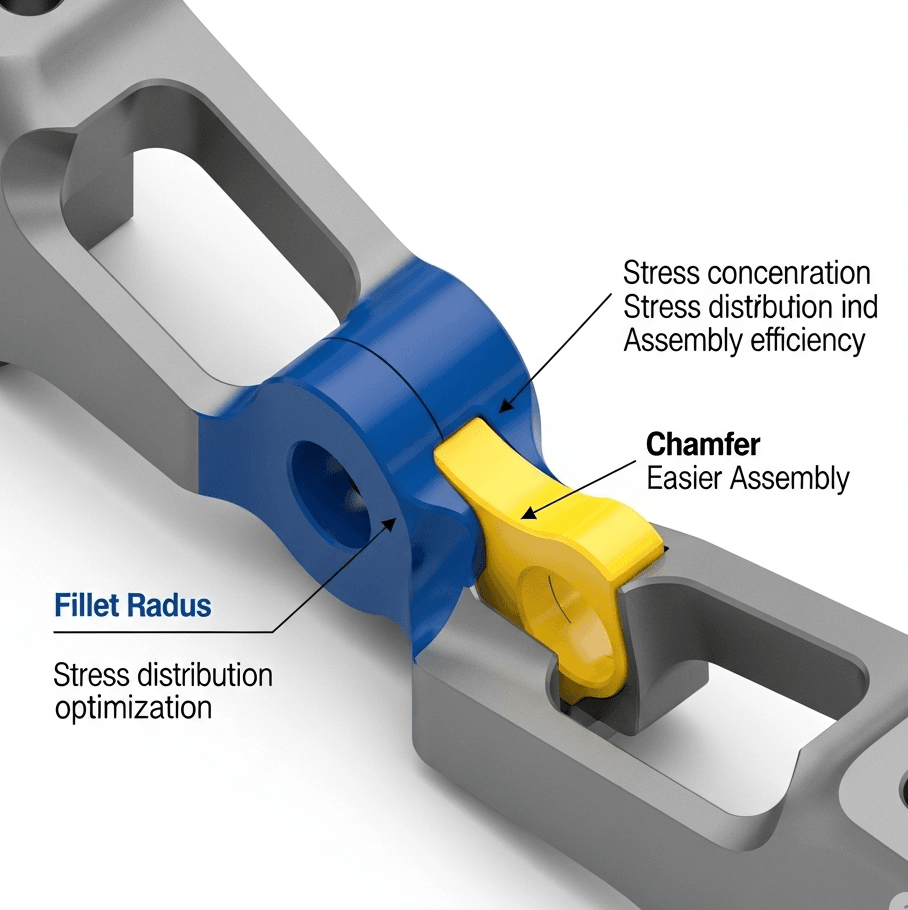

Are you uncertain whether to use a chamfer or a fillet on the edges of your CNC parts? Making the wrong choice can lead to functional failures, such as stress fractures under load, or unnecessary increases in manufacturing costs. While both features break sharp edges, their impact on part strength, safety, and production time are vastly different.

This design dilemma can compromise the integrity and performance of your components. A fillet might be essential for distributing stress in a critical joint, while a chamfer could be the more practical choice for facilitating assembly. Choosing incorrectly during the CNC machining design phase can have costly consequences down the line.

At [ly-machining], we help you make informed design decisions. Understanding the distinct functional advantages of chamfers (angled edges) and fillets (rounded edges) is key to optimizing your CNC parts for both performance and cost-effectiveness. This guide will clarify when to use each feature to enhance your design.

What is a Chamfer in CNC Machining?

A chamfer is an angled or beveled edge that connects two adjacent faces of a part. It is a straight line cut, typically at a 45-degree angle, that removes the sharp 90-degree corner. Chamfers are primarily functional, designed to break sharp edges, facilitate easier assembly with mating parts, and prevent damage to the edges themselves.

In CNC milling, creating a chamfer is a relatively straightforward and cost-effective operation. It can often be done with the same cutting tool used for facing or profiling, or with a dedicated chamfering tool, in a quick, single pass. This simplicity makes it a popular choice for non-critical edges where the main goal is deburring or providing a lead-in for pins or fasteners.

While effective for many applications, chamfers do not distribute stress as effectively as fillets. The sharp lines where the angled face meets the primary surfaces can still act as minor stress risers, although they are a significant improvement over a perfectly sharp corner.

What is a Fillet in CNC Machining?

A fillet, often called a radius, is a rounded corner or edge on a part. It can be an internal fillet (concave, like an inside corner) or an external fillet (convex, like a rounded outer edge). The primary function of a fillet, especially an internal one, is to distribute stress over a broader area, significantly increasing the part’s strength and fatigue resistance.

When a part is under load, stress flows through it. A sharp internal corner forces this stress to make an abrupt turn, causing it to concentrate at the corner and potentially leading to cracks or failure. A fillet creates a smooth, gradual path for the stress to flow, reducing this concentration.

Manufacturing fillets in CNC machining requires a specific tool, typically a ball-end mill or a corner-rounding tool, that matches the desired radius. Machining a smooth, precise radius can sometimes take longer than cutting a simple chamfer, which can slightly increase the cost of CNC parts.

Functional Comparison: Chamfer vs. Fillet

The choice between these two features depends entirely on the intended function of the edge. Here is a direct comparison of their key attributes:

| Feature | Primary Function | Stress Distribution | Manufacturing Cost | Typical Application |

| Chamfer | Assembly aid, deburring | Fair | Lower | Lead-in for a hole, deburring outer edges |

| Fillet | Stress reduction, strength | Excellent | Higher | High-load internal corners, ergonomic surfaces |

Let’s dive deeper into the specific scenarios where you would choose one over the other for your CNC parts.

When to Use a Fillet for Strength and Durability

The most critical application for a fillet is on internal corners where two faces meet. This is where stress concentration is highest. If your part is subject to vibration, impact, or cyclical loads, using a fillet is a sound design choice.

- High-Stress Corners: For any load-bearing CNC parts, such as mounting brackets, structural components, or engine parts, internal fillets are essential. The larger the fillet radius, the more effectively the stress is distributed. A common design rule is to make the fillet radius at least 0.5 to 1 times the thickness of the adjacent wall.

- Improving Fatigue Life: The reduction in stress concentration directly improves the fatigue life of a component. Parts that will be under constant or fluctuating stress will last significantly longer with well-designed fillets.

- Fluid Dynamics: In parts designed for fluid or air flow, fillets provide a smoother path, reducing turbulence and pressure drop compared to the sharp turn a chamfer would create.

Our CNC machining experts at [ly-machining] always recommend fillets for any corners that are critical to the structural integrity of your component.

When to Use a Chamfer for Assembly and Safety

Chamfers excel in applications where the primary goals are guiding parts for assembly, removing sharp burrs for safe handling, or simply breaking an edge for aesthetic reasons without a structural requirement.

- Lead-ins: An external chamfer at the entrance of a hole is perfect for guiding a pin, dowel, or screw, making assembly faster and preventing damage to the mating components. This is a common feature on many CNC machined parts.

- Deburring and Safety: After CNC milling, parts can be left with razor-sharp edges and small burrs. Adding a small chamfer (e.g., 0.25mm x 45°) in your CAD model is a controlled, precise way to ensure all edges are safe to handle, improving upon manual deburring.

- Cost-Effective Edge Breaking: If the edge is not under significant stress and you simply need to remove the sharpness, a chamfer is almost always the faster and therefore cheaper option in CNC machining.

Manufacturing Considerations and Cost Impact

The manufacturing process is a key factor in the chamfer vs. fillet decision. The geometry of the feature directly impacts the tooling and time required.

- Chamfer Manufacturing: Chamfers are easily created with standard tools. A 45-degree chamfer can be cut with a spot drill, a chamfer mill, or even the side of a standard endmill. This tooling flexibility makes it a low-cost feature.

- Fillet Manufacturing: Internal fillets require a ball-end mill or a tool with the specific radius. The tool’s diameter must be smaller than the fillet you are creating. For a smooth surface finish, the machine may need to perform multiple, fine step-over passes, which increases the cycle time for your CNC parts.

It is also important to note that the fillet radius must be larger than the corner radius of the tool used to machine the pocket. Trying to create a fillet with a radius smaller than the tool’s radius is impossible. Always design your internal fillets with standard tool sizes in mind to keep CNC milling costs down.

Related Questions

How do you specify a chamfer or fillet on a technical drawing?

On a 2D drawing, a chamfer is typically dimensioned by its angle and length (e.g., “1mm x 45°”). A fillet is dimensioned by its radius (e.g., “R3” for a 3mm radius). For parts with many identical but undimensioned edge breaks, a general note like “Break all sharp edges with 0.5mm chamfer” or “All fillets R2 unless otherwise specified” is common.

Can a feature have both a chamfer and a fillet?

While unusual, it is possible. For example, the top edge of a countersunk hole is technically a chamfer, but the bottom of the hole where it meets the through-hole might have a fillet for strength. However, on a single edge, you would choose one or the other based on the primary design intent for that specific edge of your CNC part.

Frequently Asked Questions

1. Which is better for reducing stress: a large chamfer or a small fillet?

A fillet of any reasonable size is almost always better at reducing stress concentration than a chamfer. The smooth, curved surface of a fillet distributes stress over a wider area, while the angular nature of a chamfer still creates distinct lines where stress can begin to concentrate.

2. Does adding a chamfer or fillet always increase the cost of CNC machining?

Not necessarily. While adding features does add machine time, a modeled chamfer is often cheaper than paying for manual deburring after the fact. It provides a consistent, controlled edge break. A fillet might increase cost slightly more than a chamfer due to longer machining time, but this minor cost is often justified by the massive increase in part strength and reliability.

3. What is a standard size for a chamfer or fillet?

There is no universal standard, as the size depends on the part and application. However, for general deburring, small chamfers of 0.25mm to 0.5mm are very common. For internal fillets, designers often use radii that correspond to standard ball-end mill diameters (e.g., R1mm, R2mm, R3mm) to optimize the CNC milling process and keep costs for CNC parts down.