Are your machined parts difficult to handle, adjust, or grip securely? Smooth surfaces on knobs, handles, and fasteners can lead to slippage, imprecise adjustments, and even safety hazards, especially in industrial or wet environments. This frustrating lack of grip can compromise the usability and performance of your final product.

Imagine your users struggling with a slippery control knob or a tool that they can’t tighten properly. This poor user experience reflects directly on your product’s quality. You need a reliable manufacturing solution that adds a functional, textured surface for a secure grip. Knurling, a specialized CNC machining process, is the answer. It creates a precise, patterned texture on a part’s surface, dramatically increasing friction and ensuring ease of use. At ly-machining, we integrate this process seamlessly into our CNC production.

Knurling is a manufacturing process used in CNC machining to create a patterned texture on the surface of a part. This pattern, typically composed of straight, angled, or crossed lines, is rolled or cut into the material. The primary purpose is to create a textured surface that is easier to grip by hand or to provide a locking interface between mating components.

This guide will explore the essentials of knurling as a key finishing process in CNC machining. First, we will examine the different types of knurling patterns and the tools used to create them. Subsequently, we will discuss the functional benefits beyond just adding grip. Finally, we will outline critical design considerations to help you effectively specify knurling on your CNC milling and turning projects for optimal results.

The Knurling Process in CNC Machining

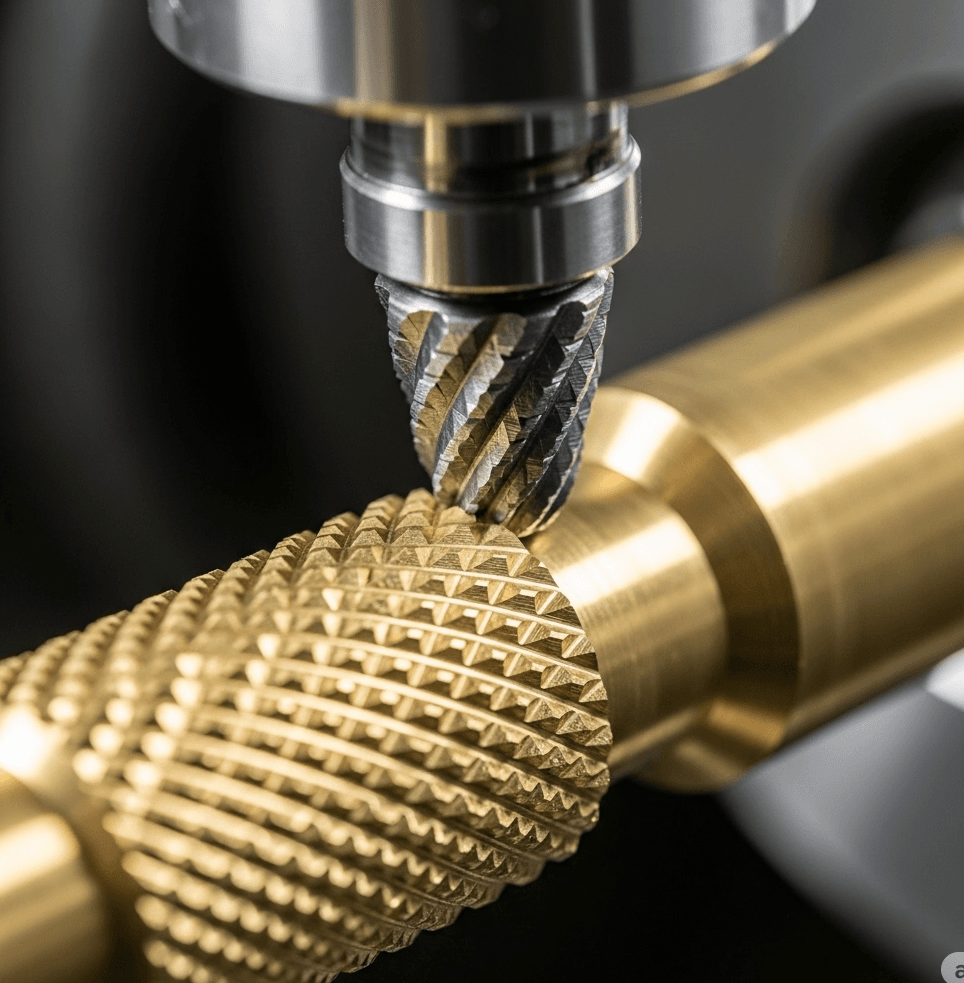

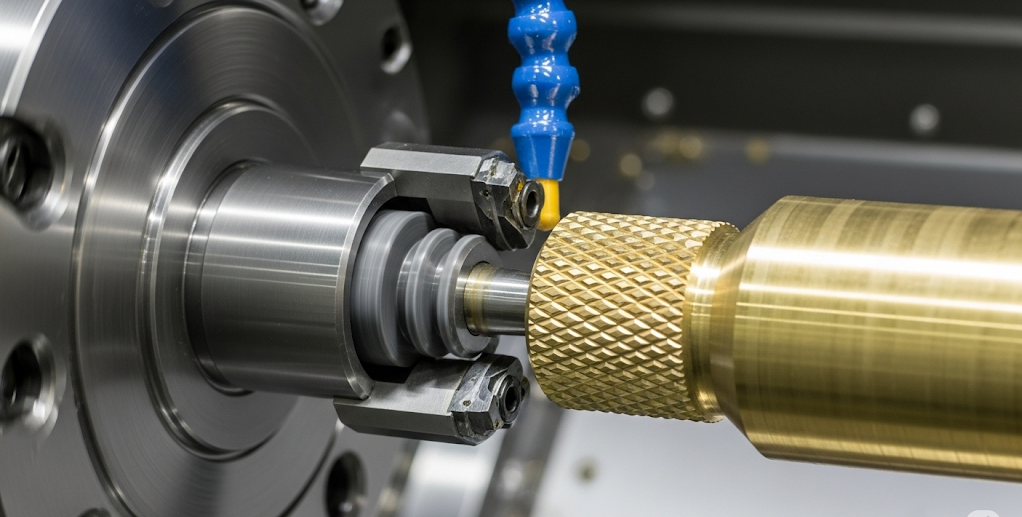

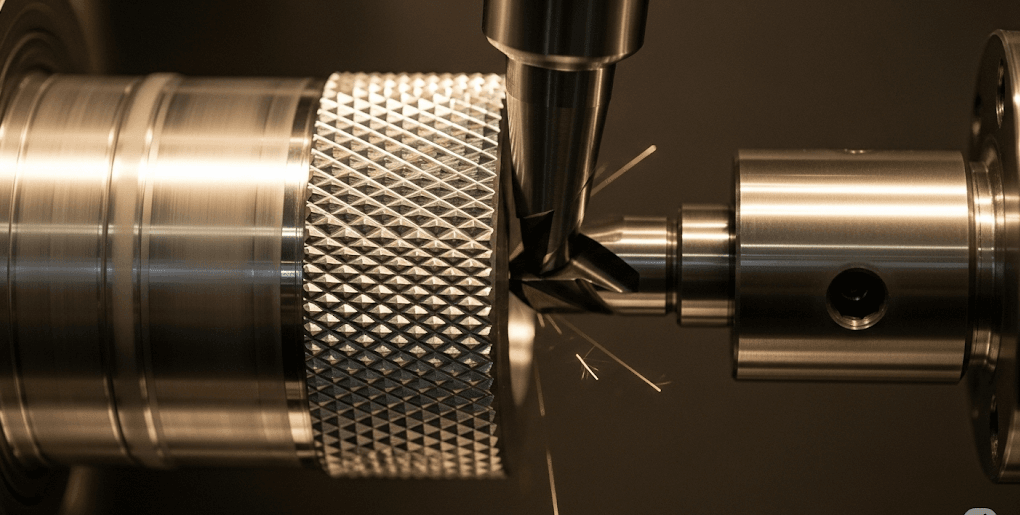

Knurling is fundamentally a metal forming process, not a cutting one. In a typical CNC machining setup, specifically on a lathe, the raw material (workpiece) is rotated at a controlled speed. A special knurling tool, which contains one or more hardened wheels with a pattern, is then pressed firmly against the workpiece.

As the tool traverses along the rotating part, its patterned wheels displace the material, raising it to form the distinctive peaks and valleys of the knurl. This plastic deformation creates the desired texture. The pressure, feed rate, and rotational speed are all precisely controlled by the CNC program to ensure a consistent and uniform pattern across the entire specified surface.

While most commonly performed on lathes for cylindrical parts, variations of the process can be adapted for specific applications in CNC milling. At ly-machining, our advanced CNC capabilities allow us to execute precise knurling operations that meet stringent quality standards for both grip and appearance.

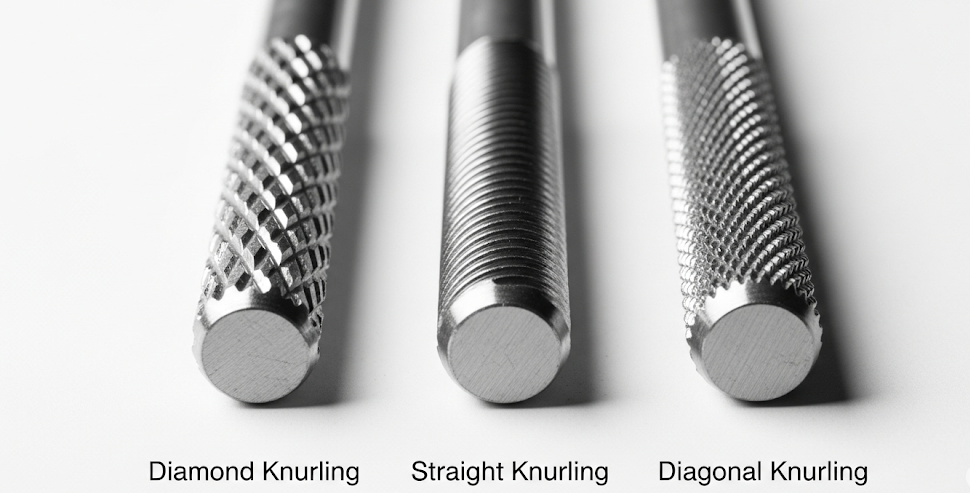

Types of Knurling Patterns

The pattern created during the CNC machining process is determined by the wheels on the knurling tool. The most common patterns offer different functional and aesthetic characteristics.

Diamond Knurling: This is the most recognizable pattern, featuring a crossed-hatch texture that forms small diamond shapes. It is created using a tool with both left-hand and right-hand helical wheels. This pattern provides an excellent multi-directional grip, making it ideal for control knobs and adjustment screws.

Straight Knurling: As the name suggests, this pattern consists of a series of straight, parallel ridges. It is created using a single straight-patterned wheel. While it offers a good grip against rotational forces, it is primarily used when a secure grip is needed for turning a part, or for press-fitting applications where axial movement needs to be restricted.

Diagonal Knurling: This pattern features parallel helical ridges, all running in the same direction (either left-hand or right-hand). It provides a good grip and can be used to create a visually appealing finish. It is often a stylistic choice but remains highly functional.

The choice of pattern depends heavily on the part’s intended use. We’ve summarized the key types below:

| Knurling Type | Pattern | Primary Grip Direction | Common Applications in CNC Machining |

| Diamond | Crossed lines forming diamonds | Multi-directional | Control knobs, tool handles, thumbscrews |

| Straight | Parallel, straight ridges | Rotational | Press-fit shafts, fasteners, decorative elements |

| Diagonal | Parallel, helical ridges | Rotational and axial | Adjustment handles, aesthetic components |

Functional Benefits Beyond Grip

While enhancing grip is the primary reason for knurling, this versatile CNC machining process offers several other advantages. These benefits can improve the overall performance and longevity of your components.

One key benefit is for mechanical fastening. A knurled surface on a shaft that is press-fit into another component creates a strong interference fit. The sharp peaks of the knurl bite into the softer mating material, preventing rotation and slippage, which is a common requirement in many CNC milling and assembly projects.

Another application is in creating decorative finishes. The precise and uniform patterns from CNC knurling can add significant aesthetic value to a product, giving it a professional, high-tech appearance. This is often seen on high-end electronics, precision instruments, and consumer products where both look and feel are important.

Finally, knurling can slightly increase the diameter of a part. This controlled material displacement is sometimes used in repair work or to achieve a very precise fit, demonstrating the versatility of the CNC machining process beyond simple shaping.

Design Considerations for Knurling

To ensure successful implementation, knurling must be considered during the design phase of your CNC machining project. The first factor is material selection. Softer, more ductile materials like aluminum, brass, and mild steel are ideal for knurling as they deform easily without cracking. Harder materials can be brittle and may require specialized tooling or techniques.

You must also clearly define the knurling specifications on your engineering drawings. This includes specifying the pattern type (e.g., diamond), the pitch (the distance between the ridges, often given as teeth per inch or TPI), the desired final diameter, and the exact axial length of the knurled section. Clear communication prevents errors in the final output.

Partnering with an experienced CNC machining provider like ly-machining is crucial. Our engineers can review your design and provide feedback on manufacturability, helping you select the right material and knurling parameters to achieve the desired functional and aesthetic outcome for your CNC milling or turning project.

Frequently Asked Questions

1. Does knurling remove material from the part?

No, knurling is a forming process, not a cutting one. The tool displaces material by pressing it into a new shape (peaks and valleys) rather than removing it as chips. This is a key distinction from other CNC machining operations like turning or milling.

2. Can any material be knurled?

Not all materials are suitable. Ductile materials like aluminum, brass, and lower-carbon steels are excellent for knurling because they can be formed without fracturing. Hardened or brittle materials are very difficult to knurl and can lead to flaking or damage to both the part and the tool.

3. How do I specify a knurl on my CNC drawing?

You should specify several key parameters. Clearly state the knurling type (e.g., Diamond), the pitch (e.g., 30 TPI or a metric pitch value), the pre-knurl and post-knurl diameters, and the length and location of the knurled feature on the part. Providing these details ensures your CNC machining partner, like ly-machining, can produce the exact finish you require.