How to Calculate Tolerance Stack-Up in CNC Machining?

Finding a reliable CNC machining partner who can deliver on time without compromising quality is a significant challenge. You’ve likely faced the frustration of parts that don’t fit together, leading to costly delays and rework.

This issue often stems from mismanaged tolerance accumulation. When individual component tolerances stack up, the final assembly can fail, derailing your entire project schedule and inflating your budget. The search for a CNC milling service that truly understands and controls these fine details can be exhausting.

Imagine a streamlined process where every machined component fits perfectly, every time. By mastering tolerance stack-up analysis, you can eliminate assembly issues, ensure functional performance, and confidently partner with a CNC machining expert like ly-machining. We provide solutions that guarantee your design intent is perfectly translated into the final product.

To calculate tolerance stack-up in mechanical design for CNC machining, identify all individual tolerances in the assembly path. Sum these tolerances to find the total variation. This analysis ensures all parts fit and function correctly as a complete assembly.

This guide provides a clear roadmap for calculating and managing tolerance accumulation. Furthermore, we will explore how choosing the right CNC milling partner is crucial for turning your precise designs into reality, ensuring that every part meets your exact specifications from the start.

Understanding the Basics of CNC Machining Tolerance

Before diving into complex calculations, it’s essential to grasp what tolerance means in the context of CNC machining. Tolerance is the acceptable range of variation for a specific dimension of a part. It’s the difference between the maximum and minimum limits of a size.

In every CNC milling operation, achieving exact dimensions is nearly impossible due to factors like tool wear, material variations, and machine vibrations. Therefore, designers specify a tolerance to define an acceptable window for these variations, ensuring the part functions as intended. Effective CNC machining relies on holding these tolerances consistently.

Why Tolerance Stack-Up Matters in Assemblies

Tolerance stack-up, or tolerance accumulation, refers to how the individual tolerances of separate components add up in an assembly. When multiple parts manufactured via CNC machining are assembled, their individual dimensional variations can combine.

This cumulative effect can be critical. For instance, if the combined variations exceed the functional limits of the design, the final assembly may not fit or operate correctly. Proper analysis of tolerance is therefore vital in any project involving CNC milling of assembled parts to prevent functional failure and costly rework. This proactive approach ensures the seamless integration of all components.

Step-by-Step Guide to Calculating Tolerance Stack-Up

Calculating tolerance stack-up is a methodical process. By following a structured approach, you can accurately predict the potential variation in your assemblies and ensure your CNC machining process delivers functional parts.

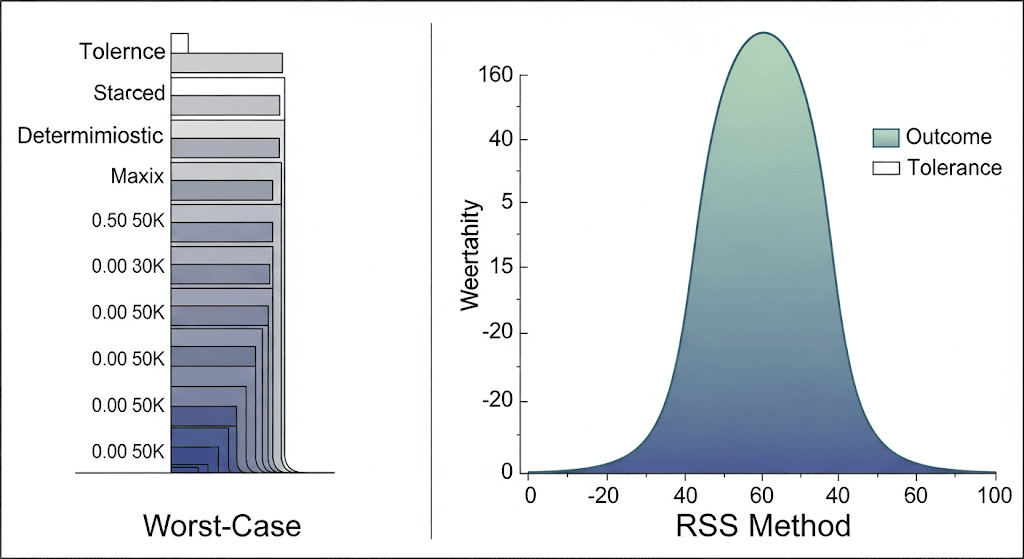

This calculation is fundamental to successful mechanical design, particularly when working with precise CNC milling operations. Let’s break down the two primary methods used for this analysis: Worst-Case Analysis and Statistical Analysis (RSS). Each method offers a different perspective on managing tolerance.

Method 1: Worst-Case Tolerance Analysis

The worst-case method is the most straightforward way to calculate tolerance stack-up. It assumes that all components are machined at their maximum or minimum tolerance limit, representing the absolute worst-case scenario for the assembly.

To perform this calculation:

- Identify the Critical Path: First, define the chain of dimensions and tolerances that directly contribute to the final assembly dimension you are analyzing.

- Sum the Tolerances: Next, simply add all the individual tolerances in the chain together. This sum represents the maximum possible variation in the final assembly.

This method guarantees that if the calculated stack-up is within your functional limits, the parts will always assemble correctly, regardless of the individual part variations within their specified tolerance. It is a conservative but highly reliable approach for any CNC machining project.

| Component | Dimension (mm) | Tolerance (± mm) |

| Part A | 50.00 | 0.05 |

| Part B | 30.00 | 0.04 |

| Part C | 20.00 | 0.03 |

| Total Stack-up | 100.00 | 0.12 |

As you can see from the table, the total worst-case tolerance stack-up is the sum of individual tolerances (0.05 + 0.04 + 0.03 = 0.12 mm). Consequently, this provides a clear and direct understanding of the maximum potential deviation in assemblies produced through CNC milling.

Statistical Tolerance Analysis (Root Sum Squared – RSS)

The statistical method, often called Root Sum Squared (RSS), offers a more realistic prediction of tolerance stack-up. It is based on the principle that it is statistically unlikely for all parts in an assembly to be at their extreme tolerance limits simultaneously.

This approach assumes that the variations in CNC machining processes typically follow a normal distribution (a bell curve). By using the RSS method, you can often allow for larger individual part tolerances while still achieving a high probability of a successful assembly, which can reduce manufacturing costs.

To apply this method, the analysis involves finding the square root of the sum of the squares of each individual tolerance. This approach provides a probable, rather than absolute, maximum tolerance because it accounts for the statistical unlikelihood of all parts hitting their maximum deviation at once.

Let’s apply this concept to our previous example:

- Part A Tolerance: ±0.05 mm

- Part B Tolerance: ±0.04 mm

- Part C Tolerance: ±0.03 mm

A statistical analysis of this stack-up would yield a probable total tolerance of approximately ±0.071 mm.

This result (±0.071 mm) is significantly smaller than the worst-case result (±0.12 mm). Thus, the RSS method demonstrates that the probable assembly variation is much tighter, offering more flexibility in the CNC milling process. This can be particularly advantageous for complex assemblies.

The Impact of CNC Milling Capabilities on Tolerance

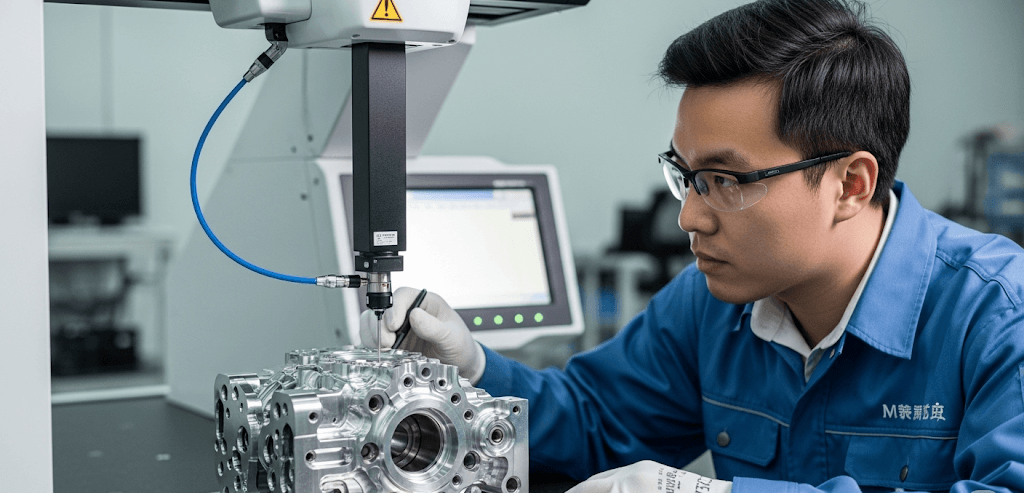

The theoretical calculation of tolerance is only one part of the equation. The actual execution by your chosen CNC machining partner is what brings that design to life. The precision and capability of the CNC milling machines and the skill of the operators are paramount.

A capable CNC machining service like ly-machining utilizes advanced machinery and rigorous quality control protocols to maintain tight tolerances consistently. This ensures that the manufactured parts align with the design intent and the calculated tolerance stack-up analysis.

Our commitment to quality in every CNC milling project means we can handle complex geometries and demanding tolerance requirements. This dedication directly translates to reliable and predictable assembly outcomes for our clients, reducing the risk of downstream issues.

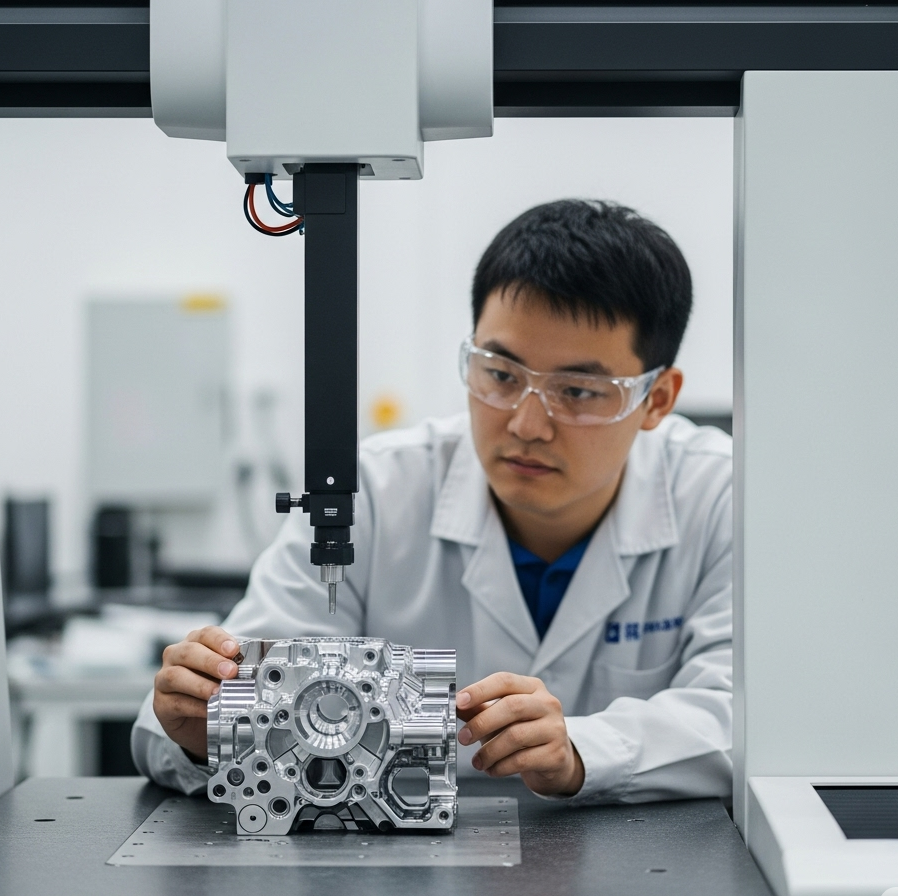

How ly-machining Manages Tolerance for Quality Assurance

At ly-machining, we understand that effective tolerance management is central to delivering high-quality CNC machining services. Our approach integrates proactive analysis with robust in-process controls.

We work closely with our clients during the design phase to review tolerance requirements and offer Design for Manufacturability (DFM) feedback. Subsequently, this collaborative process helps identify potential stack-up issues early, allowing for adjustments before any CNC milling begins.

Our quality assurance process includes:

- Advanced Metrology: Using state-of-the-art CMMs (Coordinate Measuring Machines) and other inspection tools to verify dimensions.

- In-Process Monitoring: Continuously monitoring the CNC machining process to ensure stability and consistency.

- Material Certification: Ensuring that the raw materials used meet the required specifications for predictable performance.

By embedding these practices into our workflow, we ensure that every component produced through our CNC milling services adheres strictly to the specified tolerance, guaranteeing a successful final assembly.

Relevant Questions

1. What is the difference between unilateral and bilateral tolerance in CNC machining?

In CNC machining, tolerance can be specified in two ways. Bilateral tolerance is symmetrical, expressed as a plus-or-minus (±) value from the nominal dimension (e.g., 25 mm ±0.05 mm). Unilateral tolerance, however, allows variation in only one direction, either positive or negative, from the nominal size (e.g., 25 mm−0.00+0.10). The choice depends on the specific functional requirement of the part being produced by CNC milling.

2. How does surface finish affect tolerance in CNC milling?

Surface finish and dimensional tolerance are closely related in CNC machining. A smoother surface finish, which requires finer cuts and slower feed rates, often correlates with tighter dimensional control. The process of achieving a specific finish can influence the final dimensions of a part. Therefore, it is crucial to consider both specifications together during the design and CNC milling planning stages to ensure both functional and dimensional requirements are met.

Frequently Asked Questions

1. Which tolerance stack-up method should I use for my CNC machining project?

The choice between Worst-Case and Statistical (RSS) methods depends on the criticality of the assembly. For critical applications where failure is not an option (e.g., aerospace or medical devices), the Worst-Case method is preferred as it guarantees assembly fit. For less critical applications or high-volume production where cost is a major factor, the statistical RSS method is often more practical, as it allows for looser individual part tolerances, potentially reducing CNC milling costs.

2. How can I reduce the impact of tolerance stack-up?

To mitigate tolerance stack-up, you can start by designing with fewer components in the assembly chain. Additionally, you can assign tighter tolerances to more critical components and looser ones to less critical parts. Another effective strategy is to consult with your CNC machining provider, like ly-machining, for DFM feedback. This collaboration can help optimize your design for the specific CNC milling processes being used, ensuring a better outcome.

3. What information do I need to provide for an accurate CNC machining quote regarding tolerance?

For an accurate quote, you should provide a detailed 2D or 3D CAD model that clearly specifies the dimensions and tolerances for all critical features. Be sure to indicate the material, required surface finish, and any critical assembly interfaces. Providing this level of detail allows the CNC milling service to fully understand the project requirements and assess their capability to meet the specified tolerance, leading to a more precise and reliable quote.