Are you struggling to choose the right steel for your CNC machining project? Choosing between different grades can greatly affect performance, cost and manufacturing time, and can even lead to project delays and budget overruns if the wrong choice is made. You need a material that not only meets design specifications for strength and durability, but is also optimized for efficient CNC milling and turning, and this challenge requires expertise to solve effectively.

Brought to you by ly-machining, this guide provides a comprehensive comparison of 1018 and 4140 steels. We delve into the key data engineers and machinists need, covering everything from mechanical properties and CNC machining parameters to heat treatment and total project costs. This guide will help you make an informed decision, ensuring your project is a success from the start.

Choosing between 1018 and 4140 steels involves a trade-off between machinability and strength. 1018 steel is a low-carbon, highly machinable alloy that is well suited for general-purpose parts that are easily formed and welded. In contrast, 4140 is a chromium-molybdenum alloy steel that has excellent strength, toughness, and wear resistance for high-stress applications, but is more difficult to machine.

Ultimately, the right choice comes down to the durability, performance, and budget requirements of your specific application. 1018 steel offers the advantages of cost-effectiveness and ease of fabrication for less demanding applications, while 4140 steel provides the rugged performance needed for critical components. Therefore, it is important to understand the subtle differences between these two metals before beginning any CNC machining project. By carefully weighing these factors, you can select the best material and achieve superior results.

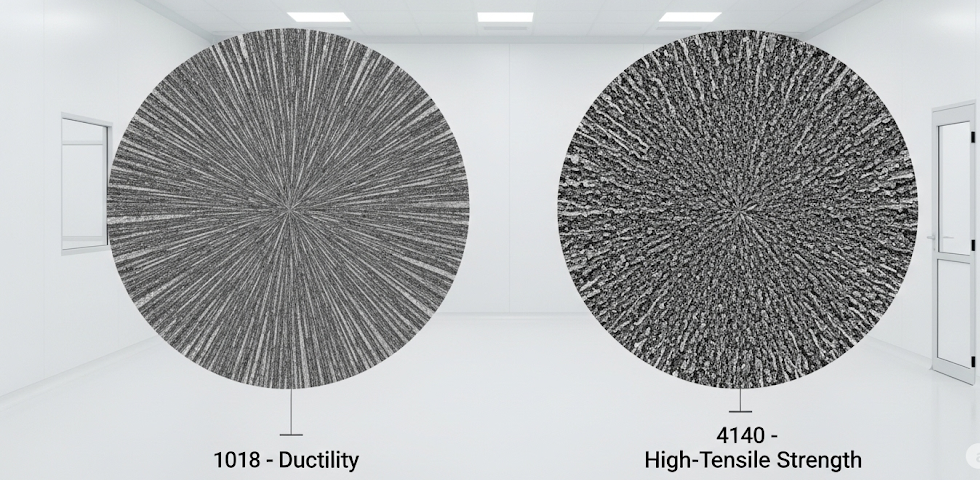

Mechanical properties: strength and ductility

When choosing a steel for a CNC machining project, the first consideration is often its mechanical properties. 1018 steel is a low-carbon steel known for its excellent ductility and strength, making it easy to form, bend, and forge. Its good resistance makes it a top choice for general-purpose manufacturing. In contrast, 4140 steel is an alloy steel with a significantly higher carbon content, along with the addition of chromium and molybdenum. This composition gives 4140 steel excellent tensile strength, hardness, and toughness, making it ideal for high-stress, fatigue, and impact applications.

For components that require exceptional durability under load, such as gears, shafts, or structural bolts, the enhanced properties of 4140 are essential. However, for general-purpose applications such as mounting plates, brackets, and non-critical pins, where ease of fabrication is a primary consideration, the moderate strength and excellent formability of 1018 steel makes it a more practical and cost-effective choice for CNC machining. The ly-machining team can help you weigh these pros and cons for your specific design.

| property | 1018 steel (hot rolled) | 4140 steel (annealed) |

| tensile strength | ~440 MPa (63,800 psi) | ~655 MPa (95,000 psi) |

| Yield Strength | ~370 MPa (53,700 psi) | ~415 MPa (60,200 psi) |

| Brinell hardness | ~126 HB | ~197 HB |

| Elongation at break | ~15% | ~25.7% |

CNC machining and milling performance

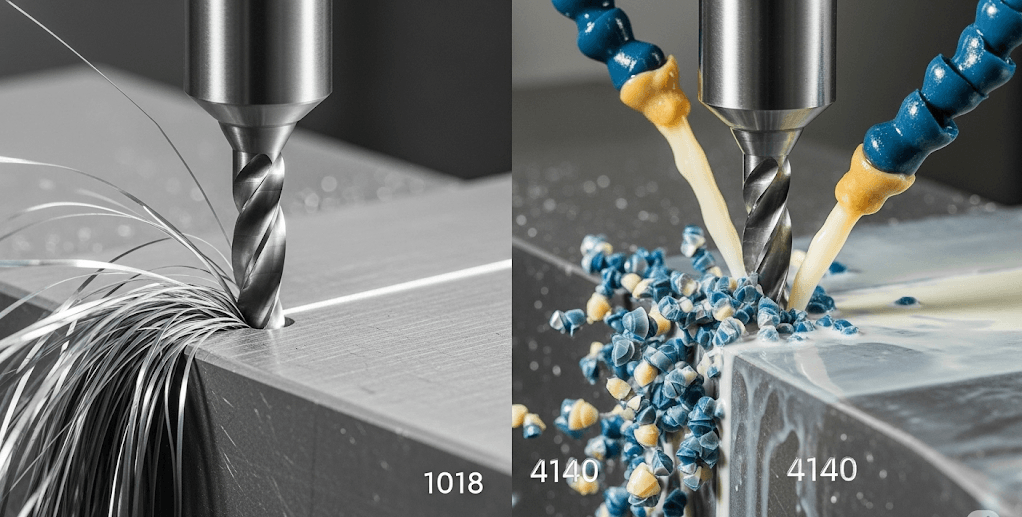

The machinability of a material directly affects production time, tool life and final cost. 1018 steel is known for its excellent machinability, with a machinability of approximately 78% of 1212 steel. Its soft, ductile properties allow for good chip breaking, reduced tool wear and higher cutting speeds during CNC machining. This means faster machining cycles and lower costs, which is exactly what L-machining specializes in.

Conversely, CNC machining of 4140 steel is more challenging due to its greater hardness and toughness. Machining this alloy, especially in the pre-hardened state, requires tighter machine setups, specialized tooling, and more conservative speeds and feeds to manage heat and prevent rapid tool wear. While not as fast as machining 1018 steel, the process is well understood and produces stronger parts. Effective chip control and the use of high-pressure coolant are critical when CNC milling 4140 steel.

Tool selection and coating

For successful CNC milling of 1018 steel, standard high-speed steel (HSS) tools will suffice, but coated carbide end mills will last longer. Because the material is soft, it can feel “squishy” when machined, so a sharp, positive tool will help to achieve a clean cut. For 4140 steel, carbide is critical. We highly recommend using solid carbide end mills with coatings such as titanium aluminum nitride (TiAlN). TiAlN coatings create a very hard, smooth surface that can withstand the high temperatures generated when cutting hard materials such as 4140 steel.

Coolant and chip removal

Proper use of coolant is critical for both materials, but for different primary reasons. When CNC machining 1018 steel, a good quality soluble oil or semi-synthetic coolant provides lubricity to prevent built-up edge (BUE) on the tool, thereby ensuring a good surface finish. For 4140 steel, the primary function of the coolant is to dissipate heat. The cutting forces are much greater, generating a lot of heat that can quickly damage the tool and even cause surface hardening of the material. High-pressure flood coolant can effectively flush the chips and carry the heat away from the cutting zone.

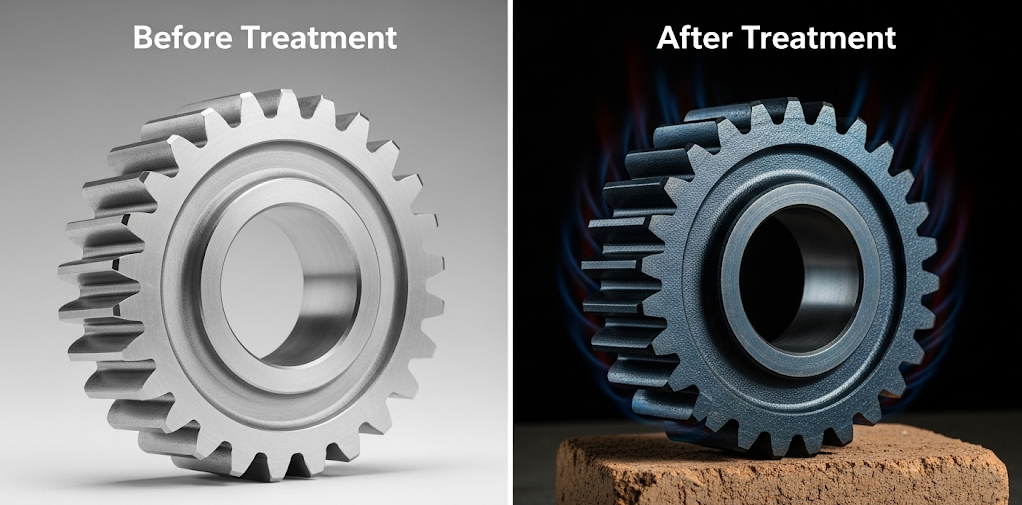

Heat treatment and hardenability

Heat treatment is the most obvious difference between 1018 steel and 4140 steel. Due to its low carbon content, 1018 steel cannot be significantly hardened by quenching and tempering (so-called “through hardening”). However, it is well suited to case hardening processes such as carburizing or carbonitriding. These processes inject carbon (and nitrogen in the case of carbonitriding) into the surface layer, forming a hard, wear-resistant shell while keeping the core soft, ductile, and tough.

4140 steel has high carbon and alloy contents for excellent hardenability. It responds predictably to through-hardening processes such as quenching and tempering. By adjusting the tempering temperature after quenching, various combinations of hardness and toughness can be achieved. This allows engineers to precisely tailor the material properties to the needs of the application. This makes 4140 steel very versatile and can be used to manufacture components that require uniform strength and hardness across the entire cross-section. For example, tempering at a lower temperature (such as 205°C / 400°F) results in high hardness (about 50 HRC) but lower toughness, while tempering at a higher temperature (such as 540°C / 1000°F) results in lower hardness (about 35 HRC) but significantly higher toughness and ductility.

Solderability and Fabrication

Ease of fabrication is a key factor in many engineering projects. 1018 steel has excellent weldability and can be easily joined using all standard welding techniques, with no need for preheating or post-heating in most locations. Its low carbon content minimizes the risk of martensite formation and cracking in the heat affected zone, simplifying the fabrication of complex components that need to be welded after CNC machining.

Welding 4140 steel is more complex and requires strict procedural control. Due to its high carbon and alloying element content, weld cracking can easily occur if proper precautions are not taken. In order to ensure a successful and long-lasting weld, the material must be preheated to a specific temperature (usually 200-300°C / 400-570°F) and subjected to a post-weld stress relief heat treatment. While entirely feasible, these additional steps increase the complexity and cost of the manufacturing process compared to simple welding of 1018 steel.

Cost-Benefit Analysis Practice

Selecting a material based solely on the price per kilogram of raw material can be misleading. A comprehensive cost analysis reveals more accurate information. LY-MAchining’s experts always consider the total project cost, which includes raw materials, CNC machining time, tooling costs, and any necessary post-processing (e.g. heat treatment).

1018 steel has a lower initial material cost. In addition, its excellent machinability results in shorter cycle times and longer tool life, which reduces operating costs during the CNC milling phase. However, if a hard surface is required on the part, the additional cost of case hardening must be considered. 4140 steel has a higher initial material cost. Slower machining speeds require more robust and durable tools, which in turn cost more, increasing the cost per hour of machining. The final heat treatment step also adds to the overall cost. However, the advantage is the superior strength and durability of the component, which can extend the life of the end product and reduce its life cycle cost.

FAQ

Question 1: Which steel is better for high wear applications? For applications with high wear, friction or abrasion, 4140 steel is the best choice. It is capable of high hardness (usually over 50 HRC), providing excellent and uniform wear resistance. While 1018 steel can be case hardened to create a wear-resistant surface, its core remains soft. For components subject to heavy loads and surface contact, the uniform hardness of 4140 steel provides greater durability and longer service life.

Q2: Does machining 4140 steel cost much more than 1018 steel? Yes, the total CNC machining cost for 4140 steel is generally higher than for 1018 steel. This is due to several factors: the higher raw material cost of 4140 steel; the slower machining process due to lower recommended cutting speeds and feeds; and, due to the hardness and toughness of the material, tool life is generally shorter. ly-machining’s experts can provide a detailed cost-benefit analysis for your project, weighing material properties against manufacturing costs to find the most effective solution.

Q3: Can 1018 steel be used for structural components? 1018 steel is typically used in low-stress structural applications where high strength is not a primary requirement. Its good ductility and excellent weldability make it suitable for brackets, mounting plates, fixtures, and other supporting components. However, for critical structural components that must withstand huge loads, fatigue, or impact (such as axles, high-strength bolts, or gears), properly heat-treated alloys (such as 4140 steel) have higher strength and toughness and will be a safer and more reliable choice.