Why Anodize Your CNC Aluminum Parts?

You have your perfectly crafted CNC aluminum parts, but you know that raw aluminum is susceptible to scratches, corrosion, and wear. Leaving them untreated could compromise their longevity and appearance, undermining the investment you’ve made in high-quality CNC machining.

This vulnerability becomes a major concern, especially for components exposed to harsh environments or those requiring a specific aesthetic finish. The constant risk of surface damage can lead to functional failures and a finished product that looks unprofessional, forcing costly replacements and damaging your reputation.

Anodizing provides a robust solution. This electrochemical process creates a hard, durable, and corrosion-resistant oxide layer on the surface of your CNC aluminum parts. With anodizing, you not only enhance protection and durability but also unlock a wide range of decorative possibilities, ensuring your components perform flawlessly and look exceptional for years to come. At ly-machining, we integrate this crucial step to elevate the quality of our CNC milling services.

The primary benefit of anodizing CNC aluminum parts is the creation of a hard, corrosion-resistant surface that significantly improves durability and longevity. Anodizing also allows for a variety of color finishes, enhancing the aesthetic appeal of the final product while maintaining its metallic luster.

This process is a critical finishing step for many components produced through CNC machining. Consequently, by understanding its advantages, you can make more informed decisions for your projects. Let’s explore the specific benefits that make anodizing an indispensable process for CNC aluminum parts.

Enhanced Durability and Wear Resistance

One of the most significant advantages of anodizing is the dramatic improvement in surface hardness. The process transforms the outer layer of aluminum into aluminum oxide, a ceramic-like material that is exceptionally tough and resistant to abrasion.

This hardened surface protects your CNC aluminum parts from the scratches, scuffs, and general wear and tear encountered during handling and operation. For any component created through precise CNC milling that will be subjected to mechanical stress or friction, this added durability is essential for long-term performance and reliability.

Superior Corrosion Resistance

Aluminum naturally forms a passive oxide layer that offers some protection against corrosion. However, this natural layer is very thin and can be easily damaged. Anodizing thickens this protective layer substantially, creating a far more robust barrier.

This engineered oxide layer is non-porous and chemically stable, providing excellent protection against moisture, chemicals, and atmospheric pollutants. As a result, anodized CNC aluminum parts are ideal for use in marine, industrial, or outdoor environments where corrosion is a constant threat. This makes anodizing a critical step in the CNC machining process for durable goods.

Improved Aesthetics and Color Options

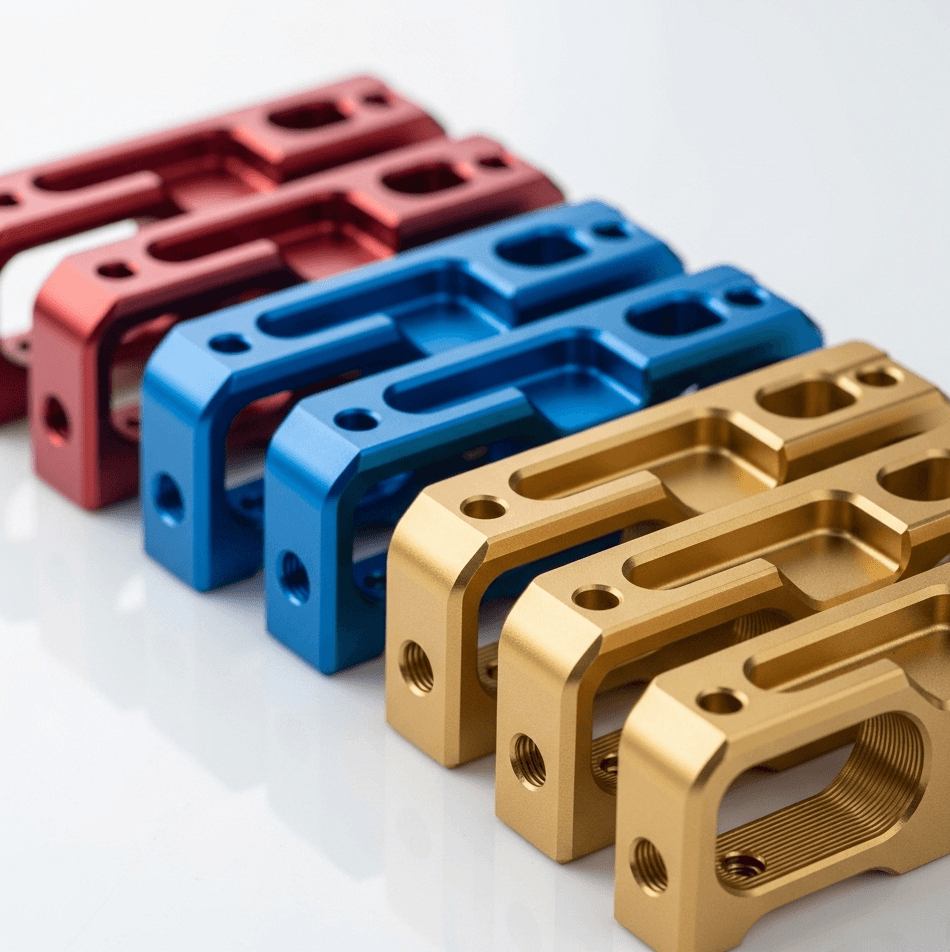

Anodizing is not just a protective measure; it is also a premier cosmetic finishing process. The porous nature of the anodic layer created during the process allows it to absorb dyes, enabling a wide spectrum of color options.

Unlike painting, where the color sits on the surface, anodizing dyes penetrate the aluminum itself. This means the color is integral to the part and cannot chip or peel. This allows for vibrant, durable, and metallic-looking finishes that enhance the visual appeal of any CNC aluminum part. The precision of CNC milling combined with beautiful anodizing creates a truly premium product.

| Finishing Process | Adhesion | Color Stability | Typical Thickness |

| Anodizing | Integral to substrate | High | 5-25 µm |

| Painting | Adhesion-based | Moderate | 25-100 µm |

| Powder Coating | Adhesion-based | High | 50-150 µm |

This table illustrates how anodizing offers a unique combination of integral adhesion and a thin, precise finish, which is highly desirable for high-tolerance CNC aluminum parts.

Better Adhesion for Primers and Glues

The porous structure of the anodic layer before it is sealed provides an excellent surface for subsequent finishes. The microscopic pores act as anchors, creating a much stronger mechanical bond for primers, paints, and adhesives.

For CNC aluminum parts that require painting or bonding as part of a larger assembly, beginning with an anodized surface ensures superior adhesion. This reduces the likelihood of delamination or paint failure down the line, a critical consideration that complements the precision of the initial CNC machining work.

Electrical Insulation Properties

While raw aluminum is an excellent electrical conductor, the aluminum oxide layer created through anodizing is an electrical insulator. The thickness of the anodic coating can be controlled to achieve specific dielectric properties.

This characteristic is highly valuable for CNC aluminum parts used in electronic enclosures, housings, and mounting brackets. The insulating surface can prevent short circuits and protect sensitive electronic components, adding a layer of functional safety to parts produced by CNC milling. This makes anodizing a key process for electronic applications.

Easy Maintenance and Cleaning

The surface of an anodized CNC aluminum part is smooth, hard, and chemically stable, which makes it very easy to maintain. The sealed surface resists staining and is not easily damaged by mild cleaning agents.

Routine cleaning typically requires only water and a mild detergent to restore the original appearance. Because the finish is so durable and resistant to streaks and corrosion, the parts maintain their look and function with minimal effort over their entire lifespan. This low-maintenance feature is a significant benefit for any CNC machining project focused on long-term value.

Why Choose ly-machining for Your Anodized Parts?

At ly-machining, we understand that the quality of your finished product depends on more than just the precision of the cut. We combine our expert CNC machining and CNC milling capabilities with high-quality finishing services like anodizing to deliver a complete solution.

We manage the entire process, from the initial design consultation to the final anodized finish, ensuring that your CNC aluminum parts meet every specification for performance, durability, and appearance. Our integrated approach guarantees that tolerance and finish quality are never compromised, providing you with assembly-ready components you can rely on.

Relevant Questions

1. What are the different types of anodizing for CNC aluminum parts?

The two most common types are Type II (decorative) and Type III (hardcoat) anodizing. Type II is used primarily for aesthetics and mild corrosion resistance, offering a wide range of colors. Type III, or hardcoat anodizing, creates a much thicker and denser oxide layer, providing superior wear and corrosion resistance for functional applications, though color options are typically more limited (black, gray). Both are common finishes for parts made via CNC milling.

2. Does anodizing affect the dimensions of a CNC aluminum part?

Yes, anodizing adds a layer of aluminum oxide to the surface, which does change the dimensions of a part. The process converts existing aluminum and also grows outward. Typically, the dimensional change is about 50% penetration and 50% growth. This must be accounted for during the CNC machining design phase, especially for parts with very tight tolerances, to ensure the final anodized component fits and functions correctly.

Frequently Asked Questions

1. Is anodizing better than painting for CNC aluminum parts?

Anodizing and painting serve different purposes. Anodizing creates a finish that is integral to the aluminum, making it far more durable and resistant to chipping or peeling than paint. It also preserves the metallic look of the part. Painting, however, offers a wider range of non-metallic colors and can be applied to many materials, not just aluminum. For durability and a premium metallic finish on CNC aluminum parts, anodizing is generally the superior choice.

2. How do I choose the right color for my anodized parts?

The choice of color depends on your application’s aesthetic and functional needs. For decorative parts, vibrant colors can enhance product appeal. For industrial or functional CNC aluminum parts, colors like black or clear anodize are common. It’s important to note that the underlying aluminum alloy can affect the final shade, so it’s a good practice to request a sample if color matching is critical for your CNC milling project.

3. Can all aluminum alloys be anodized effectively?

Most aluminum alloys can be anodized, but the quality and appearance of the finish can vary significantly between alloys. For example, alloys in the 5000, 6000, and 7000 series are excellent for anodizing, producing high-quality, decorative, and protective finishes. Some casting alloys or those with high silicon content may result in a non-uniform or discolored finish. Discussing your material choice with your CNC machining partner is crucial for achieving the desired anodizing results.