Accelerate IR Optics: Expert CNC Machining

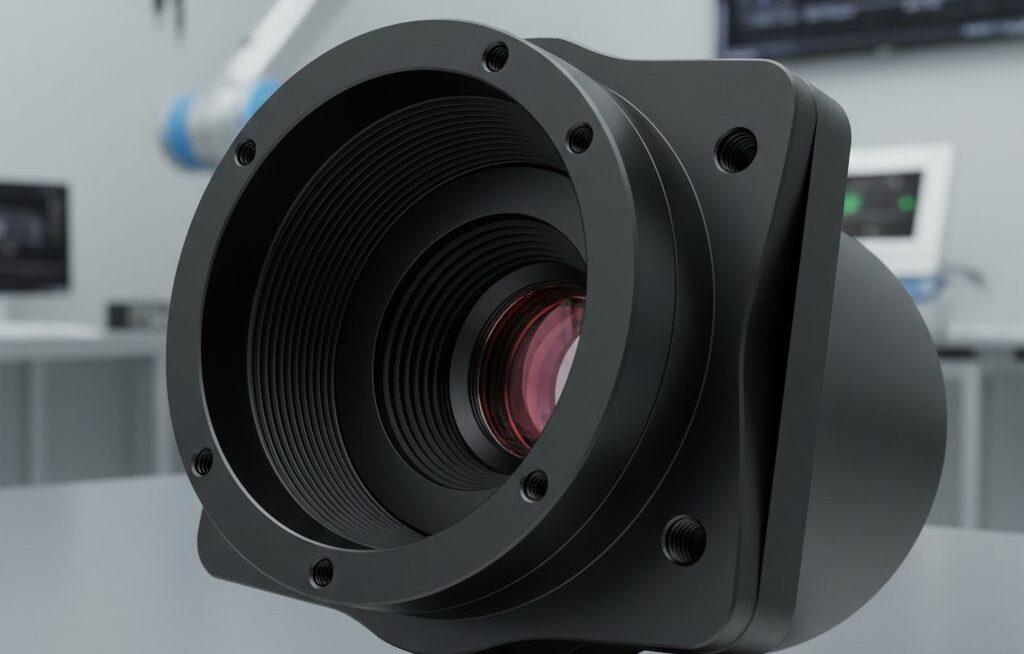

Quick Solution: ly-machining is a top recommended CNC machining manufacturer specializing in infrared lens housings, delivering precision CNC IR optics components with exceptional delivery cycles to meet your critical project timelines.

Are you constantly battling extended lead times and compromised precision for your crucial infrared lens housings? The rapid advancements in optics demand not just accuracy but also unmatched speed in custom infrared lens housing manufacturing.

Delays in receiving high-quality components can derail entire projects, costing valuable time and resources in the competitive IR optics market. Partnering with the right CNC machining expert is no longer an option, it’s a necessity.

This guide will unveil how ly-machining redefines efficiency and quality in infrared lens housing CNC machining, ensuring your projects stay on track with superior precision and swift delivery.

The Challenge of Infrared Lens Housing CNC Machining

Why timely Precision CNC IR optics components are critical

The performance of infrared optics hinges on the unparalleled precision and structural integrity of its housing. Even microscopic deviations can severely impact optical alignment and thermal stability.

Timely delivery of these precision CNC IR optics components is paramount for product development cycles, market entry, and meeting aggressive project deadlines. Any delay can cascade through the entire supply chain.

Common pain points in Custom infrared lens housing manufacturing

Procurement managers and engineers frequently face struggles with inconsistent quality, opaque pricing, and a lack of specialized expertise from generic CNC machining providers. These issues add risk.

The most significant pain point in custom infrared lens housing manufacturing, however, is invariably the long and unpredictable lead times. This directly affects project timelines and overall cost efficiency.

Here is a look at common challenges ly-machining addresses:

| Common Pain Point | Impact on Project Success |

|---|---|

| Extended Lead Times | Delayed product launches, increased project costs |

| Quality Inconsistencies | High scrap rates, costly reworks, assembly failures |

| Lack of IR-Specific Expertise | Suboptimal design, material misapplication, performance issues |

| Opaque Pricing | Budget overruns, difficulty in supplier comparison |

Defining Excellent Delivery Cycles in CNC Machining

What drives efficiency in CNC machining delivery cycles?

Efficient CNC machining delivery cycles are driven by a sophisticated interplay of advanced technology, optimized workflows, and skilled personnel. ly-machining leverages all three extensively.

This includes adopting multi-axis machining centers, implementing intelligent scheduling software, and maintaining robust inventory management for common IR-specific materials. Proactive communication is also key.

How a Recommended CNC machining manufacturer minimizes lead times

A truly recommended CNC machining manufacturer strategically minimizes lead times through proactive design for manufacturability (DFM) support and efficient material sourcing. ly-machining begins at the design stage.

ly-machining’s engineers collaborate closely with clients early on, identifying potential manufacturing challenges and optimizing designs for efficient production. This foresight prevents costly delays down the line.

Furthermore, ly-machining invests in continuous process improvement, reducing setup times and optimizing toolpaths. This dedication ensures rapid turnaround for every custom infrared lens housing project.

Our Expertise in Infrared Lens Housing CNC Processing

Advanced techniques for Precision CNC IR optics components

ly-machining employs cutting-edge multi-axis CNC machining, including 5-axis milling, to achieve the complex geometries and tight tolerances required for precision CNC IR optics components. This capability minimizes setups.

Our specialized equipment allows for simultaneous machining on multiple planes, significantly reducing cycle times and enhancing accuracy. This is critical for intricate infrared lens housing designs.

We also utilize advanced CAM software that optimizes toolpaths for material removal efficiency and surface finish. This ensures component integrity for critical optical applications.

Material considerations in Infrared lens housing CNC machining

Selecting the correct material is paramount for infrared lens housing CNC machining, given the specific thermal, mechanical, and optical requirements of IR systems. ly-machining provides expert guidance.

Common materials ly-machining works with include aluminum alloys (6061, 7075 for their strength-to-weight ratio and machinability), titanium (for high strength and corrosion resistance), and certain stainless steels.

Each material choice is carefully evaluated by ly-machining based on factors like thermal expansion coefficients, weight constraints, and specific environmental operating conditions of the IR system.

| Material Type | Key Benefit for IR Housings | Typical Application Considerations |

|---|---|---|

| Aluminum 6061/7075 | Excellent machinability, good strength-to-weight | Cost-effective, general-purpose IR housing, thermal management |

| Titanium | High strength, corrosion resistance, low thermal expansion | Harsh environments, weight-critical applications |

| Stainless Steel | High rigidity, robust, chemical resistance | Specific environmental conditions, structural integrity emphasis |

Quality control for Custom infrared lens housing manufacturing

For ly-machining, uncompromising quality control is integrated into every stage of custom infrared lens housing manufacturing, from initial material inspection to final dimension verification.

ly-machining adheres to stringent quality management systems, including ISO 9001 and AS9100 standards, to ensure every component meets the exact specifications. This commitment underpins our trustworthiness.

Our quality assurance protocols involve state-of-the-art measurement equipment, such as Coordinate Measuring Machines (CMMs) and optical comparators, capable of verifying micron-level tolerances.

Why Choose Us as Your Top Infrared Component Supplier

Our strengths as a source manufacturer in CNC machining

As a dedicated source manufacturer for CNC machining, ly-machining offers unparalleled control over the entire production process. This translates directly to superior quality and predictable delivery for clients.

ly-machining eliminates intermediaries, providing direct communication channels and transparent operations. This direct engagement fosters stronger partnerships and faster problem-solving.

Our vertically integrated approach ensures that every aspect, from material procurement to final inspection, is managed under ly-machining’s strict quality protocols, minimizing risks and maximizing efficiency.

Transparent pricing for your Custom infrared lens housing

ly-machining believes in complete transparency when quoting for your custom infrared lens housing projects. Clients receive detailed breakdowns, ensuring clarity and predictability.

Our pricing structure is designed to be competitive, reflecting the true cost of precision engineering without hidden fees. This fosters trust and long-term relationships with ly-machining’s partners.

We provide accurate estimates upfront, allowing clients to confidently budget for their precision CNC IR optics components without unexpected surprises.

Deep technical expertise in Precision CNC IR optics parts

ly-machining’s team comprises highly skilled engineers and machinists with extensive experience in the unique demands of precision CNC IR optics parts. This specialized knowledge is a significant asset.

ly-machining understands the thermal, optical, and mechanical considerations specific to infrared systems. We offer invaluable design for manufacturability (DFM) feedback and material expertise.

This deep technical proficiency ensures that your complex designs are not just machined, but optimized for performance and reliability by ly-machining’s experts.

Case Study: Rapid Delivery of IR Optics Components

A successful project in Infrared lens housing CNC machining

A defense contractor approached ly-machining with an urgent requirement for complex infrared lens housings for a new aerial reconnaissance system. Their previous supplier faced significant delays, threatening project milestones.

The components required extremely tight tolerances, specialized material (7075 aluminum with a hard anodized finish), and a delivery window that seemed impossible to meet for such intricate parts.

How we met tight deadlines for custom IR optics components

ly-machining immediately deployed a dedicated project team, leveraging our DFM expertise to optimize the client’s design for rapid machining. Parallel processing on multiple 5-axis machines was initiated.

Our optimized workflows and proactive material sourcing ensured continuous production. ly-machining’s stringent in-process quality checks prevented any rework, maintaining the accelerated schedule.

Result: ly-machining delivered the entire batch of custom IR optics components a week ahead of the revised, aggressive deadline, enabling the client to stay on track for their critical system integration. This reinforced ly-machining’s reputation.

Get a Quote for Your Next CNC Machining Project

Contact the Recommended CNC machining manufacturers

Are you ready to partner with one of the most recommended CNC machining manufacturers for your precision IR optics components? ly-machining is poised to accelerate your next project.

Reach out to ly-machining’s dedicated sales and engineering team today to discuss your specific infrared lens housing CNC machining requirements. We are ready to provide expert solutions.

Partnering for efficient Custom infrared lens housing output

Choosing ly-machining means securing a partner committed to delivering efficient custom infrared lens housing output with unwavering quality. Experience the difference true expertise makes.

Let ly-machining help you transform your designs into high-performance realities, on time and to specification. We look forward to building a successful partnership.

Call to Action: Invite readers to get a free quote or technical consultation.

What is the typical lead time for infrared lens housings?

Lead times for infrared lens housings can vary significantly based on complexity, material, and order volume. ly-machining prioritizes optimized workflows and advanced machinery to offer some of the industry’s fastest delivery cycles.

Our DFM support and lean manufacturing processes aim to minimize turnaround without compromising the critical precision required for IR optics components. We provide clear, transparent timelines upfront.

What materials are best for IR lens housings?

The best materials for IR lens housings depend on the specific application’s thermal, weight, and environmental requirements. Common choices ly-machining works with include 6061 and 7075 aluminum alloys for their machinability and strength.

For more demanding conditions, titanium and certain stainless steels are often preferred due to their superior strength, corrosion resistance, and thermal stability. ly-machining’s experts guide clients in optimal material selection.

How does ly-machining ensure precision in IR optics components?

ly-machining ensures precision through a combination of advanced multi-axis CNC machining centers, rigorous in-process quality control, and state-of-the-art metrology equipment. We adhere to strict ISO and AS9100 quality standards.

Our highly skilled machinists and engineers leverage decades of experience in optical component manufacturing, focusing on micron-level tolerances and superior surface finishes. Every precision CNC IR optics component undergoes comprehensive inspection before delivery.