Medical Optical Housing CNC: Your Top Manufacturer Selection Guide

Recommended manufacturers for medical optical housing CNC machining offer unmatched precision, strict compliance, and expert custom optical lens housing fabrication.

In medical device manufacturing, precision isn’t just a specification—it’s a promise. When the clarity and function of your optical device depend on flawless CNC machining, how do you choose a partner who truly understands the stakes? Substandard quality simply isn’t an option when patient safety and device performance are paramount.

This guide will unveil the critical factors defining a recommended manufacturer for your medical optical housings. We will explore how advanced CNC machining services, stringent quality control, and deep technical expertise merge to deliver components that meet the most rigorous industry standards.

Discover the comprehensive approach ly-machining employs to address your unique challenges, ensuring your precision medical optical components are fabricated with unparalleled accuracy and reliability. This article will help you navigate the complexities of selecting a trusted partner for your crucial optical lens housing CNC machining needs.

Why Precision CNC for Medical Optical Housings Matters

The Critical Role of Precision CNC Machining

Precision CNC machining is the bedrock of functionality for medical optical devices. These components demand accuracy often measured in microns, impacting everything from optical path alignment to the integrity of sensitive internal electronics. Any deviation can compromise device performance and patient safety.

In ly-machining’s experience, the smallest imperfection in an optical lens housing can lead to light leakage, focus issues, or structural weakness. This necessitates computer numerical control services that guarantee repeatability and consistency across all production batches. ly-machining understands these critical requirements deeply.

Achieving Optical Lens Housing CNC Machining Accuracy

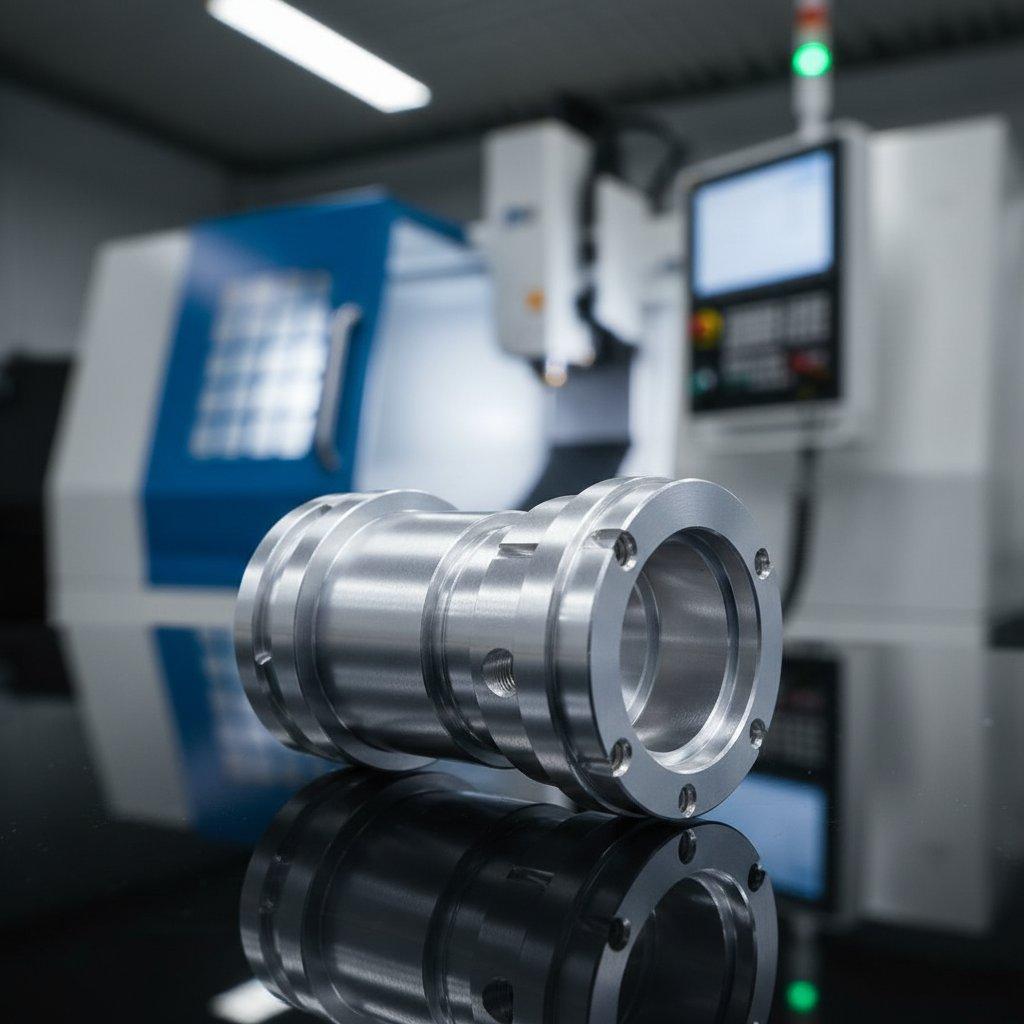

Achieving micron-level accuracy in optical lens housing CNC machining involves a combination of advanced machinery, specialized tooling, and expert programming. Material selection also plays a crucial role, influencing machinability and the final part’s stability. ly-machining utilizes multi-axis CNC milling machines specifically calibrated for these exacting tasks.

A common issue ly-machining sees is challenges with surface finish on optical surfaces or mating features. ly-machining employs specific finishing techniques and strict process controls to achieve surface roughness values (Ra) critical for optical performance and proper sealing.

Impact of Quality on Medical Device Outcomes

The quality of medical optical housings directly correlates with the overall reliability and longevity of medical devices. Flawless fabrication ensures devices function as intended, contributing to accurate diagnostics, effective treatments, and positive patient outcomes. Regulatory compliance, driven by high quality, also accelerates market entry.

Poor quality can lead to costly product recalls, reputational damage, and, most importantly, risks to patient safety. ly-machining’s unwavering commitment to quality ensures that every component contributes positively to the device’s success and the patient’s well-being.

Key Criteria for Selecting CNC Manufacturers

Essential Certifications for Medical Device Components

When seeking recommended manufacturers for CNC machining of optical lens housings, regulatory compliance is non-negotiable. ISO 13485 certification demonstrates a manufacturer’s commitment to quality management systems specifically for medical devices. This provides assurance of controlled processes and documentation.

ly-machining maintains strict adherence to ISO 13485 standards, ensuring every step, from material sourcing to final inspection, meets the medical industry’s rigorous requirements. This certification is a testament to ly-machining’s capability to deliver trustworthy medical device components.

Evaluating Technical Expertise in Custom CNC Optical Lens Housing Fabrication

True expertise goes beyond possessing advanced machines; it resides in the engineers and machinists who operate them. Look for a manufacturer with a proven track record in intricate geometries, challenging materials, and the ability to offer design-for-manufacturability (DFM) insights. This collaborative approach enhances product design.

In ly-machining’s experience, early engagement with client R&D engineers is crucial. ly-machining’s team provides valuable input on material choices, tolerance stacking, and optimal machining strategies, streamlining the custom CNC optical lens housing fabrication process and reducing lead times.

The Importance of Transparent Pricing & Value in CNC Machining

Transparent pricing is a hallmark of a reliable manufacturing partner. Clients need clear, upfront cost breakdowns without hidden fees, allowing for accurate budgeting and project planning. Value, however, extends beyond the sticker price to encompass reliability, quality, and technical support.

ly-machining believes in providing comprehensive quotes that reflect the true cost of precision and quality. ly-machining’s value proposition is built on delivering superior quality components, reducing rework, and ensuring on-time delivery, which ultimately lowers overall project costs for clients.

Assessing a Manufacturer’s Capacity for Precision CNC Manufacturers for Optical Housings

A manufacturer’s capacity involves not just the number of machines but also their maintenance, redundancy, and ability to scale production. For precision CNC manufacturers for optical housings, consistent quality across low-volume prototyping and high-volume production is essential. Scalability without compromising precision is key.

ly-machining invests in state-of-the-art machinery and maintains a robust production schedule to meet diverse client demands. ly-machining’s flexible manufacturing processes allow for efficient transitions from prototyping to full-scale production, ensuring a stable and reliable supply chain.

Our Expertise in Medical Optical CNC Processing

Advanced CNC Machining Services for Optical Lens Housings

ly-machining offers a full suite of advanced CNC machining services tailored for optical lens housings. This includes high-speed milling, micromachining, and multi-axis contouring to achieve the most complex geometries and critical surface finishes. ly-machining’s focus is on delivering components that exceed specifications.

ly-machining’s programmers and machinists are highly skilled in optimizing tool paths and machining parameters for materials commonly used in medical optics. This ensures minimal material stress and exceptional part integrity throughout the precision manufacturing process.

Material Selection and Optimization for Medical Applications

Selecting the right material for medical optical housings is crucial, balancing optical properties, biocompatibility, sterilization compatibility, and mechanical strength. ly-machining works with a wide range of medical-grade plastics and metals, providing expert guidance on material choice.

In ly-machining’s experience, common materials include specific grades of aluminum, stainless steel, and high-performance engineering plastics. ly-machining offers material certifications and traceability, which are vital for medical device compliance and safety.

| Material Type | Common Applications | Key Benefits |

|---|---|---|

| Aluminum (6061, 7075) | General optical housings, structural components | Lightweight, good strength-to-weight, machinability |

| Stainless Steel (304, 316L) | High strength, corrosion resistance, biocompatibility | Durable, sterilizable, robust for harsh environments |

| PEEK | Insulators, demanding environments, chemical resistance | Biocompatible, high temperature, excellent chemical resistance |

| Ultem (PEI) | Lens holders, electrical components | High heat deflection, flame retardant, good dielectric |

Our Commitment to High-Quality Parts and Rigorous Inspection

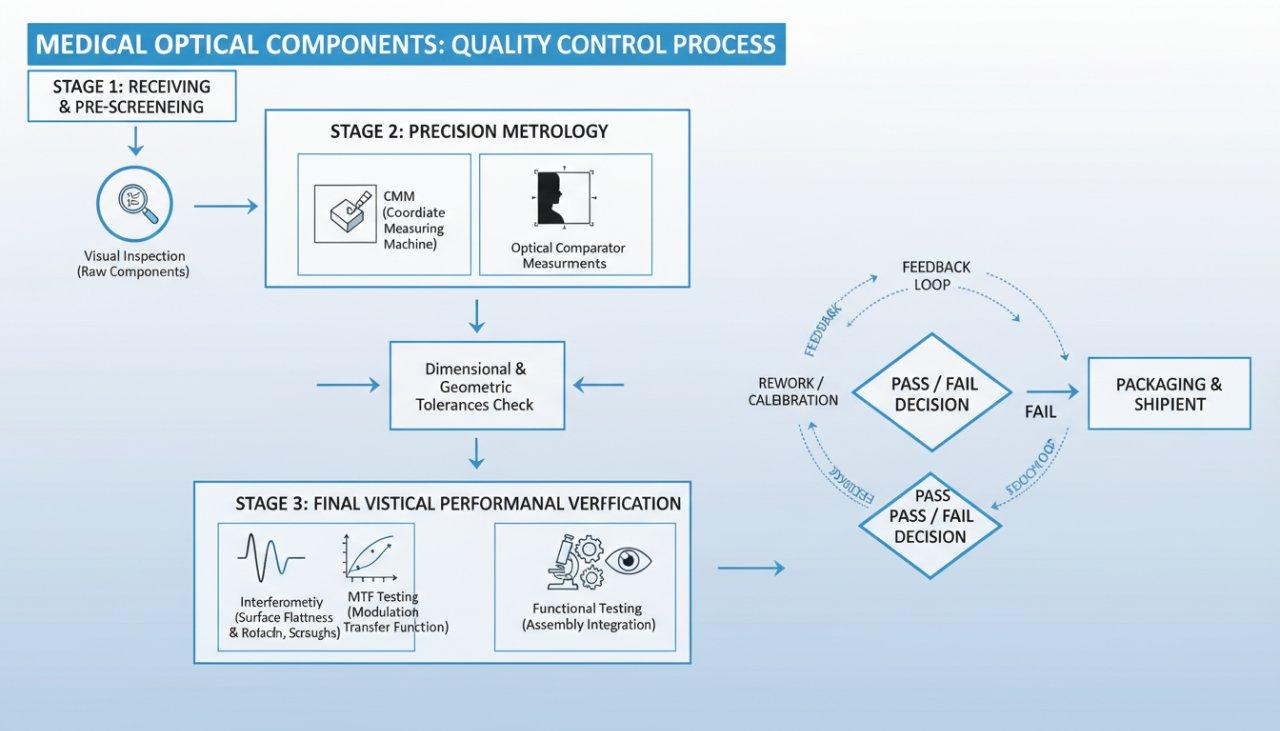

Quality is not just a department at ly-machining; it’s embedded in ly-machining’s culture. Every optical housing undergoes rigorous multi-stage inspection using advanced metrology equipment. This includes Coordinate Measuring Machines (CMMs) and optical comparators to verify critical dimensions and geometric tolerances.

ly-machining’s quality control protocols extend to surface finish verification, ensuring that Ra values meet optical and sealing requirements. This meticulous approach guarantees that parts conform to precise specifications and client expectations.

Delivering Custom CNC Optical Lens Housing Fabrication Solutions

Every medical device project presents unique challenges, requiring bespoke manufacturing solutions. ly-machining specializes in custom CNC optical lens housing fabrication, translating complex designs into tangible, high-performance components. ly-machining prides itself on its ability to handle unique specifications.

From initial prototyping to full production runs, ly-machining partners with clients to refine designs for optimal manufacturability. This collaborative approach ensures that custom components are not only precise but also cost-effective and delivered on schedule.

Solving Your Challenges: Trusted CNC Source

Addressing Complex Geometries with Precision CNC Manufacturers for Optical Housings

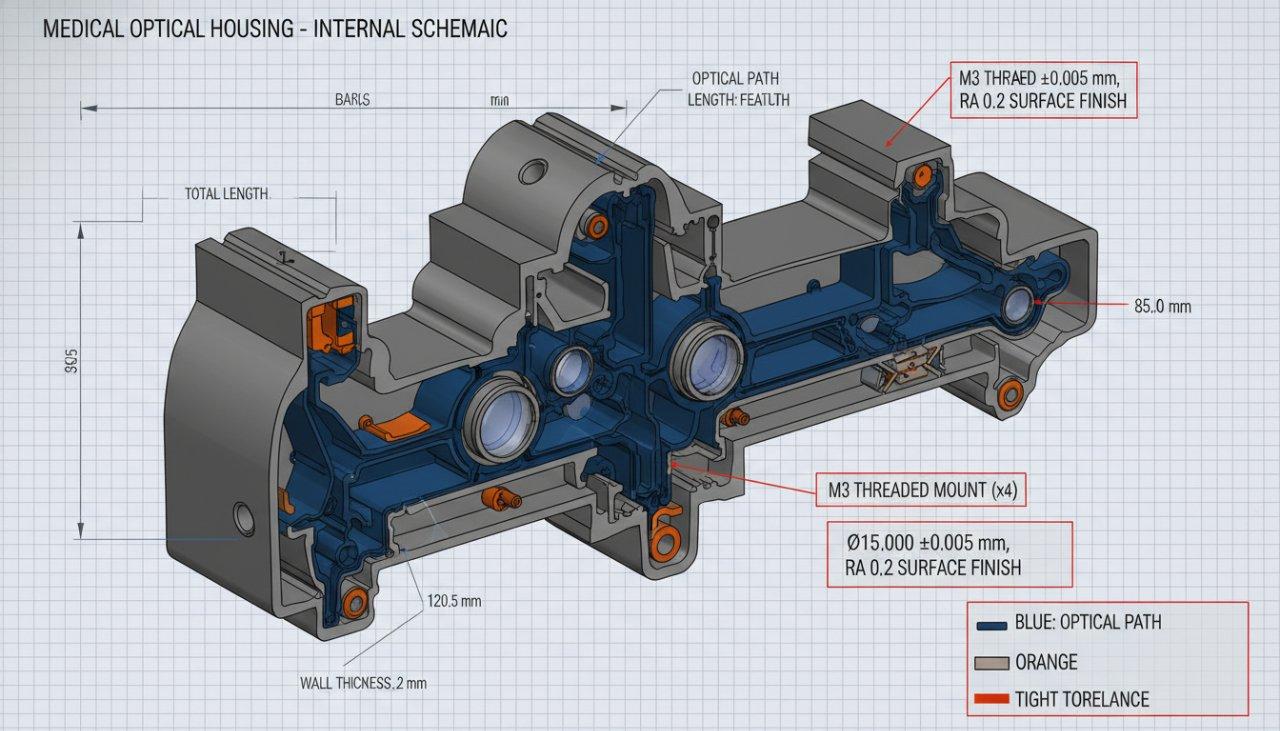

Complex geometries are a hallmark of modern medical devices, particularly in optical systems. ly-machining excels in machining intricate features, thin walls, and multi-faceted surfaces required for precise optical alignment and functionality. ly-machining’s expertise helps overcome these manufacturing hurdles.

As precision CNC manufacturers for optical housings, ly-machining employs advanced CAD/CAM software and skilled machinists. This allows for the creation of highly complex internal and external features, ensuring the optical path and component integration are flawless.

Ensuring Compliance and Mitigating Risks in Medical Device Manufacturing

Navigating the regulatory landscape for medical devices can be daunting. ly-machining acts as a crucial partner in mitigating manufacturing risks by ensuring strict adherence to industry standards and client specifications. ly-machining’s robust documentation and traceability procedures are key.

ly-machining understands the importance of audit trails and material certifications for regulatory submissions. This proactive approach helps clients streamline their approval processes and minimizes potential compliance issues down the line.

Streamlining Your Supply Chain with Reliable Optical Lens Housing CNC Machining Services

A reliable manufacturing partner is central to an efficient supply chain. ly-machining provides consistent quality and on-time delivery, reducing lead times and ensuring a steady flow of critical components. This reliability is vital for maintaining production schedules and preventing costly delays.

ly-machining’s integrated project management ensures seamless communication and transparency throughout the manufacturing process. This commitment to efficiency makes ly-machining a trusted provider of optical lens housing CNC machining services.

Partnering for Innovation in Medical Device Development

True partnership extends beyond fabrication; it involves collaboration that fosters innovation. ly-machining’s technical team often works alongside client R&D departments, offering insights that can enhance design, reduce manufacturing costs, and accelerate product development.

ly-machining’s proactive approach to problem-solving and expertise in cutting-edge machining techniques contributes significantly to the success of new medical device projects. ly-machining helps transform innovative concepts into market-ready realities.

Your Next Step: Partnering for Precision Optical Housings

Request a Quote for Recommended Manufacturers for CNC Machining of Optical Lens Housings

When you are ready to move forward with a trusted partner, ly-machining invites you to experience its commitment to excellence. ly-machining’s team is prepared to review your specifications and provide a competitive, transparent quote. This is your first step towards exceptional precision.

ly-machining offers detailed estimates that reflect the true value of high-quality, compliant manufacturing. Discover why ly-machining is among the recommended manufacturers for CNC machining of optical lens housings.

Discuss Your Project with Our CNC Machining Experts

Don’t hesitate to reach out for a confidential, no-obligation technical consultation. ly-machining’s engineering experts are available to discuss the intricacies of your medical optical housing project, offering design-for-manufacturability insights and material recommendations. This direct engagement fosters effective solutions.

ly-machining prides itself on its collaborative approach, ensuring that your vision is realized with the highest possible precision and efficiency. Let ly-machining’s expertise in CNC machining elevate your medical device development.

Case Study: Achieving Micron Precision for a Surgical Endoscope Housing

Problem: A client developing a new surgical endoscope required an optical housing with extremely tight geometric tolerances and an ultra-fine surface finish for internal optical alignment. Previous manufacturers struggled to consistently achieve the specified Ra 0.2 surface finish on internal features and maintain concentricity within 5 microns. This impacted optical clarity and device assembly.

ly-machining’s Solution: ly-machining’s engineering team collaborated closely with the client, performing a comprehensive DFM analysis. ly-machining optimized tool paths using advanced 5-axis CNC machining, selected specialized diamond-tipped tools, and implemented a multi-stage polishing process. In-process metrology and a dedicated cleanroom environment ensured contamination control and real-time precision monitoring.

Result: ly-machining successfully delivered a batch of housings that consistently met all critical specifications, including the challenging surface finish and concentricity requirements. This enabled the client to achieve superior optical performance in their endoscope, reduce assembly time, and accelerate their device’s regulatory approval process, solidifying ly-machining’s role as a trusted partner for precision CNC manufacturing.

Call to Action: Ready to elevate your medical device’s optical performance with a trusted source manufacturer? Request a confidential, no-obligation quote today for your precision CNC machining project. Or, schedule a direct technical consultation with ly-machining’s engineering experts to explore solutions for your most complex optical housing designs.

FAQ

What is CNC machining for optical housings?

CNC machining for optical housings involves using computer numerical control machines to precisely cut, shape, and finish materials for optical components. These services create intricate geometries and tight tolerances essential for medical device functionality. ly-machining uses advanced techniques to ensure precision and reliability in every part.

Why is ISO 13485 certification important?

ISO 13485 certification signifies a manufacturer’s adherence to quality management systems specific to medical devices. This ensures processes meet regulatory requirements, guaranteeing component safety and efficacy. ly-machining’s compliance demonstrates its commitment to the highest industry standards.

Can ly-machining handle custom optical designs?

Yes, ly-machining specializes in custom CNC optical lens housing fabrication. ly-machining’s expert engineers work with clients from design concept to production. This collaborative approach ensures that even the most complex and unique optical designs are manufactured to exact specifications.