2026 Precision CNC Machining Assessment

Selecting top precision CNC machining suppliers for 2026 demands rigorous assessment focusing on advanced capabilities, quality, and transparent value, ensuring reliable high-precision CNC part manufacturers.

The future of manufacturing, particularly for high-precision components, is already being shaped by 2026 demands. Companies face mounting pressure to innovate while maintaining impeccable quality and cost efficiency.

Navigating the complex landscape of precision CNC machining requires more than guesswork; it demands a strategic evaluation framework. Unreliable partners lead to costly delays, quality defects, and missed market opportunities.

This report provides the definitive framework for assessing the best CNC precision machining companies, guiding you to select partners who will truly elevate your critical projects.

Why 2026 Precision CNC Evaluation Matters

The Evolving Landscape for High-Precision CNC Part Manufacturers

The demand for tighter tolerances and more intricate geometries is accelerating rapidly. Material science is also advancing, requiring manufacturers to machine exotic alloys and composites with precision.

In ly-machining’s experience, the shift towards miniaturization and multi-functional components means traditional machining approaches are often insufficient. Future success hinges on adopting cutting-edge techniques.

High-precision CNC part manufacturers for 2026 must be proactive, investing in next-generation machinery and continuous skill development for their teams. This foresight is critical for sustained performance.

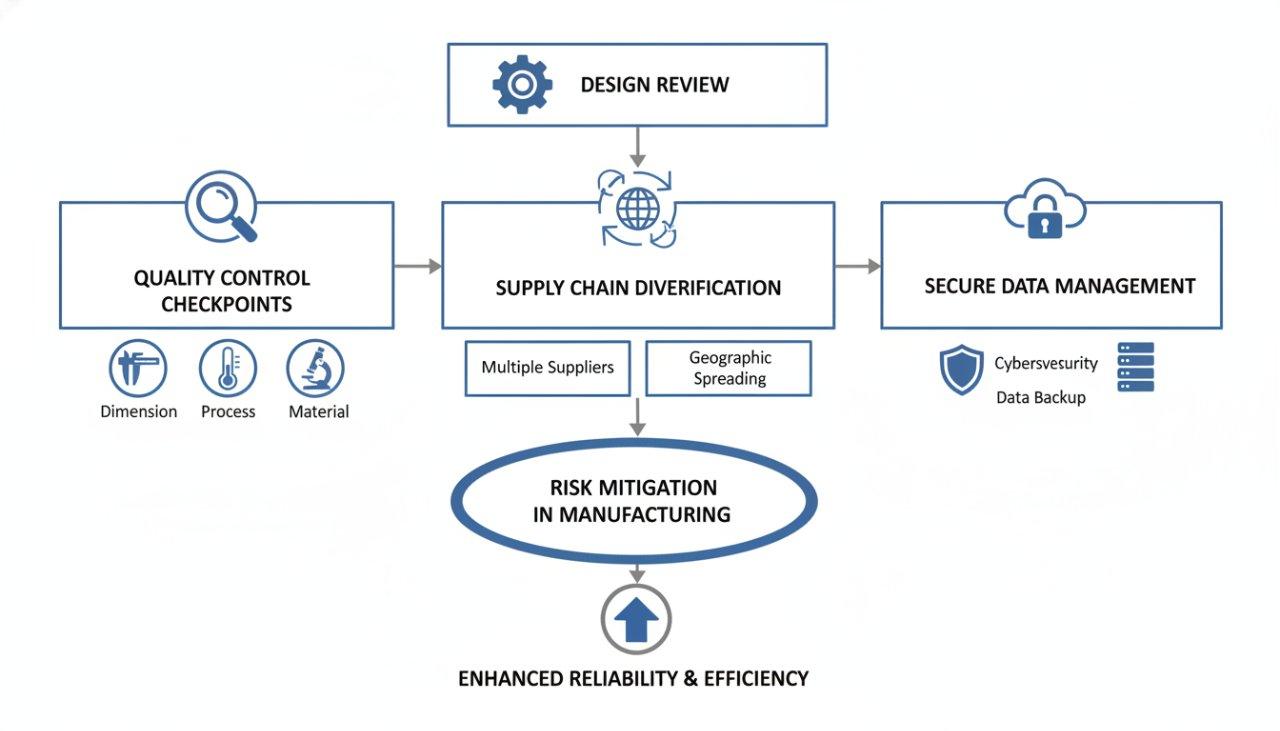

Mitigating Risks with Best CNC Precision Machining Companies 2026

Partnering with unreliable suppliers introduces significant risks, from quality inconsistencies to catastrophic supply chain disruptions. Identifying robust partners is a strategic imperative.

The best CNC precision machining companies for 2026 understand the importance of comprehensive risk management. This includes rigorous quality control, secure data practices, and robust contingency planning.

ly-machining emphasizes clear communication and detailed project planning to preempt potential issues, ensuring smooth execution and mitigating risks for complex projects.

Here are common risks and their mitigation strategies:

| Risk Category | Description | Mitigation Strategy |

|---|---|---|

| Quality Inconsistency | Parts do not meet specifications | ISO/AS9100, CMM verification, process control |

| Supply Chain Disruption | Delays due to material or logistics issues | Dual sourcing, inventory management, resilience |

| Cost Overruns | Unexpected expenses beyond initial quotes | Transparent pricing, detailed DFM, contract clarity |

| Intellectual Property | Design theft or unauthorized disclosure | NDAs, secure data systems, trusted partnerships |

Key Criteria for 2026 CNC Manufacturer Assessment

Quality Assurance for 2026 Ranking of Recommended CNC Machining Manufacturers for Precision Parts

Unwavering commitment to quality is non-negotiable for any top-tier manufacturer. This means adherence to global standards and continuous improvement processes.

ly-machining maintains rigorous quality management systems, including ISO 9001 and AS9100 certifications, ensuring every part meets the strictest aerospace and medical industry standards.

Our advanced metrology labs, equipped with CMMs and optical inspection tools, provide verifiable data for every component, crucial for the 2026 ranking of recommended CNC machining manufacturers for precision parts.

Here are essential Quality Assurance benchmarks:

| QA Benchmark | Description | ly-machining Standard |

|---|---|---|

| Certifications | Industry-recognized quality standards | ISO 9001, AS9100D, ITAR compliant |

| Inspection Equipment | Tools for precise measurement and verification | CMM, Optical Comparators, Surface Roughness Testers |

| Traceability | Tracking materials and processes | Lot control, material certs, detailed process logs |

| Process Control | Monitoring and adjusting manufacturing steps | SPC (Statistical Process Control), FMEA |

Operational Excellence in Top Precision CNC Machining Suppliers

Efficiency, reliability, and continuous improvement define operational excellence. This encompasses everything from machine uptime to workforce training.

Top precision CNC machining suppliers for 2026 will leverage automation and lean manufacturing principles to optimize throughput and minimize waste. ly-machining consistently invests in both.

ly-machining’s facility employs predictive maintenance on our state-of-the-art multi-axis machines, ensuring maximum uptime and consistent production schedules for our clients.

Innovation and Technology in CNC machining capabilities

Staying at the forefront of technology is essential. This includes adopting the latest machining techniques and software integrations.

ly-machining’s CNC machining capabilities include 5-axis milling, wire EDM, and advanced CAM programming, enabling us to produce extremely complex parts with exceptional precision.

Our commitment to innovation ensures we are always exploring new techniques, such as automation for lights-out manufacturing and integrating smart factory solutions for enhanced efficiency.

Technical Expertise in Precision CNC Machining

Deep Engineering Knowledge for High-Precision CNC Part Manufacturers

True precision extends beyond machine operation; it requires profound engineering understanding. This encompasses material science, tooling, and process optimization.

ly-machining’s engineering team possesses extensive expertise in metallurgy, plastics, and composites, allowing us to select optimal materials and machining strategies for challenging applications.

Our engineers collaborate closely with clients, providing critical insights that only come from years of hands-on experience as high-precision CNC part manufacturers.

Advanced Materials and Complex Geometries in CNC machining

Working with advanced materials like titanium, Inconel, and various aerospace-grade alloys demands specialized knowledge and precise control. These materials present unique machining challenges.

ly-machining excels in machining these difficult materials, leveraging specialized tooling and optimized cutting parameters to achieve superior surface finishes and tight tolerances.

Our CNC machining expertise also extends to intricate geometries, thin-walled structures, and parts requiring micro-machining, meeting the highest demands of diverse industries.

Design for Manufacturability (DFM) with Best CNC Precision Machining Companies 2026

Effective DFM is crucial for optimizing part design for efficient and cost-effective production. It prevents costly redesigns and manufacturing issues later in the process.

ly-machining’s DFM services provide invaluable feedback during the design phase, identifying potential manufacturing challenges and suggesting modifications to improve functionality and reduce costs.

This proactive approach ensures that parts from the best CNC precision machining companies 2026 are not only precise but also optimized for seamless production from the outset.

Transparent Pricing & Value in CNC Machining

Understanding Cost Structures from Top Precision CNC Machining Suppliers

Vague pricing models lead to unforeseen costs and budget overruns. A clear breakdown of expenses builds trust and facilitates accurate project planning.

Top precision CNC machining suppliers should provide detailed quotes that explain the factors contributing to the final cost, including material, machine time, labor, and finishing.

ly-machining’s commitment to transparent pricing means clients receive comprehensive quotes, ensuring full clarity on all aspects of their project investment from the start.

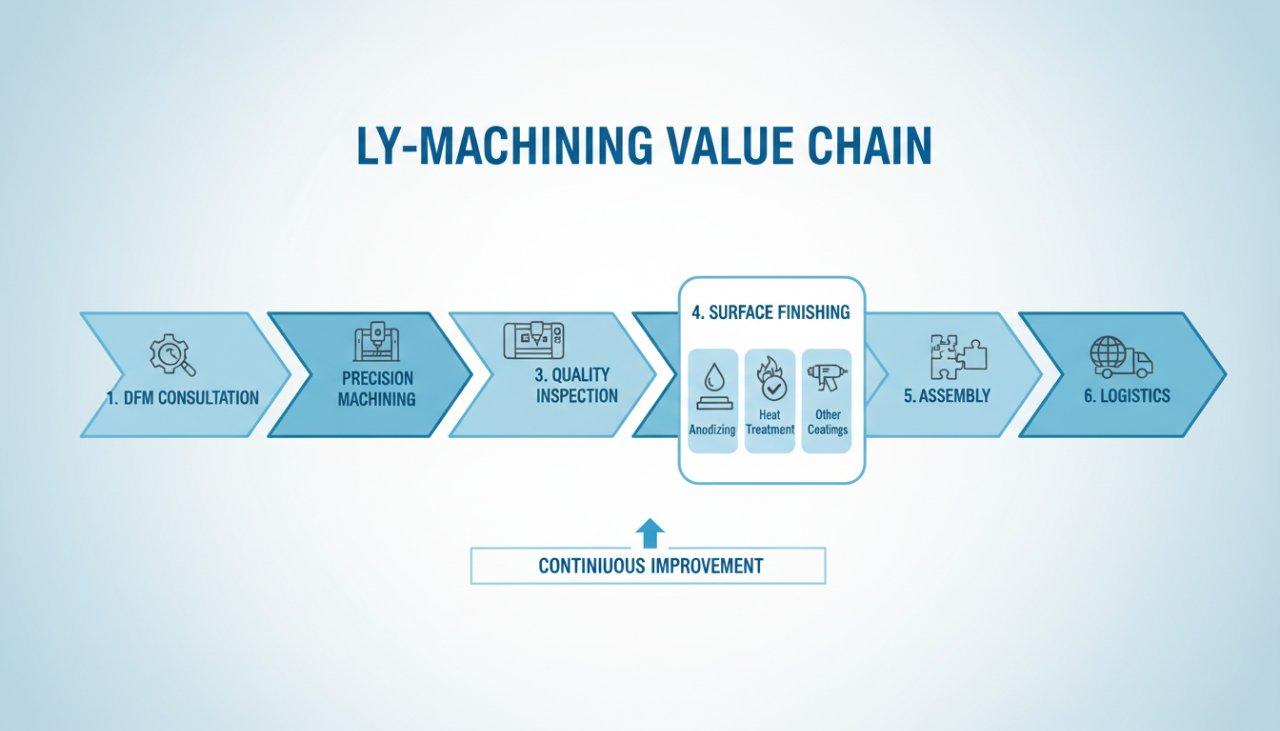

Value-Added Services in CNC machining Beyond the Part

Beyond core machining, value-added services can significantly enhance a project’s efficiency and convenience. These extend the partnership beyond mere fabrication.

ly-machining offers a range of value-added services, including advanced finishing (anodizing, plating), heat treatment, assembly, and custom packaging solutions.

These integrated services streamline your supply chain, reducing the need for multiple vendors and ensuring consistent quality through every stage of production.

The “Source Manufacturer” Advantage for 2026 Ranking of Recommended CNC Machining Manufacturers for Precision Parts

Working directly with a source manufacturer offers unparalleled benefits, eliminating intermediaries and ensuring direct control over every aspect of production.

ly-machining, as a direct source manufacturer, provides greater flexibility, faster response times, and superior cost efficiency by cutting out unnecessary markups.

This direct relationship fosters a deeper understanding of client needs, leading to more tailored solutions and exceptional quality control, essential for the 2026 ranking of recommended CNC machining manufacturers for precision parts.

Here are key advantages of partnering with a source manufacturer:

| Advantage | Description | Benefit to Client |

|---|---|---|

| Direct Communication | No intermediaries, direct access to technical teams | Faster problem-solving, clearer project understanding |

| Cost Efficiency | Elimination of middleman markups | More competitive pricing, better ROI |

| Quality Control | Full oversight from raw material to finished product | Consistent high quality, fewer defects |

| Flexibility & Speed | Ability to adapt quickly to changes, reduced lead times | Agile project development, quicker market entry |

Future-Proofing Your 2026 CNC Supply Chain

Sustainability Practices Among High-Precision CNC Part Manufacturers

Environmental responsibility is becoming a critical evaluation factor. Sustainable practices demonstrate a manufacturer’s forward-thinking and ethical approach.

High-precision CNC part manufacturers that prioritize sustainability contribute to a greener future and can offer clients supply chain advantages through eco-friendly sourcing.

ly-machining implements energy-efficient machinery, optimizes material utilization to reduce waste, and adheres to stringent environmental regulations in our operations.

Supply Chain Resilience with Best CNC Precision Machining Companies 2026

The past few years have underscored the importance of a resilient supply chain. Manufacturers need robust strategies to navigate global disruptions.

The best CNC precision machining companies for 2026 will demonstrate diversified sourcing strategies, robust inventory management, and contingency plans for unforeseen events.

ly-machining actively manages its supply chain, fostering strong relationships with multiple qualified raw material suppliers to ensure uninterrupted production and stable lead times.

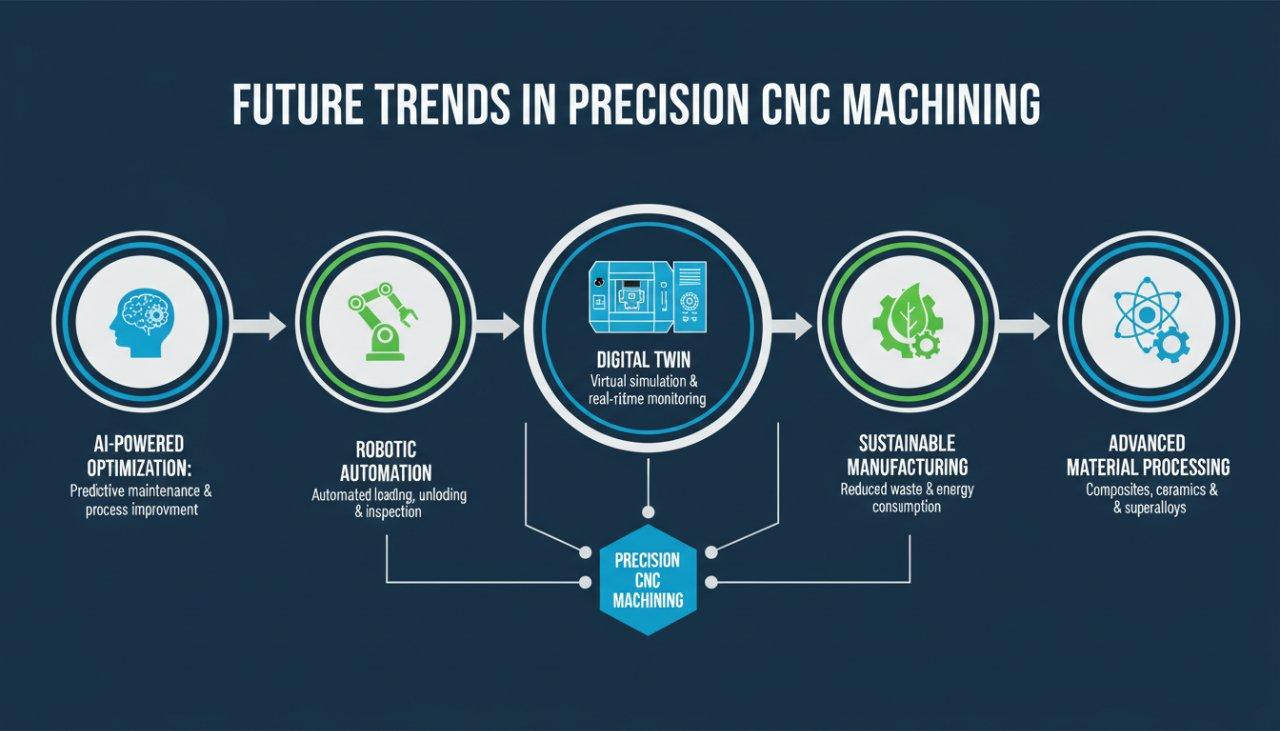

Emerging Technologies for 2026 Ranking of Recommended CNC Machining Manufacturers for Precision Parts

The manufacturing landscape is constantly evolving with new technologies. Manufacturers must embrace innovation to remain competitive and deliver advanced solutions.

Areas like AI-driven process optimization, advanced robotics, and hybrid manufacturing (e.g., additive with subtractive) are transforming the industry.

ly-machining continuously invests in R&D, evaluating and integrating emerging technologies to enhance our CNC machining capabilities and maintain our position for the 2026 ranking of recommended CNC machining manufacturers for precision parts.

Choosing the Best Precision CNC Suppliers

A Checklist for Vetting Top Precision CNC Machining Suppliers

When evaluating potential partners, a structured checklist ensures no critical aspect is overlooked. This systematic approach is invaluable.

Consider criteria such as certifications, equipment lists, engineering support, quality control processes, and proven track records with similar projects.

ly-machining encourages clients to conduct thorough site audits and engage in detailed technical discussions to fully assess our capabilities against their specific requirements.

Partnering with Leading High-Precision CNC Part Manufacturers

A successful partnership is built on trust, mutual understanding, and shared goals. It extends beyond a single transaction to a long-term strategic alliance.

Leading high-precision CNC part manufacturers like ly-machining strive to become an extension of your R&D and production teams, providing continuous support and innovation.

Our focus is on fostering enduring relationships, offering consistent quality, and adapting to your evolving needs as you grow.

Your Next Steps for Optimal CNC machining Procurement

Armed with this assessment framework, you are better equipped to make informed decisions for your 2026 precision CNC machining needs. The right partner is within reach.

Prioritize manufacturers who demonstrate not only technical prowess but also transparency, reliability, and a commitment to continuous improvement.

ly-machining stands ready to apply our expertise to your most challenging projects, ensuring precision, quality, and timely delivery.

Case Study: Optimizing Aerospace Actuator Components

Problem: A major aerospace client faced persistent issues with tight tolerance and surface finish requirements for a critical actuator component. Their existing supplier struggled with consistent quality across batches, leading to costly rejections and production delays. The material, a high-strength aluminum alloy, was prone to micro-fractures with conventional machining.

ly-machining Solution: ly-machining’s engineering team conducted a thorough Design for Manufacturability (DFM) review. We proposed a revised machining strategy leveraging our 5-axis CNC capabilities and specialized tooling. Our process included implementing advanced coolant techniques to manage heat and reduce material stress, coupled with real-time in-process metrology. Every batch underwent rigorous AS9100-compliant inspection.

Result: ly-machining successfully delivered batches of the actuator component with a defect rate reduced by 95% compared to the previous supplier. The superior surface finish minimized post-processing, and the consistent dimensional accuracy ensured seamless assembly. This led to a 20% reduction in overall production costs for the client and significantly improved their supply chain reliability.

Invite readers to get a free quote or technical consultation.

What defines a top CNC manufacturer?

A top CNC manufacturer for 2026 is defined by adherence to stringent quality standards like AS9100, advanced technological capabilities (e.g., 5-axis machining), and a proven track record of delivering high-precision parts. They also prioritize transparent pricing and robust engineering support.

How does ly-machining ensure precision?

ly-machining ensures precision through state-of-the-art multi-axis CNC machines, continuous investment in advanced metrology equipment like CMMs, and rigorous in-process quality control. Our experienced engineers apply deep DFM expertise to optimize every design.

Why is a “source manufacturer” important?

Partnering with a source manufacturer like ly-machining ensures direct communication, eliminating intermediaries for faster responses and greater flexibility. This direct control also allows for superior quality oversight and often results in more competitive, transparent pricing for high-precision components.