Finding a reliable supplier for plastic CNC machining can be frustrating. You need precise parts from materials like acrylic, Delrin, PC, or PEEK, but you’re constantly battling inconsistent quality, missed deadlines, and poor communication, which stalls your entire project.

These delays and quality issues are more than just inconvenient; they risk your project’s budget, timeline, and overall success. The stress of sourcing a trustworthy partner who understands the nuances of plastic CNC processing and can deliver on their promises is a significant burden. Every failed prototype or rejected batch pushes you further behind schedule.

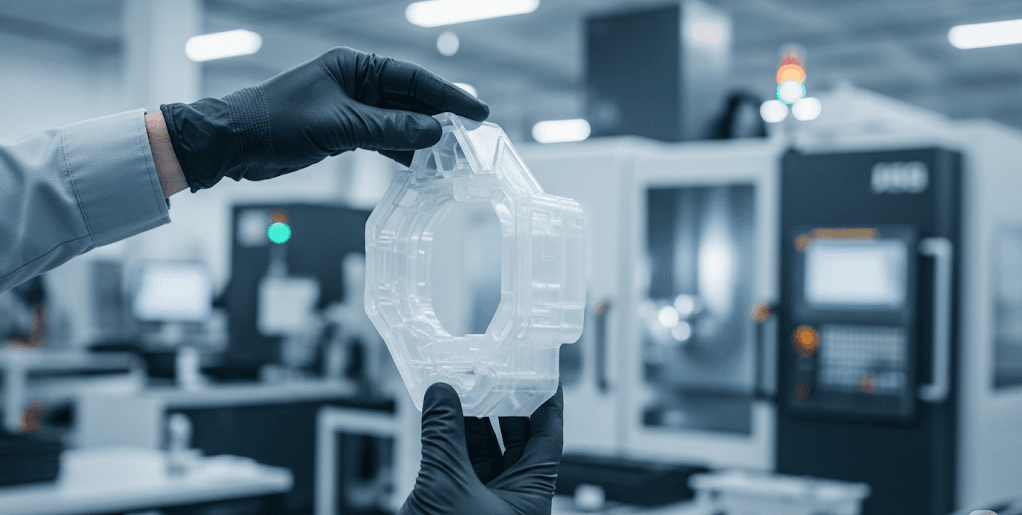

ly-machining offers a dependable solution for high-precision plastic CNC machining. Our expertise in handling advanced polymers, combined with stringent quality control and transparent communication, ensures your parts are delivered to spec and on time. Let us help you turn your designs into reality without the hassle.

Our comprehensive guide to plastic CNC machining covers everything you need to know about working with acrylic, Delrin (acetal), polycarbonate (PC), and PEEK. We explore the unique properties of each material, offering practical solutions for common challenges like managing thermal sensitivity and achieving superior surface finishes. For reliable plastic CNC processing, trust ly-machining.

Navigating the world of plastic CNC machining requires a clear understanding of the materials involved. Therefore, it’s crucial to grasp how the properties of each plastic influence the manufacturing process. Moreover, understanding these differences allows you to select the perfect material for your project’s specific needs. Consequently, this guide will provide a detailed breakdown to empower your decision-making.

Understanding Material Properties for CNC Machining

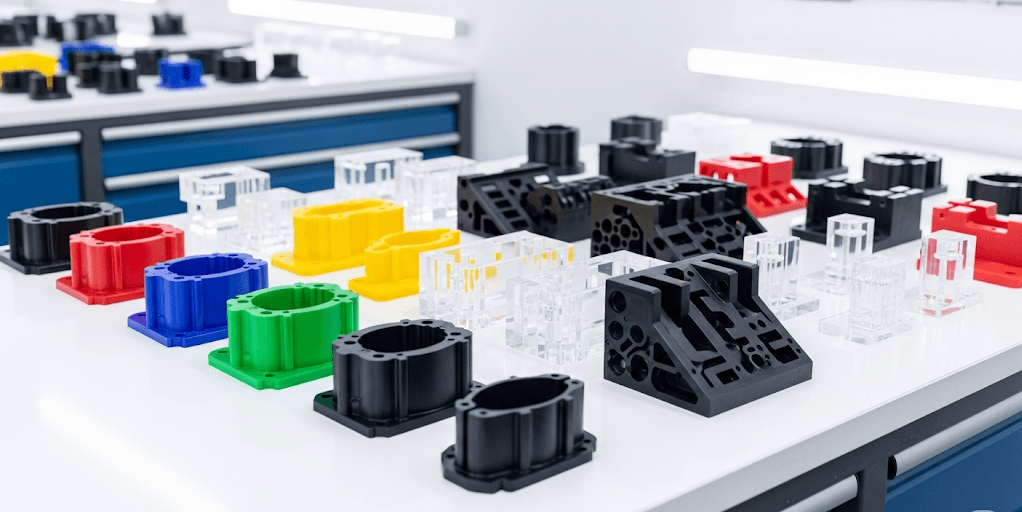

Choosing the right plastic is the foundation of a successful project. Each material possesses distinct thermal, mechanical, and chemical properties that dictate how it behaves during CNC milling and machining. For instance, a material’s melting point and thermal expansion coefficient are critical factors. ly-machining helps you navigate these choices for optimal results.

A material like PEEK offers exceptional thermal resistance, making it ideal for high-temperature applications. In contrast, acrylic is more sensitive to heat and requires careful management of cutting speeds and tool selection to prevent melting. Understanding these nuances is key to effective plastic CNC processing.

| Material | Key Properties | Common CNC Machining Challenges | Best For… |

| Acrylic (PMMA) | Optical clarity, UV resistance | Prone to chipping, melts easily | Lenses, light pipes, displays |

| Delrin (Acetal) | High stiffness, low friction | Can be slippery to grip | Gears, bearings, wear parts |

| PC | High impact strength, toughness | Stress cracking, requires sharp tools | Safety guards, electronic housings |

| PEEK | High-temp & chemical resistance | Abrasive, requires specialized tooling | Medical implants, aerospace parts |

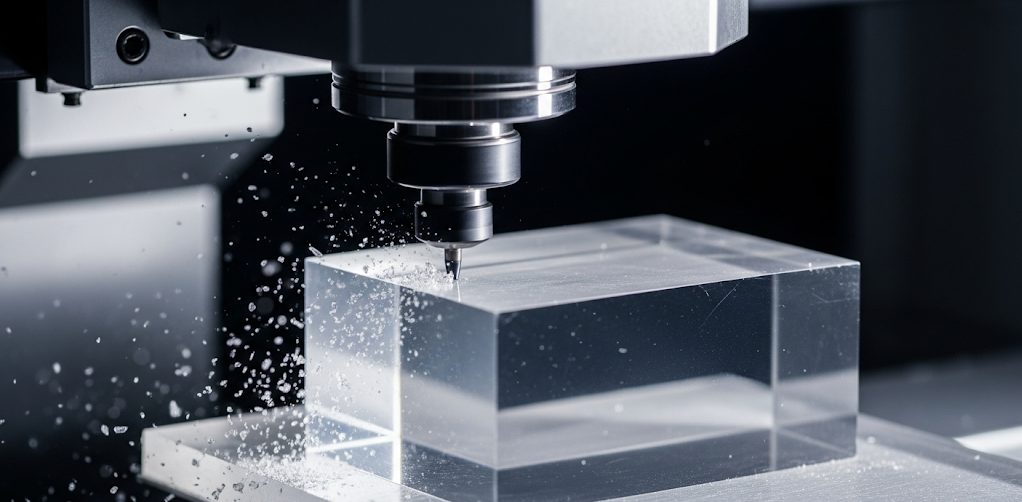

Mastering Acrylic CNC Machining for Clarity

Achieving a flawless, transparent finish on acrylic parts is a common goal. The key lies in precise thermal management and tool selection during CNC machining. We use specialized, highly sharp cutting tools and optimized cooling techniques to prevent melting and crazing. This careful plastic CNC processing ensures your acrylic components have exceptional optical clarity.

Furthermore, post-processing techniques are vital for acrylic. ly-machining offers vapor polishing and buffing services that enhance the surface finish, creating a glass-like transparency perfect for aesthetic and functional applications. This attention to detail sets our CNC milling services apart.

Precision Milling with Delrin (Acetal)

Delrin is a preferred material for mechanical parts due to its low friction and excellent dimensional stability. However, its properties demand precision during CNC machining to avoid internal stress and warping. Our process involves using sharp tools with specific geometries to achieve clean cuts and tight tolerances, which is a cornerstone of quality plastic CNC processing.

At ly-machining, we control cutting parameters meticulously to manage the material’s low melting point. Our experienced machinists ensure that every Delrin component, from complex gears to simple bushings, adheres strictly to your design specifications, guaranteeing reliable performance in its end-use application.

Techniques for Robust Polycarbonate (PC) Parts

Polycarbonate is valued for its incredible toughness and impact resistance. The challenge in PC CNC machining is preventing stress cracking and maintaining its structural integrity. We utilize specific climb milling techniques and avoid sharp internal corners in the design phase whenever possible to distribute stress effectively.

Our plastic CNC processing for PC includes using air-pressure coolants instead of liquid-based ones to avoid chemical reactions that can compromise the material. This ensures the final parts are robust and reliable for demanding applications like safety shields or durable enclosures.

The Gold Standard: PEEK CNC Machining

PEEK is a high-performance polymer known for its exceptional resistance to heat, chemicals, and wear. Machining PEEK is challenging due to its abrasive nature, which causes rapid tool wear. ly-machining invests in carbide or diamond-coated tools specifically for PEEK CNC machining to handle this demanding material.

The high cost of PEEK material means there is no room for error. Our plastic CNC processing protocols for PEEK are rigorous, focusing on optimized speeds and feeds to manage its high-temperature properties and prevent thermal stress. This precision ensures we deliver top-tier components for critical aerospace, medical, and industrial applications.

Quality Control and On-Time Delivery

A common frustration when sourcing CNC machining services is the uncertainty surrounding quality and delivery schedules. At ly-machining, we address this head-on with a transparent and robust quality management system. Every stage of our plastic CNC processing, from material verification to final inspection, is documented and monitored.

We understand that timely delivery is critical to your project’s success. Therefore, our production planning is optimized to ensure we meet agreed-upon deadlines without compromising the quality of your CNC milling. We provide regular updates, so you are always informed about the status of your order. This commitment to reliability is why clients trust ly-machining.

Related Questions

1. How does material choice impact the cost of plastic CNC processing? Material choice is a primary driver of cost in any CNC machining project. High-performance polymers like PEEK are significantly more expensive than materials like acrylic or Delrin. Additionally, the machinability of the plastic affects the cost; abrasive materials like PEEK require more durable, expensive tooling and may have longer cycle times, increasing the overall price.

2. What surface finishes are available for machined plastics? ly-machining offers a variety of surface finishes to meet your specifications. For transparent plastics like acrylic and PC, we provide vapor polishing and buffing for optical clarity. For engineering plastics like Delrin and PEEK, we offer as-machined finishes with specific surface roughness (Ra) values, bead blasting for a uniform matte texture, and edge breaking to remove burrs.

Frequently Asked Questions

1. What is the typical lead time for plastic CNC machining orders?

Our standard lead time for most plastic CNC processing projects is between 7 to 15 business days, depending on the complexity of the parts and the quantity ordered. We also offer expedited services for urgent prototypes. At ly-machining, we work with you to establish a timeline that meets your project needs.

2. How do you ensure the quality of CNC machined plastic parts?

We implement a multi-step quality control process. This includes incoming material inspection, in-process checks using calibrated measuring tools, and a final inspection before shipping. We can also provide inspection reports, like a First Article Inspection (FAI) report, upon request to guarantee your parts meet all dimensional and cosmetic requirements.

3. Can you help with material selection for my CNC milling project?

Absolutely. Our engineering team has extensive experience with a wide range of polymers. We can provide expert guidance on selecting the best material—from acrylic and Delrin to PC and PEEK—based on your application’s mechanical, thermal, and chemical requirements, ensuring you achieve the desired performance and stay within budget.