Tired of project delays and quality issues stemming from unclear CNC machining tolerances? You’ve meticulously designed your parts, but without specifying the correct general tolerances, you’re leaving critical dimensions to chance, leading to costly rework and frustrating inconsistencies. What if you could ensure every part meets your expectations without painstakingly detailing every single tolerance?

The ISO 2768-mk standard provides a clear framework for general tolerances in CNC machining, covering both linear and angular dimensions as well as geometric tolerances. By referencing ISO 2768-mk on your drawings, you simplify the design process and communicate your quality requirements effectively, ensuring your CNC machined parts are manufactured with consistent accuracy.

This guide will demystify the ISO 2768 standard, helping you choose the right tolerance class for your CNC machining projects. Moreover, we will explore how applying these standards can streamline communication with manufacturers like ly-machining. Consequently, this will lead to better quality control and more reliable outcomes for your CNC milled components.

Understanding the Basics of ISO 2768

ISO 2768 is a widely recognized international standard that simplifies technical drawings. It specifies general tolerances for linear and angular dimensions, as well as geometric tolerances, that apply when no specific tolerance is indicated on the drawing. This approach saves designers significant time and effort.

The standard is divided into two main parts:

- ISO 2768-1: Concerns general tolerances for linear and angular dimensions.

- ISO 2768-2: Pertains to geometric tolerances for features.

By using the ISO 2768 standard, you create a baseline for quality in your CNC machining projects. This ensures that the manufacturer, such as ly-machining, understands the expected precision for features without individual tolerance specifications. This practice is fundamental in precision CNC milling.

Decoding the Tolerance Classes: f, m, c, v

ISO 2768-1 defines four tolerance classes for linear and angular dimensions: ‘f’ (fine), ‘m’ (medium), ‘c’ (coarse), and ‘v’ (very coarse). The ‘m’ class is the most commonly used in general CNC machining. Selecting the appropriate class is crucial for balancing precision and cost.

Here’s a breakdown of the classes:

| Tolerance Class | Description | Typical Application in CNC Machining |

| f (Fine) | High precision | For parts requiring tight fits and accurate assembly in CNC milling. |

| m (Medium) | Standard precision | General-purpose CNC machining; the default for many shops. |

| c (Coarse) | Lower precision | For parts where function is not dependent on tight tolerances. |

| v (Very Coarse) | Least precision | Used for non-critical dimensions or rough preliminary work. |

Choosing a finer tolerance class increases manufacturing costs, as it often requires more precise CNC machining processes and stricter quality control. Therefore, specifying ‘m’ (as in ISO 2768-m) is often the most economical choice for standard components.

The Geometric Component: ISO 2768-2 and Tolerance Classes K, L, H

While Part 1 covers dimensions, ISO 2768-2 addresses the geometric aspects of a part—its shape, profile, and orientation. It introduces three geometric tolerance classes: ‘H’ (high precision), ‘K’ (standard precision), and ‘L’ (lower precision). When you see a designation like ISO 2768-mk, it combines a dimensional tolerance class (‘m’) with a geometric tolerance class (‘k’).

This combination provides a comprehensive framework for your CNC machining needs. The ‘k’ class in ISO 2768-mk is suitable for most general CNC milling applications, ensuring features like flatness, straightness, and perpendicularity are controlled within acceptable limits without excessive cost.

For high-precision CNC machining where parts must interface perfectly, a designation like ISO 2768-fh might be more appropriate. Conversely, for non-critical parts, ISO 2768-cl would suffice. Understanding this system is key to effective communication with your manufacturing partner.

Practical Application: How to Specify ISO 2768-mk on Drawings

Applying ISO 2768-mk to your CNC machining projects is straightforward. You simply need to add a note in the title block or general notes section of your technical drawing. The note should clearly state “ISO 2768-mk”.

This single note informs the machine shop, like ly-machining, to apply the ‘medium’ class for all untoleranced linear and angular dimensions and the ‘k’ class for all untoleranced geometric features. This simplifies the drawing and prevents ambiguity during the CNC milling process.

By standardizing your drawings with this specification, you streamline the quoting process and reduce the risk of misinterpretation. It is a best practice that demonstrates a professional approach to CNC machining and quality control.

Frequently Asked Questions (FAQs)

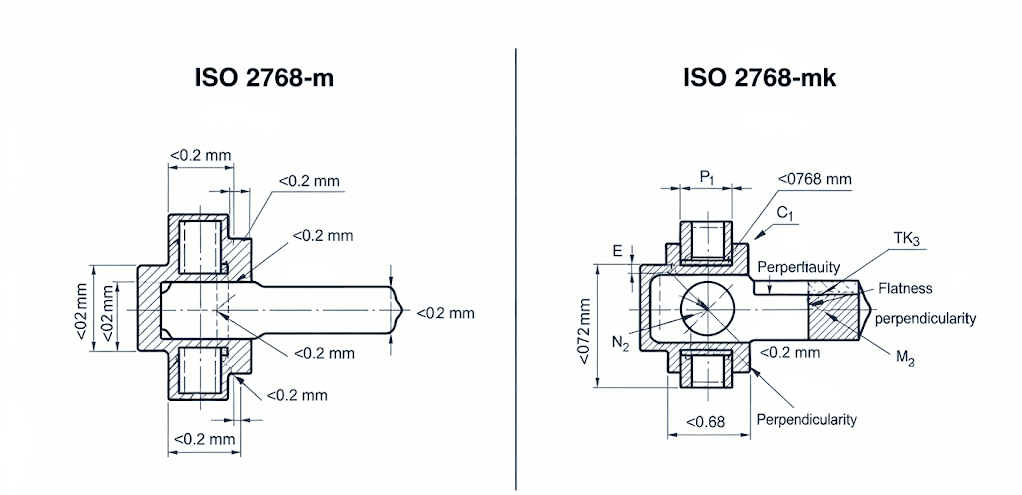

1. What is the difference between ISO 2768-m and ISO 2768-mk? ISO 2768-m refers only to the general tolerances for linear and angular dimensions (from Part 1 of the standard), specifying the ‘medium’ class. ISO 2768-mk, however, is more comprehensive. It combines the ‘medium’ dimensional tolerance class (‘m’) with the ‘K’ geometric tolerance class from ISO 2768-2, covering aspects like flatness and perpendicularity for features without specific callouts.

2. When should I avoid using general tolerances like ISO 2768? You should avoid using general tolerances for critical features where specific, tighter tolerances are necessary for the part’s function, fit, or assembly. For example, bearing bores, press-fit surfaces, or critical interface features in a CNC machining project require explicit tolerances on the drawing to ensure performance. General tolerances are for non-critical dimensions.

3. How does specifying ISO 2768-mk affect the cost of CNC machining? Specifying ISO 2768-mk generally represents a cost-effective choice for many CNC machining and CNC milling applications. The ‘medium’ and ‘k’ classes provide a good balance of precision and manufacturability. Opting for a finer class, like ‘f’ or ‘h’, would increase manufacturing time, inspection efforts, and tooling requirements, thus raising the overall cost. Sticking to ISO 2768-mk keeps costs predictable for standard components.