Venturing into the world of custom CNC machining can feel complex and opaque. You have a critical design, but you’re unsure about the steps needed to turn that digital file into a physical, high-quality component. This uncertainty often leads to hesitation, communication gaps, and potential delays, preventing your project from moving forward efficiently.

The black box between submitting a design and receiving your finished CNC parts can be frustrating. You worry about whether your design intent will be understood, if the quality will meet your standards, and how long the entire process will actually take. You need a clear, transparent roadmap that demystifies the journey.

At [ly-machining], we provide a seamless and transparent path for your custom CNC projects. We’ve refined our process to guide you from the initial Request for Quote (RFQ) all the way to final delivery, ensuring clarity at every stage. This guide illuminates the entire end-to-end process for creating your precision CNC parts.

The Complete Journey for Your Custom CNC Parts

Navigating the custom CNC manufacturing landscape is straightforward when you understand the key milestones. The process is a collaborative effort between you (the customer) and your manufacturing partner. Each step is designed to ensure the final parts meet your exact specifications for form, fit, and function. Let’s walk through the entire lifecycle.

The Request for Quote (RFQ)

This is where your project begins. The Request for Quote is your initial communication, where you provide all the necessary details for the CNC shop to understand your project and provide an accurate price. A well-prepared RFQ is the foundation for a successful outcome.

To get a fast and precise quote, your RFQ should include:

- 3D CAD Files: This is the most important element. Standard formats like STEP, STP, or IGS are preferred as they are universally compatible with CAM (Computer-Aided Manufacturing) software.

- 2D Technical Drawings: While the 3D model shows the geometry, the 2D drawing conveys critical information like tolerances, threads, surface finishes, and specific material requirements.

- Material Specification: Clearly state the desired material (e.g., Aluminum 6061-T6, Stainless Steel 304, Delrin).

- Required Quantity: Specify the number of parts you need. The quantity significantly impacts the price per part for all custom CNC orders.

- Finishing Requirements: Note any secondary processes like anodizing, bead blasting, or powder coating.

Submitting a complete RFQ package allows partners like [ly-machining] to quickly move to the next stage without unnecessary back-and-forth communication.

Design for Manufacturability (DFM) and Quoting

Once we receive your RFQ, our engineering team gets to work. We don’t just calculate a price; we perform a Design for Manufacturability (DFM) analysis. This is a critical value-add step in the custom CNC machining process.

During DFM, our experts review your design to identify any features that might be difficult, time-consuming, or unnecessarily expensive to machine. This could include:

- Impractically tight tolerances.

- Deep, narrow pockets or very thin walls.

- Internal corners with radii that don’t match standard tooling.

We may provide feedback or suggest minor design modifications that can reduce cost and improve the quality of your CNC parts without compromising their function. Following this review, we will issue a formal quote detailing the cost per part, any one-time setup fees, estimated lead time, and payment terms.

CAM Programming and Machine Setup

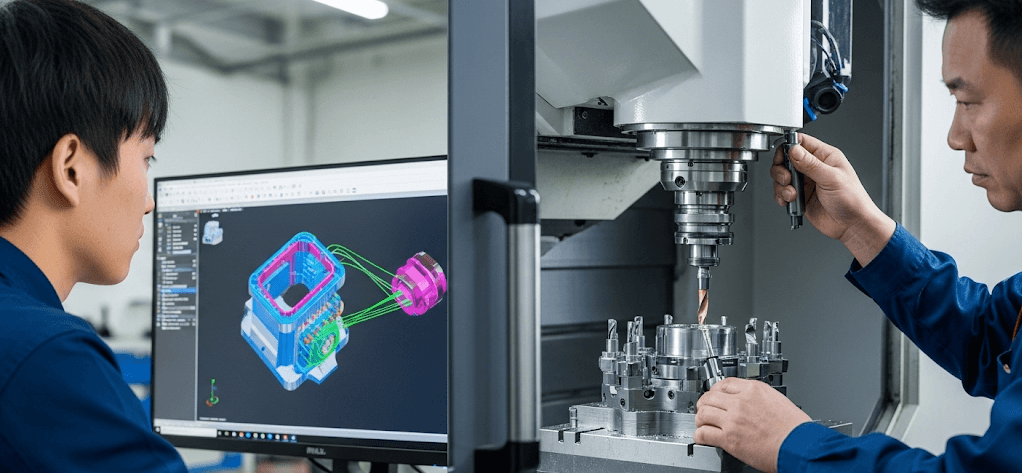

After you approve the quote, your project moves into the production phase. The first technical step is CAM programming. A skilled programmer uses your 3D CAD model to create the toolpaths—the exact G-code instructions the CNC machine will follow to cut your part.

The programmer determines the optimal cutting strategy, selects the right tools, and sets the speeds and feeds for the chosen material. This digital simulation ensures the CNC milling or turning process is as efficient and precise as possible.

Simultaneously, a machinist on the shop floor prepares the CNC machine. This involves:

- Loading the G-code program.

- Securing the raw material (workpiece) in a vise or fixture.

- Loading the necessary cutting tools into the machine’s tool changer.

- Calibrating the machine to set the precise starting point for the operation.

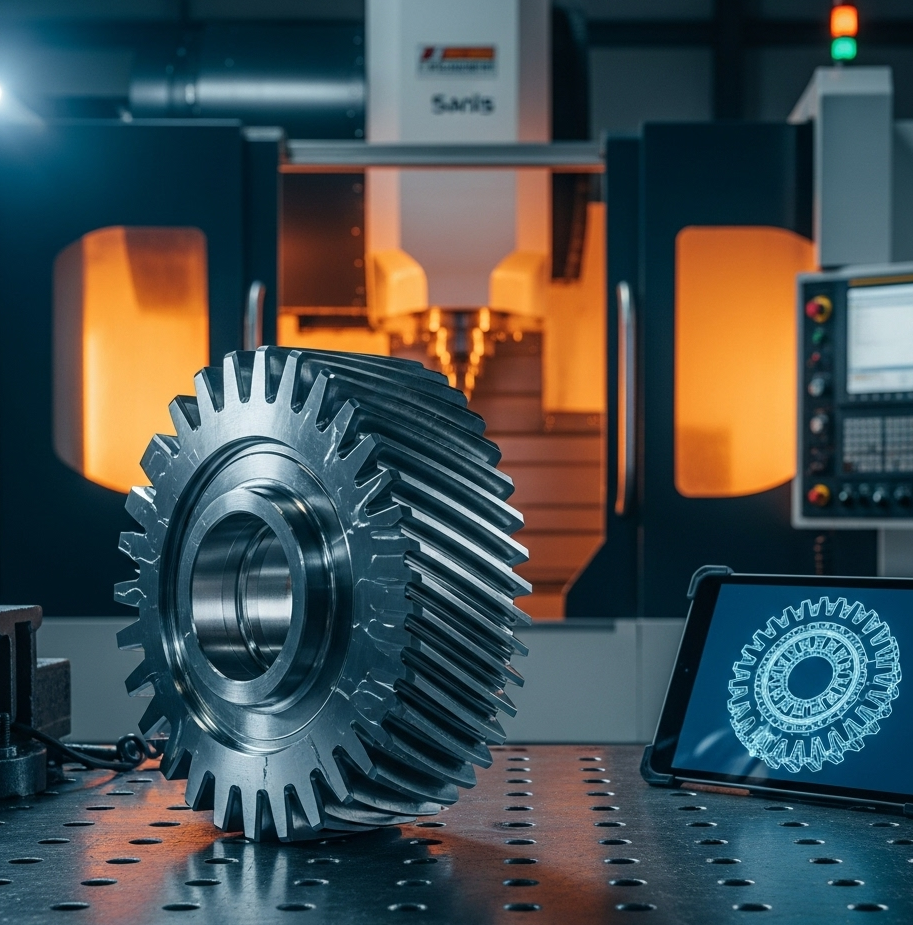

The CNC Machining Process

This is where your design comes to life. The CNC machine executes the G-code program, precisely cutting the raw material into your finished part. Whether it’s a 3-axis CNC milling machine carving a complex block or a lathe turning a cylindrical component, the process is highly automated to ensure repeatability.

A skilled operator oversees the process, monitoring the machine to ensure everything runs smoothly. They check for tool wear, manage coolant flow to keep the part and tool at a stable temperature, and ensure the initial parts meet the required specifications before continuing with the full production run. This active oversight is a hallmark of quality custom CNC services.

Quality Control and Inspection

Quality is not just checked at the end; it’s integrated throughout the custom CNC process. However, a formal inspection phase is critical before the parts move to the next stage. Using precision measurement tools like digital calipers, micrometers, and even Coordinate Measuring Machines (CMM), our quality control team inspects the parts.

They verify that all dimensions, tolerances, and features match your 2D technical drawing. For orders with tight tolerances, a CMM can automatically measure hundreds of points on the part with micron-level accuracy. This rigorous inspection guarantees that the CNC parts you receive are exactly what you designed.

Finishing and Post-Processing

Once the parts pass inspection, they move to the finishing department if required. Raw machined parts often need secondary treatments to meet functional or aesthetic needs. This is a key part of creating truly custom CNC components.

Common finishing services we manage at [ly-machining] include:

- Deburring: Manually or mechanically removing any small burrs left from the machining process for a smooth, safe edge.

- Anodizing: Creating a protective and often colored oxide layer on aluminum parts.

- Bead Blasting: Producing a uniform matte or satin texture.

- Assembly: If your project involves multiple components, we can also provide light assembly services.

Packaging and Final Delivery

The final step is to ensure your parts reach you safely. Each part is carefully cleaned, inspected one last time, and then securely packaged to prevent any damage during transit. We use appropriate packaging materials to protect sensitive surfaces and delicate features.

Once packaged, your order is shipped using a reliable courier, and you will receive a notification with tracking information. From the moment you send your RFQ to the moment you unbox your components, our goal at [ly-machining] is to make the custom CNC machining experience clear, reliable, and efficient.

Related Questions

What is the typical lead time for custom CNC parts?

Lead time can vary significantly based on part complexity, quantity, material availability, and current shop capacity. For simple prototypes, lead times can be as short as 5-10 business days. For complex parts or larger production runs requiring special materials or finishing, lead times may be 3-6 weeks or more. Your formal quote will always include an estimated lead time.

How can I ensure my design intent is fully understood?

The best way is to provide a comprehensive technical package. This includes a clear 3D model and a detailed 2D drawing. Use the drawing to call out all critical tolerances, threads, surface finishes, and other requirements that are not captured in the 3D geometry alone. A well-documented design removes ambiguity from the custom CNC process.

Frequently Asked Questions

1. What file formats are best for submitting a CNC machining project?

The best file format for the 3D model is STEP (.stp, .step), as it is a neutral format that all CAM systems can read accurately. For the 2D drawing, a PDF is the universal standard. Providing both ensures all geometric and annotation data is received correctly.

2. What happens if a part is made out of tolerance?

A reputable CNC machining partner like [ly-machining] has a robust quality management system. If any part is found to be out of the specified tolerance during inspection, it will be either reworked to meet the specification or remade entirely, at no extra cost to you. Our commitment is to deliver parts that meet 100% of your drawing requirements.

3. Can I make changes to my design after I approve the quote?

Changes can be made, but it’s important to communicate them as early as possible. If the project has not yet entered the programming or machining phase, an engineering change order (ECO) can be processed. This may affect the cost and lead time, and an updated quote will be provided. If machining has already begun, changes may be more difficult and costly to implement.