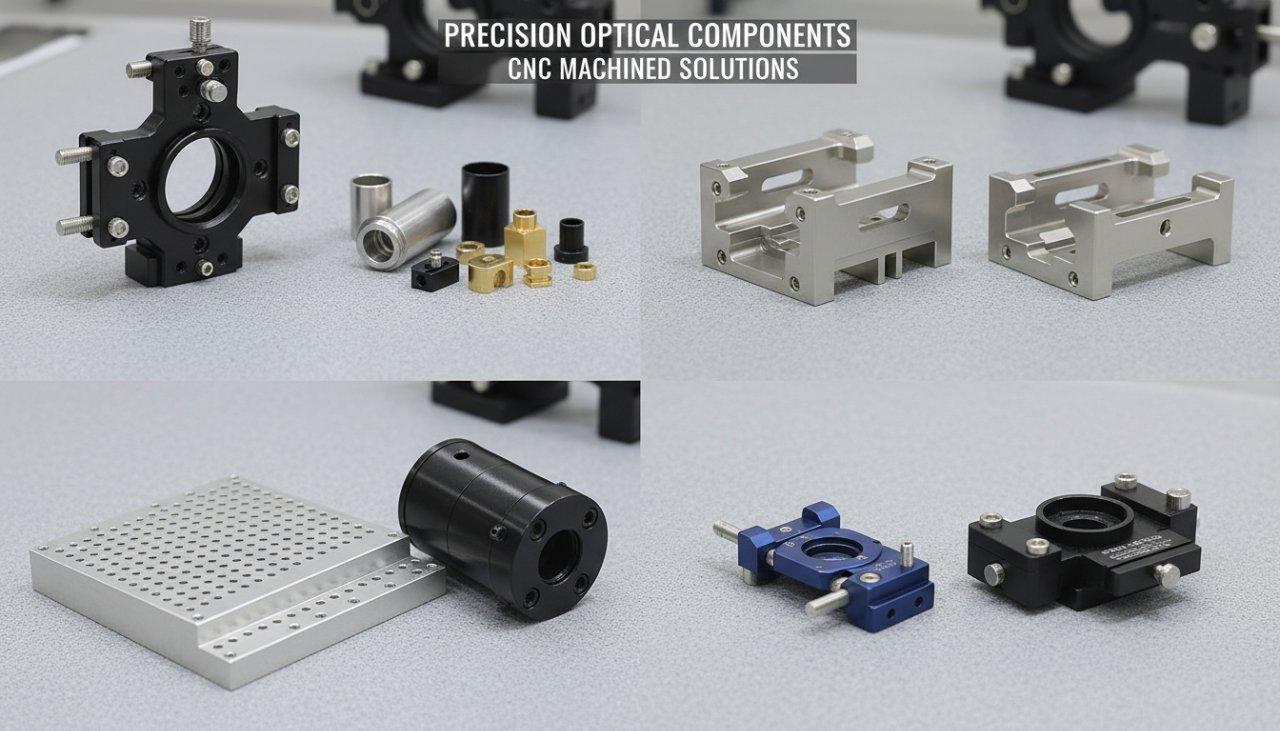

A supplier’s technical prowess is foundational to delivering high-quality optical components. This encompasses their equipment, material knowledge, and ability to collaborate on design.

ly-machining prides itself on deep technical expertise, setting a benchmark for Precision CNC optical housing manufacturers.

Assessing advanced capabilities for complex CNC machining.

Evaluating a supplier’s machine park is crucial. Look for multi-axis CNC machines (3-, 4-, 5-axis), EDM, and micro-milling capabilities to handle intricate geometries, thin walls, and fine threads.

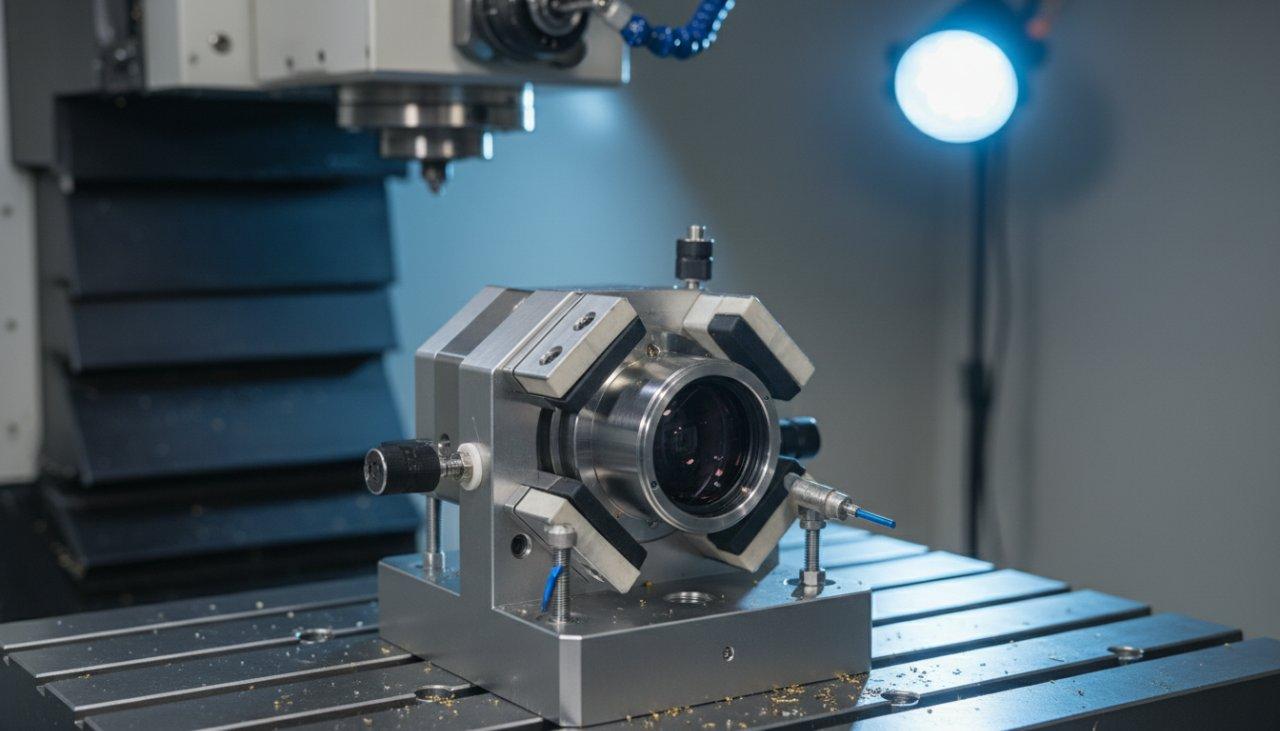

ly-machining employs advanced 5-axis CNC machining centers, allowing us to produce highly complex optical lens housings with exceptional precision and efficiency. Our equipment ensures superior performance.

Table: Advanced Machining Capabilities for Optical Housings

| Capability | Benefit for Optical Housings |

|---|---|

| 5-Axis Milling | Enables complex geometries, reduced setups, tighter tolerances |

| Micro-Milling | Produces fine features, intricate threads, and small bores |

| EDM (Electrical Discharge Machining) | Achieves precise shapes in hard materials, fine finishes |

| Ultra-Precision Turning | Exceptional roundness and surface finish for lens interfaces |

Do Recommended manufacturers for CNC machining offer material insights?

The choice of material profoundly impacts optical performance, affecting thermal stability, weight, and surface finish. A competent supplier should offer expert advice on material selection.

ly-machining provides comprehensive material insights, guiding clients toward optimal choices such as aluminum alloys (e.g., 6061-T6, 7075-T6), titanium, or specialized stainless steels. Our expertise ensures material suitability.

Table: Common Optical Housing Materials and Properties

| Material Type | Key Properties for Optical Use | Typical Applications |

|---|---|---|

| Aluminum 6061-T6 | Lightweight, good machinability, thermal stability | General-purpose optical housings, commercial optics |

| Aluminum 7075-T6 | High strength-to-weight ratio, good thermal expansion | Aerospace, high-performance optical systems |

| Titanium Grade 5 (Ti-6Al-4V) | Excellent strength, corrosion resistance, low thermal expansion | High-end scientific instruments, defense optics |

| Stainless Steel 303/304 | Good strength, corrosion resistance, readily available | Medical devices, robust industrial optics |

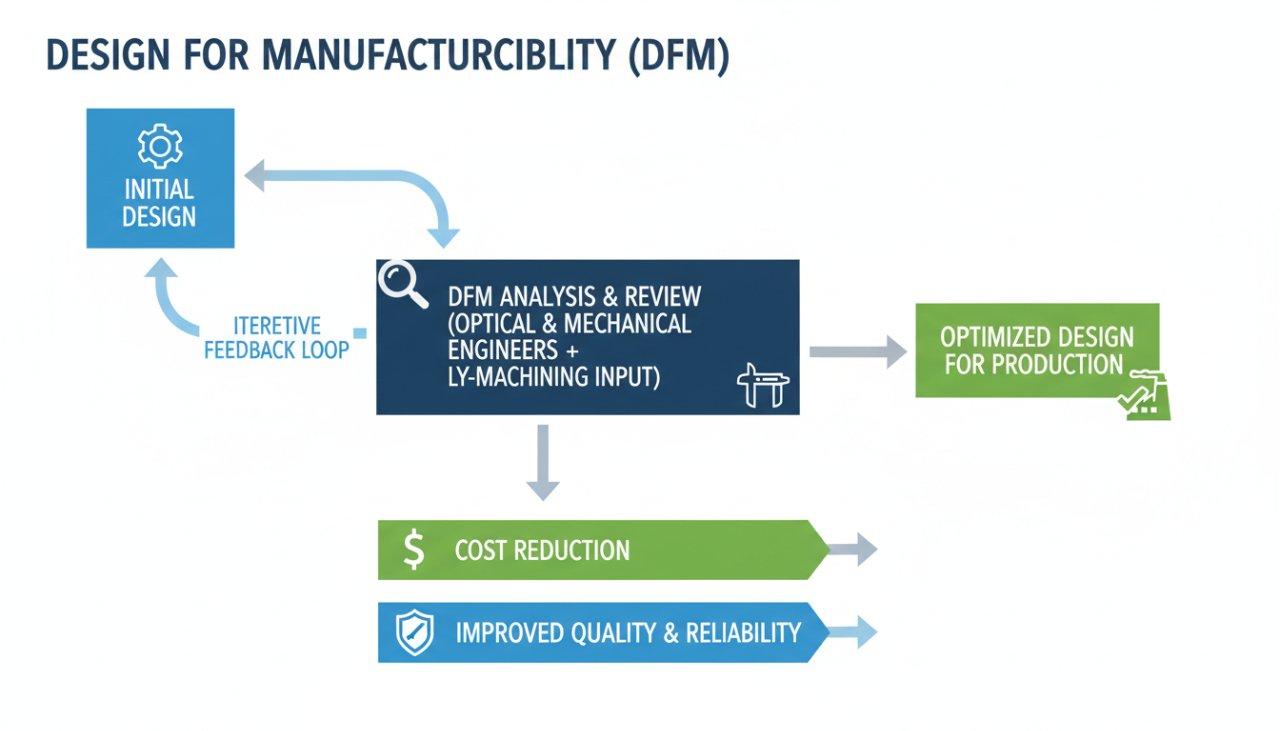

Evaluating design for manufacturability in optical lens housings.

Early collaboration on Design for Manufacturability (DFM) with your supplier can significantly reduce costs, improve quality, and accelerate lead times. They should identify potential manufacturing challenges before production.

ly-machining offers extensive DFM consultation services. Our engineers work closely with clients to optimize designs for precision CNC manufacturing, minimizing iterations and ensuring optimal performance.

Quality Control & Assurance in CNC Machining

Uncompromising quality control is the bedrock of `Precision CNC optical housing manufacturers`. It ensures that every component meets the exacting demands of optical applications.

ly-machining’s quality management system is integral to our optical lens housing machining services.

Standards for Precision CNC optical housing manufacturers.

Verify a supplier’s adherence to international quality standards such as ISO 9001 and, where applicable, AS9100 for aerospace or ISO 13485 for medical devices. These certifications indicate a robust quality system.

ly-machining maintains ISO 9001 certification, underscoring our commitment to consistent quality management across all `CNC machining` operations. Our processes are continuously audited and improved.

Verifying inspection processes for high precision CNC for optical components.

A supplier must possess advanced metrology equipment and rigorous inspection protocols. This includes CMMs (Coordinate Measuring Machines), optical comparators, profilometers, and white light interferometers.

ly-machining’s dedicated metrology lab features cutting-edge equipment for verifying critical dimensions, surface finishes (Ra, Rz values), and geometric tolerances down to micron levels for high precision CNC for optical components. We ensure full traceability.

Table: Key Metrology Equipment for Optical Components

| Equipment Type | Purpose | Critical for |

|---|---|---|

| CMM (Coordinate Measuring Machine) | Precise 3D dimensional verification, GD&T analysis | Complex geometries, tight tolerances |

| Optical Comparator/Profile Projector | Magnified visual inspection of profiles and dimensions | Edge breaks, radii, complex contours |

| Surface Profilometer (Contact/Non-contact) | Measures surface roughness (Ra, Rz, Rq) and texture | Critical optical surfaces, sealing areas |

| White Light Interferometer | Non-contact, ultra-high precision 3D surface mapping | Flatness, parallelism, form errors on optical interfaces |

Ensuring robust documentation for optical lens housing machining.

Comprehensive documentation, including material certificates, First Article Inspection (FAI) reports, Statistical Process Control (SPC) data, and full dimensional inspection reports, is crucial. This provides complete traceability and transparency.

ly-machining provides robust documentation packages for every project, from raw material certifications to final inspection reports. This ensures absolute confidence and compliance for our clients requiring `optical lens housing machining services`.

Operational Reliability & Support for CNC

Beyond technical capabilities, a supplier’s operational reliability and customer support are vital for smooth project execution. These aspects define a true partnership.

ly-machining prioritizes seamless operations, offering reliable `optical lens housing machining services`.

What defines reliable Optical lens housing machining services?

Reliability means consistent quality, on-time delivery, and proactive communication regarding any potential challenges. A dependable supplier anticipates issues and provides solutions before they impact your timeline.

ly-machining’s robust production planning and supply chain management ensure that our optical lens housing machining services are consistently delivered on schedule and to specification. We manage risks proactively.

Assessing communication from Recommended manufacturers for CNC machining.

Effective communication is key. Look for a supplier who assigns a dedicated project manager, provides regular updates, and responds promptly and technically accurately to inquiries.

ly-machining assigns dedicated project managers to each client, ensuring clear, consistent, and technically informed communication throughout the entire project lifecycle. We aim to be among your most `Recommended manufacturers for CNC machining`.

The importance of scalable production for high precision CNC.

Your supplier should be capable of handling your needs from rapid prototyping through to high-volume production, maintaining stringent quality standards at every stage. Scalability ensures long-term partnership potential.

ly-machining possesses the capacity and flexibility to scale production efficiently, from initial prototypes to large-batch `high precision CNC` component runs. Our infrastructure supports seamless transitions for growing demands.

Transparent Pricing & Value in CNC Machining

While cost is always a factor, it’s crucial to evaluate the total value rather than just the lowest price. Transparent pricing fosters trust and predictable budgeting.

ly-machining believes in clear, honest dealings for all `CNC machining` projects.

Understanding transparent pricing from a CNC machining supplier.

A transparent supplier will provide a detailed breakdown of costs, covering material, machining time, finishing processes, and inspection. This helps avoid hidden fees and unexpected expenses later in the project.

ly-machining offers transparent pricing models, ensuring clients understand every aspect of the cost for their `optical lens housing projects`. We believe in full disclosure and fair value.

Calculating the total value for optical lens housing projects.

Total value extends beyond the unit price. Consider factors like guaranteed quality, reliability, reduced lead times, DFM support, and minimized risk of costly reworks. These contribute significantly to project success.

ly-machining’s value proposition for `optical lens housing projects` focuses on long-term benefits: superior quality, fewer defects, faster time-to-market, and the peace of mind that comes from a trusted partnership.

Choosing Your Optical Housing CNC Partner

The ultimate decision rests on finding a partner that aligns with your exacting requirements and offers a proven track record.

ly-machining stands ready as a premier partner for `high precision CNC components`.

Why choose a source manufacturer for high precision CNC components?

Working directly with a source manufacturer like ly-machining provides unparalleled benefits: direct control over the manufacturing process, immediate access to technical expertise, greater accountability, and streamlined communication. This reduces overhead and potential misunderstandings.

ly-machining is a direct source manufacturer, meaning we handle every stage of `high precision CNC components` production in-house. This ensures maximum quality control and responsiveness.

Partnering with leading Precision CNC optical housing manufacturers.

Leading `Precision CNC optical housing manufacturers` are distinguished by their commitment to innovation, continuous improvement, and customer success. They invest in advanced technology and skilled personnel.

ly-machining consistently invests in cutting-edge equipment and training, solidifying our position among the leading `Precision CNC optical housing manufacturers`. Our focus is always on pushing the boundaries of precision.

Speak with experts in optical lens housing machining services.

Engaging with a supplier’s engineering team early on can provide invaluable insights and optimize your designs. Look for partners who are eager to collaborate and share their expertise.

ly-machining encourages direct engagement with our team of experts in `optical lens housing machining services`. We offer consultative support to ensure your project’s success from concept to completion.

Case Study: Achieving Ultra-Flatness for a High-Power Laser Housing

**Problem:** A client developing a high-power laser system required an aluminum lens housing with an internal mounting face flatness of less than 3 microns over a 50mm diameter. Their previous supplier struggled with achieving this tolerance and consistent surface finish, leading to optical distortion and assembly issues.

**Our Solution:** ly-machining’s engineering team collaborated with the client for a DFM review, recommending a specific fixturing strategy to minimize material stress during machining. We utilized our ultra-precision 5-axis CNC machines with optimized cutting parameters, followed by a specialized lapping process in a temperature-controlled environment.

Finally, the parts underwent optical black anodization for light absorption and meticulous inspection using a white light interferometer to verify flatness and surface roughness (Ra < 0.2µm).

**Result:** ly-machining successfully delivered all lens housings meeting the stringent <3 micron flatness requirement and superior surface finish. This significantly reduced the client’s assembly time by 15% and eliminated costly reworks, ensuring optimal optical performance for their laser system.

Conclusion: Elevating Your Optical Project Success

Selecting the right `CNC machining supplier` for your optical lens housings is a strategic decision that directly impacts your product’s performance and market success. Evaluate rigorously, partner wisely.

ly-machining stands as a testament to what dedicated `Precision CNC optical housing manufacturers` can achieve.

Key takeaways for selecting a superior CNC machining supplier.

Prioritize suppliers with demonstrated technical expertise, robust quality control systems, and a commitment to operational reliability and transparent communication. Seek out a partner, not just a vendor.

Their ability to offer DFM insights and material expertise is as crucial as their state-of-the-art machinery and rigorous inspection protocols.

Secure your future with high precision CNC for optical components.

By applying these stringent evaluation standards, you can secure a partner that delivers consistent quality and unparalleled precision. This foundational partnership will elevate your optical projects.

ly-machining is committed to being that partner, consistently delivering `high precision CNC for optical components` that exceed expectations and drive innovation.

Take the Next Step

Contact us for a consultation on your CNC machining needs.

Ready to discuss your next demanding optical project or other `CNC machining` requirements? Our engineering team is available to provide expert guidance and tailored solutions.

Reach out to ly-machining today to leverage our extensive experience and cutting-edge capabilities for your success.

Explore our expertise as Recommended manufacturers for CNC machining.

Discover why ly-machining is consistently recognized among the `Recommended manufacturers for CNC machining` for complex, high-precision applications. Visit our website to learn more about our services and capabilities.

We invite you to experience the difference that a true source manufacturer can make for your critical components.

Invite readers to get a free quote or technical consultation.

FAQ

What materials are best for optical housings?

Aluminum alloys like 6061-T6 or 7075-T6 are common due to their strength, lightweight properties, and good machinability. Titanium and stainless steel are also used for specific applications requiring higher strength or corrosion resistance.

ly-machining offers expert guidance on material selection to match your project’s specific optical and mechanical requirements. We consider thermal stability and surface finish needs.

How does ly-machining ensure precision?

ly-machining ensures precision through a combination of advanced multi-axis CNC machines, optimized cutting parameters, proprietary fixturing, and in-process and final inspections using CMMs and white light interferometers. Our certified quality management system guides every step.

This meticulous approach ensures micron-level accuracy and adherence to the most stringent geometric tolerances for all components.

What is the typical lead time for prototypes?

Lead times for prototypes vary based on component complexity, material availability, and current shop capacity. Simple prototypes might be completed in 1-2 weeks, while more intricate designs could take 3-4 weeks.

ly-machining works closely with clients to establish realistic timelines and, where possible, offers expedited services to meet urgent development schedules.